lecture10

advertisement

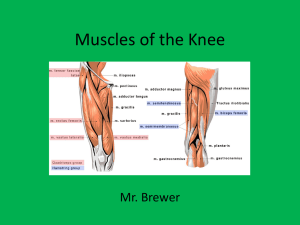

Lecture 10 Dimitar Stefanov LOWER-EXTREMITY PROSTHESES Example socket (individually fitted component) residual limb (soft tissue and bones) In case of partial amputation, inserts within a conventional shoe are can be applied. Energy-stored feet. In general, it is realized via flexible keel, which provides non-linear spring action similar to the push-off phase of walking or running. DYNAMIC RESPONSE FEET The distinguishing characteristic of this group is a plastic spring mechanism in the keel which deflects during heel off and returns to its resting position during toe off. Often called "energy storing" by manufacturers, these feet provide a subjective sense of push-off for the wearer, a more normal range of motion, and a more symmetric gait. SINGLE-AXIS FOOT Single axis solid ankle cushioned heel (SACH) prosthetic foot – provides planar flexion and smooth transition to mid-stance; increased knee stability; best suited for short-term use, such as on preparatory devices or for elders who may walk with a shuffling gait and never fully load the forefoot. In case of partial amputation, inserts within a conventional shoe are can be applied. Energy-stored feet. In general, it is realized via flexible keel, which provides non-linear spring action similar to the push-off phase of walking or running. DYNAMIC RESPONSE FEET The distinguishing characteristic of this group is a plastic spring mechanism in the keel which deflects during heel off and returns to its resting position during toe off. Often called "energy storing" by manufacturers, these feet provide a subjective sense of push-off for the wearer, a more normal range of motion, and a more symmetric gait. SINGLE-AXIS FOOT Single axis solid ankle cushioned heel (SACH) prosthetic foot – provides planar flexion and smooth transition to mid-stance; increased knee stability; best suited for short-term use, such as on preparatory devices or for elders who may walk with a shuffling gait and never fully load the forefoot. Multi-axis foot Swim prostheses The Jaipur foot •inexpensive prosthetic foot – India •Made of vulcanized rubber •Wooden keel •Consists of three inserts: fore-foot and heel of micro cellular rubber and an ankle of laminated wood •Flexibility in three planes •Well suited for walking over uneven terrain, climbing trees, etc. Below-the-knee prosthesis Important problems: •design of convenient socket; prevention of pistoning; •reduction the forces on the residual limb; •large contact area between the distal end of the limb and the socket. •Suspension through latex rubber sleeves and a waist belt attached to a cuff. •CAD-CAM design can be applied in the socket production. • The wire-frame model representation of the socket should be viewed by the prosthetist and modified. Above-the-knee prostheses Knee joint – much important component It should be lightweight and safe in operation. Design solutions of knee joint: A./ Simple mechanical device with manually operated locking mechanism. Disadvantages: •Low functionality •useful for sitting only •doesn’t allow bending during the swing phase. B./ Mechanical devices that allow knee to flex when it is unweighed and which lock when a weight threshold is exceeded. Solutions for activation of the knee lock: •Pressure of the heel •Ankle flexion C./ Hydraulic knees – •They allow stance and swing phase control; Adjustment of the swing phase to suit to individual’s pattern of walking. •Hydraulic resistance to flexion; •Lock of the knee joint in hyperextension; •Unlock the joint when the forces to the prosthetic forefoot exceed a threshold; •Manual lock for activities which require maximal stability (driving an automobile, standing on a bus, vocational activities); •Release for maximum flexibility. Solutions: •Piston and a hydraulic cylinder. •The cylinder is perforated to allow fluid to flow from one side of the cylinder to the opposite side when the piston moves. •The distribution of the holes within the cylinder determines the amount of damping. •Hydraulic cylinder and piston. • Holes on the cylinder ends and electromagnetcontrolled valve which determine the fluid flow. •Microprocessor control unit and a hall-effect sensor for knee-bending measurement. Otto-Bock knee prostheses: 3R45 Modular Knee Joint An optimal gait pattern is achieved by adjusting the independent swing phase flexion and extension resistances integrated miniature hydraulic cylinder 3R80 Modular Rotary Hydraulic Knee Joint •Weight activated; •Cadence responsive; •Precise adjustability; •135 degree flexion angle; •Independently adjustable hydraulic flexion and extension resistance. •Pneumatic cylinder and a swing-phase controller. The Endolite intelligent prosthesis •Swing-phase controller (control in different cadences) •4-bit microprocessor which controls a needle valve, via a stepper motor •The controller is programmed (by the prosthetist) to provide an optimal damping in different walking patterns. Prosthetic gait analysis and assessment Harmless prostheses design – to minimize the risk of injury associated with stumbling, slipping and falling. •Prosthethic limbs do not provide direct proprioceptive feedback. •Some force information is transferred to the user via the socket. •Often prostheses produce sound or vibrations that change with the force and cadence. People with lower-limb prostheses use a higher oxygen consumption, which varies to the different model prostheses. gait analysis, force-reactions measurement. Biomechanical techniques for assessment the adaptation of the user to the lower-limb prostheses: Lower-extremity orthoses Applied in case of lower limb paralysis Orthosis design: •The ankle is treated as a joint with a single DOF •The knee joint is modeled with two DOF joint (flexion/extension in the sagital plane and rotation in the transverse plane) •The hip is modeled with a joint with 3 DOF (abduction/adduction in the frontal plane, flexion/extension in the sagital plane, and internal/external rotation). Mechanically strong – static and dynamic loads. Walking stability and prevention of falling. The sensory feedback to the user contributes the stability increase. Ankle-foot orthosis Designed of molded plastic or metal Foot design – very important (heel high) Mechanical ankle-foot orthosis Vanini-Rizzoli Stabilizing Limb Orthosis (VRSLO) The polypropylene orthosis is inserted into a specially designed leather boot. The insole of the orthosis is angled to provide 10 to 15 degrees of planar flexion. •Attempt for development of lightweight, simple and easy to use otthosis. Knee-ankle-foot orthoses –very high energy-costs during use due to poor biomechanical efficiency. Heavy, bulky, and bad cosmetically looking Three classes devices for movement of paralyzed legs: •Purely mechanical orthoses •Hybrid devices (mechanical support + FES) •FES alone.