Mersen PV String Monitoring Solution

advertisement

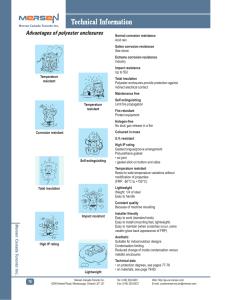

PV String Monitoring Solution Electronic Cards for use in PV Combiner Box Applications Mersen PV String Monitoring Solution The goals of PV String Monitoring – For the investor: to measure energy produced and forecasted revenues – For the operator: to detect defects for maintenance But most existing systems have huge limitations • Precision is not good enough at inverter level • Monitoring systems are proprietary • Data interpretation is not easy Need for high quality universal monitoring systems 2 Mersen PV String Monitoring Solution The advantages of string level monitoring – Detection of problems as soon as they appear – Precise localization of problems in the PV installation Pro-active maintenance Optimized PV installation performance Secured ROI, predictive revenues and reduced OPEX 3 Mersen PV String Monitoring Solution Performance Ratio Monitoring of instantaneous electrical parameters Energy produced over time T Performance Ratio = Energy expected over time T Monitoring of operating conditions: T°, sun,… 4 Mersen PV String Monitoring Solution A precise control of the installation from the PV field to the inverter String Monitoring in the combiner box Communication Gateway (GPRS, Ethernet, …) 2000 800,0 CurrentMean-PVString1 1800 CurrentMean-PVString2 700,0 CurrentMean-PVString3 1600 CurrentMean-PVString4 600,0 Pyranomètre Ens Modbus 1400 Temp ext Modbus Temp Cellule Modbus 1200 Monitoring Software Monitoring Software 500,0 400,0 W/m² °C mA 1000 800 300,0 600 200,0 400 100,0 200 0 6:00 5 7:12 8:24 9:36 10:48 12:00 13:12 14:24 15:36 16:48 0,0 18:00 Mersen PV String Monitoring Solution Product Offering – Flexible, High Performance Solution – Three Electronic Cards • MAIN Card • AUX Card • PROBE Card 6 Mersen PV String Monitoring Solution Monitor 6 to 30 strings by connecting up to (4) AUX Cards to the MAIN Card Monitor up to 8 external inputs (7 analog + 1 digital) by connecting the PROBE Card 7 Diagnostic & control: 4 digital inputs 3 external relay control Communication: MODBUS on isolated RS485 (1.2km cable) Aux Card extension: up to 4 Aux. cards in parallel 6 strings monitored per card 6, 12, 18, 24 or 30 strings can be monitored by one single box 32bits microcontrollers Modbus Communication Measurement & data processing 16Mbit memory (6 months data storage worse case) Probe Card extension: 1 digital sensor 7 analog sensors: • 4-20mA, ±1% precision • 1-10V, ±1% precision 6 PV string inputs Max voltage: ± 1000 Vdc Max current: ± 25 A Precision: ± 0.5% Autonomous power supply from PV strings 250Vdc to 1000Vdc string voltage Low power consumption: 4W @1000Vdc Reliable operating range -40°C to +70°C operating temperature Integrated Bus Bar 150A combined output (two output onboard temperature sensors (-40°C to +100°C ±2°C) terminals, 75A each) 8 Mersen PV String Monitoring Solution Features and Benefits – Built-in Power Supply – Take power directly from the PV string. Eliminates the need to purchase and install a separate power supply to power the monitoring device – Accuracy – 0.5% precision – Voltage and Current Measurement – Additional voltage measurement provides a greater level of detail and is required by some integrators 9 Mersen PV String Monitoring Solution Features and Benefits – Flexible 6-String Device – Allows for greater flexibility (can be configured for 6, 12, 18, 24 or 30 string boxes) – Integrated Bus Bar – Combines strings into 1 or 2 outputs based on ampere rating. Eliminates the need for separate comb bus bar – Increased Functionality – Option to connect up to 8 external sensors (anemometer, thermometer, sun sensor, etc…) 10 Mersen PV String Monitoring Solution Available Resources and Tools ep-us.mersen.com Installation Guide Data Sheet Tech Topics 11 PowerPoint PROBE Card MAIN Card ep-us.mersen.com 12 AUX Card