Uploaded by

Pela Mahloko

Key Takeaways from The Goal: Goldratt's Theory of Constraints

advertisement

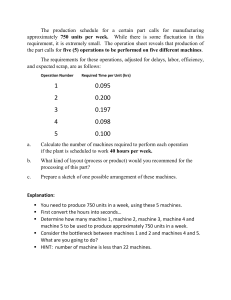

These are the key takeaways I took from Eliyahu M. Goldratt and Jeff Cox’s "The Goal" 1. Making money is an operation's main objective. The most basic lesson is to redefine the objective of an operational or manufacturing unit. Standard metrics like efficiency, cost reduction, and on-time shipments are the first things Alex Rogo looks at when evaluating the performance of his plant. These turn out to be deceptive, though. Making money now and in the future is the real objective, as Jonah teaches Alex. Three quantifiable financial indicators are used to operationalize this: Throughput: The system's rate of revenue generation from sales (as opposed to production). Revenue less genuinely variable costs (like raw materials) is what it is. Inventory: All of the funds that the system has spent on items that it plans to sell. Work-inprocess (WIP), finished goods, and raw materials are all included in this. Operational Expense: All of the funds used by the system to convert inventory into throughput, such as depreciation, utilities, and salaries. Every choice should be assessed from the standpoint of operations management in light of how it will affect these three metrics. A good action lowers inventory and operational expenses while increasing throughput. This clarity stops local optimizations that hurt the system as a whole by producing excess inventory without boosting sales, such as operating non-bottleneck machines at 100% efficiency. 2. Constraints (bottlenecks) govern the performance of any system. The fundamental idea behind the Theory of Constraints is that, in most complex systems, the output of the system is determined by a relatively small number of constraints, usually just one. Any resource that has a capacity that is less than or equal to the demand on it is said to be in a bottleneck. The crucial realization is that the capacity of the bottleneck, the plant's slowest step, limits the flow of production throughout the entire facility. Identification: Finding the constraint is the first step. This is accomplished in the book by noting which resources are continuously in use while others are idle, as well as where inventory accumulates (in front of the bottleneck). Implication: A lost hour at a bottleneck is a permanent loss for the system as a whole. On the other hand, saving an hour at a non-bottleneck is a myth; it does not affect the system's overall output. Traditional efficiency metrics that reward keeping all employees and machines busy at all times are challenged by this, which only results in bloated work-inprogress inventory. 3. A Continuous Improvement Process: The Five Key Steps The book provides a structured, ongoing methodology for managing operations, known as the Five Focusing Steps of TOC: ● Identify: Determine the system's constraint or constraints. Locate the bottleneck. ● Exploit: Make sure the bottleneck is operating as efficiently as possible ● Subordinate: Everything else should be subordinated to the decision mentioned above. Adjust the production process as a whole to the bottleneck's speed. ● ● Elevate: If subordination and exploitation aren't enough, take steps to expand the bottleneck's capacity, ● ● Prevent Inertia: The system's constraint will have shifted to another location, like the market or another machine, once a constraint is broken, like increasing the capacity of the bottleneck. 4. Flow Is More Important Than Local Efficiencies Local efficiencies are frequently the focus of traditional operations management. The Goal contends that this paradigm is defective. There are enormous lines of work-in-progress inventory when non-bottlenecks are operating at maximum capacity because they generate more than the bottleneck can manage. This inventory lengthens lead times, uses up space, and ties up capital.The other option is to give the system's efficient material flow top priority. The bottleneck determines the flow rate. Therefore, even though they may occasionally be idle, the main function of non-bottleneck resources is to support the bottleneck. 5. Dependent Events and Variability in Statistics describe the behavior of the system. The book explains why bottlenecks happen and why inventory accumulates, even in a balanced plant, using a straightforward hiking analogy involving a group of scouts. A production process is represented by the scouts moving in a line; each step must come after the one before it. To represent statistical fluctuations, each scout walks at a slightly different pace. The important insight is that statistical fluctuations accumulate rather than average out in a series of dependent events. The bottleneck, or the slowest scout, sets the line's pace. Additionally, any scout variation early in the line (such as slowing to tie a shoe) is magnified later, creating gaps and decreasing the group's overall speed. This results in accumulated delays in a factory. Instead of letting inventory accumulate at random throughout the process, this understanding explains why strategic inventory buffers are necessary at key points to guarantee that the constraint is never still.