Uploaded by

Buyo Juliana Khristyn

Introduction to Ergonomics & Human Factors Engineering

advertisement

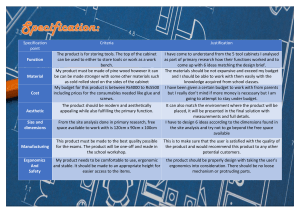

CHAPTER 1 INTRODUCTION TO ERGONOMICS 1.1 Definition of Ergonomics/Human Factors Engineering Ergonomics is the use of scientific principles, methods, and data drawn from a variety of disciplines for the development of systems in which people play a significant role. The field of applications extends from a single person using a simple tool to a complex multi-person socio-technical organization. Ergonomic specialists rely on the understanding that systems are meant to benefit people, whether they are consumers, production workers, system operators or maintenance crews. This usercentered design philosophy acknowledges human variability as a design parameter. The resultant design features utilize human capabilities, consider human limitations and have built-in safeguards to avoid or reduce the effects of human error or of system failure. Ergonomics is neutral: it takes no sides, neither employers’ nor workers. It is not for or against progress. It is not a philosophy, but a scientific discipline and practical technology. What Ergonomics Does Ergonomics focuses on the human as the most important component of our technological systems. This explains the early terms “human factors engineering,” “man-machine systems,” and the recent “human-systems integration.” The aim is to assure that all human-made tools, devices, equipment, machines, environments and their organizations advance, directly or indirectly, the well-being of humans and their performance. Accordingly, ergonomics has three related tasks: 1. Study, research, and experimentation to determine specific human traits and characteristics that need to be known for engineering design. 2. Apply this knowledge in the design of tools, machines, shelter, environments, work tasks and procedures so that they fit and accommodate the human. 3. Observe the actual performance of humans and their equipment in the real or a simulated environment, assess the suitability of the designed human-machine system and determine whether improvements are possible. 1.2 History of Ergonomics Using objects found in the environment as tools is an ancient activity. Pieces of stone, bone, and wood must have been selected for their fit to the hand and their suitability as cutters, scrapers, pounders, and missiles. Purposeful shaping of these tools naturally came next, followed by assembling raw materials to make, for example, protective clothing and shelters. These fundamental “ergonomic” activities grew into individual and communal skills and then into processes for creating finished products from diverse materials. Ergonomics 1 As human society grew more complex, organizational and managerial challenges developed. Training workers and soldiers, for example, became necessary, together with forming and controlling their behavior. Major projects, such as building the pyramids of ancient Egypt, assembling armies for warfare, sheltering the inhabitants of cities and supplying them with food and water, required sophisticated knowledge of human needs and desires; careful planning and complex logistics had to be mastered. The aims and means of training became sophisticated as well: Roman soldiers, for example, underwent wellorganized exercises and conditioning until they could perform military exercises with ease: “drying the legions” of the Roman Empire relied on the principle of adapting and improving the physiological capabilities of the recruits to meet challenging physical requirements; when they no longer showed sweat on the skin, they were “dry” and fit. Evolution of Disciplines Artists, military officers, employers and athletes apparently were always interested in body build and physical performance. Specialized “medicine men” and “herb women” treated illnesses and injuries. About 400 BC, Hippocrates (often considered the father of western medicine) described a scheme of four body types: the “moist” type was believed to be dominated by black gall, the “dry” type by yellow gall, the “cold” type by slime, and the “warm” type by blood. These “humors” had been in some balance to keep an individual healthy. Knowledge of medicine, anatomy and anthropology began to assemble. Over the centuries, more exact information accumulated into specialized disciplines. In the 15th– 17th centuries, gifted people such as Leonardo da Vinci (1452– 1519) and Alfonzo Giovanni Borelli (1608– 1679) could still master all existing knowledge of anatomy, physiology and equipment design; these individuals were artist, scientist, and engineer in one. Da Vinci, along with being an exceptional artist, understood nature, mechanics, anatomy, physics, architecture, and weaponry. His designs for machines included a bicycle, helicopter, and an airplane. Borelli’s book de Motu Animalium, published in 1680, applied the modern principle of scientific investigation by continuing Galileo’s custom of testing hypotheses against observation. Borelli extended rigorous analytical methods to biology (he can be called the “father of biomechanics”); he was the first to understand that the levers of the human musculoskeletal system favor quick motion rather than force. In the 18th century, the sciences of anatomy and physiology diversified and amassed specific detailed knowledge. Psychology began to develop as a distinct field of study. Well into the 19th century, the sciences tended to be oriented toward theories: the stereotype is the scientist in a white coat who devotes his life to research in the laboratory. But increasing industrialization with its employment of human workers, focused interest on “applied” aspects of the “pure” sciences. In the early 1800s, in France, Lavoisier, Duchenne, Amar, and Dunod researched energy capabilities of the human body. Marey developed methods to describe human motions at work. Bedaux made studies to determine work and payment systems before Taylor and the Gilbreths did similar work in the United States in the early 1900s. In England, the Industrial Fatigue Research Board considered theoretical and practical aspects of the human at work. In Italy, Mosso constructed dynamometers and ergometers to research fatigue. In Scandinavia, Johannsson and Tigerstedt developed the scientific disciplines of work physiology. In 1913, Rubner founded a Work Physiology Institute in Germany. In the United States, Benedict and Cathcard described the efficiencies of muscular work in 1913. The Harvard Fatigue Laboratory was established in 1927. Page 2|6 Ergonomics 1 In the first half of the 20th century, applied physiology and psychology were well advanced and widely recognized, both in their theoretical research “to study human characteristics” and in the application of this knowledge “for the appropriate design of the living and work environment.” Two distinct approaches to studying human characteristics had developed: one concerned chiefly with physiological and physical properties of the human, the other interested mainly in psychological and social traits. Although there was much overlap between these approaches, the physical and physiological aspects were studied mainly in Europe and the psychological and social aspects and North America. Directions in Europe Based on a broad fundament of anatomical, anthropological and physiological research, “work” physiology assumed great importance in Europe, particularly in the hunger years associated with the First World War. Marginal living conditions stimulated research on such topics as the minimal nutrition required to perform certain activities; the consumption of energy while doing agricultural, industrial, military and household tasks; the relationships between energy consumption and heart rate; the assessment of muscular capabilities; suitable body postures at work; the design of equipment and work stations to fit the human body. Another development in the 1920s was psycho-technology, which involved testing individuals for their ability to perform physical and mental work, their vigilance and attention, their ability to carry mental workload, their behavior as drivers of vehicles, their ability to read road signs, and related topics. Directions in North America Most psychologists around 1900 were strictly scientific and deliberately avoided studying problems that strayed outside the boundaries of pure research. Some investigators, however, pursued practical concerns, such as sending and receiving Morse code, measuring perception and attention at work, using psychology in advertising, and promoting industrial efficiency. A particularly important step was the development of intelligence testing, used to screen military recruits during the First World War and, later, to select industrial workers for their mental capabilities which certain jobs required. The concept of industrial psychology won acceptance. Some of the best-known, most puzzling findings in industrial psychology resulted from experiments at the Hawthorne Works near Chicago in the mid-1920s. The experiments were designed to assess relationships between efficiency and lighting in workrooms where electrical equipment was produced. The bizarre finding was that the workers’ productivity increased whenever the illumination was changed, regardless of increase or decrease; apparently, productivity responded to the attention paid to the workers by the researchers. This phenomenon became known as the observer or Hawthorne Effect. Industrial psychology⁴ divided into special branches, including personnel psychology, organizational behavior, industrial relations, and engineering psychology. Under the pressures of the Second World War, the “human factor” as part of a “man-machine system” became a major concern. Technological development lead to machines and systems that put higher demands on the attention, endurance, and strength of individuals and teams than many could muster. For example: operators had to observe radar screens over periods of many hours, with the in- tent of detecting and distinguishing some blips from others. In high-performance aircraft, the pilot had to endure forceful accelerations, for instance in tight turns and in steep dives or climbs. In these cases, the pilot might be unable to operate Page 3|6 Ergonomics 1 hand controls properly and could even black out. Crew members had to fit into tiny tank and aircraft cockpits, and (from the 1960s on) into spacecraft, which required that small persons be selected from expert aviators. Stressful conditions make it difficult to maintain morale and performance. New tasks and machinery generate new needs to consider human physique and psychology, purposefully, and knowingly, in the design of jobs, equipment, and environments. Names for the Discipline: “Ergonomics” and “Human Factors” Early on, in Europe and North America, anthropologists, physiologists, psychologists, sociologists, statisticians, and engineers used various terms to describe their activities of studying the human and applying the information obtained in design, selection, and training. In January of 1950, British researchers met in Cambridge, England, to select a name for the new society to represent their activities. Among others, the term “ergonomic” was proposed. In late 1949, KFH Murrell had derived that word from the Greek terms ergon, indicating work and effort, and nomos, meaning law or usage; apparently, he re-invented a word already used by W. Jastrzebowski in Poland nearly a hundred years earlier. That term was neutral; it implied no priority among contributing disciplines; it was easily remembered and recognized and could be used in any language. “Ergonomics” was formally accepted as the name of the new society at its council meeting in early 1950.⁶ In the United States, a group convened in 1956 to establish a formal society. They selected “human factors” instead of “ergonomics.” Often, the word “engineering” is added or substituted to indicate applications, as in “human (factors) engineering”. In 1992, the Human Factors Society renamed itself the Human Fac- tors and Ergonomics Society⁷ HFES with (in 2016) about 4500 individual members. The International Ergonomics Association IEA has 54 member societies (in 2016) with 28 in Europe, 13 in Asia, 9 in the Americas and 4 in Africa and the Oceania regions. There has been some discussion of whether human factors differs from ergonomics—whether one relies more heavily on psychology or on physiology, or is more theoretical or practical than the other. Today, the two terms are usually considered synonymous: the Canadian Society uses “human factors” in its English name, and “ergonomie” in its French version. Today’s Ergonomic Knowledge Base The development of space travel first forced humans to fold themselves into minuscule capsules; now people live and function in near weightlessness for months. Today, many professional activities involve long hours using computers of one kind or another as the primary work tools. Yet, heavy physical work still persists in many jobs in industry, in commercial fishing, in agriculture and forestry— some hard work is even new, such as in airline baggage handling. The field of ergonomics/human factors continues to grow and to change, driven by new technologies and by the resulting new tasks for people. Classic sciences still provide fundamental information about human beings (Fig. 1). The anthropological basis consists of Anatomy, describing the build of the human body; Orthopedics, concerned with the skeletal system; Physiology, dealing with the functions and activities of living body, including the physical and chemical processes involved; Medicine, concerned with injuries and illnesses and their prevention and healing; Psychology, the science of mind and behavior; and Sociology, concerned with the development, structure, interaction, and behavior of Page 4|6 Ergonomics 1 individuals or groups. Of course, physics, chemistry, statistics, and mathematical modeling supply methodology and knowledge. Figure 1.1 Origins, developments, and applications of ergonomics/human factors. Several applied disciplines developed from these basic sciences; these include primarily Anthropometry, the measuring and description of the physical dimensions of the human body; Biomechanics (Anthromechanics), describing the physical behavior of the body in mechanical terms; Industrial Hygiene, concerned with the control of occupational health hazards; Industrial Psychology, discussing people’s attitudes and behavior at work; Management, dealing with and coordinating the intentions of the employer and the employees; and Work Physiology, applying physical knowledge and measuring techniques to the body at work. Of course, associated disciplines such as Labor Relations have developed which are also part of, or contribute to, or overlap with, ergonomics. Their topical areas overlap and intertwine; their research produces practical applications in such fields as Industrial Engineering, also called Integrated Engineering, concerned with the interactions among people, machinery, and energies; Bioengineering, working to replace worn or damaged body parts; Systems Engineering, in which the human is an important component of the overall work unit; Safety Engineering and Industrial Hygiene, which focus on the well-being of humans; and Military Engineering, which relies on the human as soldier or operator. As computers have become integrated into all aspects of modern-day life, computer-aided design is used in all aspects of engineering. Naturally, other application disciplines also rely on ergonomic knowledge and data, such as oceanographic, aeronautical, and astronautical engineering. Goals of Ergonomics The (US) National Research Council asserted in 1983¹⁰ that “design begins with an understanding of the user’s role in overall system performance and that systems exist to serve their users, whether they are consumers, system operators, production workers, or maintenance crews. This user-oriented design philosophy acknowledges human variability as a design parameter. The resultant designs incorporate features that take advantage of unique human capabilities as well as built-in safeguards.” The human is never indentured to the system but is the beneficiary, the passenger, the participant, the operator, the supervisor, the controller, and the decision maker. Page 5|6 Ergonomics 1 There is a hierarchy of goals in ergonomics. The most essential and basic task is to generate tolerable working conditions that do not pose unavoidable dangers to human life or health. When this basic requirement is assured, the next goal is to generate acceptable conditions to which the people involved can voluntarily agree. The final goal is to generate optimal conditions that are so well adapted to human characteristics, capabilities, and desires that physical, mental, and social well-being is achieved. Ergonomics (human factors, human engineering, human factors engineering) is the study of human characteristics for the appropriate design of the living and work environment. Its fundamental aim is that all man-made tools, devices, equipment, machinery, and environments advance, directly or indirectly, well-being and performance of people. As more knowledge about humans becomes available, as novel opportunities develop to apply human capabilities in modern systems, and as new needs arise for protecting the person from outside events, ergonomics changes and expands. Reasons to Apply Ergonomics There are three major reasons to apply ergonomics, related to ethics, progress, and economic advantages. 1. Moral imperative: to improve the human condition and quality of life at work, especially in regards to health, safety, comfort, out- come, and enjoyment. Certainly, work must be safe and healthy, and should be comfortable. As we have all experienced, it can and should be enjoyable to achieve results at work and through work that we value personally. 2. Progress in knowledge and technology: to follow the human quest to learn more about ourselves, our desires, capabilities and limitations, and to develop and apply new theories and practices. Historically, thinkers and tinkerers, scientists and engineers have led the innate urge for progress. Stand-still seems unacceptable; we strive to improve objects and conditions. 3. Economic advantages: to reduce effort and cost in work systems that includes humans as doers, users, and beneficiaries. In many new designs of things and systems, the “human factor” already has been incorporated during the concept stage. Examples are meat cutters and computer mice, hip joint replacements and portable phones, spacecraft and modern automobiles, contemporary manufacturing and assembly plants. Some of these would be excessively dangerous, or could not function at all, without preplanning and design in human engineering. Yet, there are many older objects and work systems that were designed with little consideration of the human as user or worker, such as the type- writer or computer keyboard, or the traditional beverage delivery industry. Here, replacement, retrofit and re-design are necessary to reduce injury or strain to humans and to remedy inefficiency. Page 6|6