McGuinness & Co. Microbrewery Case Study

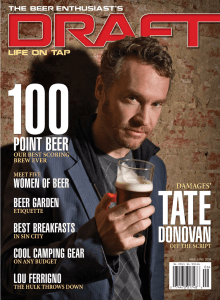

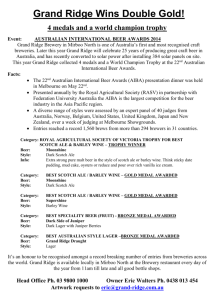

advertisement

McGuinnes & Co. Microbrewery Case Study Company Description • One of the three largest microbreweries in Atlanta area • Company started in 1995 • A 12,000sq. ft. production facility and warehouse in the Chattahoochee Industrial Park • The company is run by its owner, Mr. McGuinness • Three full-time and two-part time employees, and occasionally hires part-time help • Last year’s sales: > 35,000 cases => > $180,000 • Average weekly sales: 500-800 cases Company Products • Pale Ale: The oldest company product. Since May 2000, this product is also offered in the NY and Boston areas, through a major national distributor. • Product monthly sales over the last four years (1997-2000) in cases of beer: Sales 1600 1400 1200 1000 800 Sales 600 400 200 0 1 4 7 10 13 16 19 22 25 28 31 34 37 40 43 46 Company Products • Stout: A rather new product, offered only in the last 14 months. • Monthly sales in cases for the last 14 months: Sales 700 600 500 400 Sales 300 200 100 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 Company Products • Winter Ale: A seasonal beer, offered primarily during the winter period (from October to April). • Product monthly sales over the last 4 years: Sales 1400 1200 1000 800 Sales 600 400 200 0 1 4 7 10 13 16 19 22 25 28 31 34 37 40 43 46 Company Products • Summer Brew: A seasonal beer offered primarily during the summer season. A new product offered over the last two years. • Product monthly sales in cases over the last two years: Sales 700 600 500 400 Sales 300 200 100 0 1 3 5 7 9 11 13 15 17 19 21 23 Company Products • Octoberfest: An “image promoter” for the company, offered once a year, during the Octoberfest season. The product is delivered to the company distributors and the local restaurants only once a year, in late September or early October. • Product annual sales in cases for the last four years: Sales 450 400 350 300 250 200 150 100 50 0 Sales 1 2 3 4 Company Operations Grain cracking (1 milling machine) Fermentation (3 40-barrel ferm. tanks) Mashing (1 mashing tun) Boiling (1 brew kettle) Bottling (1 bottling station) Filtering (1 filter tank) Fermentation Times: Brew Pale Ale Stout Ferm. Time 2 weeks 3 weeks Winter Ale 2 weeks Summer Brew 2 weeks Octoberfest 8-10 weeks Company Challenges • Company production scheduled by its owner, in an ad-hoc fashion • Sustained growth strains the company production capacity • There is a dire need for a systematic methodology that will allow the company and its owner to – foresee the expected production requirements over a certain planning horizon; – organize appropriately its production activity based on the forecasted demand; – systematically manage its growth by adjusting appropriately its capacity. • Eventually, this methodology should be offered to the company in a set of user-friendly tools. A Production Planning & Control Framework Tactical Planning Demand Forecasting Production Scheduling Capacity Planning Material Requirements Planning Execution Sales order Processing Purchasing Production Control Inventory records Shop-floor data Collection Recording