Why Pavement Preservation? - Local & Tribal Technical Assistance

advertisement

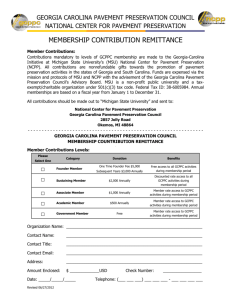

Why Pavement Maintenance and Preservation? Sponsored by: Minnesota T2 Center Presented by: Michael Marti, P.E. SRF Consulting Group, Inc. Dan Wegman, P.E. SemMaterials What Are We Talking About? FHWA Definition of Pavement Preservation Pavement preservation is a strategically-planned, engineering-based program to arrest light deterioration, retard progressive failures, reduce the need for routine maintenance and maintain safety on the existing roadway system. It is a series of cost effective maintenance strategies to delay the onset of predicted distress. Pavement preservation does not significantly improve the load carrying capacity of pavements, shoulders, or structures, but extends the useful life and improves the level of service. FHWA Practical Definition of Pavement Preservation The right treatment At the right time On the right project Done right! FHWA Maintenance: Needs vs Budget Budget: $27 billion Needs: Maintain: $50 billion Eliminate backlog: $210 billion Mn/DOT - Preventive Maintenance Funding and Operational Issues • In 1999, spent $30 million maintenance • Estimated need is $118 million! • Centralized recommendations based on pavement management program • Final decisions based on field review and local issues/input Types of Pavement Maintenance • Corrective (reactive, rehabilitation) – After deficiency occurs – More expensive • Preventive (proactive) – Protective – Retards deterioration – Extends asset’s life – Reduces need for corrective maintenance Why Pavement Preservation? Intuitive Argument • Why do you change the oil in your car? • Why do you paint the exterior of your house? You do them to preserve your initial investment and extend it’s life… You don’t measure how long they last… Pavement preservation is the same concept. Pavement Lifecycle Typical Maintenance & Rehabilitation Strategies Routine Maintenance Pavement Preservation PSI (Pavement Serviceability Index) 100 Defer Action 80 Rehabilitation 60 Reconstruction 40 20 0 Years Pavement Preservation Strategy Preventive Preservation Treatments Conventional Overlay Time or traffic Pavement Structural Condition Theory Behind Pavement Preservation – Timing Excellent Good 40% drop in quality 75% of life Fair $1 for PP here 40% drop in quality Poor Would cost $5 - $10 here Very Poor 12% of life Failed 5 10 15 Years 20 Where is the Proof? Numerous studies/resources • • • • • FHWA NCHRP NHI Foundation for Pavement Preservation LRRB Empirical facts vs Compelling data Where is the Proof? Current LRRB Study (Inv 861 Wood and Lukanen) 1256 sections (constructed since 1985, bituminous over gravel base) • 597 no preservation 659 with preservation No Maintenance Seal Coated Poly. (Seal Coated) Poly. (No Maintenance) 4.0 3.5 Seal Coated Sections y = 0.0005x 2 - 0.0419x + 4.0221 R2 = 0.8354 Average SR 3.0 2.5 2.0 1.5 No Maintenance y = -0.0041x 2 - 0.0103x + 3.9607 R2 = 0.8967 1.0 0.5 0.0 0 2 4 6 8 10 12 Years since BAB Construction 14 16 18 20 Where is the Proof? Current LRRB Study (Inv 861 Wood and Lukanen) 1256 sections (constructed since 1985, bituminous over gravel base) • 597 no preservation 659 with preservation No Maint. Seal Coated 4.0 Average RQI 3.5 3.0 2.5 2.0 1.5 1.0 0.5 0.0 0 5 10 Time since BAB Construction, yrs. 15 Where is the Proof? • Rougher roads have higher user costs • Therefore, pavement preservation yields lower user costs, but is it cost effective? Where is the Proof? TRB Report (Galehouse, Moulthrop, and Hicks) • TR News • Economic analysis (LCCA) • Based on typical costs and expectations Where is the Proof? TRB Report (Galehouse, Moulthrop, and Hicks) Where is the Proof? TRB Report (Galehouse, Moulthrop, and Hicks) • Data supports familiar graphs Where is the Proof? Typical costs in Minnesota Typical Cost per Mile New Construction $436,868 Preservation Treatments Chip Seal $5,711 Crack Repair $5,891 Crack Seal $3,624 Crack Seal/Chip Seal $9,792 Thin (1.5 -in.) Mill & Overlay $62,791 Micro-Surfacing $32,957 Thin (1.5 -in.) Overlay $18,365 Rehabilitation Medium (3 -in.) Overlay $38,220 Medium Mill & Overlay $83,654 Thick (5-in.) Overlay $54,600 Thick Mill & Overlay $104,963 Benefits of Pavement Preservation Pavement Preservation…doing the right thing at the right time. • • • • • • • Preserving initial investment Extended life or serviceability Lower life-cycle costs Lower user costs Improved safety Improved budget planning Public support Based on this, use your own data to determine if it’s The RIGHT TIME to do the RIGHT THING? Establishing a Preservation Program • Number of Technical Components • Two most important components are non-technical • Agency Top Management Commitment • Education/Outreach Program What are some of the barriers? Paradigm Shift • Moving from “worst-first” process Internal Issues • Must be understood and accepted by all • Must be committed to by top management • Must have buy-in from work force • Remove stigma that maintenance is less important or “prestigious” than new construction Marketplace Pressures • Introducing new technologies • Competition from industry (“rehab” and material suppliers) Public Perception • “Why are you fixing something that is not broken?” Examples of Preventive Maintenance Techniques • • • • • • • • Crack sealing Chip seals Macro-surfacing Slurry seals Micro-surfacing Ultra-thin bonded wearing coarse Thin overlay Mill and overlay