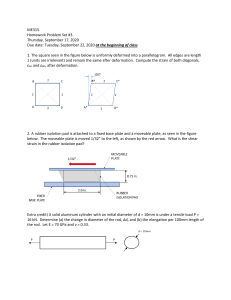

HW #5 Solutions Prob 1 A cylindrical specimen of titanium alloy with elastic modulus E = 107, original diameter d = 3.8, tensile load P = 2000, and maximum allowable elongation δ = 0.42 is considered. The maximum length L before deformation is calculated using Hooke’s law for elastic deformation: σ = Eϵ, σ= P , A ϵ= δ L where A is the cross-sectional area: A= πd2 π(3.8 × 10−3 )2 = = 1.134e − 5 4 4 Solving for L: L= EδA (107 × 109 ) × (0.42 × 10−3 ) × (1.134 × 10−5 ) = = 0.2548 = 254.8 P 2000 Thus, the maximum length is approximately 255. Prob 2 For a bronze alloy with yield stress σy = 275 and modulus of elasticity E = 115: (a) The maximum load without plastic deformation for a cross-sectional area A = 325 is: P = σy A = (275 × 106 ) × (325 × 10−6 ) = 89375 ≈ 89400 (b) The original length L0 = 115. The strain at yield is: ϵy = σy 275 × 106 = = 0.002391 E 115 × 109 The elongation is: δ = ϵy L0 = 0.002391 × 115 = 0.275 The maximum length without plastic deformation is: L = L0 + δ = 115 + 0.275 = 115.275 ≈ 115.3 1 Prob 3 A cylindrical aluminum specimen with diameter d = 19, length L = 200, and force P = 48800 is deformed elastically. Using typical values for aluminum: E = 69, Poisson’s ratio ν = 0.33. (a) The elongation in the direction of applied stress is calculated as: A= δ= πd2 π(19 × 10−3 )2 = = 2.835e − 4 4 4 PL 48800 × 0.2 = = 0.000499 = 0.499 AE (2.835 × 10−4 ) × (69 × 109 ) (b) The change in diameter is found from the lateral strain: ϵlong = 0.499 δ = = 0.002495 L 200 ϵlat = −νϵlong = −0.33 × 0.002495 = −0.000823 ∆d = ϵlat d = −0.000823 × 19 = −0.0156 The diameter decreases by 0.0156. Prob 4 For the aluminum specimen with diameter d = 0.505 (gauge length L0 = 2.000) and load-elongation data: 2 • Cross-sectional area A = πd4 = 0.2003 (a) Engineering stress σ and engineering strain ϵ are computed from the data. The plot of σ versus ϵ is shown below (not included in LaTeX, but described). (b) The modulus of elasticity is determined from the linear portion of the stress-strain curve. Using points up to ϵ = 0.004: E= σ 34199 = = 8549750ψ ≈ 8.55e6ψ ϵ 0.004 (c) The yield strength at a strain offset of 0.002 is found by drawing a line parallel to the elastic line from ϵ = 0.002. The intersection with the stress-strain curve gives: σy = 40200ψ (d) The tensile strength is the maximum stress: 2 σts = Pmax 10700 = = 53420ψ A 0.2003 (e) The percent elongation at fracture: Lf = 2.330, %elongation = Lf − L0 2.330 − 2.000 ×100% = ×100% = 16.5% L0 2.000 (f) The modulus of resilience: Ur = σy2 (40200)2 = 94.5ψ = 2E 2 × 8.55 × 106 3