Tapping A Hole - Robotics Academy

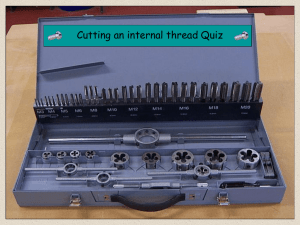

advertisement

Tapping A Hole Introduction • In this lesson you will learn to: – Produce internal threads for a specific size machine screw – Identify and select a tap for a required thread – Identify and select a drill for the required hole size – Drill and tap a hole using a hand tap Vex 1.0 © 2005 Carnegie Mellon Robotics Academy Inc. Thread Standards • Why are thread standards so important and how did they come about? – Thread standards allow parts to be interchangeable. Standards allow parts built in one plant to fit parts built in another. WWI and WWII played a large role in the development of standardized thread sizes. Henry Ford and his assembly line played a significant role in the development of standards. These standards enabled Ford’s workers to produce cars at a much faster rate. This made cars more affordable and made it easy for a mechanics to replace parts instead of making them. Vex 1.0 © 2005 Carnegie Mellon Robotics Academy Inc. Note to the teacher • In this lesson the students will learn to: – Identify the size of a machine screw – Identify the drill for the tap size by reading a tap and drill chart – Tap a hole using a hand tap • For this lesson, you will need a lab with a drill press or a hand drill, as well as the other materials listed on slide 5. Vex 1.0 © 2005 Carnegie Mellon Robotics Academy Inc. Students will be able to: • • • • • • Reason why threads were standardized Identify standard thread sizes Read a tap and drill chart Identify and select a drill for a tap Countersink a hole for thread lead-in Take measurements and apply them to tapping by using a chart Vex 1.0 © 2005 Carnegie Mellon Robotics Academy Inc. Materials List • • • • • • • • • • • • • • • Low Carbon Steel or Aluminum Block Machine Screw Screw Pitch Gauge Start and Plug Tap Tap & Drill Chart Tap Wrench Tapping Fluid Twist Drill and Drill Press Square Countersink Clamping Devices Micrometer Bench Vise Small Cleaning Brush & File Safety Glasses Vex 1.0 © 2005 Carnegie Mellon Robotics Academy Inc. Safety Note • Remember to follow safety procedures. Use proper drill speeds and feeds when working in the lab. If you do not know the proper drill speed for the material you are machining, consult your instructor. Make sure that all equipment is in proper working order and that all of your cutting tools are sharp and in good condition. Vex 1.0 © 2005 Carnegie Mellon Robotics Academy Inc. Detailed Procedure List 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. Select a machine screw that you would want to tap a hole for. Identify the diameter of the machine screw by using a micrometer or other measuring device that is accurate to within + or - .003 thousands of an inch. Identify the pitch of the thread or the number of threads per inch by using a thread pitch gauge. Identify whether the machine screw is a right hand or left hand screw by looking at the end of the threads. If the threads turn clockwise, then your threads are right handed. If they turn counter clockwise, then they are left handed threads. Use a tap and drill chart to identify the proper drill required by lining up both the diameter or decimal size and the pitch or threads per inch. Drill a through hole with the selected twist drill using the proper speeds, feeds, clamping devices and following the proper safety procedures. Countersink the hole to the required depth for the proper lead-in for the thread. Note: The proper lead-in will help you start the tap, guide the tap into the center of the hole, help keep the tap from breaking and help start the machine screw into the hole. Consult the machinist hand book for the proper depth or countersink the hole a little bigger than the diameter of the thread. Place your work piece in a bench vise so that it is level and just above the vice jaws. Note: At this point, you will need your tapping fluid, start and plug tap, tap wrench, square and a small cleaning brush. Place the starter tap in the tap wrench making sure that you hold the square part of the tap in the tap wrench. Apply a small amount of tapping fluid to the end of the threads on the tap, and place the tap in the pre drilled hole perpendicular to the top of the work piece. Turn the tap clockwise for a right hand tap, pushing slightly downward while keeping the tap perpendicular to the top of the work piece. Turn the tap two to three revolutions until the tap is slightly imbedded into the hole. Unscrew the tap wrench from the tap, leaving the tap in the hole. Check to see if the tap is perpendicular to the top of the material by using a square. ( If it is square, you can continue to tap. If not, you need to back the tap out a turn and then realign the tap using a square.) Continue turning the tap in a clockwise direction for one revolution, or until the tap gets tight. At this point, you no longer need downward force- just rotation. Turn the tap counterclockwise out of the work piece to break the chip. If you do not break the chip, you will break the tap. Continue following procedures 15 & 16 until the tap breaks through the work piece. Make sure that you have a full thread the whole way through the part. If the starter tap does not give you a full thread you can use a plug tap. Vex 1.0 © 2005 Carnegie Mellon Robotics Academy Inc. Machine Screw Assortment • Several machine screws are pictured at the left • Machine screws come in various shapes, sizes, and types of metal. Vex 1.0 © 2005 Carnegie Mellon Robotics Academy Inc. Identify the Diameter • Measure the diameter of the screw using a micrometer • Note the diameter • The diameter in the example is .375 • Convert from decimal to fractional sizes (.375 converts to 3/8 inch when converting from decimal to fractional sizes) Vex 1.0 © 2005 Carnegie Mellon Robotics Academy Inc. Identify Thread Pitch • Use a thread gauge to determine the number of threads per inch. • The example at the right shows 16 threads per inch. Thread gauge Vex 1.0 © 2005 Carnegie Mellon Robotics Academy Inc. Combine the diameter and the thread size .375 or 3/8 inch diameter 16 threads per inch These two bits of information allow us to determine that the size of the machine screw is 3/8-16. Consult the chart on the next slide to determine the drill size to cut the internal thread for this bolt. Vex 1.0 © 2005 Carnegie Mellon Robotics Academy Inc. Using a Tap & Drill Chart • Find the 3/8-16 machine screw size under the column named tap size • Read across to the left to identify the correct size of the drill you will use when preparing to drill the whole before tapping Vex 1.0 © 2005 Carnegie Mellon Robotics Academy Inc. Drill the Hole • Drill the hole with the bit that went with the tap you want to use on the chart. Note: Always use caution when drilling • Use safety goggles • Identify the proper drill speed for the material you are drilling •Secure your work . Vex 1.0 © 2005 Carnegie Mellon Robotics Academy Inc. Countersink the Hole • Countersinking the hole helps the tapping process by: – Guiding the tap – Centering the tap – Making it easier to start the screw Vex 1.0 © 2005 Carnegie Mellon Robotics Academy Inc. Tap Types • There are various types of Taps. • A starter tap is used to start threading. The large taper easily guides the tap into the hole. • A Plug Tap has less taper and has more threads for going deeper into holes. Vex 1.0 © 2005 Carnegie Mellon Robotics Academy Inc. Connect Tap & Tap Wrench • Place the starter tap in the tap wrench, making sure that the square part of the tap goes in first. Vex 1.0 © 2005 Carnegie Mellon Robotics Academy Inc. Gather your materials At this point you will need: • tapping fluid • start and plug tap • tap wrench • square • vice Vex 1.0 © 2005 Carnegie Mellon Robotics Academy Inc. Apply Tapping Fluid • Apply tapping fluid to threads next to the hole. • Place the tap in the pre-drilled hole, making sure it is perpendicular to the piece of metal. Vex 1.0 © 2005 Carnegie Mellon Robotics Academy Inc. Start the Tap • Push down and turn the Tap clockwise for a right hand tap. • Twist the tap while making sure that it is perpendicular to the metal piece. Vex 1.0 © 2005 Carnegie Mellon Robotics Academy Inc. Turn the Tap • Turn the tap 2-3 revolutions until it is slightly embedded into the hole. Vex 1.0 © 2005 Carnegie Mellon Robotics Academy Inc. Examine Tap • Unscrew the Tap Wrench from the Tap and leave it in the hole. • Check to see if it is perpendicular by using a square. Note: If tap isn’t perpendicular go back and re-align the tap before you continue. Vex 1.0 © 2005 Carnegie Mellon Robotics Academy Inc. Continue to Turn Tap • Continue to turn the tap. • Back it out before it gets tight, so you don’t break the tap. • Continue to ease it through in this manner until you have completed threads. Vex 1.0 © 2005 Carnegie Mellon Robotics Academy Inc. Check Your Work • Check your tapped hole with the correct size machine screw to make sure it works. And here you have the finished product. This is what a successfully tapped hole should look like. Vex 1.0 © 2005 Carnegie Mellon Robotics Academy Inc. Questions 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. When selecting a twist drill for a tap, why is it very important to consult a tap and drill chart? If you read 3/8-16 on a tap, what does the 3\8 and the 16 stand for? While tapping, what might happen if you do not turn the tap out to break the chip? What could be the result of not aligning the tap square to the material? How does countersinking the hole help in both the tapping and fastening process? What is the drill size for a ½-13 tap, 10-32 tap and a ¼-20 tap? Often, through much use, the size of the drill wears off so that you can not read it. What is another way to check the drill size? What is the difference between a starter tap and a plug tap? What would be the difference between a national course thread and a national fine thread? Explain why the need for standardized threads came about. Vex 1.0 © 2005 Carnegie Mellon Robotics Academy Inc.