EURO4

advertisement

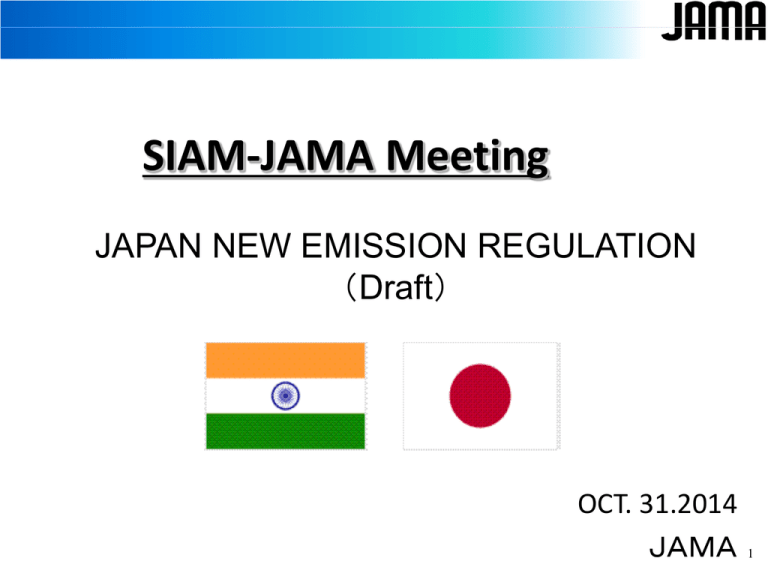

SIAM-JAMA Meeting JAPAN NEW EMISSION REGULATION (Draft) OCT. 31.2014 JAMA 1 Type I – Tailpipe emissions ・THC in Class 1 and 2 is more stringent than that of Euro4. ・Class 3 is the same as the new Euro4 (considered harmonization) Japan Current limits (WMTC mode) ≦125cc CO THC NOx 2.2 0.45 0.16 Japan 2016 limits (WMTC mode) Class 1 CO THC NOx 1.14 0.30 0.07 Class 2 CO THC NOx 1.14 0.20 0.07 Class 3 CO THC NOx 1.14 0.17 0.09 (-48%) (-56%) (-56%) <Reference> Euro3 Euro4 (-33%) (-56%) 125cc< THC 0.27 CO 2.62 (-26%) (-66%) NOx 0.21 (-37%) (-57%) Class 1, Class 2 (Vmax <130Km/h) CO THC NOx 2.62 0.75 0.17 1.14 0.38 0.07 Class 3 CO THC NOx 2.62 0.33 0.22 1.14 0.17 0.09 (-56%) (-56%) (-50%) (-58%) (-50%) (-57%) Policy: Harmonize with the international standards to be developed in new EURO5 UN-ECE/WP29 in Europe 2020. 2 Type II – emissions test (Idle/high Idle) Limit Value IDLE CO Japan EURO4 3.0% the values measured in accordance with point 4.2.3. shall be in compliance with the requirements set out in points 8.2.1.2. of Annex II to Directive 2009/40/EC if point 8.2.1.2. (a) is selected by the manufacturer, the specific CO level given by the manufacturer shall be entered on the certificate of conformity; ・・・・・ HC High IDLE CO ≦125cc 1600ppm >125cc 1000ppm ↑ HC 3 Type II – emissions test (Idle/high Idle) Annex II to Directive 2009/40/EC Type III – Crankcase emissions Requirements Japan 0g Design requirements BLOWBY GAS REDUCING DEVICE Euro4 Base Test Option1 Option2 Test Method pressurize the crankcase to 5 kPa and monitor for 300 seconds Test Condition Requirements Pressure does not exceed atmospheric pressure. Bag does not inflate during the 3 steady state tests. Crankcase pressure ≥ 0.95 times the initial overpressure for 300 seconds 5 Type IV – Evaporative emissions Limit value THC g/test Japan 2016 2.0 Euro4 2.0 Shield Housing for Evaporative Determinations HC Analyzer 6 Type IV – Evaporative emissions Precondition (Driving cycle*) Evap. test flow *Driving cycle WMTC mode (Vmax ≦50km/h EUDC) Soak (20~30℃、Max 36Hr) Fuel replacement ① Canister Aging Diurnal Breathing Loss(1hour) Exposed Non-Exposed Fuel:15.5 - 35.5℃ 15.5 - 28.8℃ Vapor:21 - 41℃ 21 - 34.3℃ Fuel Cooling Max 30℃ Driving cycle* ② Hot Soak Loss (20~30℃,1hour) Limit :①+②+(Fixed DF) ≦ 2.0g Type IV – Evaporative emissions Requirements list of evaporative emission test Euro4 CARB Japan 2016 Test Vehicle Degreened Vehicle ① >1000km Aged Vehicle① or Dgreened Vehicle② Degreened Vehicle① >1000km Canister Aging Loading & Paging ③ (EURO4) Loading & Paging ③ (CARB) Loading & Paging ③ (EURO4 or CARB) Control Device Durability test 5000 ④ cycle or The parts which finished the Type V test. Aged device ④ The parts which finished the Type V test. ④ Fixed DF 0.3g/Test ⑤ None Under discussion ⑤ Average ① and ②+③+④ ①+③+④ (or ①+⑤) Under Discussion Test ①+③+④ Calculation or ①+⑤ method ・Mechanical Endurance ・Vibration Endurance ・Thermal Exposure 8 Type IV – Evaporative emissions CARB Euro4 ①Canister Loading ①Canister Loading ・Air : Gasoline vapor 50:50 ・Flow rate : 40gr/h ・Heating a container filled with gasoline at 80℃。 2g- Breakthrough or 5000ppm by FID Up to 80% by weight of capacity Dwell time : 5min Dwell time : 10min ②Canister Purging ②Canister Purging ・Flow rate :1±0.2cfm ・Time : 7.5min ・Flow rate : 24L/min ・400 bed volume V max Test cycles ≦50km/h 90 50km/h<Vmax<130km/h 170 ≧130km/h 300 Each of the Ageing method will be allowed in the Japan regulation. Type IV – Evaporative emissions Fuel Tank heating profile for DBL test For exposed type fuel tanks: Tf = 0.3333 .t + 288.5 Tv = 0.3333 .t + 294.0 For non-exposed type fuel tanks: Tf = 0.2222 .t +288.5 Tv = 0.2222 .t + 294.0 where: Tf = required temperature of fuel (K); Tv = required temperature of vapor (K); t = time from start of the tank heat build in minutes. Definition The "non-exposed fuel tank", all parts of the fuel tank, including the fuel tank cap, fuel tank placement and structure that is not subject to direct sunlight, Or, it is proved that the handle manufacturing is equivalent to "non-exposed fuel tank" means a fuel tank Examining Authority recognized. Japan will apply the same heating profile as EURO4 and considers to add the definition of “Non-exposed type fuel tanks”. Type V - Durability requirements Mileage requirement: Disp. ≦50cc ≦125cc >125cc Japan Current 6,000km 8,000km 24,000km Japan 2016 6,000km 8,000km 24,000km ・Full Distance ・Test Mode Japanese Mode Vmax <130 km/h Vmax ≧130 km/h EURO4 20,000km 35,000km EURO5 20,000km 35,000km ・Half/Full Distance、Fixed DF ・Test Mode SRC or AMA Plan to achieve full harmonization with the European legislation next regulations (2020 Implementation) 11 Type VIII – J-OBD1 Monitoring requirements Basically, OBD in the Japan 2016 regulation is to monitor the malfunctions of the following components caused by an open/short circuit. - Barometric pressure sensor - Manifold absolute pressure sensor - Intake air temperature sensor - Engine coolant temperature sensor / Engine temperature sensor - Throttle position sensor - Camshaft position sensor - Crankshaft position sensor - O2 sensor - O2 sensor heater - Ignition coil primary control circuits - Secondary air injection system Fuel system 12 Type VIII – J-OBD1 Functional requirements Malfunction information to be stored in the on-board ECU Malfunction indicator light to be in conformity with ISO 2575 Data link connector between the vehicle and the diagnostic tester to be in conformity with ISO 15031-3 (SAE J1962) An alternative connection interface may be used when the vehicle manufacture prepares an adapter which enables connection to the diagnostic tester conforming with ISO 15031-3 (SAE J1962) Adaptor ECU Specific connector by each manufacture - Small size - Waterproof ISO 15031-3 (SAE J1962) -Big size -Non waterproof 13 OBD Connector Time Line of ISO TC22/SC38/WG4 OBD Connectorは Autumn/2016にInternational Standard 予定 P-14 Plan to achieve full harmonization with the European legislation next regulations (2020 Implementation) 4次規制(2020年頃実施)は欧州法規との完全基準調和を図る予定 item Japan 2016 Euro4 mg/km g/km Tailpipe Durability Japan Next (=EURO5?) 1,2 3 <130km/h ≧130km/h CO 1140 1140 0.17 THC 380 170 0.09 NOx 70 90 Class 1 2 3 Class CO 1.14 1.14 1.14 THC 0.3 0.2 NOx 0.07 0.07 Class ALL CO 1000 THC 100 NMHC 68 NOx 60 Test mode : Japan mode 6,000/8,000/24,000km Test mode:AMA or SRC ・Full/Half distance (20,000km/35,000km) ・Fixed DF(1.3/1.2/1.2) EVAP 2g/Test Aging EURO4 or CARB Fixed DF (under discussion) 2000mg/Test Aging EURO4 Fixed DF 0.3g OBD J-OBD1 Open, short Circuit Fuel System OBD stage1 ・Open Short Circuit ・Emission thresholds、Rationality check, …) OBD stage2 ・Emission threshold ・Misfire, CAT diagnosis Noise UN-R41 Stationary noise UN-R41 UN-R41 mg/km Test mode: SRC ? ・Full/Half distance (20,000km/35,000km) ・Fixed DF(1.3/1.2/1.2) Under Discussion 1500mg/Test 15 Schedule for implementation 2013cy 2014 71st 2015 GRPE (informal doc) EPPR Draft Roadmap (Test type VIII) Jun Jan Jun 72nd GRPE (formal doc) applicable Japan’s Regulation 2016 enforcement regulation study announcement 16 END Thank you for your attention . 17