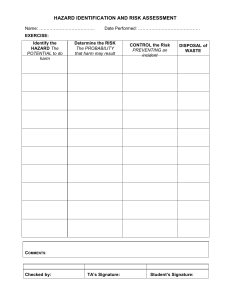

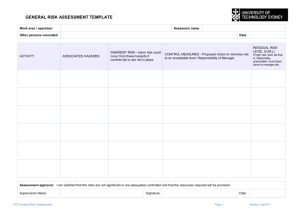

Introduction to Safety Understanding the Importance, Evolution, and Key Concepts of Safety What is Safety? • A state of being free from harm, danger, or risk • Involves measures, practices, and precautions to prevent accidents and injuries • Encompasses safety in workplace, transportation, environment, and health • Risk assessment and hazard control play a crucial role Need for Safety • Preservation of Life and Health – Prevents accidents, injuries, and illnesses • Quality of Life – A safe environment promotes wellbeing and growth • Social Stability & Cohesion – Prevents conflicts, builds trust, and fosters unity • Protection of Resources – Safeguards human, natural, and infrastructural resources • Legal & Ethical Considerations – Ensured through laws, regulations, and moral responsibility Evolution of Safety (Four Ages) Technical Age (First Age) – Focus on eliminating hazards via engineering solutions Human Factors Age (Second Age) – Addressing human errors, fatigue, and stress Organizational Age (Third Age) – Identifying hidden organizational factors causing errors Systems Age (Fourth Age) – A holistic approach addressing interactions between humans, technology, and organizations Technical Age Industrial Revolution (1750-1760) Focused on eliminating hazards through engineering solutions. Assumed accidents were caused by technology failures. Engineering controls aimed at removing hazards at the source. The Three Mile Island reactor accident challenged this belief, as it highlighted the role of human error. Human Factors Age • Mid-20th Century • Emerged after recognizing human error as a major factor in accidents. • Focused on: • Fatigue • Stress • Workload • Aimed at understanding human behavior and decision-making in safety management. Organizational Age • Beyond Human & Technology Factors • Shifted focus to organizational influences on safety. • Found that accidents were not just due to humans or technology but also workplace culture, policies, and systems. • Organizational weaknesses such as poor management, inadequate safety measures, and communication failures became key areas of concern. Systems Age • Early 21st Century – A Holistic Approach • Emerged after the Columbia Space Shuttle disaster (2003). • Recognized that accidents occur due to complex interactions between: • Technical factors • Human behavior • Organizational structure • Required a systems-thinking approach to address interconnected risks comprehensively. Safety Terminologies (1/2) • Hazard – Any source or situation with the potential to cause harm • Risk – The likelihood of harm occurring due to exposure to a hazard • Incident – An unplanned event that could disrupt normal operations or cause harm • Accident – An unexpected event causing harm, injury, or damage Safety Terminologies (2/2) • Warning – Indicates high severity, potential serious injury or death • Emergency – A sudden and unforeseen situation requiring immediate action • PPE (Personal Protective Equipment) – Safety gear to minimize hazard exposure • Safety Culture – Shared values and behaviors promoting safety in organizations • Risk Assessment – Identifying, evaluating, and Importance of Near Miss Reporting Near Miss – Events that could have caused harm but did not • Helps identify potential hazards before accidents occur • Improves preventive measures and enhances safety culture. 1. Hazard (A potential source of harm) • Example 1: A wet floor in a hallway can cause someone to slip and fall. • Example 2: Exposed electrical wires in a workplace can cause electric shocks. • A hazard is something that has the potential to cause harm. • It does not mean harm will definitely happen—that depends on risk and exposure. 2. Risk (The likelihood and severity of harm from a hazard) • Example 1: Walking across a wet floor while wearing slippery shoes has a higher risk of falling. • Example 2: A child playing near exposed electrical wires has a higher risk of getting shocked than an adult standing far away. • Risk depends on exposure and probability—a hazard alone does not guarantee harm. • Managing risk means reducing likelihood (e.g., putting up a warning sign) or severity (e.g., wearing protective shoes). Hazard vs Risk 3. Incident (An unplanned event that may or may not cause harm) • Example 1: A worker slips on a wet floor but catches a railing and avoids injury. • Example 2: A machine malfunctions and stops working, but no one is hurt. • Incidents do not always result in harm (unlike accidents, which do). • An incident can be a warning sign of a future accident if ignored. 4. Accident (An unexpected event causing harm or damage) • Example 1: A worker slips on the wet floor and breaks their arm. • Example 2: A person touches an exposed wire and gets an electric shock. • Accidents result from hazards when risk is not properly managed. • An accident causes actual harm, whereas a hazard is only a potential danger.. 5. Caution (A lower-level warning of a potential minor injury or damage) • Example 1: A “Caution: Wet Floor” sign warns people to walk carefully. • Example 2: A label on a tool says, “Caution: Sharp Blade. Handle with Care.” • Caution signs indicate lower-risk situations, helping prevent minor injuries. • They are different from warnings, which indicate higher-risk situations. 6. Warning (A stronger alert about serious risks, including death) • Example 1: A “Warning: High Voltage” sign near an electrical panel. • Example 2: A chemical container labeled “Warning: Toxic Fumes. Use Protective Gear.” • Warnings are more serious than cautions because they involve higher risk and severity. • Ignoring a caution might cause minor injury, while ignoring a warning could be fatal. 7. Emergency (A sudden, urgent situation requiring immediate action) • Example 1: A fire breaks out in a factory, requiring evacuation. • Example 2: A worker collapses due to a heart attack and needs CPR. • Emergencies require immediate response to prevent loss of life or major damage. • They often involve accidents or incidents that escalate quickly. 8. PPE (Gear worn to minimize hazards) • Example 1: A construction worker wears a helmet and gloves to prevent head and hand injuries. • Example 2: A lab technician wears goggles and a face mask to avoid chemical exposure. • PPE helps reduce risk but does not eliminate the hazard. • Different PPE is used for different hazards (e.g., gloves for chemicals, helmets for falling objects). 9. Safety Culture (Shared beliefs and behaviors about safety in an organization) • Example 1: A company rewards employees for reporting hazards, encouraging proactive safety behavior. • Example 2: A factory conducts daily safety briefings, reinforcing a culture of awareness and responsibility. • A strong safety culture reduces accidents by promoting responsible behavior. • Without a good safety culture, people may ignore rules, increasing risks. 10. Risk Assessment (Identifying, evaluating, and controlling risks) • Example 1: Before repairing electrical wiring, an engineer checks for live currents and secures the power supply. • Example 2: A workplace evaluates fire hazards, ensuring fire exits and extinguishers are in place. • Risk assessment helps prevent incidents, accidents, and emergencies. • It is an ongoing process of identifying hazards, analyzing risks, and applying safety controls. 11. First Aid (Immediate care given to an injured or ill person) • Example 1: Applying a bandage to a deep cut to stop bleeding before seeking medical help. • Example 2: Performing CPR on someone who has stopped breathing until an ambulance arrives. • First aid does not replace professional medical care but can save lives in emergencies. 12. Safety Inspection (A systematic examination to identify hazards and ensure compliance) • Example 1: A factory supervisor checks if machines have proper safety guards to prevent accidents. • Example 2: A restaurant inspector examines kitchen cleanliness and food storage practices to prevent contamination. • Regular inspections prevent hazards from turning into incidents or accidents. • Unlike risk assessments (which analyze risks), inspections focus on enforcement and compliance. 13. Near Miss (An event that could have caused harm but didn’t) • Example 1: A worker almost gets hit by a falling object but moves away in time. • Example 2: A car nearly collides with another vehicle but stops just in time. • Near misses are learning opportunities—they help identify risks before actual harm occurs. • Reporting near misses helps prevent future accidents. HAZARD (Has the potential to cause harm) RISK (Likelihood & severity of harm from the hazard) Caution (Lower risk) & Warning (Higher risk) INCIDENT → (Unplanned event, may or may not cause harm) (If not managed, it can lead to…) ACCIDENT → (Unplanned event, causes actual harm or damage) Prevention & Control Measures PPE – Reduces exposure to hazards Safety Culture – Promotes safety awareness in an organization Risk Assessment – Identifies and mitigates hazards before incidents Safety Inspection – Ensures compliance with safety standards First Aid – Immediate care to prevent worsening of injuries Thank You! "A commitment to safety today ensures a secure tomorrow."