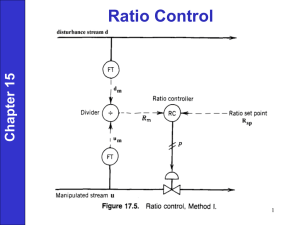

Controller Process

advertisement

Hur får man system att uppföra sig som man vill? Reglerteknik och intressanta tillämpningar Carl-Fredrik Lindberg, 2013-04-25 Single and Double Inverted Pendulum Movie found on internet http://vimeo.com/2952236 2 Automatic Control (“Reglerteknik” in Swedish) Modeling the tank dynamics 𝑑 𝐴ℎ =𝑢−𝑞 𝑑𝑡 Tuning the PID controller 𝑡 𝑢 𝑡 = 𝐾𝑝 𝑒(𝑡) + 𝐾𝐼 0 𝑒(𝑠) 𝑑𝑠 + 𝐾𝐷 𝑑 𝑒 𝑡 𝑑𝑡 ● Automatic control gives: ● ● ● ● Stability Fast disturbance rejection Small variations in controlled variables Etc. 3 How a control engineer sees the world Feedforward Setpoints Controller Measureable disturbances Non measureable disturbances Measurement noise Control signals Process Σ Measured outputs Feedback 4 Automatic Control ● Modeling ● Physical models, grey-box, black-box, … ● Controller design ● Feedback, feedforward, stability, performance, robustness, adaptive, … ● Estimation ● States, model parameters, … ● Diagnostics ● Fault detection and isolation, … ● Optimization 5 Project examples 6 EM Stabilizer in Galvanizing Lines Stabilization of strip gives reduced zinc over-coating 7 EM Stabilizer in Galvanizing Lines Improved strip position damping with EM Stabilizer 8 Water model EM Control Control of the steel flow in the mold gives higher steel quality Continuous casting process Validation of model with PIV measurements in water model Simulation of the flow 9 Paper Machine Steam Energy Fingerprint By quantifying steam flows and identifying energy waste, suggestions on how to improve energy efficiency are given Histogram for ton steam / ton dry paper for different grades (during 19 days) 50 Lightest Light Heavy Heaviest 45 40 35 % 30 25 20 15 10 5 0 10 1.8 1.9 2 2.1 2.2 ton steam / ton dry paper 2.3 Arc Furnace Control By control, optimization and EMS, the yield, energy efficiency and productivity is increased 11 SVC Voltage Control with Feedforward Improved disturbance rejection after TSC switching 12 Wireless Control ● New possibilities with wireless control ● Increased flexibility to install sensors ● Cost for wiring disappears ● Large challenges ● ● ● ● Reliability Latency Safety Co-existence with other wireless systems ● 90% of the communication could often be saved by smarter sampling ● Different sampling strategies have been developed ● Sample as seldom as possible without losing control performance ● Taking into account that information packages may be delayed or lost Step response with event based sampling 2 r y u 1.5 1 0.5 0 -0.5 -1 0 50 100 150 200 250 200 250 time [s] Sampling time 20 15 10 5 0 0 50 100 150 time [s] 13 Diagnostics Control loop diagnostics ● On-line methods which automatically alarms for poor control loop performance. ● Examples ● Detection of oscillations and changed signal variance. ● Control performance measurements, Harris index etc. ● Classification of some faults, e.g. valve stiction, external disturbances. Process section diagnostics ● Faults are both detected and isolated ● Fault examples: ● ● ● ● Detection of bias in a sensor Detection of clogging of a valve Detection of erosion in a pump Track heat transfer rate in heat exchanger ● Benefits: ● Early detection gives higher availability ● Reduced maintenance costs. ● Avoids wrong dosing when sensor has drifted. Example of fault isolation. The red bar indicates the most probable faulty signal. 14 Waste Water Treatment Some examples from my Ph.D. Effluent nitrate in line 1 & 2, ammonium and DO set-point in line 1 20 18 16 Adaptive control of external carbon flow rate 14 Nitrate 1 Nitrate 2 Ammonium DO set-point mg/l 12 10 8 6 4 2 0 0 1 2 3 4 time [days] 5 6 7 8 Control of dissolved oxygen concentration Estimation of dissolved oxygen dynamics 𝑦 𝑡 + 1 = 𝑦 𝑡 + ℎ∗ 𝑄 𝑡 𝑉 𝑦𝑖𝑛 𝑡 − 𝑦 𝑡 + 𝐾𝐿 𝑎 𝑢 𝑡 𝑦𝑠𝑎𝑡 − 𝑦 𝑡 − 𝑅(𝑡) 15 Thank you! Questions? 16