to *

advertisement

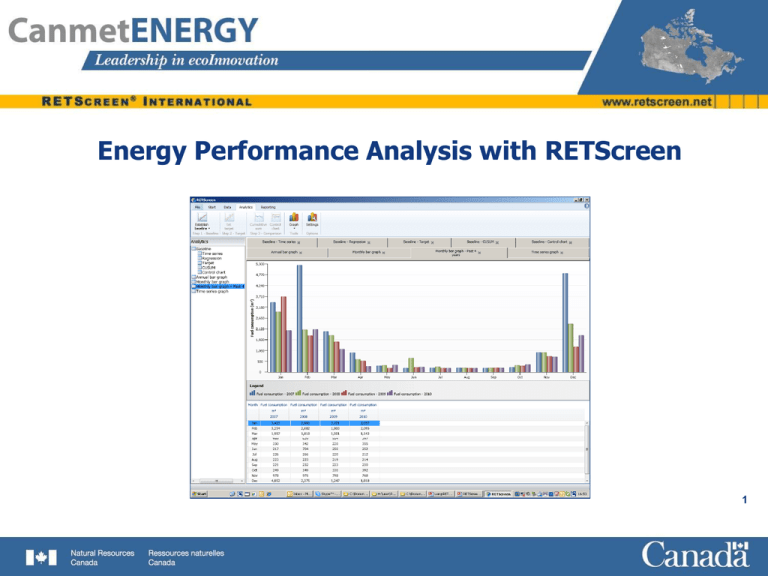

Energy Performance Analysis with RETScreen 1 Learning Objectives Review basics of energy performance analysis Illustrate methods and techniques for Monitoring, Targeting & Reporting (MT&R) Highlight key concepts of Measurement & Verification (M&V) Introduce the energy management software tool within RETScreen – the Performance Analysis Module Understand basic structure of the RETScreen Plus Performance Analysis Module Be able to use the software to monitor, analyse, and report key energy performance data 2 Monitoring, Targeting & Reporting (MT&R) MT&R provides a systematic approach to gaining and maintaining control over energy consumption (or production) through measurement and analysis followed by well-directed actions The key steps to effective MT&R are: measurement of energy consumption (or production) over time measurement of influencing factors (weather, production level, occupancy) over corresponding time intervals development of a relationship (a model) between energy and the influencing factors establishment of energy reduction (or production) targets frequent comparison of actual consumption (or production) with targets reporting of consumption (or production) and target variances initiation of actions to ensure targets are met 3 MT&R Feedback Loop Result Measure Data Take Action Analyse Information 4 Develop Relationship: Energy & Influencing Factors How does energy consumption or energy production vary with a factor of influence (i.e. driver, such as weather)? How does the relationship change with time? Consumption or Production Factors of influence Fuel consumption Weather Electricity consumption Occupancy Water consumption Production level Electricity production Solar radiation 5 Models Predict Energy Consumption or Production Historical consumption or production Static, not dynamic with drivers Statistical model E = Function of drivers Mathematical relationship between energy consumption (or production) and the “driver” exists It’s often linear, of the form y = mx + b Simple linear regression Multivariable non-linear regression 6 Establish Energy Reduction (or Production) Targets Energy Consumption or Production Reduce Variability Increase Efficiency Reduce Non-Productive Energy (waste) Driver(s) or Factor(s) of Influence 7 Typical Tools Used for Energy Performance Analysis Data visualization (e.g. monthly graphs) Time series graphs Regression analysis Cumulative sum (CUSUM) charts Targeting Control charts Reports “tools that help to identify, understand, quantify and display the relationship between energy and what drives it” 8 Reporting Pathways for a MT&R System 9 RETScreen Plus Performance Analysis Module Helps user monitor, analyse, and report key energy performance data to facility operators, managers and senior decision-makers Energy management software tool Monitoring, Targeting & Reporting (MT&R) Measurement & Verification (M&V) Energy tracking Data Analytics Integrates near-real-time NASA satellite-derived weather data for entire surface of planet Reporting 10 Performance Analysis Module - Structure Start Project information Site reference conditions Data Step 1 – Consumption/production Step 2 – Factors of influence Step 3 – Data processing Analytics Step 1 – Baseline Step 2 – Target Step 3 – Comparison Reporting Step 1 – Report Step 2 – Edit Step 3 – Output 11 12 13 14 15 16 Project Example: MT&R Office Building, Burns Lake, BC, Canada See template Photo Credit: Jeff Ragsdale, Village of Burns Lake 17 Measurement & Verification (M&V) A process of quantifying energy consumption (or production) and water consumption before and after an Energy Conservation Measure is implemented to verify and report on the savings actually achieved International Performance Measurement and Verification Protocol (IPMVP) http://www.evo-world.org 18 Select IPMVP Option A. Partially Measured Retrofit Isolation With assumption/stipulations MBRP Process M&V Process Prepare the M&V Plan Step 1, 2 & 3 Prepare the Organization Select IPMVP Option Step 4 Select Implementation Method Define Base Year Performance B. Retrofit Isolation Fully measured C. Whole Facility Or sub-metered part Identify, Select and Assess the ECM's Define Post ECM Period Step 5 & 6 Design Energy Savings Program Develop Performance Model Implement the Implement the ECM's Prepare the ECM's M&V Plan Revise Performance Model NO, Needs Revision Step 7 Implement the ECM's Step 8 Implement the M&V Plan NO, Approach not Suitable Test Performance Model for Uncertainty etc.. Model OK Yes D. Calibrated Simulation With software Apply M&V Performance Model to Ongoing Management Save ! Define & Specify Metering Equipment Define Ongoing M&V Activities Document the M&V Plan Done 19 A. Partially Measured Retrofit Isolation Example: T12 to T8 lighting retrofit Instantaneous measurements of lighting power before and periodically after retrofit Assumptions (stipulations) for operating hours and burnout rates Calculation of heating interaction from electrical savings & boiler efficiency 20 B. Retrofit Isolation Example: boiler replacement Three separate test of boiler efficiency were made before and after retrofit Boiler was effectively isolated by gas meter on the input and heat meter on the output Savings are reported under base year conditions 21 C. Whole Facility Example: multiple energy conservation measures (ECM), operator training & occupant awareness Gas & electricity modeled by correlation to heating degree days (HDD) Adjustments made for new computers Savings calculated under post retrofit conditions as “avoided costs” 22 D. Calibrated Simulation Example: ECM’s in one non-metered building of a multi-building complex New electric and steam metered installed RETScreen Energy Model - Energy efficiency measures project Fuels & schedules Schedule Description Temperature - space heating Temperature - space cooling Post retrofit energy use was computed with software calibrated to match readings Show data Fuel Fuel type Fuel consumption - unit Fuel rate - unit Fuel rate Temperature - unoccupied Occupancy rate - daily Monday Tuesday Wednesday Thursday Friday Saturday Sunday Occupancy rate - annual Heating/cooling changeover temperature Length of heating season Length of cooling season Fuel type 1 Electricity MWh $/kWh 0.100 Fuel type 2 Natural gas - m³ m³ $/m³ 0.400 Fuel type 3 Fuel type 4 Fuel type 5 Fuel type 6 #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A Unit Schedule 1 24/7 Schedule 2 Schedule 3 Schedule 4 Schedule 5 Schedule 6 °C °C 23.0 23.0 +/-°C h/yr % °C d d Occupied Occupied Occupied Occupied Unoccupied Unoccupied Unoccupied Unoccupied Occupied h/d Occupied h/d Occupied h/d Occupied h/d 0 0% 0 0% 0 0% 0 0% 16.0 242 123 Facility characteristics Show: Fuel saved h/d 24 24 24 24 24 24 24 8,760 100% Occupied 21.0 24.0 Unoccupied 3.0 Occupied h/d 18.0 18.0 18.0 18.0 18.0 18.0 18.0 6,570 75% Show data Heating GJ Cooling GJ Electricity GJ Incremental initial costs $ Fuel cost savings $ Incremental O&M savings $ Simple payback yr 0 - - 0 0 0 - - 0 - 0 0 0 - 2,686 0 - 60,000 28,659 0 2.1 0 0 60,000 28,659 0 2.09 Include measure? Heating system Boiler Cooling system Air-conditioning Baseline computed from “calibrated model” and base year weather Building envelope Appartment building Ventilation Lights Electrical equipment Hot water Other Total Savings = baseline - post Show data Fuel Fuel type Natural gas Total Project verification Fuel type Natural gas 2,686 Summary Energy Energy - base case Energy - proposed case Energy saved Energy saved - % Benchmark Energy unit Reference unit User-defined Benchmark Energy Energy - base case Energy - proposed case Energy saved Fuel consumption unit m³ $ Base case Fuel rate 0.400 Fuel consumption 160,194.2 $ $ Proposed case Fuel cost 64,078 64,078 Fuel consumption unit m³ Fuel consumption historical Fuel consumption Base case 160,194.2 Fuel consumption variance Heating GJ 4,204 2,324 1,880 44.7% Cooling GJ 0 0 0 Electricity GJ 0 0 0 Total GJ 4,204 2,324 1,880 44.7% Electricity kWh/m² 0.0 0.0 0.0 Total kWh/m² 155.7 86.1 69.6 kWh m² m² 7,500 2,000 Heating kWh/m² 155.7 86.1 69.6 Cooling kWh/m² 0.0 0.0 0.0 Fuel consumption 88,546.3 $ $ Fuel cost 35,419 35,419 Fuel cost savings Fuel saved 71,647.8 $ $ Fuel cost savings 28,659 28,659 23 Project Example: M&V Photovoltaic Power System, Toronto, ON, Canada See template Photo Credit: Carmanah Solar 24 Conclusions Implementing an energy monitoring, targeting and reporting (MT&R) system can be a powerful way to better manage energy project investments as well as identify additional project opportunities The RETScreen Plus Performance Analysis Module can be used worldwide to monitor, analyse, and report key energy performance data to facility operators, managers and senior decision-makers A Data worksheet enables the user to create, import, calculate, filter, merge and store various datasets needed to prepare an analysis An Analytics worksheet helps the user establish a baseline for the project, predict the energy consumption or production of a facility using regression analysis, set a target and then track the energy performance of an ongoing basis The Reporting worksheet allows the user to create, edit and output various datasets and figures needed to properly present the analysis of the project The measurement and verification (M&V) of actual savings (or production) achieved by a clean energy project is an important final step in the energy decision chain 25 Questions? www.RETScreen.net 26