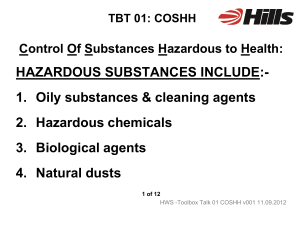

COSHH & Ballast Dust Awareness for Line Managers

advertisement

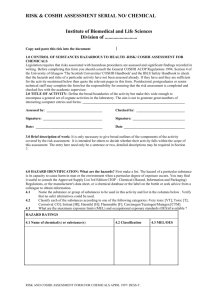

Awareness about COSHH and Ballast Dust for Line Managers Ballast Dust Working Group . About Control of Substances Hazardous to Health (COSHH) 2002 (as amended) • An employer legally has to control exposure to their staff of substances hazardous to health • Deciding how to prevent harm is built into the risk assessment process under COSHH which considers the hazard and potential exposures levels Ballast Dust Working Group . About Control of Substances Hazardous to Health (COSHH) 2002 (as amended) • Harm is eliminated/reduced through the provision of appropriate control measures applied to work processes and staff • Employers provide training and information to staff on the risks and controls for normal operations and for emergency conditions • Feedback loops should be in place to check controls are working such as site monitoring or staff health surveillance Ballast Dust Working Group .COSHH assessment detail: The COSHH assessment has the following requirements: – It needs to be activity specific – Identify the substances potential hazards in the form it is present – The potential health effects from exposure need to be understood Ballast Dust Working Group .COSHH assessment detail: – An estimation of risk needs to be undertaken where possible – Individuals/roles need to be understood as to what the exposure levels are – Control measures need to be implemented – The risks understood once the control measures have been implemented – The BDWG have produced a number of task specific COSHH assessments - where the potential exposure to ballast dust is known to be a risk – These cover a number of ballast delivery and treatment mechanisms i.e. using an Autoballaster Ballast Dust Working Group . Example of a COSHH assessment Ballast Dust Working Group .What do I do with these COSHH assessments? • Steps to take – First read through the risk assessments (COSHH assessments for ballast dust) where you – – – – carry out the activities and become familiar with them Brief the staff on the presence of the risk assessments and use the Tool Box Talks to brief the staff on the potential risks of inhaling ballast dust Review the work plan and provide controls (see the guidance note on SSoW controls) that can be implemented and that mitigate dust exposure Build these controls into your own Safe System of Work – as relying on these assessments alone doesn’t mean that you will be compliant with relevant legislation Check on the effectiveness of the controls – this includes checking maintenance regimes for equipment providing protection for employees – examples are seals on cabs, and non disposable Respirable Protective Equipment (RPE) Ballast Dust Working Group .Working safely in partnership • Report any issues with ballast dust to your relevant control who will escalate the issue to NDS 24/7 Control/or report it through the Close Call system