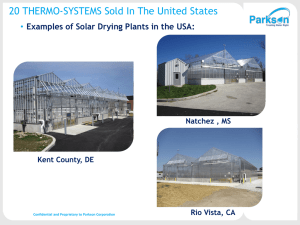

Packaged domestic wastewater treatment

advertisement

PACKAGED DOMESTIC WASTEWATER TREATMENT PLANTS (WWTP) AQUATEC type AT6-AT50 PACKAGED DOMESTICWASTEWATER TREATMENT PLANTS AQUATEC TYPE AT6–AT50 Packaged domestic wastewater treatment plants AT6 – AT50 are designed to treat sewage water from family houses, inhabitable buildings, terrace houses and other sources of wastewater (eg: apartments, restaurants, schools, hotels, factories). The treated wastewater can be: discharged directly to the surface water; recycled and reused for irrigation of vegetation; after tertiary treatment reused for toilet flushing. The treated wastewater can be: • ·discharged directly to the surface water • recycled and reused for irrigation of vegetation • after tertiary treatment reused for toilet flushing According to the European Standard EN 12566-3 and Building product regulations n. 90/1998, this product was liable to the technical certification and a certificate of conformity. The technical certification was issued by The Technical and Test Institute, certificate OM 04. After completing the tests of the model AT and application of an internal control of the producer, the certificate of conformity was issued. The certificate of conformity is in accordance with The European Union legislation. After the certification of the equipment, the producer is allowed to market the produced wastewater treatment plants up to 50 PE under the certificate brand CE and over 50 PE under the certificate brand C SK. Basic description The wastewater treatment plant consists of a biological reactor with an inside technological structure. The cleaning effect is based on the utilization of a low-loaded activated sludge process with an aerobically stabilization of sludge. The biological reactor is covered with a PP (polypropylene) cover. The maximum achievable treatment efficiency is based on the utilization of a low-loaded activated sludge process with aerobically stabilized sludge. We apply in the wastewater treatment plant of type AT the proved continually working biological wastewater treatment process innovated by Slovak patent SK 4324 U and SK 2750 and international patent WO2007022899A1. Using this patented technology is achieved the high quality of treated water, low investment and operating costs. The technology is also known under the name of VFL® “Vertical Flow Labyrinth”, resulting in a high quality of the effluent and low 0perational cost. A delivery of a wastewater treatment plant AT is based on a binding order. The terms of delivery and payment are based on the mutual agreement between the parties. Small treatment plants AQUATEC type AT6-50 treat the volume of sewage wastes at a rate of 0.5 up to 7.5 cub.m per day, when the wastewater is received from: · A single house, · Apartment houses, apartments, · Hotels and boarding houses, · Restaurants, · Schools, · Camping sites, · Small-scale companies, etc. Type of plant AT6 AT8 AT10 AT12 AT 15 AT 20 AT 30 AT 40 AT 50 Persons 4 6 8 10 12 18 25 35 50 Capacity (m3/d.) 0,9 1,2 1,5 1,8 2,25 3 4,5 6 7,5 Diameter of the plant (mm) 1400 1400 1750 1750 2050 2050 2300 2850 2950 Height of the plant (mm) 1800 2200 2000 2200 2200 2700 3000 2700 3000 Height of the inlet pipe (mm) 1300 1700 1500 1700 1700 2200 2500 2200 2800 Height of the outlet pipe (mm) 1150 1500 1250 1500 1500 2000 2300 2000 2600 Average electric consumption (kW/annum) 208 270 411 582 783 1564 2689 2359 4254 The excess sludge removal (m3/annum) 1 1,5 2 2,5 3 4,5 6,3 8,8 12,5 Advantages of AQUATEC VFL patented wastewater treatment plants: · high-performance, removes nitrogen and phosphorus; · employs no chemical substances; · diffuses no offensive odour; · insensitive to peak flows; · low power consumption (4 persons treatment plant uses less than 208 kWh/per annum); · low generation of excess sludge (1 cub. m./per annum of excess sludge 4PE) · occupies less space and spoils no aesthetic scenery, thus allows making the most of the available space; · easy-to-use, cost-effective assembling and can be easily conveyed; · can be left free of wastewater for 30 and more days, thus causing no problems in planning longterm trips and holidays; · can operate under any weather conditions – due to the biological processes running in the plant, the contents of the tankages remains non-freezing even under a very low temperature; · conforms to the highest ecological standards and produces no impact on the nature. Moreover, · AQUATEC VFL plant can be assembled and launched within 1 working day. · Wastewater treatment parameters are available as of the moment the plant is started. · The water treated in AQUATEC VFL wastewater treatment plant can be reused as service water. The treatment technology The treatment technology is based on a continually operated modified activated sludge process. The biological reactor comprises of a non-aerated chamber, aerated chamber, final clarification chamber and an integrated retention chamber. The chambers are connected by internal circulation and recirculation conduits between the compartments of the non-aerated chamber, between the non-aerated chamber and final clarification chamber and between the aerated chamber and final clarification chamber. The nonaerated chamber is divided by a series of overflowed and underflowed baffles into compartments creating a so called Vertical Flow Labyrinth (VFL®). In the final clarification chamber, a flow control device is incorporated, which enables the usage of the volume of the integrated retention chamber in all the tanks of the wastewater treatment plant during peak flows and thus protect against the overloading of the plant. This makes possible a more effective tertiary treatment and water recycling, because the discharged secondary treated wastewater does not clog the filtration layer in the subsurface dispersal system or in the filtration equipment. The aeration and the maintaining of the activated sludge in suspension within the aerated chamber is ensured by finebubble diffusers. Mixing, circulation, and recirculation of the activated sludge is provided by compressed air introduced by air pumps, side channel blowers via an air distribution system, it being possible to regulate the flow of compressed air. The operation of the individual air-lift pumps and the aeration is controlled by a control unit. The production of excess sludge is lower than by other conventional technologies. VFL treatment technology satisfies the highest ecological requirements. The biologically treated water can be reused because of the high cleaning parameters. All wastewater treatment process is being performed in one single radial polypropylene content. At first, wastewater flows into non-aerated zone, where mechanical pretreatment takes place (2). The non-aerated zone is divided by several internal dividing walls, where internal circulation is established. Further, using gravity, the wastewater flows into anaerobic fermentation zone (3), mixes with activated sludge and flows into denitrification zone (4), where proceeds denitrification processes. From the denitrification zone wastewater overflows into aeration zone (5) . The compressed air through single-bubble aeration elements – diffusers (6)- is incorporated into aeration zone and into airlifts for circulation and re-circulation of the activation mixture. The air supply is from the only mechanism in the system – air blower (9). In the aeration zone proceed wastewater oxidation and nitrification processes. Further, the mixture of activated sludge flows into bottom of sedimentation section (7), where activated sludge by airlift is recycled into denitrification (non-aeration) or nitrification (aeration) zone of plant. 1 1 Inflow 2 Mechanical treatment 3 Anaerobic fermentation zone 4 Denitrification zone 5 Aeration zone 6 Diffuser 7 Final clarification zone 8 Air distribution panel 9 Air blower 10 Air distribution panel 11 Flow regulator 12 Outflow The compressed air through single-bubble aeration elements – diffusers (6)- is incorporated into aeration zone and into airlifts for circulation and re-circulation of the activation mixture. The air supply is from the only mechanism in the system – air blower (9). In the aeration zone proceed wastewater oxidation and nitrification processes. Further, the mixture of activated sludge flows into bottom of sedimentation section (7), where activated sludge by airlift is recycled into denitrification (non-aeration) or nitrification (aeration) zone of plant. European Union The wastewater treatment plant AT with an integrated retention chamber already fulfils the highest requirements of the EU standard concerning the resistance to peak-flows and ensures the treatment stability even in case of peak-flows during emptying a bath tub + washing-machine. This is the way how the problem of flowing away the flocs of activated sludge during peakflows can be solved by domestic wastewater treatment plants. Technological parameters The quality of the treated wastewater must comply with the requirements of The Government regulations n. 296/05 ( surface and subsurface waters). Guaranteed and normally attainable parameters in the outflow: Parameter CHOBCr BOB5 SS N-NH4 Ntot Ptot Average values 35 mg/l 10 mg/l 10 mg/l 2 mg/l 15 mg/l 3 mg/l Guaranteed values 75 mg/l 15 mg/l 20 mg/l 5,0 mg/l 25 mg/l 7,0 mg/l Placing of the wastewater treatment plant The wastewater treatment plant AT is placed into an excavated ditch on a concrete slab approx. 15 cm (thick) the way that the top of the tank is above the ground by approx. 5cm. When required or in accordance with the design, concrete casing is prepared round of the tank with the height specified in design documentation. The tanks of the treatment plant must be filled with water up to the outflow pipe level before backfilling the earth or making the concrete casing. Installation of the AQUATEC WWTP Assembling of the AQUATECWWTP is very simple, so customers or engineering companies will be able to assemble the plants themselves according to the charts and instructions provided by our company. The location for the wastewater treatment plant must be prepared in the manner the purified water could self discharge. The treatment plant cannot be assembled in the place of accumulation of the rain or ground water. The plant’s lid must be accessible for regular inspection. (1) The holes for the plants assembled are excavated in two stages. On the first stage, the hole is excavated by the digger, but no up to the provided project altitude. On the second stage, a 20-30 cm layer is dug manually. This is the way to ensure the assembling of the plant on the unmoved ground. The depth of the hole depends on the deepening of the wastewater pipe at the location the plant is assembled at (2). The plants must be assembled on a concrete base in order to ensure horizontal and vertical position of the plants. The thickness of the ground embed in concrete on the thickened ground is approximately 15-20 cm with the standard reinforcing mesh. Alternatively it is possible to use the underbodies of the reinforced concrete collars (KCD) of the required diameter. When the level of ground water is high, the assembled plant must be anchored to the concrete base. In this case, a binding gravel of 40 cm thickness is poured and thickened on a concrete base prepared in advance, and then plant’s tankage is fixed to the concrete base by means of assembling lifting hugs. (3) After placing the plant in the hole and examining its project position (depth, horizontal and vertical positions), inflow and outflow pipelines (the pipes must rest on firm base and stay fixed) are equipped. It is required for diameters of the plant’s sleeves to match the diameters of the inflow and outflow pipes for treated water. The depth of the wastewater supply pipe is to match with the depth of the plant’s sleeve. (4) The location for the air blower is selected according to the technical requirements; the air blower can be assembled both in the air-conditioned premises (in a garage, warehouse, etc.) and outdoor. The air blower assembled inside the premises must be out of the contact with a wall or any other building structure. If the air blower is to be assembled outdoor, it must be protected from humidity, rain and dust. If the air blower was provided to be assembled next to the plant, then an electric cable 220V- 3X1.5Cu (5) must be lead with the household wastewater pipeline to the plant. In case when the air blower is assembled inside the premises, when installing the air-supply pipes from the air blower up to the plant, it is required to reduce the air pressure loss to a minimum. This must be done by reducing the number of elbows in the system. According to the technical specifications of the air blowers, the distance from the air blower up to the plant cannot exceed 6 m. The plant placed on the project position is gradually filled with water and the gap between the hole and the plant is filled with binding gravel (free of solid stones). Gradually means when water is filled into the plant and binding gravel is filled around the plant by 20-30 cm layers. Binding gravel is thoroughly thickened up to the required density. The plant is filled with the water up to the level of the outflow pipe. (7) After the assemblage of the plant is completed, specialists perform the precommissioning of the plant. The plants are entered into service by delivering the active sludge from the already running biological treatment plants (the sludge index does not exceed 150 mg/l or the sludge is not older than 20 days).When starting up the plants, the following actions are to be conducted: · After starting the air blower and opening the air valves, the air flow is directed to the air-lift pumps and aeration elements. The time is programmed and the air amount is adjusted in the plant; · A thick layer of sludge is thinned and re-pumped to the aeration zone. This must be done in the way to ensure the entire plant would not be over swamped with the sludge; · Wastewater inflowing into the plants is initiated. (8) Taking into consideration the peculiarities of the location for assembling, a solution for discharge of the water treated is selected. The water treated in the household wastewater treatment plant can be infiltrated into the ground (via infiltration wells, filtration fields), discharged to the roadside, reclamation pits, released to open water sources and reused. (9) 1. Preparing of the hole for the plant 2. Delivery of the plant by hands 3. Installation of air-pump 4. Filling up the plant with water 3. Installation of air-pump 6. The plant is put into operation 7. Example of plant design on site 8. Example of plant design on site Authorized Representative for the Islamic Countries Intera Global Middle East Construction C. Afghanistan, Kabul, Email: intera.construction7@gmail.com, Tel.: +93 799 88 88 87, +93 790 66 00 06, Tel.: UA office +38 057 731 22 23