Johnson ARW2011 Thermal imaging platform

advertisement

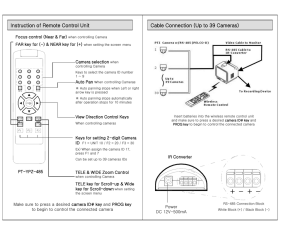

Development of a Remotely Controlled, Mobile, Thermal Imaging Platform. Adrian Johnson Senior Operations Technician Diamond Light Source Adrian Johnson. ARW2011 10-15 April 2011 Overview of Diamond • • • • Opened for Users in 2007. Currently 18 operational Beamlines. 4 Beamlines currently under construction. Total of 32 Beamlines by 2017. Adrian Johnson. ARW2011 10-15 April 2011 Overview of Diamond Accelerators • 100MeV Linac. • 3GeV Booster. • 3GeV Storage Ring. • Stored Beam currently at 200mA (running in Top up). • Target of 300mA (running in Top up). • Stable beam to provide steady conditions for Users. • Beam position to be stable and reproducible. • Beam profile to stable and reproducible. • Minimise beam downtime. Adrian Johnson. ARW2011 10-15 April 2011 The Need • Assessment of beam induced heating. • Assessed by calculation, but needs verifying. • Entry with handheld camera after beam dropped not adequate. • As we head towards 300mA beam, want to perform thermal surveys of the Storage Ring with stored beam present. • To do this needs a remote control thermal imaging camera. Adrian Johnson. ARW2011 10-15 April 2011 The Working Environment • • • • • • Inside the ‘Locked up’ Vaults. Stored Beam present. Blue lighting. Smooth Flooring. Few obstacles. Trenches. Adrian Johnson. ARW2011 10-15 April 2011 The Working Environment • Accelerator vaults divided into PSS search Zones. • Zone gates at either end and on entrance. • Zone gates are interlocked. • Traps remote control camera in one Zone. • Access only during Machine Development shifts. Adrian Johnson. ARW2011 10-15 April 2011 Design Requirements • Capable of capturing Thermal Images. • Capable of being fielded in the Accelerator Vaults with beam present. • Without affecting the machine operation. • Remotely Controlled from the Control Room. • Stable and Controllable. • Able to recharge batteries to facilitate long term use. • Locked in a zone for at least 1 week. • Inexpensive. • Height Adjustment on Thermal Camera. Adrian Johnson. ARW2011 10-15 April 2011 Hardware Thermal Camera FLIR A320 Pan / Tilt Head Visible light Camera Motorised Lab Jack CoroBot ‘Robotic’ Drive unit Adrian Johnson. ARW2011 10-15 April 2011 Network set up • Camera Platform controlled over a Wireless network. • FLIR and Axis cameras connected to CoroBot LAN port via a Network switch. • CoroBot LAN and WiFi connected via ‘Network Bridge’ in Windows XP. • Wireless access point connected to existing ‘secondary’ network in Vault. Adrian Johnson. ARW2011 10-15 April 2011 Software • Control Software. • Microsoft Robotics Studio, written in C#. • Modular Services running concurrently (i.e. each one on a separate thread). • Services read from sensors or sends commands to actuators or read/write to other services. • Control by communication between services. • Used original CoroBot Drive, Motor Encoder control and Input / Output Board Services. • New Services written: • Motor Control Board (to control Height adjustment motor). • Robot Drive Control. • Robot Power. Adrian Johnson. ARW2011 10-15 April 2011 Battery charging • Modifications for Battery Charging. Adrian Johnson. ARW2011 10-15 April 2011 Height Adjustment • Addition of Camera Height adjustment. • Speed controlled to accelerate / decelerate smoothly, to prevent tipping. • 25cm (40cm full travel) of height adjustment, to put Thermal Camera 1m from floor level. Adrian Johnson. ARW2011 10-15 April 2011 Control • Controlled from the Main Control Room. • Driven by the on duty Operator. • Two Remote desktop sessions. • 1st to the Robot PC. • Control GUIs for Driving, Battery Charging and Pan/Tilt head. • 2nd to another Windows PC. • FLIR camera software. • Axis Camera web page (used for Navigation). • Can also be controlled from any PC/Laptop connected to the Network. Adrian Johnson. ARW2011 10-15 April 2011 Control User Interfaces Adrian Johnson. ARW2011 10-15 April 2011 Usage. • Storage Ring Survey. • Nov / Dec 2009 – started survey 250 & 275mA stored beam. • High current running and surveys being carried out during Machine Development shifts. • Two Zones completed. • High current running delayed due to RF cavity issues. • 2010. • Verification of correct water flow to Booster RF Cavity following adjustment and manifold modifications. • Confirmation that a set of Vacuum bellows was not damaged following a Girder movement. • Monitoring of new components installed, during a major lattice change. Adrian Johnson. ARW2011 10-15 April 2011 Vacuum Vessel Bellows - Results RF Off RF On 50kW CW 150mA 600 bunches 200mA 900 bunches Adrian Johnson. ARW2011 10-15 April 2011 New Installation - Results RF Off 200mA 900 bunches 200mA hybrid fill Adrian Johnson. ARW2011 10-15 April 2011 New Installation - Results RF Off 200mA 900 bunches 200mA hybrid fill Adrian Johnson. ARW2011 10-15 April 2011 Costs Item Cost (as of 2009) FLIR A320 Thermal Camera £7500 CoroBot £3000 Axis 213 Camera £1400 Pan / tilt head £130 Motor Control Card £100 Modified Lab Jack £150 Networking Components £50 Misc. £200 Total £12530 • Estimated ½ man year of effort from concept to use. Adrian Johnson. ARW2011 10-15 April 2011 • Limitations. Limitations • The platform can only be used in one PSS zone at a time, due to the Zone Gates. • Viewing of components on the ‘far side’ of the Storage Ring is limited to static placement. • Battery life when roaming, approx. 1 hour. • Radiation damage to the Axis camera. • Battery life degradation. Adrian Johnson. ARW2011 10-15 April 2011 Summary • An inexpensive Remote Control, Mobile, Thermal imaging camera platform has been developed. • It has been in use in the Diamond accelerator vaults, with beam present, for over a year. • It has proved to be a useful tool. Adrian Johnson. ARW2011 10-15 April 2011 End of Presentation Adrian Johnson. ARW2011 10-15 April 2011 Hardware Details (appendix) • FLIR A320 Thermal Camera. • 320x240 pixel, uncooled microbolometer. • -20ºC to +120ºC or 0ºC to +350ºC temperature range, ± 2ºC accuracy. • TCP/IP communication. • Hague Pan/tilt camera mount. • USB controlled. • CoroBot ‘robotic’ drive unit. • 1.5GHz PC, 512MB RAM, 802.1g WiFi card, 80GB Hard drive, Windows XP. • 4 wheel motorised drive, with differential speed steering controlled via a Lynx motion SSC-23 servo control board. • A Phidgets 8/8/8 Interface card to provide 8 Analogue and 8 Digital inputs and 8 Digital Outputs. • 10AHr 12V rechargeable batteries, ~2.5hours of run time. • Axis 213 PTZ camera. • TCP/IP camera. • ±170º Pan, -10º to +90º tilt. • Low Light mode, with built in Infra Red LED light. Adrian Johnson. ARW2011 10-15 April 2011 Timescales (appendix) • Oct 2008 - Project initiated. • Dec 2008 – Specification issued. • Jan 2009 – Orders placed. • Apr 2009 – All Hardware delivered. • June 2009 – First test fielding in Linac (no charging). • Hardware and Software Modifications made to facilitate charging. • Nov & Dec 2009 - Survey of Storage Ring started, 250 and 275mA stored beam. • High current running and surveys being carried out during Machine Development shifts. • High current running delayed due to RF cavity issues. Adrian Johnson. ARW2011 10-15 April 2011 Timescales (appendix) Jan to May 2010 – Modifying Robot to fit Height adjustment and write software. • Jun 2010 – Monitoring of Booster RF Cavity water temperatures after flow adjustment. – Monitoring suspect set of bellows in the Storage Ring (150mA 900 bunches). • July 2010 – Monitoring Booster RF Cavity water temperatures with increasing power. • Aug 2010 – Monitoring suspect set of bellows in the Storage Ring (150mA & 200mA 600 bunches). • Sept to Nov 2010 – Monitoring of new ‘Mini Beta’ components in Storage Ring (200mA, 900 & 600 bunches and hybrid fills) • Apr 2011 - Monitoring of second installation of ‘Mini Beta’ components in Storage Ring. • Adrian Johnson. ARW2011 10-15 April 2011 Booster RF Cavity Cooling – Results (appendix) RF Off RF On 50kW CW RF On normal ramp Adrian Johnson. ARW2011 10-15 April 2011 Remote desktop set up (appendix) Adrian Johnson. ARW2011 10-15 April 2011