What Is Six Sigma? - New Jersey IIBA Chapter

advertisement

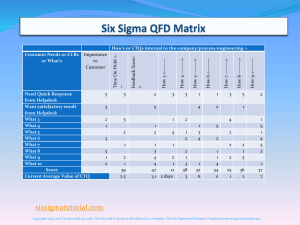

Six Sigma and Business Analysis Side – By Side Comparison Beverly A Place Certified Six Sigma Black Belt Quest Diagnostics Beverly.A.Place@QuestDiagnostics.com 1 Presention Objectives • Introductions • Provide an overview of the process methodologies • Lean and Six Sigma • Lean Group Exercise • Side by Side Comparison with BABOK 2 About the Instructor • Education and Experience – – – – – Bloomfield College – Computer Science Project Management for More than 20 Years Six Sigma for More than 9 Years Certified Black Belt Since 2004 Employed with Quest Diagnostics since 1997 • Personal – Married 20 Years – Two Boys age 13 and 21 – Active Member of BDPA 3 Six Sigma Way: Look Beneath The Surface Doing Things Differently 4 Why Six Sigma? Our Strategic Intent: To Be The Gold Standard in Healthcare Services From a Survey by RW Johnson Foundation: 95% of physicians have witnessed a serious medical error…61% of health care providers surveyed…say they accept common errors as routine practice... ...“We want to see a Toyota in health care. That’s been one of the barriers in health care. No one can point to a health system and say ‘That’s how it ought to be done’...” USA Today May 9, 2001 Virtual Perfection Is Demanded In Healthcare 5 Six Sigma Delivers Bottom Line Results Not Just Dramatic Defect Reduction… Cost Savings: Motorola: Saved $2.2 Billion From 1987 - 1991. $14 Billion From 1987 – 1997. GE: Plant & Equipment Expense/Depreciation Dropped From 1.2x To .8x (hidden factory) Revenue Growth: GE Capital - Over 50% Of Benefit Is Revenue Growth Versus Cost Reduction Net Income: GE - Operating Margins Up From 13.6% to 19.6% from 1995 - 2001 Mount Carmel Health System - Net Income increased 144% to $35 million in first 24 months A Proven Approach 6 Why Six Sigma? – Customer Focus Example: Draw to Test Report Process (data is for illustration and is not actual) Physician collects specimen Specimen Transported by Courier Specimen accessioned at lab Six Sigma’s focus on the Customer broadens perspective. Specimen is tested and result is generated Report is created Report is sent to physician Courier or Post Office delivers report Physician receives report Internal View: Application on system - average time to test a specimen - 68 minutes Client’s View: “ I fill out a requisition & collect the specimen - 1 to 4 days later (sometimes more than 1 week) I receive the test results” 7 What Is Six Sigma? What is Six Sigma? It Is More Than A Goal… s DPMO Target Metric Methodologies DMAI2C DFSS Process Mgmt Total Business Commitment 1s 2s 3s 4s 2 308,537 3 66,807 4 6,210 5 233 6 3.4 5s 6s Deployment Strategy Typically deployed to achieve a cultural transformation 8 Focus on Process Improvement If we accepted the goal of 99.9%, then we would have: – One hour of unsafe drinking water every month – Two unsafe plane landings per day at O’Hare airport in Chicago – 16,000 pieces of mail lost by the U.S. Postal Service every hour – 500 incorrect surgical operations each week – 50 newborn babies dropped at birth by doctors each day – 22,000 checks deducted from the wrong bank accounts each hour – 32,000 missed heartbeats per person, per year 9 The Methodologies: Process Focused Process Management • “Big Y” metrics for core processes • Operating mechanisms to identify gaps between “Big Ys” and Customer CTQs • Identifies need for either process improvement or process design work Process Improvement (DMAI2C) • Improves existing processes Six Sigma Process Methodologies Process Design (DMADV) • Fundamental re-design or development of new process Process Management is the base of the Six Sigma methodologies 10 Our Six Sigma Model: 3 Process Methodologies DMAIIC • Lean tools • Change Leadership tools • Design of Experiments methods • Business Analysis • Etc. DMADV Six Sigma Process Methodologies • Lean tools • Change Leadership tools • Quality Systems • Lean tools • Change Leadership tools • Design of Experiments methods • Business Analysis • Etc. • Business Analysis • Hoshin Planning (Policy Deployment) • Behavior Assessment • Etc. Three major Process Methodologies. Each uses a wide variety of tool sets…All incorporate Business Analysis 11 Process Improvement – What is it…what do you get? Improving Existing Products & Services Define Measure • Project Charter • Process Map • Define the Y • Measurement System Assessment • Data Collection • Baseline Performance • Project Goals Business Analysis is incorporated beginning with the Define Phase in order to ensure that the proper requirements are identified Analyze Innovative Improvement Control • Key Variables Identified • Solution Selected • Final Documentation • Quick Hits Identified • Proven Solution Deployed • Hand-Off to Process Owner • Control Plan Implemented Sample of DMAIIC Tools Used • • • • • • • • • • VOC CTQs Process Mapping Capability Studies Cause & Effect (Ishikawa) Graphical Analysis Statistical Techniques Standardized Work Workload Leveling Process Control Plans 5S 12 ‘Voice of the Process’ Versus ‘Voice of the Customer’ LSL Defects USL Acceptable Defects Voice of the Customer Voice of the Process Inadequate Process Capability Unstable Parts & Materials Inadequate Design Margin Voice of the Process is independent of the Voice of the Customer 13 What are the Limits to Improvement? Relative Problem Level Basic Tools Wall Design Wall Statistical Tools to Improve Process Clean Sheet Designing for Six Sigma (DFSS) Basic Quality Tools 2 sigma 3 sigma 4 sigma 5 sigma 6 sigma 14 LEAN Methodology If it’s Not Required Get Rid of It ! 15 What is “Lean”? Lean is the elimination of anything not absolutely required to deliver a quality product or service, on time, to our customers. What Does Lean Do? Increases Productivity by producing or servicing MORE with the SAME resources Improves Quality Reduces Inventory Reduces Lead Time Improves On-Time performance Increases Sales by using freed up resources and capacities to increase production and invest in new products or services 16 Lean Defined • A way to understand value from the viewpoint of the customer and eliminate activities that don’t add value • A methodology to increase velocity and create a continuous flow of value-adding activities, pulled by the customer • A set of tools to continuously improve this flow LEAN Lean principles and tools are important parts of the three process methodologies (Management, Improvement, and Design) 17 What is Lean and how does it fit into DMAI2C? Lean adds powerful tools and methods to the Six Sigma toolkit that are focused primarily on the flow and speed of processes as well as waste reduction Lean complements the Six Sigma discipline around variation (stability) & defect reduction (capability) Adding the Lean tools, methods and concepts to the DMAI2C methodology will boost performance 6s As a Six Sigma deployment progresses, new tools are added to the process methodologies. 18 Value Added Defined • The activity physically changes the work product (or adds important information) • The activity must not be rework • The customer must be willing to pay for it Business Value Pure Waste Value Added 19 Understanding Waste – Identification of waste should be initiated during the “Value Stream” process – Waste should be viewed through the eyes of the customer • Ask: Who’s paying for this? – The pursuit of waste elimination is never ending Waste = Lost Profits 20 Wastes (Muda) There Are Seven Types of Waste... • Defects • Over production • Transportation • Waiting • Inventory • Motion • Processing DOTWIMP is a common acronym to capture the seven types of waste. 21 Continuous Flow The ideal is continuous flow, like the flow through a pipe: In traditional processes, work moves in batches or is stuck in queues Reducing the move quantity and increasing the move frequency will make the flow “more” continuous: Continuing to reduce move quantity and increase move frequency will ultimately result in a one-at-a-time flow: 5S Overview – a Lean tool The methodology for creating and maintaining an organized, clean, and safe work environment to deliver and achieve high performance! • Sort (Seiri) – Keep only what is required • Store (Seiton) – Arrange and identify for ease of use, organize • Shine (Seiso) – Clean regularly. Clean up everything that’s left • Standardize (Seiketsu) – Eliminate causes to reduce variations, make standards obvious • Sustain (Shitsuke) – Set discipline, plan, schedule, Train … AND STICK TO IT! 5S sets the stage for improvement! 23 DFSS Methodology 24 Process Design Overview Six Sigma Process Methodologies • What is DFSS? – Design For Six Sigma – a very common acronym for the Process Design methodology – The center of a New Product Introduction framework: used to design or re-design a product or service from the ground up – not for making improvements 25 Process Design – What is it…what do you get? Designing new products & services Define • Project Charter Measure • Prioritized Customer Segments • Prioritized Customer Needs • Specified CTQs Sample of DMADV Tools Used • • • • • • • • • • Analyze • Selected Design Concept • High Level Design • High Level Design Capability Evaluated Design Verify • Detailed Design • Verified Design • Detailed Design Capability Evaluated • Full-Scale Implementation • Pilot Plan • Hand-Off to Process Owner Quality Function Deployment Conjoint Analysis Value Stream Mapping Simulation Modeling Design of Experiments Failure Modes Effect Analysis Demand Flow Design Work Cell Design Mistake-Proofing (Poka-Yoke) Visual Controls When DFSS is systematically deployed, you will have a culture of innovation which creates delighted customers. 26 DFSS Methodologies: Additional Examples DMADOV • Define project goals • Measure/determine customer needs and specifications; benchmark competitors and industry • Analyze options • Design process to meet CTQs • Optimize selected process • Verify design performance and ability to meet CTQs DCCDI IDOV • Define project • Identify the CTQs goals • Design: translate • Customer CTQs into analysis functional • Concept ideas requirements and developed, reviewed, selected solution alternatives, select • Design process to best solution. meet CTQs • Implementation • Optimize selected process to develop and commercialize the • Validate design product/ service performance and ability to meet CTQs DMEDI • Define project goals • Measure/ determine customer needs and specifications; benchmark competitors and industry • Explore options • Develop process to meet CTQs • Implementation to develop and commercialize the product/ service There are many variations in the naming of phases. Most are similar in practical content. Each implies Project Management concepts 27 Process Management Overview Six Sigma Process Methodologies Process Management – A management system that integrates process planning, control and improvement into the daily activities that organizations perform to serve their customers and stakeholders. Think Project Managemen t Through Process Management, opportunities for process improvement and design are identified, prioritized, and implemented. 28 Setting the stage for Process Management Effective Process Management Systems start with good measures… Assuming that a measure has been defined appropriately, there are two fundamental questions to answer regarding that measure: • How is the process performing? • Has the process performance changed? Data gathered over time are required to answer the two questions above! A Control Chart is typically used to answer the two questions. The three methodologies…which one to use? Identify Strategic Needs (part of Process Mgmt) Existing process, product, or service? Meet client require ments? Yes Yes No No No Incremental Improveme nt sufficient? Is the solution a new process, product, or service? Yes No Yes Design For Six Sigma DMAIIC Finish DMAIIC Process Management Six Sigma summarized: Process Design Design new processes / products: Process Improvement Improve existing processes: • Delighted customers • Customer-focused organization • Culture of innovation • Culture of continuous improvement Three integrated process methodologies to drive performance Start here Process Management Manage our business: • Aligned and focused Organization • Exceptional talent 31 Connecting Six Sigma and BABOK 32 ‘Shared’ Competencies • Problem Solving – Analytical Thinking – Decision Making – Systems Thinking • Business Knowledge – Business Principles and Practices – Business Process – Organization Knowledge • Communication Skills – Facilitation – Negotiation – Leadership and Influencing • Application Knowledge – General (MS Office Suite) – Specific (Minitab, EngineRoom, BA Software, Modeling Tools) 33 Other ‘Shared’ Techniques • • • • • • • • • • Acceptance and Evaluation Criteria Benchmarking Brainstorming Business Rules Analysis Data Flow Diagrams Decision Analysis Document Analysis Estimation Lessons Learned Metrics and KPI’s 34 Measures, Metrics, Project Management, Business Analysis and Process Methodologies ………………. Questions… 35