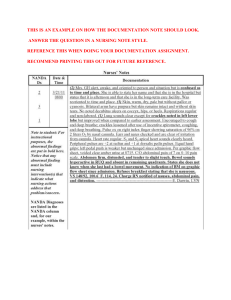

Additive Manufacturing 2025/2026 Lab 1 - 3D Printed Capsule competition Project Work Syllabus 1 Project Work overview This project work is for all the students attending the course of Additive Manufacturing. In this project, students are expected to develop knowledge regarding the process characteristics and determine the optimal design of a space capsule prototype, which will compete in a simulated landing (drop test). By the end of the project, students are expected to have executed a series of preliminary printing tests, aimed at realizing and testing different designs. The final design will be 3D printed and tested in a drop challenge from a defined altitude. The first three teams of the competition ranking will receive a prize. A scheme of the project workflow is shown here below. Figure 1: workflow of the project Students will describe their work in a report, discussing the design choices, the evaluation of performances, all the process-related decisions (parts orientation, parameters choices, etc.) and the results. The overall project evaluation will be based on this document. Evaluation criteria and grading table are shown in the following paragraph of this document. 2 3D Printing Sessions During the project, you will have the chance to print your lunar capsule using one of the FDM machines available in the Additive Manufacturing Lab (building B23). Here, five BambuLab X1 Carbon 3D printers will be available to fabricate your own prototype. The image and table below show the main machine characteristics and some of the default process parameters. The instruction on how to use the 3D printers and how to get access to the labs will be shared on WeBeep and presented during the exercise lecture. Figure 2: BambuLab X1 Carbon 3D printers Figure 3: Default Parameters for the first printing session Tip: you can use the specific Bambu Stick Glue that will be available in the Lab to improve adhesion of the first layer. Note that, on the printer, you must uncheck the following parameters: - Use AMS Flow Calibration Here you can see the preview: Figure 4: Printer preview The scheduling for the available printing sessions will be published on WeBeep. Before the end of the course (December), three slots will be opened to print your prototypes. In the first printing session, students are expected to get an understanding of the FDM 3D printing process, to identify its potentialities and limits and to realize the first prototype. The following sessions will be meant to improve the preliminary results, by modifying process parameters, part orientation, model design, etc. All the modification must be preliminary discussed with tutors during the tutoring sessions. During the printing sessions, all the team members will be admitted in the lab. More details will be given in the aforementioned material. Note: After the first printing, you are strongly encouraged to try your design, record a preliminary test (we will give you a camera with a neutral background and a defined heigh), and analyze the dropping. You can also comment the tests with the tutors during tutoring sessions. You are allowed to perform your official trial with our setting just one time per group. 3 Constraints The design of the component should consider some constraints, which are mandatory to compete in the final competition. Not conforming capsule will be excluded to the final competitions. • Additional components. The capsule must be made only of TPU. No other materials will be accepted (no scotch, no glue, etc.). You can print a modular capsule but only 3D-printed with TPU. • Dimensions. Final dimensions cannot exceed the ones listed here: − Width (X-axis): up to 200 mm − Depth (Y-axis): up to 200 mm − Height (Z-axis): up to 200 mm H=200 mm Figure 5 Dimensional constraints • • Process constraints. BambuLab X1 Carbon 3D printers will be used, equipped with TPU filament (1.75 mm of diameter) and a nozzle of 0.4 mm. For the first printing session, student are strongly encouraged to use the default process parameters, given at the beginning of the project (see WeBeep folder LAB CLASSES). Any change in process parameter is allowed, but it must be discussed with tutors during tutoring sessions before any printing session. Please note that If you own a 3D printer, you are allowed to perform additional test with your personal machine. However, the final design will be realized only with the POLIMI 3D printers. Printing time. The printing time is automatically estimated by Bambu software, as depicted in Figure 4. It must not exceed 6 hours. Figure 4: BambuLab Software. The estimated printing time is shown after slicing process. • Dimensions of the ball to encapsulate: diameter of 4 cm. Glass ball (without any other links). We will provide you the glass balls. You cannot insert material you bought by yourself. Any other connections to the ball will be removed. Figure 6: Example of possible ball to be encapsulated 4 Drop competition and evaluation criteria After the last printing session, all the printed capsules will compete in a drop competition. More in details, each capsule will be launched from mezzanine corridor of building B23 for 3 times to ensure reliability. The teams will be evaluated considering three criteria with the following weights for the final ranking: 1. Breakage of a Christmas ball incapsulated (50%). The capsule will contain a Christmas ornament ball, which must remain intact throughout the launch and landing process. 2. Lightness (25%). In parallel, the model that you print will be weighted. You should find a good trade-off between low amount of material and elastic mitigation. Prior to the final drop competition, capsule’s weight (without any other external loads) will be measured with a scale available in our laboratories (precision = 0.1 g). 3. Printing time (25%). Be careful! Lighter design does not necessarily mean faster process. The presence of supports, as well as process parameters choice and the presence of small features in the selected design can strongly influence the overall printing time. Printing time will be evaluated using the GCODE preview available on Bambu Studio. The winners of the final competition will receive a final prize. 5 Final Report The result of the final competition will not be the only criterion for the final project evaluation. Indeed, students are required to write a report discussing their design choice, the testing methodologies, the evaluation methods to decide which aspects need to be improved, and the results. The report should be concise, yet complete in terms of the methodology employed and the design steps which brought to the final design of the capsule. Report length is expected to be between 20 pages max. A possible structure of the final report is as follows: 1. Introduction 2. Existing designs 3. First printing session 3.1. Design-related choices 3.2. Process related choices 3.3. Printing results 4. Improved design 4.1. Change in design choice 4.2. Change in process parameters choice 4.3. Performance’s evaluation 5. Cost analysis 6. Conclusions and Future developments 7. Appendix 1 – Assembly instructions The final report will be evaluated considering the following criteria: • • • • • Report structure, clarity, brevity, completeness. Ability of designing the capsule, considering the FDM capability (in terms of possibility of designing complex, monolithic and lightweight structures) and its limits. Ability of re-designing the capsule to improve its performances, in terms of elastic behavior and lightness. Discussion on process-related choices, such as material parameters, printing parameters modification, supports displacement etc., defects mitigation (if any), improvements of performances and the reduction of printing time. For all the previous points, ability of identifying different improvements possibilities, ability of screening and scoring the considered options to select the best one, and ability of testing the new printed solutions. The team leader will oversee any communication to and from the team, and he/she will be in charge of uploading the final project report in the “LAB 1 – UPLOAD PROJECT REPORT” folder on WeBeep. All the files/documents material are due December 31st (midnight). 6 Grading The final grading will be determined considering the report quality criteria. Grading from project work is between 0 and 6. ANNEX 1 Citation style A useful application (NOT MANDATORY) for creating a research database and adding citations to a text is Mendeley (https://www.mendeley.com). A word plug-in is available. At the end of a literature review, a chapter with the bibliography/references should be provided. In order to cite works from literature in a scientific text the Vancouver citation style should be employed as in the following example: Text As investigated by Thombansen and Abels molten pool monitoring may be conducted using both a pyrometer and a high speed camera [1]. Similarly Furumoto et al. observed the laser powder bed fusion process [2]. References [1] Thombansen U, Abels P. Observation of melting conditions in selective laser melting of metals (SLM) 2016;9741:97410S. doi:10.1117/12.2213952. [2] Furumoto T, Ueda T, Rizal M, Hosokawa A. Investigation of laser consolidation process for metal powder by two-color pyrometer and high-speed video camera. CIRP Ann - Manuf Technol 2013;62:223–6. doi:10.1016/j.cirp.2013.03.032. Presentation In a presentation it is sufficient to cite the author/s, journal of publication and year. If in a slide the following figure is shown, beneath the figure the citation should be added: [1] Furumoto et al., CIRP Annals, 2013 Citations in presentations should also be numbered progressively. At the end of the presentation a backup slide with the bibliography should be reported.