Uploaded by

Masoud Sadrameli

Feecon Fixed Oscillation Bumper Turret Manual - Operation & Service

advertisement

608-10 I 1025-13

------~•. -.......

---..-----.......--.-..----...

FIXED OSCILLATION

NON-ASPIRATING

AIR POWERED BUMPER TURRET

WITH POWER PATTERN CONTROL

FEECON PRODUCTS DIVISION

NATIONAL FOAM, INC.

150 GORDON DRIVE

P. 0. BOX 270

EXTON, PA 19341-1350

7100

1298-9706-7

FEECON FIXED OSCILLATION NON-ASPIRATING AIR-POWERED BUMPER TURRET

TABLE OF CONTENTS

Page

Text

Table of Contents ............................................................................................................................ i - ii

Feecon Address and Telephone Number ............................................................................................ ii

Warning-Failure to Read Manual ....................................................................................................... iii

Safety Information ............................................................................................................................... iii

CHAPTER 1 - INTRODUCTION

Caution - Bumper Turret Installation ................................................................................................. 1-·1

Caution - Customer Modification of Equipment ................................................................................ 1-1

Note - Operating Instructions ........................................................................... :................................. 1-1

1-1. General Description .. .. ... .. .. .... ........ .. .. .. .. ... ... .. ...... ..... .... ... .. ..... .. .. .... .... ........ ... .... . ... ...... .. ... ..... ... .. .. .. ... . 1-1

1-2. Mechanical Analysis ........................................................................................................................... 1-1

1. Turret Motion ............................................................................................................................... 1-1

a. Horizontal .............................................................................................................................. 1-1

b. Vertical .................................................................................................................................. 1-2

2. Automatic Turret Oscillation ...................................................

1-2

1-3. Turret Model Numbers ..................................................................... ,................................................. 1-2

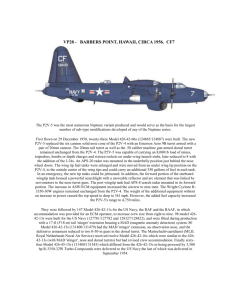

Outline DrawingFixed Oscillation Air Powered Bumper Turret with Non-Aspirated Nozzle .............................. 1-3

00 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CHAPTER 2- TURRET INSTALLATION

2-1.

2-2.

2-3.

2-4.

2-5.

2-6.

Bumper Turret Mounting .................................................................................................................... 2-1

Joystick Mounting ...................................................................... :....................................................... 2-1

Air Tubing Connections ..................................................................................................................... 2-1

Harness Connections .......................................................................................................................... 2-1

Elevation Shaft Cover Mounting ........................................................................................................ 2-1

Air Filter Installation .......................................................................................................................... 2-1

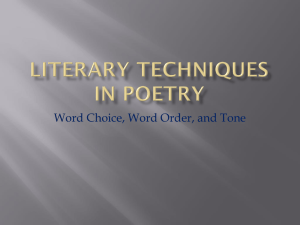

Installation Drawing ........................................................................................................................... 2-2

CHAPTER 3 - TURRET FUNCTIONS

3-1.

3-2.

3-3.

3-4.

3-5.

7/00

Turret Manual Rotation (Oscillation)-Elevation/Depression ............................................................. 3-1

Turret Automatic Rotation (Oscillation) ............................................................................................ 3-2

Adjustment of Cylinder Speed Control .............................................................................................. 3-3

Nozzle Discharge Pattern ................................................................................................................... 3-4

Turret Discharge Valve ...................................................................................................................... 3-4

-i-

FEECON FIXED OSCILLATION NON-ASPIRATING AIR-POWERED BUMPER TURRET

TABLE OF CONTENTS

Text

Page

CHAPTER 4- OPERATING PROCEDURES

4-1

4-2

Operation ............................................................................................................................................ 4-1

Shutdown ............................................................................................................................................ 4-1

CHAPTER 5 - RECOMMENDED INSPECTION AND MAINTENANCE

Recommended Inspection and Maintenace .................................................................................................. 5-1

CHAPTER 6- TROUBLESHOOTING

Troubleshooting ............................................................................................................................................ 6-1

CHAPTER 7- PARTS DRAWING AND PARTS LIST

Parts Drawing and Parts List ........................................................................................................................ 7-1

CHAPTER 8 -ELECTRICAL AND TUBING SCHEMA TICS

Electrical Schematic ........................................................................................ Drawing Number: 01788520

Tubing Detail .................................................................................................... Drawing Number: 01790420

9706-7.P65

(7/00)

NATIONAL FOAM, INC.

150 GORDON DRIVE

P. 0. BOX 695

EXTON, PA 19341-0695, USA

TELEPHONE 610-363-1400- FAX 610-524-9073

7/00

- ii -

FEECON FIXED OSCILLATION NON-ASPIRATING AIR-POWERED BUMPER TURRET

WARNING: This manual has been prepared as an aid and guide for personnel involved in the

installation, operation and maintenance of a Feecon Fixed Oscillation Air-Powered

Bumper Turret. All instructions must be read and understood thoroughly before

attempting any operation or service to this turret. Failure to follow any instructions

could result in personal injury and/or damage to this equipment.

SAFETY INFORMATION

Various Danger, Warning, Caution and Note signal

words appear in the Operating and Maintenance Manual

text which must be observed for safe personnel and equipment operation. Signal word selection is based upon hazard classification.

A

-is used with the

The International Alert Symbol signal word to gain and direct operating personnel's attention to the signal word.

The following explains each signal word. Personnel operating and maintaining equipment must familiarize

themselves with each particular signal words intent.

DANGER signal words indicate an extremely

hazardous situation which, if not avoided, will

result in death or serious injury to the operator.

WARNING signal words indicate a potentially

hazardous situation which, if not avoided, could

result in serious injury, or death to the operator.

if not avoided, may result in minor or moderate

mJury

2. A potentially hazardous situation which, if not

avoided, may damage or destroy equipment or

cause a loss of operating effectiveness

3. Alert operating personnel to unsafe practices

CAUTION signal words indicate the following:

1.

A potentially hazardous situation which,

It is the responsibility and duty of all personnel involved in

the operating and maintenance of this equipment to fully

understand the DANGER, WARNING, CAUTION and

NOTE procedures by which hazards are to be reduced or

eliminated. Personnel must become thoroughly familiar

with all aspects of safety and equipment prior to operation

or maintenance of the equipment.

7/00

NOTE signal words indicate statements which must

be observed for essential and effective operating

procedures, conditions, and as a statement to be

highlighted.

Operating and Maintenance Instructions and layouts shall

be posted at control equipment with a second copy on file.

All persons who may be expected to inspect, test, maintain

or operate foam-generating apparatus shall be thoroughly

trained and kept thoroughly trained in the functions they

are expected to perform.

- iii -

FEE CON FIXED OSCILLATION NON-ASPIRATING AIR-POWERED BUMPER TURRET

CHAPTER 1 - INTRODUCTION

A

CAUTION: Install the Bumper Turret in accordance with instructions in this manual. Failure to do so

may affect performance or cause equipment failure.

A

CAUTION: Customer modification or alteration of this equipment, or the use of replacement parts other

than those specified by Feecon, may affect the performance of this equipment and may void

the warranty.

NOTE: READ ALL OPERATING INSTRUCTIONS BEFORE USING EQUIPMENT.

It is the responsibility and duty of all personnel involved in the installation, operation,

inspection and maintenance of this equipment to read and understand this entire manual

before using the equipment.

1-1. GENERAL DESCRIPTION

The Feecon Fixed Oscillation Bumper Turret is an airpowered oscillating foam and water turret mounted on the

front bumper of the fire fighting vehicle. The operational

functions of this turret are: nozzle discharge pattern

control and turret rotation-elevation/ depression. These

functions are controlled at the turret joystick which is

located in the vehicle cab and is controlled by the turret

operator.

The turret provides foam or water protection to the tires

as the vehicle reaches the fire site and it also assists in

extinguishing the fire.

The following function controls are mounted directly

on the joystick handle:

• The turret discharge pattern selector toggle switch

which controls the nozzle discharge pattern

• Two electrical switches that regulate the customer

provided turret discharge shutoff valve

• A two-position toggle switch controlling the manual

and automatic turret oscillation

The turret discharge pattern and rotation, elevation/

depression are regulated by flow control needle valves,

mounted on the solenoid valve manifold assembly.

The turret air supply is provided through the vehicle at

a recommended pressure setting of approximately 100 psi

(65 psi minimum - 130 psi maximum). The water/foam

supply inlet connection accepts a 2" victaulic coupling

only. All turrets are available in black gloss finish only.

Nozzles for this bumper turret are available in non-aspirated models only. Refer to the chart which follows for the

flow rate (75 gpm- 500 gpm), appropriate voltage (12 or

24 VDC) and part number for your particular turret.

1-2. MECHANICAL ANALYSIS

The following descriptions provide a detailed analysis of the mechanical functions of the major turret components.

1. Turret Motion

a.

Horizontal

The two major components that rotate the bumper

turret are the rotation rack and rotation drive gear.

When the operator moves the joystick handle from

side to side, the corresponding solenoid valve actuates the rotation cy Iinder causing it to move in the

7100

appropriate direction. The rotation rack is attached to

rotation cylinder rods by two actuator arms. As the

rotation cy Iinder actuates the rotation rack, the rotation

rack turns the rotation drive gear. In turn, the rotation drive

gear rotates the attached rotation tube and this mechanical

sequence results in the desired turret rotation.

1-1

FEECON FIXED OSCILLATION NON-ASPIRATING AIR-POWERED BUMPER TURRET

b. Vertical

The two major components that elevate the

bumper turret nozzle are a two-piece swivel

shaft and a pivoting linlc One end of the swivel

shaft attaches to the elevation cylinder rod and

the other end is attached to the turret head by the

pivoting link.

The operator moves the joystick handle either forward

(to depress the turret nozzle) or back (to elevate the

turret nozzle) and the corresponding solenoid valve

actuates the elevation cylinder rod/swivel shaft in the

appropriate direction. The turret head, which is connected to the swivel shaft through the pivoting link, thus

moves the nozzle to the desired position.

2. Automatic Turret Oscillation

Automatic turret oscillation is controlled by electrical circuits only. For example, when the operator

moves the oscillation toggle switch down, the left

rotation solenoid is energized through a normally

closed set of contact points in a relay. The turret

rotates left until a magnet, located on the rotation

rack, activates the left limit rnicroswitch. This

activation energizes a circuit relay that, in tum,

sends a signal to the right rotation solenoid. An

electrical holding circuit maintains an energized relay

that allows the turret to continue rotating to the right until

the magnet reaches and activates the right limit

micros witch. As the right .limit switch is activated, the

electrical holding circuit is broken and the turret returns

to the left rotation mode. This chain of events continues

until the oscillation toggle switch is moved up to the

manual oscillation position.

1-3. TURRET MODEL NUMBERS

NOTE:

This manual is applicable to the following model turrets:

Turret

Flow Rate

Tip

Part

gpm (lpm)@

Part

Number

200 psi (14 Bar)

Voltage

Number

1252-7001-0 ..................... 75 (285) ........................ 12 VDC ..................... 3233-0087-6

1252-7001-5 ..................... 75 (285) ........................ 24 VDC ..................... 3233-0087-6

1252-7002-0 .................... 100 (380) ....................... 12 VDC ..................... 3233-0087-8

1252-7002-5 .................... 100 (380) ....................... 24 VDC ..................... 3233-0087-8

1252-7003-0 .................... 150 (570) ....................... 12 VDC ..................... 3233-0088-3

1252-7003-5 .................... 150 (570) ....................... 24 VDC ..................... 3233-0088-3

1252-7004-0 .................... 200 (760) ....................... 12 VDC ..................... 3233-0088-4

1252-7004-5 .................... 200 (760) ....................... 24 VDC ..................... 3233-0088-4

1252-7005-0 .................... 250 (950) ....................... 12 VDC ..................... 3233-0102-8

1252-7005-5 .................... 250 (950) ....................... 24 VDC ..................... 3233-0102-8

1252-7006-0 ................... 300 (1150) ...................... 12 VDC ..................... 3233-0089-2

1252-7006-5 ................... 300 ( 1150) ...................... 24 VDC ..................... 3233-0089-2

1252-7007-0 ................... 500 (1900) ...................... 12 VDC ..................... 3233-0098-9

1252-7007-5 ................... 500 (1900) ...................... 24 VDC ..................... 3233-0098-9

7/00

1-2

FEECON FIXED OSCILLATION NON-ASPIRATING AIR-POWERED BUMPER TURRET

1.5 (38) NPT

-,_ - - ~

_[f'l}- ·-

/ __ r

; II

I

:;:

I

'

II

{':)\--

-~_Q_q

,;- ~.:_ ,~-~ "'' ,'~ /

/

\

OPTIONAL

16 PPS (7.26 Kg/S]

DRY CHEMICAL KIT

PiN: 3217-7015-4

(SHOWN IN PHANTOM

- - ~ 'IY J_ -- .

\

REMOVABLE 1/4-18 (6) NPT

PLUG FOR~:ti~~~~~

""

10.36

(263)

FLANGED HEAD-NOZZLE

8.27

(210)

2.25

(57)

(FOR FLOWS OVER 300 GPM)

__ _L_j_ ___

j

WIRING HARNESS INLET

AIR SUPPLY INLET

1/8" (3) FNPT

NOTES:

Elevation: 45°

Depression: 20°

Rotation: 180°

Inlet Connection: 2" Victaulic Rear Feed

Pneumatic Requirements:

0.69 CFM @ 60 PSI and

1.34 CFM @ 130 PSI (4 to 9 Bar)

Electrical Requirements:

12 VDC- 2 Amps;

24 VDC- 1 Amp

Electrical Harness Length: 12 Foot

Automatic Oscillation:

Factory Set at 90°(45° each side of center);

Field Adjustable from 20° to 180°

Material: Bronze Waterway

Aluminum Panel

Weight: 56 Lbs. (25 Kg)

Paint: Black Polyester Powder

ACCESS COVER·-·

THREADED HEAD-NOZZLE

OAFOBT9706-5.0Sf'

(FOR FlOWS 300 GPM & BELOW)

\_.=

1

I

I\

::='):.:on.. '

I

I

I

d-'_-_/ __,~ :;u-11

~

3.06

(78)

~t.~.

(164)

PATTERN

~---CABLE

-·~--

L

~--~---·--------

18.18

(461.95)

OUTLINE DRAWING

FIXED OSCILLATION AIR POWERED BUMPER TURRET

WITH NON-ASPIRATED NOZZLE

7/00

1-3

FEECON FIXED OSCILLATION NON-ASPIRATING AIR-POWERED BUMPER TURRET

CHAPTER 2- TURRET INSTALLATION

NPT port. The recommended air supply pressure to

the turret is 60 to 130 psi (4 to 9 Bar). Air supplied to

the turret should be dry and filtered to 40 microns in

order to prevent possible malfunctioning of the solenoid valves.

2-1. BUMPER TURRET MOUNTING

1. Mount the turret to the bumper of the truck with the

wiring and tubing connections facing the passenger

side of the truck.

2.

Using the mounting dimensions shown on the installation drawing, page 2-2, secure the turret with (4) 5/16

screws and nuts (not supplied).

2-2. JOYSTICK MOUNTING

1. Mount the joystick to the truck cab dashboard or

console using the joystick mounting dimensions

shown on the installation drawing, page 2-2<

2.

Secure the joystick with (4) No. 10 machine screws

and nuts (not supplied).

2-3. AIR TUBING CONNECTIONS

1. Locate the 118 NPT air supply inlet labeled "Air

Supply" on the side of the turret.

2. Remove the plastic plug.

3. Connect the customer supplied tubing to the 118

2-4. HARNESS CONNECTIONS

Attach the inter-connecting electrical 12 foot harness to

the turret box and the control joystick as shown on the

installation drawing, page 2-2,.

2-5. ELEVATION SHAFT COVER MOUNTING

Mount the shaft cover to the bottom cover of thet u r ret

using the (3) 8-32 self-tapping screws and the (3) stat-aseals provided.

2-6

AIR FILTER INSTALLATION

The air filter must be mounted in an area which is not

subject to sub-freezing temperatures and is as close to th;- ·turret as reasonably possible.

Bumper Filter Kit (with Filter, Bracket & Element):

Feecon Part Number ............................. 3212-6000-4

NOTE: Refer to Installation Drawing, page 2-2.

7/00

2-1

FEECON FIXED OSCILLATION NON-ASPIRATING AIR-POWERED BUMPER TURRET

~~ J

181NCHELECTRICALHARNESS

\

FROMJOYSTICKCONTROL

\

TO CUSTOMER CONNECTIONS

rlTr

AMPMATE-N-LOKPINCONNECTOR

PIN 1 (RED):POWERSOURCE

,o/

r

PIN2(BLACK):GROUNDTOCHASSIS

PIN3(WHITE):DISCHARGESIGNAL

PIN 5 (BARECOPPER): HARNESS SHIELD GROUND

\

NOTE:CUSTOMERMUSTPROVIDEAMPMATE-N-LOK \

=:;============:;;c= SOCKETCONNECTOR(HOUSINGP/N: 1-480273&

®>-f.

''

®

W

;.

.

7

~~

'

f

~,-

\

\

5CONTACTSP/N:60617 -1)

f¥SPP!l!!

I

j

12FT.ELECTRICAL

CONNECTOR

16PIN

·

9PIN

~------.._____.

HARNESS FROM ____TURRETBOXTO

JOYSTICK CONTROL

j

~.._../

;W

3.00

I

11.51

(292)

(89)

I

l__--f~~~

I

m

i:!

r

!

I

5.06

(129)

,

t

I

~-(76)'-'l

3.50

3.50

3~0

.

(76}

--

3

--~(76)

~-

1_~--,

1.50 (38)

I

-------'---;lJJ

J L

BUMPINST.DSF

02.62

(66)

20.50

(521)

I

---n-:

------4t

I I

1r:1

1

h .. !

D!i

a.oo

(203)

9.50

(241}

~·

MOUNTING PATTERN

(TURRET)

INSTALLATION DRAWING

FIXED OSCILLATION AIR POWERED BUMPER TURRET

WITH NON-ASPIRATED NOZZLE

2-2

FEE CON FIXED OSCILLATION NON-ASPIRATING AIR-POWERED BUMPER TURRET

CHAPTER 3 - TURRET FUNCTIONS

3-1. TURRET MANUAL ROTATION (OSCILLATION)-ELEVATION/DEPRESSION

The turret has three directional functions: it rotates (oscillates) up to 180°, elevates to +45°, and depresses

to -20°.

Turret direction (rotation) and elevation/depression are controlled by joystick movement. The joystick is

a pivot type controller, that is, the handle originates from

a console and pivots forward/back and left/right to initiate

turret movement. The joystick movement is not limited to

forward/back and left/right. For example, when the operator moves the handle to the right and forward simultaneously the turret will respond accordingly.

(oscillation) mode when the two-position toggle switch

lever is switched completely !lll ("MAN"). Refer to Fig. 13, Turret Joystick, for toggle switch location and identification.

To rotate the turret to the left (CCW), move the

joystick handle left. To rotate to the right (CW), move the

joystick handle to the right.

To elevate the turret, move the joystick handle back

(toward the rear of the vehicle). To depress, move the

joystick handle forward (toward the front of the vehicle).

To maintain the turret position, release the joystick handle.

CAUTION: Do not twist the joystick.

In order for the turret to rotate (oscillate) in the

manual mode, the Auto/Manual Oscillating Toggle Switch

must be placed in the "MAN" position.

The switch is located on the extreme left top end

of the joystick handle - assuming the operator is fa c in g

the front of the vehicle. The turret is in the manual rotation

Turret movement is initiated as the joystick handle

is moved to the desired position and contacts the appropriate switch or switches, which in tum, completes an electrical circuit that activates a solenoid valve. These solenoid

valves cause the turret to move to the desired position.

When the handle position is changed, solenoid valves for

the previous movement(s) are deactivated and an identical

process is started for the new desired position.

TURRET .JOYSTICK CONTROLLER

FRONT OF

~ VEHICLE

TURRET

ROTATION

(OSCILLATION)

TURRET

DISCHARGE

VALVE

NOZZLE

DISCHARGE

PATTERN

MOMENTARY

TRIGGER

SWITCH

7/00

3-1

FEE CON FIXED OSCILLATION NON-ASPIRATING AIR-POWERED BUMPER TURRET

3-2. TURRET AUTOMATIC ROTATION (OSCILLATION)

The turret can be operated in an automatic oscillation

mode. It is factory set for automatic oscillation at a 90° arc,

that is, 45° on each side of the turret centerline (facing the

front of the vehicle).

The Automatic/Manual Oscillation Toggle Switch is

located on the extreme left top end of the joystick handle

- assuming the operator is facing the front of the vehicle.

The turret is in the automatic oscillation mode when

the two position toggle switch lever is switched completely

down ("OSC").

The turret is in the manual oscillation mode when

the two position toggle switch lever is switched completely

!!l2 ("MAN").

Automatic turret oscillation is the result of a closed

electrical circuit activated by the toggle switch.

CAUTION: Adjustments to the Oscillation

Arc Control Switch cannot be made while the

7/00

turret is operating. Automatic arc adjustments

must be done before an emergency situation

arises to insure proper arc and coverage from

the turret.

•

Instructions for Oscillation Control Switch

Adjustment (Setting Automatic Arc of Oscillation)

1. Loosen switch mounting bracket locking

screw.

2. Slide switch to desired oscillation set point.

NOTE: Centerline of switch body should

be aligned with desired label markings.

3. Tighten switch mounting bracket locking

screw.

4. Check turret automatic oscillation sweep for

desired movement and repeat Steps 1 thru 3 if

necessary.

3-2

FEECON FIXED OSCILLATION NON-ASPIRATING AIR-POWERED BUMPER TURRET

3-3. ADJUSTMENT OF CYLINDER SPEED CONTROL (Rotation, Elevation/Depression & Pattern)

A

CAUTION: All switches and speed controls have been factory set to operate within turret specifications.

Feecon recommends that all adjustment(s) to turret functions, if required, be performed

only by an authorized factory representative or other qualified personnel. Improper

function adjustment(s) will cause the turret to malfunction in an emergency situation.

NOTE: See illustration below.

3. Rotate the Allen wrench clockwise to decrease and

counterclockwise to increase the turret function speed.

1. Locate the correct end of the bleed control plate to

adjust the desired turret function.

2.

CAUTION: Closing the needle valves too

much may cause the turret function to operate

slowly or stop entirely. Conversely, opening

the valves too much may create difficulty while

trying to control the nozzle discharge rate.

Insert a 1/8" Allen wrench into the socket hex located

at the end of the bleed control plate.

ROTATION

ELEVATION/DEPRESSION

· PATTERN

BLEED CONTROL

PLATES (QTY. 3)

1/8"

ALLEN

WRENCH

---7

I

DECREASE

SPEED

MANIFOLD-

INCREASE~

SPEED

ELEVATION

DEPRESSION

FAN

PATTER~

~

r

LEFT

ROTATION

[j[]o~

VIEW "8-B"OF

BLEED CONTROL PLATES

VIEW "A-A"OF

BLEED CONTROL PLATES

ADJUSTMENT OF CYLINDER SPEED CONTROL

7/00

3-3

FEECON FIXED OSCILLATION NON-ASPIRATING AIR-POWERED BUMPER TURRET

3-4. NOZZLE DISCHARGE PATTERN

The nozzle discharge pattern toggle switch is located

on the extreme right top end of the joystick handle assuming the operator is facing the front of the vehicle.

The operator controls the nozzle discharge pattern by

moving the toggle lever to the desired pattern position.

When the desired pattern is achieved, the operator releases

the toggle lever and the pattern will be locked in until

changed or adjusted by the operator. The nozzle discharge

pattern can be changed while the turret is discharging

without disrupting operation.

•

To discharge a solid stream pattern, move the toggle

lever completely up to "SS" and hold for approximately four seconds. This pattern results in the maximum discharge range.

stream to full dispersed (fan) depending on the requirements and desires of the operator.

•

Adjustment of Discharge Pattern

NOTE: The discharge pattern may need adjusting as a result of nozzle maintenance or other

conditions which may cause the turret to not conform to NFPA 414 standards.

In order to adjust the nozzle discharge pattern, simply

loosen the nuts and lockwashers on either side of the ear on

the water tip sleeve to the desired position. Retighten the

nuts and lockwashers to lock the sleeve into the position on

the cable end, and discharge the nozzle to verify the

discharge pattern is correct.

To discharge a dispersed (fan) pattern, move the toggle

lever completely down to "DIS" and hold for approximately four seconds. This pattern provides the best

protection as the vehicle moves closer to the hazard

area.

CAUTION: Do not position the sleeve beyond

the 0-ring/piston seal between the sleeve and

the tip body in order to prevent the water from

leaking backwards through the sleeve during

discharge.

Nozzle pattern is completely variable from straight

3-5. TURRET DISCHARGE VALVE

NOTE: The following items are customer supplied and must be provided to operate this component of the turret.

switch, move the toggle lever completely up to the

"OPEN" position.

•

•

•

•

Turret Discharge Valve

Solenoid or Relay

Discharge Valve Actuator

The customer supplied turret discharge valve, located

in the foam/water supply piping, controls the discharge

flow to the turret. The operator controls this valve through

two electrical switches, a two-position toggle switch and a

momentary trigger, mounted on the joystick handle.

The two-position toggle switch is the middle

toggle lever at the top end of the joystick - assuming the

operator is facing the front of the vehicle. This toggle

switch, activated by the thumb, provides a continuous

turret discharge flow.

To open the turret discharge valve with the toggle

7/00

To close the turret discharge valve, move the

toggle lever completely backward (down).

The momentary trigger switch, located on the front of

the joystick and activated by the index finger, dis- charges

the turret for as long as the trigger is depressed.

The toggle lever must be moved completely down to the

"CLOSE" position to use the trigger switch.

•

To open the discharge valve with the momentary

trigger switch, depress the trigger switch and hold

for desired duration of turret discharge.

•

To close the valve, release the trigger switch .

An open turret discharge valve results from an energized solenoid or relay which in tum activates the discharge valve actuator. A closed valve results from a

deenergized solenoid or relay.

3-4

FEECON FIXED OSCILLATION NON-ASPIRATING AIR-POWERED BUMPER TURRET

CHAPTER 4- OPERATING PROCEDURES

4-1. OPERATION

1. Engage the water pump, operating air pressure supply

and proportioning system, if necessary, in accordance

with the truck manufacturer's instructions.

2. Check to see that the pattern sleeve is in the approximate position for the desired discharge pattern.

3. Grasp the joystick control handle and aim the turret

nozzle in the general direction of desired application.

4. Move the turret discharge toggle switch to the "OPEN"

position or depress the momentary trigger switch on

the joystick to initiate discharge.

discharge toggle switch to the ''CLOSE" position to

interrupt the turret discharge.

5. Manually direct the discharge stream or engage the

automatic oscillation feature by moving the oscillation

toggle switch lever down to the "Oscillation" position.

CAUTION: Automatic arc adjustments must

be performed before an emergency situation.

Adjustments to the automatic arc cannot be

made while the turret is operating.

6. Set the nozzle discharge pattern to that which provides

the most effective pattern for the situation.

Release the momentary trigger switch or move the

4-2. SHUTDOWN

WARNING: Only after the fire is extinguished

and danger to the vehicle and its personnel is

not present, shall the operator shut down and

flush the turret.

l.

Release the momentary trigger switch or move the

turretdischage valve toggle lever down to the "CLOSE"

position.

3. Flush the turret and its piping with clean water.

4. Disengage the pumps and proportioners in accordance

with truck manufacturer's recommended procedures-:- ·5. Position the turret for transport to the fire station.

2. If appropriate, disengage the automatic oscillation

feature.

7/00

4-1

FEECON FIXED OSCILLATION NON-ASPIRATING AIR-POWERED BUMPER TURRET

CHAPTER 5 -RECOMMENDED INSPECTION AND MAINTENANCE

NOTE: The following recommendations are based on normal operating conditions. Due to

environmental or other conditions unique to specific installations, the frequency of

some inspection and maintenance procedures may need to be adjusted. Additional

inspection and maintenance procedures may be required.

WARNING: Moving components and gears may cause injury if accidentally activated during

inspection or maintenance. Never perform any maintenance on the inside of the turret

mounting box without first disconnecting the air source to the turret manifold. Also,

disconnect the tubing to the cylinders in order to release the pressure contained in all of the

cylinders. Keep hands and fingers away from moving parts when disconnecting the tubing.

Disconnect the wiring harness to the turret box to eliminate the possibility of electrical shock.

Description

5-l. Inspect unit for physical damage and repair.

5-2. Check all mounting bolts, nuts and fasteners for

tightness.

Start- After

500

Semi2000

Up

Use Monthly Annually Cycles Cycles

• •

•

5-3. Cycle all turret functions and observe for smooth

operation.

5-4. Flush and clean all exposed surfaces of tip and

pattern sleeve with clean water to remove excess

I

dirt and debris.

5-S. Flow test and observe for symmetrical stream pattern.

Non-symmetrical pattern may indicate partial

blockage of tip which will require removal and

cleaning.

5-6. Disassemble tip and clean tip exterior and sleeve in

a mild soap solution.

~

~

7100

•

•

•

•

•

•

•

•

•

•

•

•

-

•

CAUTION: Do not use an abrasive material on

inner diameter of the sleeve.

CAUTION: Do not apply grease or other

lubrication to sleeve, tip, piston ring

or o-ring. Teflon coating on tip

provides the needed lubrication.

5-1

FEECON FIXED OSCILLATION NON-ASP IRA TJNG AIR-POWERED BUMPER TURRET

CHAPTER 6 - TROUBLE SHOOTING

PROBLEM

POSSffiLE CAUSE

CORRECTIVE ACTION

6-1. Rotation tight or

restricted movement

Corrosion on rotation shaft

Remove turret mounting box from the

coverplate and apply a generous amount

of grease to the rotation rack and drive

gear cylinder rods, elevation shaft

assembly and other moving parts.

6-2. Operational failure

Moisture in air tubing lines

causing them to freeze

Contact NF Service Department.

6-3. Slow turret functions

Leakage from the pneumatic

tubing, fittings or components

Locate problem, tighten, replace or repair.

7/00

6-1

FEECON FIXED OSCILLATION NON-ASPIRA T!NG AIR-POWERED BUMPER TURRET

CHAPTER 7- PARTS DRAWING AND PARTS LIST

7/00

7-1

>-

...J

[IJ

l:

w

Ill

Ill

c(

X

lfi

\.

>-

0

0

[IJ

w

Ill

c(

[IJ

BASE BODY/BOX ASSEMBLY

7/00

7-2

0

0

.

w

.

·a..~ !*lAm!~ IWB"'D S"UlJ.

I

w

•--.cr;~ tMISII

Oft' 'JDNWt

0

·--ll.l.uorrNilllllf:l

WJ ..L.illlfU SlH.L #CJ SMEJHI'tCBIII

~

w

>

0

0

~

0

_J

ww

..J[]l

N

Noll

0

Z::E

Ill.

OI..'J

4

wo

~

IO

:E

a.

(TI

WI!J

0

Will

03:

40

W_J

lli:U.

I

I- Ill

0

L1.

..J

NO

NO

om

z

I Ill

ow

4>

~0

(II

0)1:

wo

I..'J...J

ZU.

<(

...Jill

u.o

u.

THREADED HEAD NOZZLE & FLANGED HEAD NOZZLE

7/00

7-3

:::

0

I

0

3

w

H

>

>_j

rn

:2:

w

Vl

Vl

<(

':;L

u

H

f-

Vl

>-

0

0

J

0£:

w

0

:::

rn

I

rn

z

H

_j

:::

>u

3

z

0£:

w w

H

> ff<(

a_

Vl

Vl

w

u ~

I 0..~

u ww

:::

DO

z

3

w '-.H

_j

H

>>> wu

_j

w

:::

.JOYSTICK ASSEMBLY - PATTERN AND ELEVATION/DEPRESSION CYLINDERS

7/00

7-4

FIXED OSCILLATION

NON-ASPIRATING

AIR POWERED BUMPER TURRET

REPLACEMENT PARTS LIST

(ASSY P/N: 1252-70XX-X)

ITEM

DESCRIPTION

PART NUMBER

1 ................ Base ......................................................................... 3202-1066-5 ................................. 1

2 ................ Body ........................................................................ 3202-8069-5 ................................. 1

3 ................ Head, Flanged ......................................................... 3215-3014-0 ................................. 1

3 ................ Head, Threaded ....................................................... 3215-3016-5 ................................. 1

4 ................ Hinge ....................................................................... 3215-6000-1 ·................................. 1

5 ................ Manifold Assy 12 VDC .......................................... 3219-3010-2 ................................. 1

5 ................ Manifold Assy 24 VDC .......................................... 3219-3010-3 ................................. 1

6 ................ Harness .................................................................... 3215-2030-6 ................................. 1

7 ................ Pattern Cylinder ...................................................... 3 209-0048-7 ................................. 1

8 ................ Rotation Cylinder .................................................... 3209-0007-5 ................................. 1

9 ................ Elevation Plate ........................................................ 3222-5040-5 ................................. 1

10 ............... Arm .......................................................................... 3201-0027-1 ................................. 2

11 ............... Rack ......................................................................... 3 224-0008-1 ................................. 1

12 ............... Mount ...................................................................... 3220-0013-6 ................................. 2

13 ............... Cylinder Plate ......................................................... 3222-5029-5 ................................. 1

14 ............... Turret Plate ............................................................. 3 222-5100-6 ................................. 1

15 ............... Turret Box ............................................................... 3208-4027-9 ................................. 1

16 ............... Access Plate ............................................................ 3208-4008-8 ................................. 1

17 ............... Bracket .................................................................... 3203-3272-1 ................................. 2

18 ............... Gasket ...................................................................... 3213-7031-8 ................................. 1

20 ............... Gasket ...................................................................... 3213-7030-0 ................................. 1

21 ............... Caution Nmplte ...................................................... 3220-2239-0 ................................ 1*

22 ............... Nameplate ............................................................... 3220-2198-6 ................................. 1

23 ............... Nameplate ............................................................... 3220-2031-2 ................................. 1

25 ............... Cable ....................................................................... 3204-4005-0 ................................. 1

26 ............... Relay 12 VDC ......................................................... 3225-1002-9 ................................. 2

26 ............... Relay 24 VDC ......................................................... 3225-1003-4 ................................. 2

7/00

7-5

27 ............... Switch ...................................................................... 3231-2014-7 ................................. 2

28 ............... Bracket .................................................................... 3203-3298-2 ................................. 2

29 ............... Channel ................................................................... 1272-3521-6 ................................. 1

30 ............... Switch ...................................................................... 3231-2003-0 ................................. !

31 ............... Magnet ..................................................................... 3219-2002-0 ................................. 1

32 ............... Spacer ...................................................................... 3229-0021-5 ................................. 3

33 ............... Spacer ...................................................................... 3229-0017-1 ................................. 3

34 ............... Adapter .................................................................... 3200-5040-0 ................................. 1

35 ............... Bushing ................................................................... 3204-1011-5 ................................. 2

36 ............... Clamp ...................................................................... 3205-7008-0 ................................. 1

37 ............... Roll Pin ................................................................... 3221-6072-5 ................................. 1

38 ............... Pin ............................................................................ 3221-6008-0 ................................. 1

39 ............... RetE Ring ............................................................... 3225-7021-5 ................................. 2

40 ............... Link ......................................................................... 3218-5035-0 ................................. 1

41 ............... Boot ......................................................................... 3203-0003-5 ................................. 1

42 ............... 0-Ring ...................................................................... 3220-8002-5 ................,................. 1

43 ............... 0-Ring ..................................................................... 3220-8024-5 .................. ;.............. 1

44 ............... Guide ....................................................................... 3214-7008-7 ................................. 1

46 ............... Shaft ........................................................................ 3227-3039-0 ................................. 1

47 ............... Plug .......................................................................... 3222-7012-l ................................. 1

48 ............... 1/8 Tube Fitting ...................................................... 1242-9151-0 ................................. 6

49 ............... 1/4 Tube Fitting ...................................................... 1242-9151-3 ................................. 1

50 ............... Connector ................................................................ 3207-2008-0 ................................. 1

51 ............... 1/8 OD Tubing ........................................................ 3233-5045-0 ................................ -*

52 ............... 1/4 OD Tubing ........................................................ 3233-5033-5 ................................ -*

53 ............... Tie ............................................................................ 3232-8001-3 ................................. 3

54 ............... #4 Screw .................................................................. 3226-8169-5 ................................. 6

55 ............... #6 Screw .................................................................. 3226-8195-3 ................................. 3

56 ............... #8 Screw .................................................................. 1262-5325-1 ................................. 5

57 ............... #8 Screw .................................................................. 1262-2135-4 .: .............................. 10

58 ............... #10 Screw ................................................................ 1262-2160-0 ................................. 4

59 ............... #10 Screw ................................................................ 1262-2158-7 ................................. 4

60 ............... #10 Screw ................................................................ 1262-2158-6 ................................. 2

61 ............... #10 Screw ................................................................ 3226-8162-5 ................................. 2

7/00

7-6

62 ............... #10 Screw ................................................................ 1262-1211-0 ................................. 2

63 ............... 1/4" Screw ............................................................... 1262-1240-0 ................................. 2

64 ............... 5/16" Screw ............................................................. 1262-1311-1 ................................. 2

65 ............... 1/4" Screw ............................................................... 3226-8087-5 ................................. 1

66 ............... #6 Nut ...................................................................... 3220-7007-5 ................................. 2

67 ............... #8 Nut ...................................................................... 3220-7008-0 ................................. 8

68 ............... #1 0 Nut .................................................................... 3220-7006-0 ................................. 7

69 ............... 1/4 Nut ..................................................................... 3220-7058-0 ................................. 1

70 ............... 1/4 Nut ..................................................................... 3220-7012-5 ................................. 5

71 ............... 5/16 Nut .................................................................. 3220-7016-0 ................................. 8

72 ............... 3/8 Nut ..................................................................... 3220-7015-5 ................................. 1

73 ............... 1/2 Nut ..................................................................... 3220-7011-5 ~ ................................ 2

74 ............... #4 Nut ...................................................................... 3220-7022-0 ................................. 6

75 ............... #8 Washer ............................................................... 3234-2054-5 ................................ 15

76 ............... #1 0 Washer ............................................................. 1263-3240-0 ................................. 2

77 ............... #10 Washer ............................................................. 3234-2054-0 ................................. 7

78 ............... 1/4" Washer ............................................................ 1263-3272-0 ................................. 3

79 ............... 5/16" Washer .......................................................... 1263-3304-0 ................................. 2

80 ............... 5/16" Washer .......................................................... 3234-2058-5 ................................. 4

81 ............... 3/8" Washer ............................................................ 3234-2057-5 ................................. 1

82 ............... Elevation Cylinder .................................................. 3209-0030-5 ................................. 1

83 ............... Bracket .................................................................... 3203-3302-7 ................................. 1

84 ............... Cam ......................................................................... 3204-5006-1 ................................. 1

85 ............... Rotation Tube ......................................................... 3233-4026-0 ................................. 1

86 ............... Gear ......................................................................... 3213-9049-5 ................................. 1

87 ............... Bearing Seal ............................................................ 3226-9003-0 ................................. 1

88 ............... 3/4 Nut ..................................................................... 3220-7078-5 ................................. 1

89 ............... Screw ....................................................................... 1262-1247-0 ................................. 1

90 ............... Bearing .................................................................... 3202-2048-5 ................................. 1

91 ............... Bearing .................................................................... 3202-2001-5 ................................. 1

92 ............... Bearing .................................................................... 3202-2014-5 ................................. 1

93 ............... Cap ........................................................................... 3204-7033-5 ................................. 1

94 ............... 0-Ring ..................................................................... 3220-8043-0 ................................. 2

95 ............... 0-Ring ..................................................................... 3220-8074-5 ................................. 1

7/00

7-7

96 ............... 0-Ring ..................................................................... 3220-8035-0 ................................. 4

97 ............... 0-Ring ..................................................................... 1268-5002-2 ................................. 1

98 ............... 0-Ring ..................................................................... 3220-8014-0 ................................. 1

99 ............... 0-Ring ..................................................................... 3220-8013-0 ................................. 1

100 .............. 0-Ring ..................................................................... 3220-8005-5 ................................. 1

101 .............. #10 Screw ................................................................ 3226-8228-5 ................................. 1

102 .............. 1/4 Screw ................................................................ 3226-8182-0 ................................. 1

103 .............. Key .......................................................................... 3217-5006-0 ................................. 1

104 .............. Plug Pipe ................................................................. 3222-7045-5 ................................. 1

105 .............. 1/4" Washer ............................................................ 3234-2057-0 ................................. 1

106 .............. Ring Ret .................................................................. 3225-7072-0 ................................. 1

107 .............. Harness .................................................................... 3215-2007-3 ................................. 1

108 .............. Nameplate ............................................................... 3220-2241-0 ................................. 1

109 .............. #10 Screw ................................................................ 3226-8157-0 ................................. 2

110 .............. #10 Washer ............................................................. 1263-3240-0 ................................. 3

111 .............. #10 Nut .................................................................... 1262-7132-4 ................................. 2

112 .............. Tip ........................................................................ See Section 1-3 ............................... 1

113 .............. Pattern Sleeve ......................................................... 3228-4018--6 .................................. J

114 .............. 0-Ring ..................................................................... 3220-8036-5 ................................. 1

115 .............. 0-Ring ..................................................................... 3220-8034-0 ................................. 1

116 .............. Piston Ring .............................................................. 3222-2201-1 ................................. 1

117 .............. Trigger Assy ........................................................... 3222-5096-0 ................................. 1

118 .............. PC Board 12 VDC .................................................. 3202-7000-1 ................................. 1

118 .............. PC Board 24 VDC .................................................. 3202-7000-2 ................................. 1

119 .............. Switch ...................................................................... 3231-2002-5 ................................. 4

120 .............. Bearing .................................................................... 3202-2054-0 ................................. 1

121 .............. Cover ....................................................................... 3208-4010-2 ................................. 1

122 .............. Boot ......................................................................... 3203-0003-0 ................................. 1

123 .............. Plate ......................................................................... 3222-5067-5 ................................. 1

124 .............. Nameplate ............................................................... 3220-2108-0 ................................. 1

125 .............. Spring ...................................................................... 3229-6027-5 ................................. 4

126 .............. Body ........................................................................ 3202-8028-0 ................................. 1

127 .............. Plunger .................................................................... 3222-8001-5 ................................. 4

128 .............. Shaft Control ........................................................... 3227-3019-5 ................................. 1

7/00

7-8

129 .............. Cover ....................................................................... 3208-4018-1 ................................. 1

130 .............. Handle ..................................................................... 3215-7008-6 ................................. !

131 .............. #4 Screw .................................................................. 3226-8218-0 ................................. 8

132 .............. #6 Screw .................................................................. 1262-5320-1 ................................. 4

133 .............. #10 Screw ................................................................ 3226-8166-0 ................................. 4

134 .............. #6 Screw .................................................................. 3226-8174-5 ................................. 3

135 .............. #6 Screw .................................................................. 3226-8046-5 ................................. 3

136 .............. #6 Screw .................................................................. 3226-8045-5 ................................. 1

137 .............. #6 Screw .................................................................. 3226-8230-5 ................................. 1

138 .............. #10 Screw ................................................................ 1262-2168-4 ................................. 4

139 .............. 1/2" Screw ............................................................... 3226-8266-5 ................................. 4

140 .............. #4 Washer ............................................................... 1263-3131-2 ................................. 8

141 .............. #10 Washer ............................................................. 1263-3240-0 ................................. 4

142 .............. Ret Ring .................................................................. 3225-7048-0 ................................. 1

143 .............. #10 Nut .................................................................... 3220-7006-0 ................................. 4

144 .............. Nameplate ............................................................... 3220-2162-4 ................................. 1

145 .............. Harness .................................................................... 3215-2007-9 ....................

00 . . . . . . . . . . .

1

146 .............. #6 Washer ........................................ ., ..................... 1263-3148-2 ................................. 4

147 .............. 5/16 Nut .................................................................. 3220-7017-0 ................................. 1

148 .............. Shaft ........................................................................ 3227-3014-5 ................................. !

149 .............. Button ...................................................................... 3204-2006-0 ................................. 1

150 .............. 1/4 Nut ..................................................................... 3220-7013-0 ................................. 1

151 .............. Tip ........................................................................ See Section 1-3 ............................... 1

152 .............. Sleeve ...................................................................... 3228-4030-4 ................................. 1

153 .............. 0-Ring ..................................................................... 1268-5006-2 ................................. 1

154 .............. Shaft ........................................................................ 3227-3011-5 ................................. 1

155 .............. Button ...................................................................... 3204-2018-5 ................................. 1

156 .............. 1/4 Nut ..................................................................... 3220-7058-0 ................................. 1

157 .............. 1/4" Washer ............................................................ 1263-3272-0 ................................. 1

158 .............. #10 Nut .................................................................... 3220-7006-5 ................................. 1

159 .............. Piston Ring .............................................................. 3222-2201-1 ................................. 1

1.60 .............. 0-Ring ..................................................................... 3220-8091-5 ................................. 1

161 .............. 5/16" Washer .......................................................... 1263-3304-0 ................................. 4

162 .............. 5/16" Screw ............................................................. 1262-1317-1 ................................. 4

7/00

7-9

163 .............. Plug .......................................................................... 1298-4300-2 ................................. 1

164 .............. Head ........................................................................ 3215-3014-0 ................................. 1

Kit, Bumper Filter,Bracket, Element .................... 3212-6000-4 ................................ 1*

Nameplate, Filter Inlet ........................................... 3220-2031-2 ................................ 1*

* Indicates Not Shown

7/00

7-10

FEECON FIXED OSCILLATION NON-ASPIRATING AIR-POWERED BUMPER TURRET

CHAPTER 8- ELECTRICAL AND TUBING SCHEMATICS

7/00

8-1

0

0

0

0

0

-A-

@

if©

LO\\ER

FIT11NG

~ MOUNTING PLATE

0

UPPER ____/

FITTING

0

0

LOWER

FITTING

Q

@I

UPPER

FITTING

.f-

:e-!

\

~

I@

0

ir=l

=a_Fc=r==c:FLJ~~Fl-1==1r---~==r-c=::r-~~-.---..,-----,--~·

@

@

@

'M-fiTEI'rHLOW

\'MITE

RED

UPPER FITTING: CLOSEST TO MOUN11NG PLATE

LOWER FIT11NG CLOSEST TO ACCESS PLATE

0

I

0

II:CESSPLATI:

J

0

..-:l i'JA TIDNAL FOAH, I1\J[.

~

LIONVILLE, PENNSYLVANIA \9341

TUBING DETAIL

BUMPER TURRET

OI<WG. NO.

017904-20

TURRET

WIRING

~---...1---------c-1

TUR~~r TO ~OYSTICK

1-iAk~iESS

~-

--

I

- --- -"-- -

-~-·

-~

I

.JOYSTICK

WIRING

r;;I;;;l

1---1

~IT'E/'r'EllC\1'

llEHl'E!>S

lCLB'flJJO

~t~mt.c.

1

VHITE/'I'ELLOW

J

1 --"'-"-'""c._"---------,

@f----L7 )-,---"'""'.lE'-------1'--+-1'-___/f'------,

IR~E

,+.

-----------'-"""'-"~"--rl~ """"

-~

_ _ _ _ _ _ _ ______;:<R~>NO~E-..1.-{S

~~~-------

-~E~:to

---=-rt1

!OlEO

- ·~ -~

Pl.J~LI::

~~ lJ~ :~~==-.:·~~-~~_t-=-=---:~_=+XL___!-:~

=-~

~

I

I

liEl--,"~~

l

""'""

J

I

.,GH,IU"CICLA

"'"'"""""nO'<

l

I ®1-o-1- = ' - - - - - - - - - - '

~~rrn

O

o

,

•

LEFTOSCillAf!UN

i:~ON~~~TO<

1

1-

,

+!:.&:lie

r~::~·~

~

1.e.

I

L_

?-~

,:

~

1

~"

/

/

1-JN.C:

WITHI'CJKA!NETIC

FIELO

CUSmMER DISCHARGE SIGNAL ('WHITE)

f - - - - - - - 12VOC POWER SUURCE < REO )

UFT LrMIT 1"'ITCH

1-0!N.C, 1-lN.Q

WtTl-IBL.I.OEN:lT

OEPAESSSJ

LEFT

SI1..9'«JIO

NOTE:

FOR 24VOC TURRETS, SUBSTITUTE ALL 12VOC

RELAYS AND POWER SOURCES AND SOLENOID

VALVES WITH 24VOC SUPPLIES

FEECONEJ

~l£:e3Hgj

ELECTRICAL SCHEMATIC

~LSf~~~?6so-i.

OIV~wrJ~~!r~~~SHC.

ELECTRICAL SCHEMATIC

FXD DSC BUMPER TURRET

ORWG. NO

01788520

n

Feecon Products Division

National Foam, Inc. • 150 Gordon Drive • P.O. Box 270 • Exton, PA 19341-1350 • USA

Telephone: 610-363-3558 • Fax: 61 0-524-~073