Paul Baker, GCU

advertisement

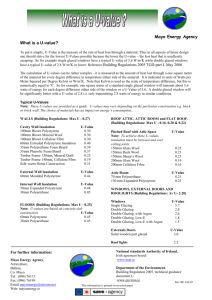

Research on improving the thermal performance of traditional windows and thermal performance monitoring Dr Paul Baker Centre for Research on Indoor Climate & Health School of Engineering & the Built Environment Glasgow Caledonian University Introduction Summarise recent work on improving the thermal performance of tradition windows including field trials of ‘slim-profile’ double glazing replacement panes in Georgian sash windows in Edinburgh. Presentation of methodology for in situ thermal performance testing. Comparison of measured results with calculation methods. Traditional Windows • There are c.44 million single-glazed sash windows in the UK (Source: English Heritage) • 20% of domestic properties in UK are pre-1919, i.e. traditional buildings (Source: Scottish House Condition Survey) • Single glazing & poor window insulation can account for 20% of a home’s heat loss (Source: Energy Saving Trust) • An average house with 7 timber single-glazed sash windows can lose £211 a year through these windows (Source: www.energyratedwindows.co.uk) • 72% of heat loss from a single-glazed window occurs through the glazing (Source: Historic Scotland Technical Paper 1: Thermal performance of traditional windows, 2008) Traditional Windows Easy option for replacement with modern double glazing? Draughty, prone to condensation and hard to maintain. Major problem – poor thermal performance of single glazing: • U-value> 5 W/m2K But, with good care and maintenance traditional windows can outlast modern replacements, define the ‘look’ of a building and can be considered as a sustainable resource. Traditional Windows Secondary glazing – seen as most effective option to preserve existing traditional windows and reduce heat loss. There has been little information on the performance of more traditional (and cheaper) methods of reducing heat loss, such as, draught proofing, shutters, blinds and curtains. Research carried out for Historic Scotland & English Heritage has sought to quantify the benefits of • Draught-proofing • Blinds, curtains, & shutters • Secondary glazing • Replacing single glazed panes with double glazing Lab based tests using environmental chamber Heavy Curtains Traditional Shutters Insulated Shutters with Spacetherm Modern Roller Blind Blind with low-e foil applied Victorian Blind Honeycomb Blind Metallised interior of honeycomb Low-e Secondary Glazing U-values Effect of Shutters Draughtproofing 80 HS WINDOW AS RECEIVED 70 HS WINDOW AFTER DRAUGHT-PROOFING HS WINDOW DRAUGHT-PROOFED + 2ndry GLAZING AIR FLOW [cu.m/h] 60 50 40 Professional draught proofing reduces air leakage by 86% compared with the as-received condition 30 20 10 0 0 5 10 15 20 25 30 35 PRESSURE DIFFERENCE DP [Pa] 40 45 50 Slim-profile double glazing trial Lister Housing Co-operative, Edinburgh Changeworks/Historic Scotland Changeworks Slim-profile double glazing trial • Georgian (1820s) tenements • Traditional sash & case windows with single glazing • World Heritage Site/‘B’ listed • DG not currently permitted • Social housing • High fuel bills/Electric heating • Excessive condensation, etc. Slim-profile double glazing trial DG unit thicknesses 9,11, 12, 16mm. Low-e coated glazing Gas fill: • Air • Argon • Krypton • Xenon & Krypton Quoted U-values: • 1.8 – 2.6 W/m2K Vacuum Glazing http://www.pilkington.com/resources/pilkingtonspaciaenglish1.pdf Beauty is in the eye of the beholder In Situ U-value Measurements Measured U-values Heat loss through whole window Slim-profile double glazing trial - conclusions Two years on ... second series of measurements indicates no significant changes in thermal performance. Vacuum glazing superior to conventional slim-profile DG. Secondary glazing generally superior to conventional slim-profile DG. Design of slim-profile units not systematic in terms of cavity width and gas type – manufacturers should follow standard calculation procedures to optimise thermal performance. Some concerns about deterioration of conventional edge seal materials due to reaction with putty. No such concerns with vacuum glazing with glass edge seal. Suggested reading for improving energy efficiency of traditional windows Historic Scotland Technical Paper 1 (to be revised) www.historicscotland.gov.uk/thermal_performance_of_traditional_windows_2010.pdf Historic Scotland Technical Paper 9 www.historic-scotland.gov.uk/slim-profile_double_glazing_2010.pdf English Heritage - Improving the Thermal Performance of Traditional Windows www.climatechangeandyourhome.org.uk/live/research_generic.aspx In situ Thermal Performance Testing Main approach has been to measure the in situ U-values of building envelope elements using heat flux sensors. In situ U-value Measurements RoomTemperature ExternalTemperature Heat Flux Meter Interior Surface Temperature External Surface Temperature Analysis of in situ heat flux data – averaging method • Generally, the heat flux and wall surface temperatures are measured over a suitable period: a minimum of 14 days is usually sufficient. Averaging over the monitoring period is used to obtain the U-value: Ut 1 it Tsi Tse i 0 i it Q 0 Temperature difference across element i rint rext Heat Flux Can also use “parameter identification” techniques Use full dynamic data. Take into account the thermal capacity of the wall. Appropriate if there are large diurnal swings in external conditions as may be experienced during spring, or changes in the weather pattern during the test period. Example of a wall modelled as a network of conductances and capacitances Checking result....cumulative average U-value Use of in situ values Traditional buildings may have unknown construction details or material properties – difficult to estimate U-value using U-value Calculators. Comparison of in situ measurement with calculated values have shown that calculated values often overestimate U-value (SPAB, HS & EH projects). – Databases of U-value calculators are focussed on modern materials. – Lack of information on traditional material properties. Stone rubble wall ? ? +voids? Stone rubble wall The influence on the calculated Uvalue of the assumed proportion of mortar in a 600mm sandstone wall with 25mm lime plaster on the hard. Sandstone =2 W/mK Lime Mortar =0.7 W/mK Use of in situ values Recommend that where possible measured in situ U-values should be used as data for input into performance assessments – e.g. SAP. Acceptable as an alternative to default values used in RDSAP? No current standard for measurement. Use in situ U-value & airtightness measurements Measure Heat Loss through building envelope In situ U-value measurements in representative locations for walls, floors & ceiling. Centre-of-pane for glazings. Airtightness – background ventilation Blower door tests Air leakage rate @ 50Pa Calculate Element Areas from Building dimensions A1…etc. Calculate UxA values For windows and doors use centre-ofpane values in BRE U-value calculator to first calculate whole window Uvalues. Use same procedure as SAP ‘Heat losses..’ worksheet to calculate Heat Loss Coefficient, etc. Use in SAP Measured in situ Heat loss Heat loss coefficient, parameter, 2 W/K W/m K Rating SAP2005 using default U-values 366 4.9 D56 SAP2005 using in-situ U- values 318 4.2 D60 In Situ Thermal Performance Testing - Conclusions A robust method of measuring the in situ thermal performance of building elements has been developed over a number of campaigns, producing new data on our traditional buildings. The tests have shown the need for improved material properties/default values for calculation methods. Where feasible, recommend in situ U-value measurements to improve accuracy of energy performance assessment, particularly before upgrading insulation in traditional buildings. Impact on Green Deal? Standard or Guidelines on in situ measurements required. Historic Scotland Technical Paper 10 www.historic-scotland.gov.uk/hstp102011-u-values-and-traditionalbuildings.pdf Thank You