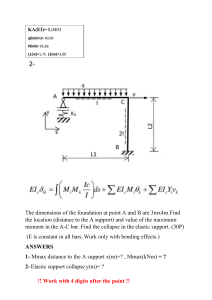

Copyright: Dr. Ahmed Kamel PENG 3305 COLLAPSE PRESSURE ➢ Collapse strength is defined as the external pressure required to collapse the specimen of casing. ➢ Primary collapse loads are generated by the hydrostatic head of the fluid column outside the casing string. ➢ With any external pressure, Pe and internal pressure, Pi , the classical elasticity theory for this 2-D problem can be applied at any r, between ri and ro. ➢ Assuming the pipe is subjected to only an external pressure, Pe (i.e. Pi=0) yields: d n t − 1 Pcr = Pe = 2( yield )eff 2 dn t Pcr is called “yield-strength collapse” Copyright: Dr. Ahmed Kamel PENG 3305 COLLAPSE PRESSURE ➢ Strength of the casing under external pressure depends on: ▪ Length, ▪ Diameter, ▪ Wall thickness of the casing, ▪ Physical properties of the casing material (yield point, elastic limit, Poisson's ratio, etc.). ➢ Casing, having a low dn/t ratio and low strength, reaches the critical collapse value as soon as the material begins to yield under the action of external pressure. This is so-called 'yield range'. ➢ In contrast, casing with high dn/t ratio and high strength, collapses below the yield strength of the material (collapse can occur at lower pressures than predicted by the previous equation). Copyright: Dr. Ahmed Kamel PENG 3305 COLLAPSE PRESSURE ➢ In this case, failure is caused by purely elastic deformation. The collapse behavior is known as failure in the elastic range. ➢ The transition between the failure modes is governed by the tube geometry and material properties. ➢ The transition from yield-strength collapse to elastic collapse is not sharp but covers a significant range of dn/t values. ➢ Based on the results of many experimental tests, API has adopted two additional collapse-pressure equations to cover the transition region: ▪ A plastic collapse rating for dn/t values just above the yieldstrength collapse region. ▪ A transition collapse region between the plastic collapse and elastic collapse regions. Copyright: Dr. Ahmed Kamel PENG 3305 COLLAPSE PRESSURE 1 Copyright: Dr. Ahmed Kamel 2 3 PENG 3305 COLLAPSE PRESSURE Yield-strength Collapse dn t − 1 Pcr = Pe = 2( yield )eff 2 dn t Upper Limit for the yield strength collapse: F3 + (F1 − 2) (F1 − 2) + 8 F2 + ( yield )eff d 1 n = t F3 2 F2 + ( yield )eff 2 Copyright: Dr. Ahmed Kamel PENG 3305 COLLAPSE PRESSURE Plastic Collapse F1 Pcr = ( yield )eff − F2 − F3 d n t Upper limit of the plastic collapse range is calculated by: 2 dn ( ) (F − F ) = t ) (F − F ) F + ( yield eff 3 Copyright: Dr. Ahmed Kamel yield eff 1 4 2 5 PENG 3305 COLLAPSE PRESSURE Transition (between elastic and plastic) Collapse F4 Pcr = ( yield )eff − F5 d n t Upper limit of the transition or lower limit of elastic collapse range is calculated by: F2 2+ F1 dn = 3 t F2 3 F1 Copyright: Dr. Ahmed Kamel PENG 3305 COLLAPSE PRESSURE Elastic Collapse Pcr = Copyright: Dr. Ahmed Kamel 46.95 106 d n d n − 1 t t 2 PENG 3305 COLLAPSE PRESSURE F1 = 2.8762 + 0.10679 10 −5 Y + 0.21301 10 −10Y 2 − 0.53132 10 −16Y 3 F2 = 0.026233 + 0.50609 10 −6 Y F3 = −465.93 + 0.030867Y − 0.10483 10 −7 Y 2 + 0.36989 10 −13Y 3 3(F2 / F1 ) 46.95 10 2 + (F2 / F1 ) F4 = 2 3(F2 / F1 ) F2 3(F2 / F1 ) Y − 1 − ( ) 2 + F / F F1 2 + (F2 / F1 ) 2 1 3 6 F5 = F4 F2 F1 Y is the effective yield strength Copyright: Dr. Ahmed Kamel PENG 3305 COLLAPSE PRESSURE EXAMPLE #1 Compute the collapse pressure rating for 5 1/2 in., N-80 casing with a nominal wt./ft of 20 lbm/ft. Copyright: Dr. Ahmed Kamel PENG 3305 COLLAPSE PRESSURE Biaxial and Tri-axial Loading ➢ Performance properties are only for zero axial tension & no pipe bending. ➢ Many casing properties are altered significantly by axial tension or compression & bending stresses. ➢ The table values for the performance properties often must be corrected before they are used in a casing design application. ➢ The effect of axial stresses on internal or external pressure is explained by Ellipse of Plasticity equation: + P + P t i = 1− 3 z i 4 yield yield 2 1 z + Pi + 2 yield ➢ (σt+ pi) / σy is positive if the pipe is subjected to an internal pressure (burst) and negative if it is subjected to an external pressure (collapse). Copyright: Dr. Ahmed Kamel PENG 3305 COLLAPSE PRESSURE Biaxial and Tri-axial Loading ➢ Axial tension has a detrimental effect on collapse pressure rating and a beneficial effect on burstpressure rating. ➢ Axial compression has a detrimental effect on burstpressure rating and a beneficial effect on collapse- pressure. ➢ In casing design practice, it is customary to apply the EOP only when a detrimental effect would be observed. Copyright: Dr. Ahmed Kamel PENG 3305 COLLAPSE PRESSURE Biaxial and Triaxial Loading ➢ API recommended procedure for determining the collapse pressure in the presence of a significant axial stress, z . ▪ Effective yield stress, (σyield)e, is first computed by: 2 yield e 3 1 z z = 1− − 2 4 yield yield yield ▪ This equation is the EOP with Pi=0 (worst case) ▪ The effective yield strength is used in collapse (dn/t) equations to determine the mode of failure. ▪ Collapse equations are then used for determining effective collapse pressure. ▪ For an elastic mode of failure, collapse pressure is independent of effective yield strength, and a corrected collapse pressure does not have to be computed. The nominal collapse pressure shown in tables can be used. Copyright: Dr. Ahmed Kamel PENG 3305 COLLAPSE PRESSURE Biaxial and Triaxial Loading EXAMPLE #2 Compute the corrected collapse-pressure rating for 20-in., K-55 csg with a nominal wall thickness of 0.635-in. and a nominal wt/ft of 133 lbf/ft for in service conditions where the axial tension will be 1,000,000 lbf. Also, compute the minimum external pressure required for failure if the internal pressure will be 1,000 psig. Copyright: Dr. Ahmed Kamel PENG 3305