Oxyacetelyne Torches

advertisement

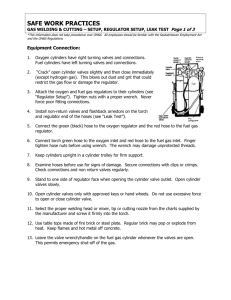

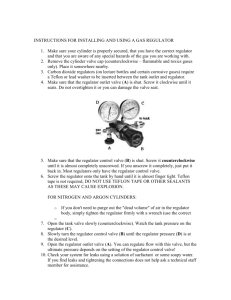

Oxyacetylene torches Harkness career center Complete torch assembly Oxygen tanks When full, can have up to 2400 psi Attaches regulators using Right handed threads Tank should be labeled “Compressed Oxygen” -If tank is not labeled come and exchange tank with proper ID one Never transport tank with out safety cap on the valve Acetylene tank When full contains 250 psi Regulator uses left hand threads Acetylene over 15 psi is Unstable. Porous mass inside tank consists of Aston and Balsa wood – to keep the Acetylene stable Should be stored standing up, if laid down it must stand for 8 hours before using Regulators • Regulators are designed to control and reduce high gas pressure from a cylinder or pipeline, in one or two stages, to the working pressure required for the equipment using it. Safety Precaution • Do not use any oils, thread sealers, or grease on regulator fittings. They pose a fire / explosion hazard. Regulator Set – up cont. Before connecting a regulator to a cylinder or pipeline, open (crack) cylinder valve for a few seconds, allowing gas to force out any possible foreign matter (dust, dirt, pollen, etc.) Connect regulator inlet connection to cylinder or pipeline and tighten it firmly with a suitable regulator wrench. Regulator Set – up cont. •Connect and similarly tighten the hose nut to regulator outlet and attach other equipment as needed. • CAUTION ! Do not force connections that do not fit. Acetylene fittings are LEFT – HANDED thread (usually indicated by a line or slash mark on the fitting). Regulator Set – up cont. • Test connections by applying a soap solution of a capful (¼ oz.) of Ivory Liquid detergent or equivalent per gallon of water. • Bubbles indicate leakage. • If no bubbles appear, the system is ready for use. Flash back arresters • Are mounted in-line between the lines and the torch handle. • Are to prevent the flame from reaching the tanks in a case of a flash back. (flame burns inside the handle) The Oxyacetylene Torch Mixing Handle (the cutting torch handle) • Attach Torch Mixing handle • The torch mixing handle should be attached to the hose end. Do not over tighten either mixing handle or regulator end hose connections. • Where rubber o – ring seals are used hand tightening is sufficient. Regulator Set – up cont. • Before opening cylinder valve, turn adjusting screw to the left (counterclockwise) until no spring tension is felt. • Never open cylinder valve until spring tension on adjusting screw has been released in this manner. Regulator Set – up cont. • SLOWLY open the cylinder or station valve, to avoid a sudden pressure surge that may damage internal regulator parts. • DO NOT STAND IN FRONT OF OR BEHIND THE REGULATOR WHILE OPENING THE VALVE. Stand with the tank valve between you and the regulator. Regulator Set – up cont. • Fully open the oxygen valve (it has a double seating valve). • Only open the acetylene tank valve ¼ to ½ of a turn (this makes it easy to close in the event of an emergency). Regulator Set – up cont. • Slowly turn adjusting screw clockwise until the outlet gauge shows the desired working pressure. • Set acetylene regulator pressure to 7 psi. • Set oxygen pressure to about 15 psi. Safety Precautions • A regulator which is not working properly should not be used until all required repairs have been made and the unit has been tested to ensure that it is in proper operating condition. • No repairs or maintenance should ever be attempted by anyone not qualified to do so. Regulator Set – up cont. • To prevent igniting explosive gas mixtures, in the hoses or other equipment attached to the regulator outlet, before lighting the torch, purge the system. • This is done by opening the equipment valves (cutting handle, etc.), allowing gas to flow for about 5 seconds per 50 feet of hose. Regulator Set – up cont. • CAUTION ! • Do not purge gases in the presence of flame, lit cigarettes, or other sources of ignition, or towards persons. The Spark Lighter • Squeezing the handle moves a piece of flint across a rough metal surface thus producing a shower of sparks. Lighting the Torch • Open the acetylene mixer valve a small amount while operating a striker or a spark lighter in front of the tip. • KEEP THE TIP FACING IN A SAFE DIRECTION. HAVE YOUR WELDING GOGGLES IN POSITION. Flame Adjustment • When the acetylene ignites, adjust the flame until it is hovering about 1/8 in. from the tip. Carbonized flame Flame Adjustment cont. • Immediately open the attachment oxygen valve and adjust the flame. By starting with a neutral flame (long yellow acetylene feather). Flame Adjustment cont. • In order to obtain a oxidized flame slowly close the acetylene valve until sharp blue tips are present. Making the Cut • In an oxyacetylene torch, the preheating flame is maintained at the tip through small orifices or openings around the center orifice. • The preheating flame is held close to the work at the point where the cut is to start. Making the Cut cont. • Hold the torch at a right angle to the work with the preheat flames just clear of the surface. • When the spot has been heated to a bright cherry red or hotter, depress the oxygen jet lever. Making the Cut cont. • When the stream of pure oxygen strikes the heated area, it will cut (burn) through the steel. • As soon as the cut starts, move the torch along the work. Move as rapidly as the cutting will allow. Keep the oxygen lever fully depressed. Making the Cut cont. • If the cutting action stops, release the oxygen lever and with the preheat flames (they burn continuously), preheat again. • Note how the cutting torch removes a narrow kerf (cut) and how the molten metal (slag) is blown out from beneath the work. Shut Down • Close cylinder valve whenever regulator is not in use, as follows. • Close the cylinder or station valve. • Open the equipment valve to drain the line towards a safe area. • After gas is completely drained , release adjusting screw and close equipment valve.