Reliability in Quality Management: Presentation

advertisement

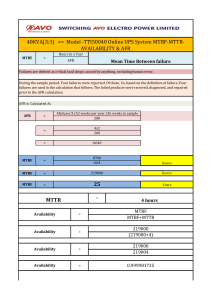

Module 13 Reliability 1 Key Dimensions of Quality • Performance – primary operating characteristics • Features – “bells and whistles” • Reliability – probability of operating for specific time and conditions of use • Conformance – degree to which characteristics match standards • Durability – amount of use before deterioration or replacement • Serviceability – speed, courtesy, and competence of repair • Aesthetics – look, feel, sound, taste, smell 2 Key Dimensions of Service Quality • Reliability – ability to provide what was promised • Assurance – knowledge and courtesy of employees and ability to convey trust • Tangibles – physical facilities and appearance of personnel • Empathy – degree of caring and individual attention • Responsiveness – willingness to help customers and provide prompt service 3 Reliability • Generally defined as the ability of a product or service to perform as expected over time • Formally defined as the probability that a product, piece of equipment, or system performs its intended function for a stated period of time under specified operating conditions 4 Maintainability • The probability that a system or product can be retained in, or one that has failed can be restored to, operating condition in a specified amount of time. 5 Examples 6 Types of Failures • Functional failure – failure that occurs at the start of product life due to manufacturing or material detects • Reliability failure – failure after some period of use 7 Types of Reliability • Inherent reliability – predicted by product design • Achieved reliability – observed during use 8 Reliability Measurement • Failure rate (l) – number of failures per unit time (e.g. # of operating hours) • Alternative measures – Mean time to failure – Mean time between failures (1/ l) 9 Cumulative Failure Rate Curve 10 Average Failure Rate 11 Failure Rate Curve (Bathtub Curve) “Infant mortality period” 12 Reliability Function • Probability density function of failures f(t) = le-lt for t > 0 • Probability of failure from (0, T) F(T) = 1 – e-lT • Reliability function R(T) = 1 – F(T) = e-lT 13 Reliability Function (Example) • So an item having a reliability of 0.97 over 100 hours of normal use, determine the failure rate (l): Reliability function: R(T) = e-lT 0.97 = e-100l ln 0.97 = -100 l l = -(ln 0.97)/100 0.0304/100 = 0.0003 failure rate (per hour) 14 Series Systems 1 2 n RS = R1 R2 ... Rn 15 Series Systems (Example) So a two component series system with failure rates of 0.001 and 0.004 per hour: Rs(T) = e-(0.004+0.001)T e-0.005T The probability of survival for 100 hours would be: Rs(100) = e-0.005(100) e-0.5 0.6065 or 60.65% 16 Parallel Systems 1 2 n RS = 1 - (1 - R1)*(1 - R2)...*(1 - Rn) 17 Series-Parallel Systems C RA RB A B RC RD D C RC • Convert to equivalent series system RA RB A B RD C’ D RC’ = 1 – (1-RC)(1-RC) 18 Reliability Engineering • Standardization (Certified Components) • Redundancy (Series systems vs. Parallel) • Physics of failure (Weathering) • Reliability testing – Accelerated life testing • Burn-in – Component Stress Testing – Infant Mortality Periods 19 Exam Review • Demming’s 14 Points (Modules 3, 4) • Juran’s Principles (Modules 3, 9/10) • Definitions of Quality (Module 1) • Key Dimensions of Quality (Module 4) – Manufacturing & Service • Continuous Improvement (Module 1, 2) • Quality in Services (Module 2, 4, 13) • Customer Needs (Module 4) • Leadership (Mission/Vision) (Module 5) • Process Management (Scope, Principles) (Module 7) 20 Exam Review • Performance Measures (COQ and ROQ) (Module 8) • Capability Studies (Module 9/10) – Variation – Six Sigma • Sampling & Measurement (R&R) (Module 11) • Control Charts (Module 12) – How to read & interpret • Reliability & Maintainability (Module 13) • Total Quality Management (Modules 1) 21 22 23 Reliability Management • Define customer performance requirements • Determine important economic factors and relationship with reliability requirements • Define the environment and conditions of product use • Select components, designs, and vendors that meet reliability and cost criteria • Determine reliability requirements for machines and equipment • Analyze field reliability for improvement 24 Configuration Management 1. Establish approved baseline configurations (designs) 2. Maintain control over all changes in the baseline programs (change control) 3. Provide traceability of baselines and changes (configuration accounting) 25 Maintainability • Maintainability is the totality of design factors that allows maintenance to be accomplished easily • Preventive maintenance reduces the risk of failure • Corrective maintenance is the response to failures 26 Design Issues • Access of parts for repair • Modular construction and standardization • Diagnostic repair procedures and expert systems 27 Availability • Operational availability MTBF AO = MTBM MDT • Inherent availability MTBF AO = MTBF MTR MTBM = mean time between maintenance MDT = mean down time MTBF = mean time between failures MTR = mean time to repair 28