Control of Hazardous Energy - National Precast Concrete Association

advertisement

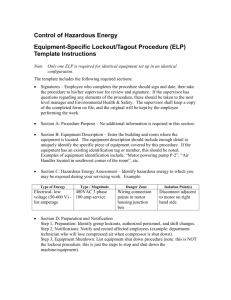

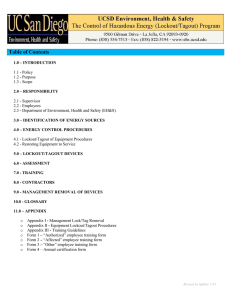

Control of Hazardous Energy – Lockout/Tagout 29 CFR 1910.147 Compliance Training Presentation NPCA Safety, Health and Environmental Committee Disclaimer • As a committee of a national organization, the Safety, Health & Environmental Committee of NPCA must reference federal standards. However, users of this information are informed that state and local agencies may have more stringent standards than those cited here. It is the users responsibility to ensure that the federal standards referenced herein are applicable in their locale. If more stringent standards apply locally, you must adhere to those local requirements. Purpose • The purpose of this standard is to establish requirements and procedures to prevent the unintended release of energy. • This applies to electrical energy, potential energy, gravity, hydraulics, pneumatics, etc. • When present this energy could cause a circuit to energize, or a machine / machine part to move or fall, causing injury to an employee. Definitions • Affected Employee – an employee whose job requires him/her to operate equipment or work in an area where lockout / tagout is performed. • Authorized Employee – A person who services or performs maintenance on equipment that requires lockout / tagout. • Energy Isolation Device – A mechanical device that physically prevents the transmission or release of energy. Definitions (cont) • Lockout – The placement of a device, such as a keyed lock, or other energy isolation device to prevent the operation of the equipment until the device is removed. • Lockout Device – a device that utilizes a positive means such as a lock to hold an energy isolating device in the safe position and prevent the energizing of the machine or equipment. Definitions • Servicing and/or Maintenance – Workplace activities where the employee may be exposed to the unexpected energizing or startup of the equipment or released hazardous energy. • Tagout – The placement of a tag, in conjunction with a lockout device, to indicate the owner of the lockout device. • Tagout Device – A prominent warning device, such as a tag and a means of attachment, which can be securely fastened to the energy isolating device, to indicate that the equipment may not be operated until the device is removed. Exemptions • Minor tool changes and adjustments, or; • Servicing or maintenance of equipment during normal production if: – The safeguards are effective in preventing worker exposure to hazards that could be created. • Work on cord and plug connected electrical equipment if the equipment is unplugged and the authorized employee is in control of the plug. General Requirements Locks and Tags: • Make locks and tags available to all authorized employees • Each authorized employee must use his or her own lock/tag. They are to keep the key with them while performing the work • Each lock must have only one key. Locks with a master key are not permitted. • Only the authorized user removes the lock they installed. General Requirements Written Procedures • The energy control procedures contain the instructions for the means to control the hazardous energy. • Specific steps should be included. • Pictures of disconnect equipment or shut off devices are helpful. • Explain how to test the machine to determine if the lockout is effective in controlling the hazard. General Requirements • Procedures are not required when all of the following exist: – The machine has no stored or residual energy – The machine has a single energy source – The lockout of the single source will completely de-energize the equipment – The machine is isolated and locked out from that source during serving or maintenance General Requirements • Procedures are not required when all of the following exist (continued): – The lock out device is under the exclusive control of the authorized user – No other hazards for employees are created – No accidents involving the release of hazardous energy have occurred on this machine or equipment Generic Procedure for LOTO • Only authorized employees perform LOTO • All affected employees are notified of LOTO • Identify the powers source(s) for the equipment • Perform normal shutdown on the equipment • De-energize the power source Generic Procedure for LOTO • Place lockout and tagout devices on the power source • Test the equipment for potential energy • Return all controls to the neutral of off position • Maintenance or servicing can now be performed Removal of LOTO • Make sure all tools are stored • Verify that the switches are in the neutral or off position • All guards must be in place Removal of LOTO • Personnel must be clear of the equipment • Each authorized person shall remove only his or her own lockout and/or tagout device • Return to energy isolating device to its on position Additional Instructions • When the authorized employee is not available, the following actions may be taken: – Make a reasonable attempt to contact the authorized employee. – Remove all tools and material from the equipment area. – Make sure all affected employees are clear of the area. Additional Instructions • When the authorized employee is not available, the following actions may be taken: (cont) – With the approval of the Plant Manager, the lock and/or tag can be removed. – Upon the return of the authorized employee, immediately notify them of the removal of their lockout device. Training • Authorized Employees: – Instructed in the recognition of applicable hazardous energy sources. – Instructed in the procedures for lockout / tagout – Instructed in the proper procedures for deenergizing an energy control device. – Instructed in the use of the locks and tags. – Instructed in the procedures for restoring energy. Training • Affected Employees – Instructed in the purpose of lockout / tagout – Instructed to refrain from attempting to start or re-energize any machine or equipment that is locked out or tagged out • Other Employees – All employees will be instructed to stay clear of equipment or machines that are locked out or tagged out Training • Authorized and Affected Employees need to be retrained when: – there is a change in job assignment – there is a change in machines, equipment, or processes that present a new hazard – there is a change in the energy control procedures – periodic inspections reveal that there are deviations in the energy control procedures – the employer believes that there are deviations from, or inadequacies in, the employee’s knowledge or use of the energy control procedures Training • The objective of retraining is: – to introduce new or revised control methods and procedures as necessary, and – to reestablish employee proficiency • Initial training and retraining needs to be certified by the employer • The certification needs to contain the instructor, date of training, and content of the training, as well as the employees name Monitoring and Enforcement • The use of the energy control procedures must be periodically monitored. • The Plant Manager will be responsible for the implementation and enforcement of this policy. • Failure to follow this energy control policy will result in disciplinary action. • Disciplinary action may lead to employee’s termination of employment. Failing to enforce these procedures could lead to disaster! Annual Review and Inspection • The hazardous control policy must be reviewed annually. This review will include: – an inspection of the written procedures; – a review that the procedures are being followed. • The Plant Manager and Safety Department will ensure that this review and inspection is performed. • A lockout / tagout inspection checklist will be used to document this inspection • Procedures will be updated as necessary • Employees re-trained as necessary Annual Review and Inspection • The annual review and inspection will be documented. The following shall be recorded: – – – – The date of the review The procedure(s) or equipment being reviewed The employees performing the procedure if applicable The name of the employee performing the inspection • The annual review and inspection must be performed by an authorized employee other than the one being reviewed. Additional Resources • 29 CFR 1910.147 Control of Hazardous Energy (Lockout/Tagout) • 29 CFR 1910.333 Selection and Use of Electrical Work Practices • The NPCA Safety Manual • www.osha.gov Disclaimer • This publication is designed to provide accurate and authoritative information in regard to the subject matter covered; however, National Precast Concrete Association acts as mediator without approving, disapproving, or guaranteeing the validity or accuracy of any data, claim or opinion appearing herein. Information is provided and disseminated with the understanding that National Precast Concrete Association is not engaged in rendering engineering, legal, or any other professional services. If engineering, legal, or other professional assistance is required, the services of a competent professional should be obtained. National Precast Concrete Association does not assume and hereby disclaims liability to any person for any loss or damage caused by errors or omissions in the material contained herein, regardless of whether such errors result from negligence, accident, or any other cause whatsoever.

![Written Lockout/Tagout Program University of South Carolina [ENTER DEPARTMENT NAME HERE] ________________________________________________________________](http://s2.studylib.net/store/data/014237654_1-f6fe0126f82f5a7e8f94ca4512b4ab2f-300x300.png)