Marian Chertow

advertisement

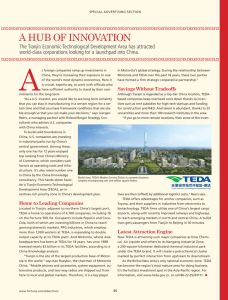

Taking Action on Materials: Global Examples of By-Product Synergy Professor Marian Chertow, Yale University Presentation - US Business Council for Sustainable Development July 17, 2013 Outline for Today Introduction and Vocabulary for Industrial Ecosystems/Symbiosis/By-Product Synergy Examples China – Tianjin Economic-Technological Development Area (TEDA) India – Nanjangud Industrial Area, Mysore Korea – Korean Industrial Complex Corporation (KICOX) Industrial ecology is concerned with managing the physical resources of our modern technological society “In an industrial ecosystem, the consumption of energy and materials is optimized, waste generation is minimized, and the effluents from one process serve as the raw material for another” R.A. Frosch, and N. Gallopoulos, Strategies for Manufacturing, Scientific American, 260 (3), 144, 1989 The first great article of industrial ecology… The Industrial Ecosystem of Kalundborg, Denmark Statoil Refinery Liquid Fertilizer A-S Bioteknisk Jordrens Sulfur Water Sludge (treated) Water Farms Municipality of Kalundborg District heating Energy E2 Power Station Sludge (treated) Yeast slurry Steam Lake Tissø Steam Gas Steam Water Cooling water Boiler water Sludge Pharmaceutical Scrubbe r Sludge Heat Fly ash Wall-board Plant Fish farming Cement; roads Recovered nickel and vanadium Sample Benefits of Industrial Symbiosis/ By-Product Synergy to Kalundborg Participants Water savings Input chemicals/products Oil refinery – 1.2 million cubic meters Power station – total consumption reduced by 60% System: Ground water 2 million cubic meters/year (530 million gallons) Surface water 1 million cubic meters/year (265 million gallons) 170,000 tons of gypsum 97,000 cubic meters of solid biomass (NovoGro 30) 280,000 cubic meters of liquid biomass (NovoGro) Wastes avoided through interchanges 50,000-70,000 tons of fly ash from power station 2800 tons of sulfur as hydrogen sulfide in flue gas from oil refinery 240,000 tons CO2 reduction annually Industrial Symbiosis Industrial symbiosis engages traditionally separate industries in a collective approach to competitive advantage involving physical exchange of materials, energy, water, and/or by products The keys to industrial symbiosis are collaboration and the synergistic possibilities offered by geographic proximity. M. Chertow 2000 Annual Review of Energy and Environment (Also Wikepedia) Jurong Island, Singapore EU, Vienna, Austria UK Monfort Boy’s Town, Suva, Fiji Tianjin Economic-Technological Development Area: TEDA as a Salt Pan in 1984 Tianjin Economic-Technological Development Area (TEDA) - 2006 Summary of all symbiotic exchanges identified in TEDA Resource exchanged I-I exchange (%) I-E exchange (%) Average distance (km) 2 (3%) Subtotal (%) 7 (9%) Energy 5 (6%) Water 12 (15%) 0 (0%) 12 (15%) 3.5 Material 16 (20%) 46 (56%) 62 (76%) 28.2 Subtotal 33 (41%) 48 (59%) 81 (100%) 2.9 Nanjangud Industrial Area, Karnataka India 20km Nanjangud 45 facilities – 900,000 tons of potential discards Profile of industrial enterprises in NIA A sugar refinery and a coffee/beverage producer account for ~60% production volume Printed circuit boards, paper, textiles, automotive parts, distillery Micro-enterprises: granite cutters, oil producer, food processors Surrounded by a large agricultural community Industrial food web in Nanjangud Industrial Area Mysore, India Final disposition of all materials generated by NIA facilities in Mysore, India EIP master plan for South Korea Korea Industrial Complex Corporation Phase 1 5 EIP pilot projects (US$ 17 million) Phase 2 Diffuse EIP concept to 8 industrial parks (US$ 68 million) 2005 ~ 2009 2010 ~ 2014 Phase 3 2 to 3 new EIP (US$ 6.8 million) 2015 ~ 2019 Overview of Ulsan National Industrial Parks Category Ulsan Mipo Onsan Total Food 8 - 8 Textile 5 - 5 Wood / Papers 14 3 17 Petrochemicals 135 63 198 Non ferrous 29 9 38 Steel 132 66 198 Machinery 13 21 34 Electrical, Electronics 84 7 91 Transport Equipments 223 70 293 Others 27 7 34 Services 93 29 122 Total 763 275 1,038 Source : KICOX (As on Apr. 2011) Overall Objectives for Ulsan National Industrial Parks Pollution reduction Cascading Zero-Emission via Resource recycle Environmental Quality Improvement Cost Reduction and Enhanced competitiveness Harmony with New business Eco-Polis Ulsan Community Sustainable Society Zero Emission via Resource Circulation Enhancement of Industry Competitiveness Implementation: Top-down IS network Air emission CO2 generation CO2 generation CO2 reuse BOILER Cogeneration Plant & BOLIER PROCES S PROCES S STEAM supply Outside steam Outside sale Economic benefit : 6.6 million US$/yr (Steam selling and B-C replacement) Environmental benefit: Reduction of 63,643 tons CO2/yr, 1691.5 ton /yr air pollutants Thank you and Next! Chinese EIP standard Added industrial value per capita, and rate of growth of value Eco-efficiencies (per added industrial value) Energy consumption Freshwater consumption Wastewater generation Solid waste generation COD emissions Industrial water Middle water Solid waste Treatment percentage of wastewater Availability of common waste collection, wastewater treatment systems Reuse ratios Shared services/utilities Management systems Environmental management system Availability of information management system Release of public environmental report Public satisfaction with environmental quality Public relations Source: Geng et al, 2009 Kalundborg as an Adaptive System Changes in footprint: Refinery doubles in size with North Sea oil claims Changes in flows: Power station switches fuel to meet regulations for CO2 reductions Changes in organization: Pharmaceutical operation splits into two companies to separate biotech operations; an international company buys out the Danish gypsum board company Kalundborg Symbiosis Institute spread over ~ 7 km The Symbiosis Activities Kalundborg Symbiosis Institute 26

![Symbiosis[1]](http://s2.studylib.net/store/data/005449742_1-2c9de7b7b178f521480e9109673f342e-300x300.png)