Boiler Operation

advertisement

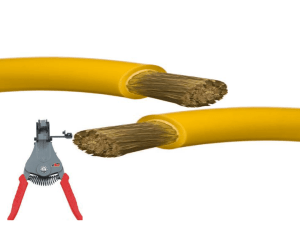

INSTRUCTOR: ROBERT A. MCLAUGHLIN ZAILI THEO ZHAO 1 HIGH PRESSURE FITTINGS 16:06 POWER EQUIPMENT LEARNING OBJECTIVES 16:06 A boiler and pressure vessel. A level 1 boiler and a critical pressure boiler. The various pressure fittings used on boilers. The types of safety valves on boilers. The components of a boiler gauge glass. The proper procedures for removing a boilers gauge glass from service, disassembly of the gauge, inspection and replacement and rebuild of a typical gauge glass. 2 BOILER A steam boiler is a closed pressure vessel in which water is heated to generate saturated steam. 16:06 The water is heated by the gasses of combustion. A pressure vessel that produces hot water heated by the gasses of combustion is also a boiler. 3 BOILER - CLASSIFICATION Boilers can be divided into two pressure related categories: 16:06 Low pressure – boilers operating at 15 psi and below. High pressure – boilers operating above 15 psi. 4 16:06 Boilers can also be categorized into Level ratings. A Level 1 boiler is When the temperature and pressure of a boiler equals 1500 or more. All of the components of a level one boiler designed with a safety factor of 5 and are tested and given serial numbers. 5 WHAT IS THE FACTOR OF SAFETY? Ultimate strength divided by allowable working stress or bursting pressure divided by safe working pressure. It can vary between four and seven depending on age, type of construction, and condition. Use five for most calculations 16:06 T St E p (R)(FS) 6 CRITICAL PRESSURE Many boilers operate at pressures 1000 to 3000 psi. Some operate at critical pressure – 3206 psi and 705.08oF Critical pressure is the pressure at which steam and water at the same density. All critical pressure boilers must have separate a pump to create circulation. 16:06 7 EXTERNAL FITTINGS AND CONNECTIONS All steam and water sections must have these. The superheater will have drains. The drums and headers will have drains. 16:06 Drains 8 EXTERNAL FITTINGS AND CONNECTIONS 16:06 Vent high pressure globe valve at high point in the boiler used when filling and emptying the boiler. 9 EXTERNAL FITTINGS AND CONNECTIONS connections used for taking boiler water samples. Drains, vents, and sampling connections will all have high pressure rated globe valves attached to the connection. 16:06 Sample 10 EXTERNAL FITTINGS AND CONNECTIONS stop and check valves 16:06 Feed to manually regulate the flow of water to the drum. 11 EXTERNAL FITTINGS AND CONNECTIONS stop valves 16:06 Steam located at the superheater and desuperheater outlets. Used to cut the boiler in or out of the main steam line. 12 EXTERNAL FITTINGS AND CONNECTIONS valve two types (huddling chamber and nozzle reaction type). They are not relief valves. 16:06 Safety Question What is the difference between the safety and relief valves? 13 EXTERNAL FITTINGS AND CONNECTIONS blower Fixed and retractable 16:06 Soot 14 INTERNAL FITTINGS 16:06 15 16:06 16 EXTERNAL FITTINGS AND CONNECTIONS Water gage glass – attached directly to the drum, they allow the operator to see the water level in the drum. All boilers operating over 400 psi are required to have two independent means of determining water level. One will be a gauge glass attached directly to the steam drum; one will be a remote water level indicator. 16:06 17 EXTERNAL FITTINGS AND CONNECTIONS and pressure gauges Superheated steam flow indicators 16:06 Temperature 18 THE OPERATOR CONTROL THE SAFE OPERATION OF THE BOILERS. 16:06 19 GAUGE GLASS Two independent means of indication 16:06 These can consist of two gauge glasses attached to the drum, or a single gauge glass, and a remote water level indicator. A gauge is located so that: the lowest visible part of the glass is 2” above the lowest permissible drum water level the upper most visible part of the glass is located 2” below the upper most 20 GAUGE GLASS Boilers operating at pressures below 250 psi can be fitted with tubular type gauge glasses Above 250psi, flat type gauge glasses are required. Isolation valves are required on each leg of the gauge glass 16:06 21 GAUGE GLASS 16:06 There are high pressure glass type indicators that can be used instead of flat gauge glasses, for example, bicolor gauge glasses. Figure gauge glasses work on the principle of light refraction 22 GAUGE GLASS Every gauge glass will have valves to isolate the gauge from the drum pressure for maintenance and emergency situations. 16:06 The isolation valves are usually of the quick closing type, capable of being closed with ¼ turn of the handles. The handles will be connected by chain pulls so that an operator can pull on the chain and close both valves at the same time from a remote location. The bottom isolation valve will always be fitted with a ball check device to prevent hot water from flowing through a broken gauge glass. 23 GAUGE GLASS Each gauge glass assemble will be fitted with a blowdown connection to: 16:06 Insure that the connections between the drum and gauge do not become clogged. To help the operator tell the level in the glass. If you are in doubt of the level in the glass, blow the glass down (open the gauge drain valve). If you blow a glass down, and you see the water level go up through the glass, then the drum level is high. If no level appears, then the level is high. 24 GAUGE GLASS 16:06 Leaks above the actual water level will indicate higher than normal levels. Leaks below the actual level will indicate lower than normal levels. 25 GAUGE GLASS To blow a glass down for normal maintenance: 16:06 Disconnect the pull chains Close the top valve and open the drain valve (blowdown valve). Let it drain for a few seconds. Open the top isolation valve and close the bottom isolation valve. Leave the drain open for a few more seconds. Close the drain valve. Open the bottom isolation valve and reattach the chains. 26 FLAT TYPE OF GAUGE GLASS CONSTRUCTION 2. 3. 4. 5. 6. 7. 8. BODY FLAT GUAGE GLASS MICA SHEET ASBESTOS GASKETS ASBESTOS CUSHIONS COVERPLATES STUDS NUTS 16:06 1. 27 GAUGE GLASSES AND TRY COCKS Both the water column and gauge glass must blowdown daily 16:06 Prevent sludge accumulations from blocking lines Observe the level when it is blown. When the valve is opened, the water should drop out of the glass rapidly. When the valve is closed, it should return rapidly to its previous level. If the glass water drains slowly This is an indication of clogging up. The situation must be corrected as quickly as possible, even if the coiler has to be shut down. 28 There is one adjustment on the muddling chamber type safety valve 16:06 Adjusting ring Question Who can adjust the boiler safety setting pressure? 29 There are two adjustments Adjusting ring Nozzle ring 16:06 Question How to increase the blowdown pressure? 30 THE WIRES FOR REMOTE RELEASING SAFETY VALVE 16:06 31 GATE VALVE RISE STEM 16:06 32 GLOBE VALVE 16:06 33 SWING CHECK VALVE 16:06 34 BALL VALVE 16:06 35 BUTTERFLY VALVE 16:06 36 MARINE BOILER EXAMPLE WHAT ARE THESE FITTINGS? 1 - Gauge Glass or Water Column 2 - Main Steam, Safety, Auxilary Steam Valves 3 - Pressure Gauge 4 - Surface Blow 5 - Skin Valve (through ship's side) 6 - Bottom Blow 16:06 7 - Hydrokineter (to increase water circulation) 8 – Furnaces 9 - Fire-Tube bundles 10 - Main Feed Valve 11 - Auxiliary Feed Valve 12 - Deep Blue sea 37 16:06 38 16:06 THANK YOU 39