Six Sigma

Dr. Ron Lembke

SCM 462

DMAIC

SELECTION CONSIDERATIONS

Financial return

Impact on customers and organizational effectiveness

Probability of success

Impact on employees

Fit to strategy and competitive advantage

SELECTING PROJECTS

Conformance Projects

Unstructured Performance Projects

Problems because system poorly specified

Efficiency Projects

Acceptable products, not meeting internal goals

Product Design

Not meeting customer CTQ

Process design

DMAIC

Define

Measure

Analyze

Improve

Control

(Alternate meaning: Dumb Managers Always Ignore

Customers)

DEFINE

Charter / rationale for the project

Why this, not others, need for project, costs, benefits

Developing a project charter (statement of the project)

Scoping:

Improve motor reliability

Most problems from brush wear

Problem with brush hardness

Reduce variability of brush hardness

DEFINE

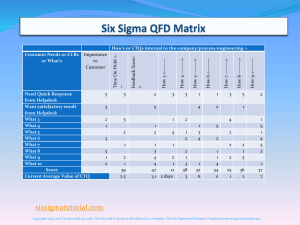

Gather voice of the customer data to identify critical-to-quality (CTQ) characteristics important to customers

Select performance metrics

What are current levels

Expected improvements

What will need to be done, by whom

DEFINE

SIPOC Understand the relationships between

Suppliers

Inputs

Process

Outputs

Customers

MEASURE

Develop operational definitions for each CTQ characteristic

Figure out how to measure internal processes affecting each

CTQ, KPOV (Key process output variables), KPIV (Input Vars)

Y = F(x)

Figure out what data we need to collect

Easy to collect correctly

Interrupt process as little as possible

Collectors understand why collecting

“gage study” to determine the validity (repeatability and reproducibility) of the measurement procedure for each CTQ

Baseline data

Collect baseline capabilities for each CTQ

Determine the process capability for each CTQ

Y=F(X)

CHECKSHEET

Consider all possibilities

Be clear – no guessing, training?

You might have forgotten some

Might need to revise – some cover too many things

Learn about different cases

PARETO CHART

3. Collect the data

5. Tabulate the data – Do as %, if you want to

(6. Put each problem into dollars of cost, most complaints, lost employee minutes, etc.)

8. Sort biggest to smallest, graph.

Analyze – p. 87 – what would you fix?

PARETO CHART

Further study of major categories

Grouping together smaller ones

Look for common causes

ANALYZE

Understand why defects and variation occur

Find the root causes

5W = 1H

Identify key causes

Experiments to verify impact

Formulate hypothesis, collect data

ANALYZE

Does the process work the way we think it does?

Identify upstream variables (x’s) for each CTQ

Process mapping

Operationally define each x

Collect baseline data for each x

Perform studies to determine the validity (repeatability and reproducibility) of the measurement process for each x

Establish baseline capabilities for each x

Understand the effect of each x on each CTQ

IMPROVE

Brainstorm ideas of potential root causes– everyone participates

Generate ideas about potential root causes

Understanding the process, not solving the problem yet

CAUSE AND EFFECT DIAGRAM

Ishikawa, Fishbone

Puts things in an organized way

Separate things into manageable parts (like KJ in that way)

Methods, Materials, Machines, People,

Environment, Information

Create the diagram

Analyze the diagram – look for cost effective solutions!

WHY-WHY

Ask “why” 5 times, or as many as it takes

List of next steps, things to investigate

GRAPHS

Scatter plots - Look for trends

Run charts – same thing

DJIA = Financial Performance?

IMPROVE

Determine optimal levels of critical x’s to optimize the spread, shape and center of the CTQ’s

Action plans to implement the optimal level of the x’s

Conduct pilot test of the revised process

RUN INTO RESISTANCE?

Force Field!

FORCE FIELD

ANALYSIS

For and against

Action items for each

Strength of each

CONTROL

Risk abatement planning and mistake-proofing to avoid potential problems with the revised settings of the x’s

Standardize successful process revisions in training manuals

Control revised settings of the critical x’s

Turn revised process over to the process owner for continuous improvement using the PDSA cycle

REPORT PHASE

Tell everyone what you did, so they can learn from it

HW – P. 97

Questions 3, 4, 6, 7, 10, 16