Vinod Tare_Model-Projects_PPP

advertisement

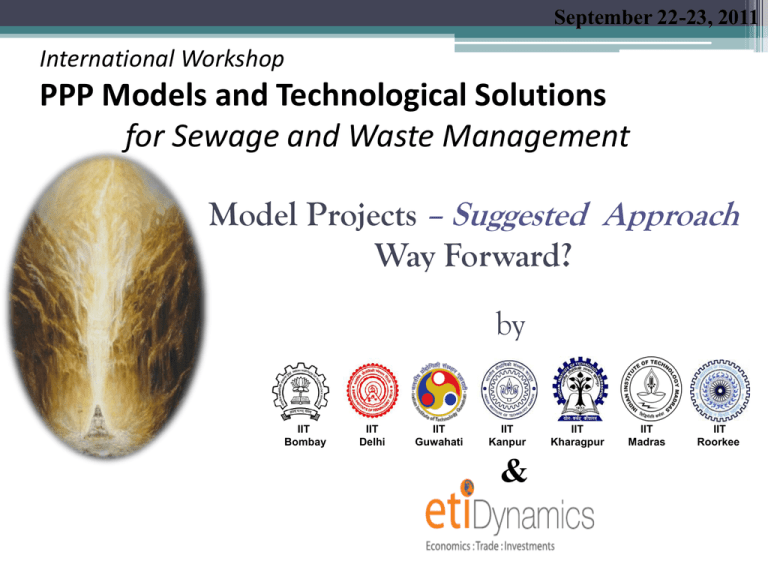

September 22-23, 2011 International Workshop PPP Models and Technological Solutions for Sewage and Waste Management Model Projects – Suggested Approach Way Forward? by IIT Bombay IIT Delhi IIT Guwahati IIT Kanpur & IIT Kharagpur IIT Madras IIT Roorkee September 22-23, 2011 International Workshop PPP Models and Technological Solutions for Sewage and Waste Management Model Projects 1. Cluster of Pulp and Paper Industries in Uttarakhand and Uttar Pradesh 2. Tannery Effluents and Sewage Treatment in Kanpur, Uttar Pradesh 3. Sewage Treatment in Patna, Bihar 4. Sewage Treatment in Kolkata, West Bengal 5. Distillery Industries in Ganga Basin Ganga Basin Drainage Area of the Ganga River Covering 11 States in India (AIWFS Data) Uttarkashi Rishikesh Haridwar Garh Mukteshwar Delhi Lucknow Haryana Mathura UP Agra Kanpur Rajasthan Bihar Allahabad Banaras Patna Madya Pradesh West Bengal DBFO Model for STPs Central Governm ent State Governm ent ULBs Public Service Provider / Operator DBFO Model for Sewage Treatment - Essential Components • The service provider/operator builds, and then maintains and operates the facility for the contract period after commissioning. • Responsibility for the arrangement of uninterrupted power supply for the facility is with the service provider/operator. • The service provider/operator and ULB will have joint rights (as stipulated in the contract) for the commercial exploitation of the products, i.e., treated water, sludge and sludge-derived products generated through sewage treatment. A special purpose vehicle (SPV) may be set up for this purpose by the service provider/operator and ULB using the PPP model. • Any treated sewage, sludge, etc. discharged from the sewage treatment facility during the contract period to be disposed of by the service provider/operator in a safe manner and as per provisions of the contract. DBFO Model for Sewage Treatment - Essential Components • The facility reverts back to the ULB after the end of the contract period unless the contract duration is extended. • Any liabilities arising out of site contamination during the construction period and contract period for operation of the facilities by the service provider/operator lie with the service provider/operator, even after conclusion of the contract period. • The facility reverts back to the ULB after the end of the contract period unless the contract duration is extended. • Any liabilities arising out of site contamination during the construction period and contract period for operation of the facilities by the service provider/operator lie with the service provider/operator, even after conclusion of the contract period. DBFO Model for Sewage Treatment - Essential Components In this model, the income to the service provider/operator will be from two sources: ▫ Payment made to the service provider/operator in the form of annuities. The expected amount of annual payments (for each year of operation after commissioning) will be clearly specified in the contract. However, the actual annual payments shall be linked to the quantity of treated sewage (of specified quality) produced by the service provider/operator in that year. ▫ Profit (if any), from commercial exploitation of resources generated through sewage treatment, i.e., sale of treated water, sludge and sludge-derived products, as per provisions specified in the contract. In return, the service provider/operator is expected to invest the entire funds required for initial creation of the sewage pumping and treatment infrastructure as per the approved DPR and also take care of operation and maintenance of the facility through the operation and maintenance contract period. DBFO Model for Industry Central Pollution control Board State Pollution Control Board Industry Industry Associati on (Compan y Ltd) Service Provider / Operator DBFO Model for Industry Clusters/Groups • Most of the ETPs perform much below the expected level and most of the times effluent discharge norms are violated. • Lack of knowledge and expertise to manage the ETPs and lack of resources and man power for enforcing the regulations and taking actions have been cited for poor performance. • In several instances causes beyond technical and financial are responsible for unabated pollution of rivers. DBFO Model for Industry Clusters/Groups • It is recommended that ETPs are planned on DBFO model with third party involvement as a company floated by the Association of Industries. The ETPs will be in the premises of the industry. Land for the ETP is to be provided by the industry. • The company will be responsible for managing the effluent recycling plants through service provider/operator using DBFO model and will receive funds in the beginning of the year from each of the industry towards supply of treated water of industrial grade produced from effluents discharged by the same industry. • The service provider/operator will get the payment based on quantity of industrial grade water produced from the effluents on monthly basis. • Renewing consent to operate the industry may be linked to deposition of funds in the accounts of the company floated by the Association. Pollution of River Ganga: Contribution of Pulp and Paper Industries Through Tributaries - Ram Ganga and Kali Wastewater Discharge in Ram Ganga Uttarakhand: 162 mld; Uttar Pradesh: 74 mld Industrial Waste in Kali 86 mld; 13,000 TPD BOD Load Pulp and Paper Industries Contribution: Through Ram Ganga Uttarakhand: 146 mld (90%); Uttar Pradesh: 39 mld (53%) Through Kali 37 mld (43%) Gangotri Glacier Delhi Kolkata Mumbai Chennai Ganga Sagar Bay of Bengal River Ganga – Origin (Gangotri) to Destination (Ganga Sagar) Ramganga Ganga “Kannauj – Kanpur” Stretch On River Ganga (Ramganga) at Kannauj Kannauj u/s (Fatehgarh) Kali Kannauj d/s (after confluence of Ramganga and Kali) On River Kali at Kannauj Kanpur u/s at Bithoor Kanpur d/s at Jajmau/Jane Kanpur u/s at Shuklaganj Pulp and Paper Industries in Ganga Basin Clusters: Kashipur – Thakurdwara (15+3+3+3) Muzaffarrnagar (8+7+2+6) Meerut (2+3+3) Moradabad (4) Water Consumption/Wastewater Generation is High; Not Closely Spaced; Conveyance Costs are High; CETPs are not viable options; Particularly if ZLD is to be achieved Pulp and Paper Industries in Ganga Basin Present Status Scale of Operation: 25 – 250 TPD Mills with 100 TPD Producing Bleached Variety of Paper have CRP Others making Craft Paper from Agro Residues do not have CRP All mills have ETP PC, AT, SC Performance! Pulp and Paper Industries in Ganga Basin Water Requirements for Four Different Categories Category Existing Water Consumption m3 / T paper (Average) Achievable Water Consumption m3 /T paper* (Average) Best Achieved Water Consumption m3 /T paper (Average) Bench mark for water Consumption m3 /T paper (Average) A1: Agro Based Writing & printing paper mills 100 80 60 50 A2: Agro Based Kraft paper mills 75 45 45 30 B1: RCF Based Writing & printing paper, Duplex board, newsprint 50 20 30 20 B2: RCF based Kraft paper mills 35 10 15 10 * as per discussions with the representatives of the pulp and paper industries Pulp and Paper Industries in Ganga Basin Typical Characteristics of Water and Wastewater Parameters pH Raw Water Effluent A1: Agro A2: Agro Based Kraft B1: RCF Based Based Writing paper mills Writing & printing & printing paper, Duplex board, paper mills newsprint mills B2: RCF Based Kraft paper mills 7.5 -7.8 7.0 -7.8 6 6.8 -7.3 6 TDS, mg/l 290 1100-6800 1560 800-1720 840-3240 TSS, mg/l Nil 384-1950 466 160- 4387 56-680 COD, mg/l Nil 776-5048 1010 262-1715 704-2016 BOD, mg/l Nil 450-2234 543 180- 958 593-1058 Colour Nil -* -* - - Turbidity, NTU Nil 35-19 106 2 -35 22- 299 Hardness, mg/l 180 -185 as CaCO3 * Mills are using RCF only at present Pulp and Paper Industries in Ganga Basin Estimated Capital and Operation and Maintenance Costs for ETPs 0–5 Treatment Cost up to Tertiary Treatment without RO , `/m3 (including capital, O & M, and Reinvestment Cost assuming 15 Years Life of ETP as on 2010) 15 Treatment Cost up to Tertiary Treatment with RO , `/m3 (including capital, O & M, and Reinvestment Cost assuming 15 Years Life of ETP as on 2010) 100 5 - 20 10 100 Capacity, MLD Note: Actual cost will be technology and location specific Pulp and Paper Industries in Ganga Basin Estimated Production Cost and Selling Price for Different Grades of Paper Grade of Paper A1: Agro Based Writing & printing paper A2: Agro Based Kraft paper ( 100 % agro) B1: RCF Based Writing & printing paper B2: RCF Based Kraft paper Production cost ` / T paper Selling Price ` / T paper 32000 – 34000 38000 – 40000 19000 – 20000 23000 – 24000 32000 – 33000 35000 – 36000 22000 – 22500 23000 – 24000 Pulp and Paper Industries in Ganga Basin Estimated cost of Water Reuse/ Recycle after Tertiary Treatment in a Typical Mill of Capacity 25 TPD Paper and Pulp Mill Category A1: Agro Based Writing & printing paper mills A2: Agro Based Kraft paper mills Achievable Water Consumption m3 /T paper* (Average) Average Estimated Cost, ` / T paper Productio Chemical Attaining Complete n Cost Recovery from Zero Recycling `/T Black Liquor Discharge of Effluent paper Using CRP/CCRP Paradigm Percentage Increase in the Average Production Cost 80 33000 163 1,200 (5,875)# 1,363 (6,038)# 4.1 (18.3)# 45 19500 163 675 (3,225)$ 838 (3,388)$ 4.3 (17.4)$ # Considering 25 and 55 m3/T paper without and with RO treatment respectively; $ Considering 15 and 30 m3/T paper without and with RO treatment respectively; Cost of recovery of solids from RO Reject on drying is included in the RO treatment Pulp and Paper Industries in Ganga Basin Estimated cost of Water Reuse/ Recycle after Tertiary Treatment in a Typical Mill of Capacity 25 TPD Paper and Pulp Mill Category B1: RCF Based Writing & printing paper, Duplex board, newsprint mills B2: RCF Based Kraft paper mills Estimated Cost, ` / T paper Achievable Average Chemical Water Producti Complete Attaining Recovery from Consumption on Cost Recycling Zero Black Liquor m3 /T paper* `/T of Discharge Using (Average) paper Effluent Paradigm CRP/CCRP Percentage Increase in the Average Production Cost 20 32500 Not Applicable 300 (2,000)* 300 (3,000)* 0.9 (6.2)* 10 22250 Not Applicable 150 (1,000)* 150 (1,000)* 0.7 (4.5)* *Considering RO treatment; Cost of recovery of solids from RO Reject on drying is included in the RO treatment Pulp and Paper Industries in Ganga Basin Recommendations: B1 and B2 Categories • Increase in average production cost for B1 and B2 categories of industry is in the range of 4 – 6 %. • The cost of tertiary treatment of the trade effluent is not prohibitive and is technically feasible. • Achieving zero liquid discharge implies only an increase in cost of the paper production by a few percent of the production cost for B1 and B2 category of industry and must be enforced to save the precious resources like river Ganga in particular and Ganga system in particular. • The implementation of this may result in slight reduction in profit margin or alternatively the cost will be passed on to the consumers. • Thus it is strongly recommended that the “polluter pays principle” must be strongly adhered to achieve zero discharge paradigm in case of the pulp and paper industries. • This will immensely help saving the rivers, in particular the river Ganga, from adverse impacts without significant impact on the industry or economy or employment opportunities. Pulp and Paper Industries in Ganga Basin Recommendations: A1 and A2 Categories • Increase in average production cost for A1 and A2 categories of industry to attain zero discharge paradigm is in the range of 17-19 %. • This is on the higher side. • However, in the nations’ larger interest zero discharge paradigm must be enforced to protect rivers like Ganga, and the Ganga system. • At the same time these category of industry are important from several considerations including utilization of renewable agro based residues that will otherwise be burnt and create air pollution problems. • Hence closure of these types of industry is not in the larger interest. Pulp and Paper Industries in Ganga Basin Recommendations: DBO Model for ETPs • The past experiences reveal that most of the ETPs perform much bellow the expected level and most of the times effluent discharge norms are violated. • Number of reasons, including lack of knowledge and expertise to manage the ETPs, has been cited by the industry for poor performance. • Also the regulating agencies, such as State Pollution Control Boards (SPCBs), have cited many reasons including lack of resources and man power for enforcing the regulations and taking actions for unabated pollution of rivers due to discharge of industrial effluents. • In several instances, as shown in the case of pulp and paper industries, causes beyond technical and financial are responsible for unabated pollution of rivers. Pulp and Paper Industries in Ganga Basin Recommendations: DBO Model for ETPs • Experience with other industrial sectors, particularly in water scarce areas, suggests that third party involvement and ETPs producing industrial grade water have been performing well. • As such it is recommended that ETPs are planned on design, build and operate (DBO) model with the involvement of a company floated by the Association of Industries. • This company will be responsible for managing the effluent recycling plants through service provider using DBO model and will receive funds in the beginning of the year from each of the industry towards supply of treated water of industrial grade produced from effluents discharged by the same industry. • The ETPs will be in the premises of the industry. Land for the ETP is to be provided by the industry. The service provider will get the payment based on quantity of industrial grade water produced from the effluents on monthly basis. • Consent to operate the industry is to be given only upon deposition of funds in the accounts of the company floated by the Association of Industries by the member industries. Pulp and Paper Industries in Ganga Basin Highlights Pulp and Paper Industries, both agro and RCF based, are important for growth and development. Shifting towards zero liquid discharge paradigm is feasible and must be implemented to save rivers and help maintain “Nirmal and Aviral Dhara”. Improvements in technology and following best practices can lead to substantial reduction in water consumption and lower the cost of attaining zero discharge paradigm. Black liquor from agro based pulp and paper industries must be sent to CCRP for smaller units (< 100 TPD). Larger units may be allowed to have their own CRP. Pulp and Paper Industries in Ganga Basin Highlights ETPs must be upgraded to tertiary level treatment. Some or all, depending on requirement, tertiary treated water may have to be treated using RO. The cost of treatment up to tertiary treatment including RO treatment may increase the production cost only by 4-6 % for RCF based industries and must be enforced. The cost of treatment up to tertiary treatment including RO treatment may increase the production cost by 17-19 % for agro based industries, but also must be enforced. However, some concessions may be offered to promote agro based industries. CETPs do not appear to be viable for Pulp and Paper Industries in the identified clusters in the Ganga River Basin. However, all ETPs are to be managed by a company formed by association of industries. Pulp and Paper Industries in Ganga Basin Highlights Consent to operate the industry is to be given only on annual advance payment to the company for producing industry grade water by operating state-of-the-art ETP in each industry. DBO model is to be applied for all ETPs. Service provider is to be selected by the company and paid on the basis of quantity of industry grade water produced from the effluents. Flow meters to be installed at the inlet and outlet of each ETP. Industries are allowed to take fresh water only to make up for the losses due to evaporation, minor leakages, etc. Typical City / Town Different aspects of Upgradation of Tanneries CETP @ Jajmau, Kanpur – IL&FS Study • There are 418 tanneries in Jajmau, the total installed capacity is 39270 hides per day. • Average capacity to process number of hides in all tanneries in Jajmau area (operational and temporarily closed) is anywhere between 20000 to 30000 hides per day with average weight of hide of about 28 kgs. • About 1400 liters of water is consumed per hide in processing from raw to finish. Corresponding estimated effluent quantity would be 24 to 28 MLD. Different aspects of Upgradation of Tanneries CETP @ Jajmau, Kanpur – IL&FS Study • Jajmau is mixed agglomeration of tanneries, houses, shops and other commercial establishments in a very intricate fashion. • About 4-8 MLD sewage is expected to get mixed with effluent. Thus design flow for the plant is estimated to be 32 MLD. Costs Involved in the Tanning Process Buffalo Cow Goat 700-1000 800-2000 60-120 34-40 32-36 4-5 Price per sq ft. 17 – 30 20-50 12 – 30 Cost of Tanning, Rs /sq. ft 1. Raw Hide to Wet Blue 6.5 – 7.0 5.0 – 6.0 3.0 – 4.0 2. Wet Blue to Crust Felt (Chroming / 8.0 – 9.0 Oiling) 3. Crust Felt to Finished Leather 4.0 – 5.0 6.5 – 7.0 4.0 – 5.0 3.0 – 3.5 2.5 – 3.0 Cost of Raw Hide Market Price for Raw Hide, Rs. Surface Area, sq.ft Total Cost Production Cost, Rs. / sq. ft 40 - 45 50 – 55 30 - 35 Domestic Selling Price, Rs. / sq. ft 45 - 50 55 - 60 35 - 40 Export Price, Rs. / sq. ft Production Cost Price per Hide, Rs. 4-5 % higher than domestic selling price 1400-1800 1600 - 2000 120 - 180 Different aspects of Upgradation of Tanneries CETP @ Jajmau, Kanpur – IL&FS Study Characteristics of Tannery Effluents to be Received at CETP in Jajmau, Kanpur Parameters pH Total solids TSS TDS COD BOD N-NH4 Cl Sulfides SO4 Total Chrome Suggested Design Value after Presettling and Equalization 7.0-9.0 10000-13000 2000-3000 8000-10500 4000-6000 1800-3000 100-250 3000-4500 150-300 800-1500 40-80 All values in mg/l except pH Different aspects of Upgradation of Tanneries CETP @ Jajmau, Kanpur – IL&FS Study • Industries agree to constitute a special purpose vehicle (SPV) for implementing the project. • SPV will be responsible for operating and maintaining all components of the up-graded CETP and to meet the discharge norms stipulated from time to time. Tannery Wastewater Treatment: Desired Features The desired features in any renovated tannery wastewater facility proposed for the Jajmau area in future are the following: • The portion of wastewater from tanneries containing high concentrations of chromium should be conveyed to a chrome recovery plant. The recovered chrome and other solid residues from the chrome recovery plant must be reused or disposed in a hazardous waste landfill. Effluent from the chrome recovery plant to be sent to the CETP for further treatment. • The remaining tannery wastewater must be screened for removal of large objects at the tannery premises itself, before discharge into the tannery wastewater conveyance system. Tannery Wastewater Treatment: Desired Features • Treated tannery wastewater to be reused / recycled in the tanneries, such that the freshwater requirement in tanneries is reduced. • No direct use of treated tannery effluent for sewage farming. Direct discharge of treated tannery wastewater into the river Ganga is not allowed. • Tannery wastewater in the conveyance system must be screened again before being pumped through rising mains to the CETP. • CETP to be designed for the treatment of tannery wastewater to tertiary levels. • The tertiary treated wastewater may be diluted with treated domestic sewage for reduction of TDS, and/or other advanced processes (e.g., RO with suitable reject management) must be incorporated for reduction in TDS concentration. Comprehensive Cost of Wastewater Treatment per Buffalo Hide as per ZLD Concept Production Cost, Rs. / Hide 1400 - 1800 Cost of Wastewater Treatment 75 – 90 (without RO), Rs./ Hide (4.1 – 6.5 % of Production Cost) Cost of Wastewater Treatment (with RO), Rs./Hide 225 – 300 (12.5 – 21.5 % of Production Cost) Cost of Wastewater Treatment Currently Paid by the tanneries in Jajmau to UPJN, Rs. / Hide 4 (0.22 – 0.28 % of Production Cost) Sewage Treatment in Kanpur, UP Name of Sewage Treatment Plant Parameters Year of Construction Installed Capacity (MLD) Current Utilized Capacity (MLD) Adopted Technology Capital Cost (Rs. in Millions) O&M Cost/Year (Rs. in Millions) Mode of Disposal Remarks 5 MLD Plant at Jajmau 130 MLD Plant at Jajmau 36 MLD CETP at Jajmau 1987-89 5 4 1999 130 60 1994 36 22-26 Up-flow Anaerobic Sludge Blanket (UASB) Activated Sludge Process (ASP) Up-flow Anaerobic Sludge Blanket (UASB) 9.5 310 235 113 56.7 To Irrigation channel or in the Ganga River The plant is under loaded due to inadequate sewage conveyance and pumping infrastructure Summary of Information on Sewage Treatment Plants in Patna, Bihar Sewage Treatment Plant Parameters Saidpur Beur Pahari Karmali Chak Year of Construction 1936 1969 - Under construction Installed Capacity (MLD) 45 35 25 4 Current Utilized Capacity (MLD) 33 16 Not in operation Under construction Activated Sludge Process (ASP) Aerated Lagoon(AL) Oxidation Pond (OP) Activated Adopted Technology Sludge Process (ASP) Total WW Generation: 143 MLD Total STP Capacity (installed): 110 MLD Utilized Capacity : 49 MLD Summary of Information on Sewage Treatment Plants in Patna, Bihar Parameters O&M Cost (Rs. in millions) Saidpur Fund Requirement 7.96 Fund Allocation 0.708 Mode of Disposal Remarks Sewage Treatment Plant Beur Pahari Karmali Chak 12.5 7.815 Under construction 1.104 4.33 For For Irrigation For Irrigation & & Ganga Irrigation & Punpun River Ganga River River The STP is underutilized due to insufficient pumping by the intermediate pumping stations For Irrigation The plant is not The plant is not working in operation In complete construction due to continuously due mechanical the problem of acquisition of due frequent and electrical land power failures failures Spatial Distribution of STPs in Patna, Bihar Summary of Information on Sewage Treatment Plants in Kolkata City, West Bengal Sewage Treatment Plant Parameters Garden Reach Bangur South Suburban(East) BhagaJatin Year of Construction 1996 1997 2002 - Installed Capacity (MLD) 47.5 45 30 5 Current Utilized Capacity (MLD) 30 20-25 - - Oxidation Pond (OP) Aerated Lagoon(AL) Adopted Technology Activated Sludge Activated Sludge Process (ASP) Process (ASP) Capital Cost (Rs. in millions) 774.4 114 - - Mode of Disposal River Ganga through canal River Ganga through canal River Ganga through canal River Ganga through canal Total WW Generation: 618 MLD Total STP Capacity (installed): 127.5 MLD Utilized Capacity : 50 - 55 MLD Estimated Pollution Load from Distilleries in the States of Gangetic Planes State Number of Distilleries Installed Capacity (million liters/year) BOD load (tonnes/ year) 88 41 Effluent Generated (million liters/year) 1323 615 Bihar Haryana Madhya Pradesh Rajasthan Uttar Pradesh West Bengal 13 5 21 7 469 14 7036 202 58288 1616 43 6 617 24 9252 371 74016 2968 10584 4920 Spatial Distribution of Sugar and Distillery Industries in the Ganga Basin Distillery Industries in Ganga Basin • The problem posed by distillery effluents runs, literally, pretty deeprun-off effluents percolate into surrounding fields, thereby polluting soil and damaging its structure. • The task at hand is twofold: to dispose of effluents in an environment-friendly manner, and to reclaim the effluent-loaded sites that have turned into wastelands. • The CPCB has been advocating Zero Liquid Discharge (ZLD) for distilleries. However, the situation on ground is that almost all industries do not even meet the specified effluent discharge standards. It is necessary to adopt the concept of ZLD through stateof-the-art technological solutions and introduce third party (other than industry and regulating agency) through appropriate DBFO models. Epilogue • Prospects of generating resources through sale of treated water, energy from waste, and sludge or sludge derived products. • Changes and/or introduction of new policies/legislations/regulations at the central, state and local government level to facilitate establishing market for or generating resources from sale of treated water, energy and sludge or sludge derived products. • Performance assurance to be obtained from private party and required payment guarantee for successful implementation of the proposed or any other DBFO or equivalent models. • Prospects of finding private entities interested in technology transfer and investments in recycle and reuse of sewage and industrial effluents. Epilogue • Framework for concession agreements or contract documents amongst urban local bodies (ULBs), state governments, central government and private entities for sewage treatment and reuse/recycle. • Framework for concession agreements or contract documents amongst industries, industry associations, state and central government and private entities for treatment and reuse/recycle of industrial effluents. • Road map for working on technology transfer and developing PPP models for management of both sewage and industrial effluents. • Road map for building on model projects through bilateral and/or other funding agreements for achieving the target of Clean Ganga Mission of the Government of India by 2020. Thank You !!