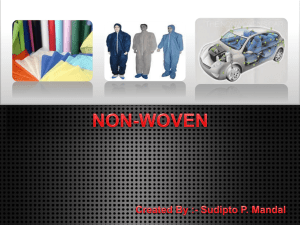

Non-woven Fabric: Introduction

advertisement

Non Woven Fabric Dr. Jimmy Lam Institute of Textiles & Clothing Non-woven • • • • Introduction Web formation methods Bonding Systems Discussion Introduction • Fabrics can be made from fibres as well as from yarns. • Conventional fabric production: – Fibre Yarn Fabric (knitting or weaving) • Non-woven production – Fibre Fabric • It eliminates the yarn production process and makes the fabric directly from fibres. Introduction (2) • The great advantages in non-woven fabrics is the speed with which the final fabric is produced. • All yarn preparation steps are eliminated, and the fabric production itself is faster than conventional methods. • To produce 500,000 meters of woven sheeting requires 2 months of yarn preparation, 3 months of weaving on 50 looms and 1 month for finishing and inspection. • Non-woven fabric can deliver the same quantity of sheeting within 2 months from order. Introduction (3) • Not only are production rate are higher for nonwovens, but the process is more automated, requiring less labour than even most modern knitting or weaving systems. • The nonwoven process is also efficient in its use of energy. Production Rate Fabric production method Weaving Rate of fabric production 1 m/min Knitting 2 m/min Nonwoven 100 m/min Applications • Nonwoven fabrics can be engineered to give a wide variety of properties. • Nevertheless, their aesthetic properties (handle, drape, appearance) are such that they are not in direct competition with conventional fabrics in the outerwear market. • Woven and knitted fabrics will not be replaced by nonwovens in the near futrue. • Currently, the main areas of growth in nonwovens are in geotextiles, medical and hospital uses, disposable products and filters. Making Non-woven products • • There are normally two steps for making non-woven products. They are: 1. Web formation; and 2. Bonding systems. Web formation • A nonwoven fabric is basically a web of fibres held together in some way. • The web may be made of staple fibres or filaments, or from portions of polymer film. Web formation from Staple Fibres Web from staple fibres Carding for parallel-laid web (1) • Carding is a time-honoured way of making web from staple fibres. • In a carded web the fibres are aligned more or less parallel to each other and to the direction in which the card produces the web. Such web is stronger when pulled lengthwise than crosswise because there is more friction between the fibre in lengthwise direction. • Carded webs are usually thin, they may be too thin for some nonwoven end-uses. To increase the final thickness, a number of webs can be layered. Photos Parallel-laid web from carded fibres Webs from staple fibres Cross-laid web (2) • To increase the strength of web in both lengthwise and crosswise directions, cross laid web is used. • To achieve this, the fibres which make up the web will be orientated equally in both lengthwise and crosswise directions. Photos Cross Laid-web The properties of cross-laid webs do not vary with direction as much as do those of straight-laid web Web from staple fibres Random web (3) • The Rando-Webber creates such a randomly orientated web by blowing the fibres about in a stream of air and then sucking them onto the surface of a perforated drum to form a layer. • This randomizing process produces a remarkably uniform web from staple fibres. • Dry-laid (air-laid card) webs account for three-quarters of non-woven produced Photos Random Webs The Rando-Webber gives a randomly orientated web, with no Directionality in its properties Other Web formation methods • Apart from carding methods (drylaid), webs from short staple fibres are created by 1. Wet laying; 2. Electrostatic web formation; and 3. Spraying. Wet-laying Paper-making from web • Wet laying is used in paper-making. The pulped fibres are mixed with water and then scooped into uniform layers on wire screens or on rotating, perforated drums. • Short, pulped acrylic fibres are made into a wet-laid web from a salt solution. As the water evaporates, the salt chemically bonds the fibres into a strong, synthetic, water proof paper. Web formed by electrostatic laying • In electrostatic laying, fine fibres are given a static electric charge between the plates of a condenser, and are then allowed to fall on a moving belt to form a randomly orientated but uniform web. Spraying method • Short thermoplastic fibres can be SPRAYED onto a belt to produce a random web. • The are subsequently fused by the application of heat and pressure. Webs from filament Webs from filament • It is possible to tangle filaments together to form a web. Such webs are much stronger than web made from staple fibres. • Freshly extruded filaments are allowed to drop in curls and spiral onto a moving belt. • The belt may contain patterns outlined in pins to form lace-like patterns. • The thermoplastic filaments are welded to each other to form a strong fabric suitable for curtains, tablecloths. • Sometimes, the filaments are textured before web formation, this allows greater extensibility of the fabric in use. New web formation method • Spun-laced webs is a new method of entangling fibres to create lace-like nonwoven fabrics uses fine, precisely controlled, jets of water. • When the jets pass through the web of fibres, they form a small vortex at each point of contact. • This creates sufficient fibre movement to entangle the fibres. • The resultant fabric does not need any further reinforcing by heat or adhesive. • It is pliable, resistant to damage during washing, drip-dry, light, warm and soft, excellent for curtains, table cloths and other lace-type application. Conclusion • This section we discuss what non-woven is and their applications in textile. • We also discuss the web formation methods for both staple fibres and filament fibres. • Next section, we will discuss the bonding systems for non-woven in order to make the fabrics with certain thickness and weight for specific end uses