Cooling the Modern Day Wiring Closet

advertisement

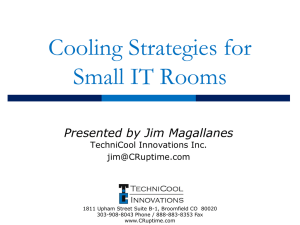

LAN Room and Wiring Closet Cooling Presented by Jim Magallanes TechniCool Innovations Inc. jim@CRuptime.com 1811 Upham Street Suite B-1, Broomfield CO 80020 303-908-8043 Phone / 888-883-8353 Fax www.CRuptime.com Outline Wiring Closet – General Description Electronic Equipment Trends Cooling Load Best Cooling Practices Cooling Solutions Portable Systems Mini Split Systems A/C Computer Cabinet Systems A/C Ceiling Systems Precision Ceiling Systems Conclusion Jim Magallanes LAN Room and Wiring Closet Cooling – CTM 2012 Operations Seminar Wiring Closet – General Description Wiring Closet - Critical subsystem of a network environment Small Room with Servers/Telecom/Electrical Equipment/ UPS Floor Space is a Premium: <100 ft2 Contents: 1 – 3 Equipment Racks Heat Load per Rack: 1.0 - 2.0 kW Avg. Typical Cooling: None or Building Cooling During Day Remote location of building Security: Medium Locked Door and/or Locked Cabinet “The average wiring closet contains $150,000 - $300,000 of equipment and a typical small server room often houses more than three times that amount.” - Mitch Medford, NetBotz CTO Jim Magallanes LAN Room and Wiring Closet Cooling – CTM 2012 Operations Seminar Electronic Equipment Trends Power = Heat Servers Blade Servers Smaller & More Powerful IP & VOIP Telecom Equip High-powered switches and equipment Low-powered legacy Requires UPS support Overheated IT equipment Figure: Product Heat Density Chart (The Uptime Institute) Reduced Life / Hardware Damage Reduced Reliability Slower Network Costly System Downtime General Rule Every 10°C temperature rise in nominal temperatures produces a 50% reduction in the lifetime and long-term reliability of IT hardware - MIL-HDBK 217 / Arrhenius Models Jim Magallanes LAN Room and Wiring Closet Cooling – CTM 2012 Operations Seminar Electronic Equipment Trends Power = Heat Servers Blade Servers Smaller & More Powerful IP & VOIP Telecom Equip High-powered switches and equipment Low-powered legacy Requires UPS support Overheated IT equipment Figure: Product Heat Density Chart (The Uptime Institute) Reduced Life / Hardware Damage Reduced Reliability Slower Network Costly System Downtime General Rule Every 10°C temperature rise in nominal temperatures produces a 50% reduction in the lifetime and long-term reliability of IT hardware - MIL-HDBK 217 / Arrhenius Models Jim Magallanes LAN Room and Wiring Closet Cooling – CTM 2012 Operations Seminar LAN Room Heat Problem Businesses dependent on computers and telecom equipment 2008 2004 for day-to-day operations Recommended Recommended Need to keep IT equipment cool Tight controls/monitoring Redundancy LAN Room/Wiring Closets Temperatures in the upper 60Fs/lower 70s are practical Jim Magallanes Range Min Max ASHRAE Technical Committee 9.9 Temperatures 64.4 80.6 68 77 Thermal Guidelines (°F) Humidity Levels Inlet Temperatures 44 - 60 25 - 48 40 - 55 40 - 55 (%RH) Costly to rely on building A/C Dew Point (°F) 41.9 59 N/A N/A Data Centers ASHRAE – Thermal Guidelines for Data Processing Environments Upper range temperatures acceptable Range Min Max Looser controls/monitoring No redundancy Ceiling-Mount A/C : Cost Effective Solution for Server Rooms Cooling Load Determining the cooling load in a wiring closet Incremental load from equipment Nameplate rating Usually overstated ASHRAE TC 9.9: Load during operating conditions Not yet adopted by manufacturers Determine cooling load from UPS load Load from all equipment connected to the UPS Dependent on day and time Monitor over a period time to get worst case scenario Other sources of heat Lights/windows/outside wall/etc… Electrical power to rejected heat conversion 1 kW = 3,413 Btu/hr. Jim Magallanes 12,000 Btu/hr = 1 ton of A/C LAN Room and Wiring Closet Cooling – CTM 2012 Operations Seminar Cooling Solutions & Best Cooling Practices Cooling Solutions Primary cooling for IT equipment Nights & Weekends when building a/c is off Added denser IT equipment Seasonal: Summer or Winter Redundancy / Emergency backup to primary cooling Shut down building a/c when people are not in the building Supplemental Cooling LAN Room/Wiring Closet is not air conditioned Planned or unplanned shut downs: Inexpensive insurance plan Best Practices Spot Cool vs. Traditional A/C Managing Air Movement Direct cold air to front of server: Airflow = Front to Back Telecom equipment: Airflow = Side to Side Do not cool down the entire room Back of the rack: Up to 36°F Hotter Use blanking panels Unoccupied rack space: Recirculation of warm air Organize cabling Jim Magallanes Maximize airflow LAN Room and Wiring Closet Cooling – CTM 2012 Operations Seminar Cooling Solutions – Portable Systems Portable Systems A self contained packaged air conditioner that is on wheels and is easily movable to spot cool “hot spots” Power: 115 VAC, 230 VAC, & 460 VAC Heat rejection: Ceiling plenum Air or water cooled Condensation removal Tank: Emptying depends on humidity Pump: Drain/sink/water line End-user Installation Connect accessories (15 – 20 minutes) Non-standard applications may require contractor Cooling Capacity Jim Magallanes 1 – 5 Ton units available LAN Room and Wiring Closet Cooling – CTM 2012 Operations Seminar Cooling Solutions – Portable Systems Portable system features Wide cooling capacity range Voltage: 115V, 230V, or 460V Condensation removal Tank: Empty periodically Pump to drain/sink/water line Operational features Approx. 1.5 Tons at 115V Automatic Restart Air delivery Grille or nozzle Ducting Capabilities Jim Magallanes Exhaust Long ducting runs Return/Make-up Air LAN Room and Wiring Closet Cooling – CTM 2012 Operations Seminar Cooling Solutions – Portable Systems Pros Low cost Relocate unit from room to room Moves with tenant Little installation required No outdoor equipment Cons Floor space required Small heat load on building’s A/C Condensate removal Typically not a problem Tank or pump No Humidity Controls Jim Magallanes LAN Room and Wiring Closet Cooling – CTM 2012 Operations Seminar Cooling Solutions – Mini Split Systems Mini Split Systems Consists of 2 units connected by refrigerant lines Indoor Unit – Inside the wiring closet Discharges cold air Refrigerant lines Transfers heat to the outdoor unit Outdoor Unit – Outside the building Discharges hot air to the environment Designed for comfort cooling High latent cooling Contractor Installation Removes moisture from air Mounting/electrical/refrigerant lines/condensate line System comes with pre-charged refrigerant lines Cooling Capacity Jim Magallanes 1 – 3 Ton units available LAN Room and Wiring Closet Cooling – CTM 2012 Operations Seminar Cooling Solutions – Mini Split Systems Installation Guidelines Wiring Closet Indoor Unit Outside Building Refrigerant Lines 70 FT 25 FT Outdoor Unit Jim Magallanes LAN Room and Wiring Closet Cooling – CTM 2012 Operations Seminar Cooling Solutions – Mini Split Systems Pros Low cost No floor space required No affect on building’s A/C system Cons Comfort cooling Location Restrictions Landlord Approval Leasehold improvement No Humidity Controls Reliability Maximum height difference: 25 Ft Maximum piping length: 70 Ft Possible leaks at quick-connect Condensate removal Does not work in extreme low temperatures Jim Magallanes LAN Room and Wiring Closet Cooling – CTM 2012 Operations Seminar Cooling Solutions – A/C Computer Cabinet Air Conditioned Computer Cabinet A standard 19” computer cabinet housing a self contained packaged air conditioner Power: 115 VAC and 230 VAC Heat rejection: Ceiling plenum Condensation removal Pump: Drain/sink/water line Evaporative: Exhausts condensation in warm condenser air End-user Installation Delivers data center infrastructure to LAN room/wiring closet Connect accessories (20 – 30 minutes) Cooling capacity per computer cabinet Jim Magallanes ½ - 1 Ton units available LAN Room and Wiring Closet Cooling – CTM 2012 Operations Seminar Cooling Solutions – A/C Computer Cabinet A/C Computer Cabinet Features Cooling capacity to match IT load Voltage: 115V or 230V Airflow Pattern Air conditioner Location Pump to drain/sink/water line Evaporate in exhaust: Poor IAQ Backup Cooling Bottom of cabinet to prevent water leak Condensation Removal Most IT Equipment: Front to Back Telecom Equipment: Side to Side Backup UPS for cooling Fresh outside air Automatic Restart Airflow Pattern Front to Back Environmental Monitoring Airflow Pattern: Side to Side Jim Magallanes LAN Room and Wiring Closet Cooling – CTM 2012 Operations Seminar Cooling Solutions – A/C Computer Cabinet Pros Low cost Relocate unit from room to room Moves with tenant Little installation required No outdoor equipment Efficient cooling Brings cooling directly to IT heat source Creates cold aisle/warm aisle for cold inlet temperatures Delivers data center infrastructure to wiring closet Cons Small heat load on building’s A/C Typically not a problem Manufacturer specific cabinet No Humidity controls Condensation removal Jim Magallanes LAN Room and Wiring Closet Cooling – CTM 2012 Operations Seminar Cooling Solutions – A/C Ceiling Systems A/C Ceiling Systems An A/C ceiling system is a packaged air conditioner that fits above the drop ceiling plenum that only has A/C capabilities. Packaged system Contractor Installation Air Cooled Water-cooled Minimal labor Unit comes pre-charged with refrigerant Cooling Capacity Jim Magallanes 1 – 5 Ton units available LAN Room and Wiring Closet Cooling – CTM 2012 Operations Seminar Cooling Solutions – A/C Ceiling Systems Precision ceiling features Cooling capacity: 1 – 5 Tons Voltage: 115V or 230V Condensation removal Pump to drain / sink / water line Gravity drain Air delivery Supply air ducting Exhaust air ducting Return air ducting Optional Features Automatic restart BMS compatibility Jim Magallanes LAN Room and Wiring Closet Cooling – CTM 2012 Operations Seminar Cooling Solutions – A/C Ceiling Systems Pros Configurable No floor space required Low profile fits most ceiling plenums Ducting capabilities Air-cooled or water-cooled Cold supply air Exhaust air Cons Contractor installed Landlord Approval Leasehold improvement No humidity controls Small heat load on building’s A/C Jim Magallanes Typically not a problem LAN Room and Wiring Closet Cooling – CTM 2012 Operations Seminar Cooling Solutions – Precision Ceiling Systems Precision Ceiling Systems A precision ceiling system is an air conditioner that fits above the drop ceiling plenum that has humidity and reheat capabilities. Engineered system for specific applications Packaged or split systems Packaged: (1) component inside building Split: Components inside and outside building Contractor Installation Air-cooled/water-cooled/chilled water-cooled systems Copper piping/electrical/mounting/condensate line Charges with refrigerant on-site Cooling Capacity Jim Magallanes 1 – 8 Ton units available LAN Room and Wiring Closet Cooling – CTM 2012 Operations Seminar Cooling Solutions – Precision Ceiling Systems Precision ceiling features Wide cooling capacity range Voltage: 115V, 230V, or 460V Condensation removal Operational features Pump to drain/sink/water line Gravity drain Automatic Restart Air delivery Jim Magallanes Grille LAN Room and Wiring Closet Cooling – CTM 2012 Operations Seminar Cooling Solutions – Precision Ceiling Systems Pros Highly configurable No floor space required Multiple Options Packaged or Split Air-cooled/Water-cooled/chilled water-cooled Humidity controls/alarms/etc… Cons Very high cost May require outdoor heat rejection equipment Plenum space above ceiling is limited Air Delivery is fixed location Landlord Approval Leasehold improvement Engineered for application Jim Magallanes Contractor installed: Expensive LAN Room and Wiring Closet Cooling – CTM 2012 Operations Seminar Cooling Solutions – Comparison Chart Cost / Adaptable Portable Systems Mini Split Systems Low / Flexible Low / Specific Buildings A/C Computer Cabinet Moderate / Flexible A/C Ceiling Systems Moderate / Flexible Precision Ceiling Systems Jim Magallanes High / Flexible Ideal Wiring Closet Comments Loads: 1 – 5 Tons Requires floor space Works with any building Ideal for backup cooling • Cost effective solution • Loads: 0 – 3 Tons • Close proximity to outside • No floor space • Comfort cooling design • • • • • • • • Loads: .5 – 1 Ton/cabinet No floor space required Works with any building Optional alarm/Mini DC • Little installation required • Moves with tenant • Air or water cooled • Cost effective solution • Leasehold improvement • Cost effective solution • Efficient cooling system • Little installation required • Moves with tenant • Loads: 1 – 5 Tons • Low height in plenum • No floor space • Air or water cooled • Loads: 1 – 8 Tons • No Floor space • Alarms needed • Better ROI > 3 Tons • Cost effective solution • Leasehold improvement • Site monitoring system • Leasehold improvement LAN Room and Wiring Closet Cooling – CTM 2012 Operations Seminar Wiring Closet – Cooling Solution Conclusion Wiring Closet Dedicated a/c system Electronic equipment benefits Increased life/reliability/server speed Improve security with locked door Selecting a cooling solution Building structure Budget Closet requirements Floor space Location within building Available power Own/Leasehold improvement Insurance Policy – Mission Critical IT Network Jim Magallanes Redundant cooling solution for shut-downs (planned/unplanned) LAN Room and Wiring Closet Cooling – CTM 2012 Operations Seminar LAN Room and Wiring Closet Cooling Questions www.CRuptime.com jim@CRuptime.com 303-908-8043 Phone Jim Magallanes LAN Room and Wiring Closet Cooling – CTM 2012 Operations Seminar