"/

REBOILERS

10

REBOILERS

Contents

10.1 Introduction

444

10.2 Types of Reboilers

444

10.3 Design of Kettle Re boilers

449

10.4 Design of Horizontal Thermosyphon Reboilers

10.5 Design of Vertical Thermosyphon Re boilers

10.6 Computer Software

488

467

473

10

/ 444

10/444

REBOI LERS

REBOILERS

10.1 Introduction

10.1

A reboiler is a heat exchanger that is used to generate the vapor supplied to the bottom tray of a

distillation column. The liquid from the bottom of the column is partially vaporized in the exchanger,

which is usually of the shell-and-tube type. The heating medium is most often condensing steam,

but commercial heat-transfer fluids and other process streams are also used. Boiling takes place

either in the tubes or in the shell, depending on the type of reboiler.

reboiler. Exchangers that supply vapor

for other unit operations are referred to as vaporizers, but are similar in most respects to reboilers.

Thermal and hydraulic analyses of reboilers are generally more complex than for single-phase

exchangers. Some of the complicating factors are the following:

•9 Distillation bottom liquids are often mixtures having substantial boiling ranges. Hence, the

physical properties of the liquid and vapor fractions can exhibit large variations throughout the

reboiler. Thermodynamic

Thermodynamic calculations are required to determine the phase compositions and

other properties within the reboiler.

•9 A zone or incremental analysis is generally required for rigorous calculations.

•9 Two-phase flow occurs in the boiling section of the reboiler and, in the case of thermosyphon

units, in the return line to the distillation column.

•9 For recirculating thermosyphon reboilers, the circulation rate is determined by the hydraulics

in both the reboiler and the piping connecting the distillation column and reboiler. Hence, the

reboiler

re boiler and connecting piping must be considered as a unit. The hydraulic circuit adds another

iterative loop to the design procedure.

Even with simplifying assumptions, the complete design of a reboiler system can be a formidable

task without the aid of computer software. For rigorous calculations, commercial software is a

practical necessity.

10.2 Types of Reboilers

Reboilers are classified according to their orientation and the type of circulation employed. The

most commonly used types are described below.

10.2.1 Kettle reboilers

10.2.1

reboilers

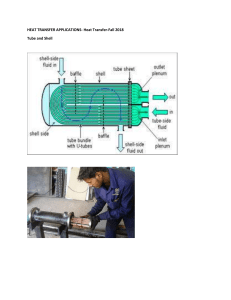

10.1) consists of a horizontally mounted TEMA K-shell and a tube bundle

A kettle reboiler (Figure 10.1)

comprised of either U-tubes or straight tubes (regular or finned) with a pull-through (type T) floating

head. The tube bundle is unbaffled, so support plates are provided for tube support. Liquid is fed by

gravity from the column sump and enters at the bottom of the shell through one or more nozzles.

The liquid flows upward across the tube bundle, where boiling takes place on the exterior surface

of the tubes. Vapor and liquid are separated in the space above the bundle, and the vapor flows

overhead to the column, while the liquid flows over a weir and is drawn off as the bottom product.

Low circulation rates, horizontal configuration and all-vapor return flow make kettle reboilers

relatively insensitive to system hydraulics. As a result, they tend to be reliable even at very low

(vacuum) or high (near critical) pressures where thermosyphon reboilers are most prone to operational problems. Kettles can also operate efficiently with small temperature driving forces, as high

heat fluxes can be obtained by increasing the tube pitch [1].

[1]. On the negative side, low circulation

rates make kettles very susceptible to fouling, and the over-sized K-shell is relatively expensive.

10.2.2

10.2.2 Vertical

Vertical thermosyphon reboilers

A vertical thermosyphon

thermosyphon reboiler (Figure 10.2)

10.2) consists of a TEMA E-shell with a single-pass tube

bundle. The boiling liquid usually flows through the tubes as shown, but shell-side boiling may be

used in special situations, e.g., with a corrosive heating medium. A mixture of vapor and liquid is

returned to the distillation column, where phase separation occurs. The driving force for the flow

is the density difference between the liquid in the feed circuit and the two-phase mixture in the

10/ 445

R EBO ILE RS

REBOILERS

10/445

(-L

~. Vapor

Vapor

,..

Level

Level

control

" ~

l

I

-.:.:.-:..-,-:.:.:.-.

:ii~':~;~:.'.:__.i-_.k:_'.7:

:':-'..'_~:~

l~'

:::~-::--i[ii:-::~-:i~f-i~-~":.!.!!ii.'

."];-.::.-:?I

Feed-

Bottoms

~ Bottoms

reboiler (Source: Ref.

[1]).

10.1 Typical configuration for

Ref. [1]).

for a kettle reboi/er

Figure 10.1

Figure

V or I

Vapor

'

'

Liquidf>~E

~

taui,

Levelcontroll-~~q

control 1

Level

qili,!i~i~i:i..~ii:l III

fI

I

i~i~~:i~i~i~i!?i~!i~i:

I

I

I

I

Fi I~:::i:ii:i~!ii?/!eed

:?:ii;!i": ;

Feed

I

I

I

t___~ 7

B oBottoms

ttoms

10.2 Typical

for aa vertical

Ref [1]).

reboiler (Source:

{1 ]).

vertical thermosyphon

(Source: Ref.

configuration for

thermosyphon reboi/er

Figure 10.2

Typical configuration

Figure

in the

usually

boiling region

sump isis usually

column sump

forvacuum

region and

line. Except

and return

the column

return line.

vacuum services,

services, the

Exceptfor

liquid in

the liquid

boiling

close to

to that

uppertubesheet

static

an adequate

in the

level close

adequate static

provide an

ataa level

the upper

that of

tubesheetin

ofthe

maintained at

reboil erto

to provide

the reboiler

maintained

typically maintained

maintained at

50-70% of

head. For

operations, the

Forvacuum

ofthe

liquid level

tube height

at 50-70%

vacuum operations,

height to

to

the liquid

level isis typically

the tube

head.

reduce the

liquid fed

the reboiler

re boiler [3].

[3].

elevation of

boiling point

the boiling

the liquid

to the

point elevation

ofthe

fed to

reduce

distillation columns,

to distillation

usually attached

are usually

costs

Vertical thermosyphon

attached directly

so the

columns, so

the costs

directly to

thermosyphon reboilers

reboilers are

Vertical

TEMA E-shell

the required

are minimized,

and piping

piping are

ofsupport

required plot

E-shell isis

minimized, as

support structures

structures and

plot space.

space. The

TheTEMA

as isis the

of

attained in

relatively high

high velocity

in these

advantage isis that

that the

Another advantage

the relatively

relatively inexpensive.

velocity attained

also relatively

these

inexpensive. Another

also

fouling. On

to minimize

other hand,

limited by

the other

hand, tube

tends to

height of

by the

minimize fouling.

units tends

On the

ofliquid

the height

tube length

in

liquid in

length isis limited

units

the cost

the liquid

ofraising

limitation

the skirt

increase the

heightto

to increase

raisingthe

skirt height

and the

the column

This limitation

cost of

liquid level.

level. This

sump and

column sump

the

make these

duties. The

units relatively

services with

relatively expensive

these units

boiling

for services

large duties.

expensive for

to make

with very

tends to

The boiling

very large

tends

is

due

drawback

increase

with

for

the

head

services

point

temperature

large

static

to

small

another

point increase due to the large static head is another drawback for services with small temperature

difficult, especially

the vertical

vertical configuration

makes maintenance

drivingforces.

maintenance more

especiallywhen

forces. Also,

configuration makes

Also, the

when

more difficult,

driving

on the

the area

the outside

of the

heating medium

the heating

unit isis

the unit

causes fouling

near the

tubes and/or

the tubes

area near

medium causes

fouling on

outside of

and/or the

the

congested.

congested.

thermosyphon reboilers

Horizontal thermosyphon

reboilers

10.2.3 Horizontal

10.2.3

although

employaTEMA

reboilers(Figure

thermosyphonreboilers

Horizontalthermosyphon

a TEMAG-,

10.3)usually

(Figure10.3)

or X-shell,although

usuallyemploy

H-,orX-shell,

Horizontal

G-, H-,

used.The

bundlemay

configuredfor

Thetube

]-shellsare

asshown,

E-and

maybe

tubebundle

passas

sometimesused.

beconfigured

singlepass

andJ-shells

aresometimes

shown,

foraasingle

Estraight tubes

passes. In

the latter

case, either

tubes (plain

orfinned)

orfor

be

multiple passes.

In the

either U-tubes

finned) may

formultiple

(plain or

latter case,

U-tubes or

may be

or straight

or

the shell

ofthe

from the

upward across

tube

bottom of

fed toto the

shell and

flows upward

Liquid from

the column

the bottom

column isis fed

across the

the tube

used. Liquid

and flows

used.

10/446

10/446

REBOILERS

REBOILERS

bundle.Boiling

Boilingtakes

takesplace

placeon

onthe

theexterior

exteriortube

tubesurface,

surface,and

andaamixture

mixtureofvapor

of vaporand

andliquid

liquidisisreturned

returned

bundle.

the column.

column. As

Aswith

withvertical

verticalthermosyphons,

thermosyphons, the

thecirculation

circulationisisdriven

drivenby

bythe

thedensity

densitydifference

difference

toto the

betweenthe

theliquid

liquidininthe

thecolumn

columnsump

sumpand

andthe

thetwo-phase

two-phasemixture

mixtureininthe

thereboiler

reboilerand

andreturn

returnline.

line.

between

Theflow

flowpattern

patternininhorizontal

horizontalthermosyphon

thermosyphonreboilers

reboilersisissimilar

similartotothat

thatininkettle

kettlereboilers,

re boilers,but

butthe

the

The

highercirculation

circulation rates

rates and

and lower

lowervaporization

vaporizationfractions

fractionsinin horizontal

horizontalthermosyphons

thermosyphonsmake

makethem

them

higher

less susceptible

susceptible toto fouling.

fouling. Due

Due toto the

the horizontal

horizontal configuration

configuration and

and separate

separate support

support structures,

structures,

less

theseunits

unitsare

arenot

notsubject

subjectto

torestrictions

restrictionson

onweight

weightor

ortube

tubelength.

length.As

Asaaresult,

result,they

theyare

aregenerally

generallybetbetthese

tersuited

suitedthan

thanvertical

verticalthermosyphons

thermosyphonsfor

forservices

serviceswith

withvery

verylarge

largeduties.

duties.The

Thehorizontal

horizontalconfiguraconfigurater

tionisisalso

alsoadvantageous

advantageousfor

forhandling

handlingliquids

liquidsof

ofmoderately

moderatelyhigh

highviscosity,

viscosity,because

becauseaarelatively

relativelysmall

small

tion

statichead

headisisrequired

requiredtotoovercome

overcomefluid

fluidfriction

frictionand

anddrive

drivethe

theflow.

flow.Arule

A ruleofthumb

of thumbisisthata

that ahorizontal

horizontal

static

ratherthan

than aavertical

vertical thermosyphon

thermosyphon should

shouldbe

be considered

consideredififthe

thefeed

feedviscosity

viscosityexceeds

exceeds0.5

0.5cp.

cp.

rather

10.2.4 Forced

Forced flow

flow reboilers

reboilers

10.2.4

In aa forced

forced flow

flow reboiler

reboiler system

system (Figure

(Figure 10.4)

10.4) the

the circulation

circulation isis driven

driven by

by aa pump

pump rather

rather than

than

In

by gravity.

gravity. The

The boiling

boiling liquid

liquid usually

usually flows

flows in

in the

the tubes,

tubes, and

and the

the reboiler

reboiler may

may be

be oriented

oriented either

either

by

horizontally or

orvertically.

vertically. AATEMA

TEMAE-shell

E-shellisisusually

usuallyused

usedwith

withaatube

tu bebundle

bundleconfigured

configuredfor

foraasingle

single

horizontally

pass. These

These units

units are

are characterized

characterized by

byhigh

high tube-side

tube-sidevelocities

velocitiesand

andvery

verylow

lowvaporization

vaporizationfractions

fractions

pass.

(usually less

less than

than 1%

1% [1])

[1]) in

in order

order to

to mitigate

mitigate fouling.

fouling. The

The main

main use

use of

offorced

forced flow

flow reboilers

reboilers isis in

in

(usually

services with

with severe

severe fouling

fouling problems

problems and/or

and/ orhighly

highlyviscous

viscous (greater

(greaterthan

than 25

25cp)

cp) liquids

liquidsfor

forwhich

which

services

kettle and

and thermosyphon

thermosyphon reboilers

reboilers are

are not

not well

well suited.

suited. Pumping

Pumping costs

costs render

render forced

forced flow

flow units

units

kettle

uneconomical for

for routine

routine services.

services.

uneconomical

!

'

Vapor

Level

Level

>.

control

control

. Liquid,

. . . . " >�---�

~

r---,L'qutaf

fi

t

f.

9 t

l'

-4i-----.~

i

I

f

i

Feed

Feed

/

9

1

Bottoms

Bottoms

10.3 Typical

for aa horizontal

horizontal thermosyphon

reboiler (Source:

(Source: Ref.

et. [1]).

[1)).

thermosyphon reboiler

configuration for

Typical configuration

Figure 10.3

Figure

Level

Level

control

control

Vapor

Vapor !

~"-- _ . . ~

fl~ i !

,' -- -

Liquid

. ,

ii! !! !iiiiii!!iill

I

-

Feed

Feed

~

?

Bottoms

~ Bottoms

reboiler (Source: Ref. [1]).

[11).

Figure 10.4 Typical configuration for a forced flow reboiler

Figure

REBOILERS

R

EBOILERS

447

10// 447

10

reboilers

10.2.5 Internal reboilers

10.2.5

re boiler (Figure 10.5) consists of a tube bundle (usually U-tubes) that is inserted

inserted directly

An internal reboiler

required, it is the

least

the sump of the

the least

connecting piping is required,

the distillation column. Since no shell or connecting

into the

accommodated

expensive type of reboiler.

area that

that can be accommodated

reboiler. However, the

the amount of heat-transfer area

expensive

cause operational

is severely limited. Also, formation of froth and foam in the

the column sump

sump can cause

used.

reboiler is infrequently used.

this type of reboiler

result, this

problems. As a result,

problems.

versus once-through

10.2.6 Recirculating

operation

Recirculating versus

once-through operation

10.2.6

systems can be

the recirculating

be of either

either the

Figures 10.2 and 10.3,

re boiler systems

Thermosyphon reboiler

recirculating type, as in Figures

Thermosyphon

from the

type shown

tray

bottom tray

latter case,

once-through type

the once-through

Figure 10.6. In the

or the

case, the

the bottom

shown in Figure

the liquid from

the latter

or

trap-out, from

from which

the return

reboiler. The

The liquid

is collected

liquid fraction

return flow

which it flows to the

collected in a trap-out,

fraction of the

the reboiler.

is

as the

collects in

product. Thus,

bottom product.

Thus, the

the bottom

passes

the column

in the

the liquid passes

drawn as

from which

which it is drawn

sump, from

column sump,

collects

reboiler only once,

kettle reboiler.

reboiler.

as with

through the

the reboiler

once, as

with a kettle

through

feed lines

provides a larger

smaller feed

lines and

operation requires

generally provides

Once-through operation

requires smaller

temperature

and generally

larger temperature

Once-through

mixtures, the

force in

recirculating

point of

the boiling

boiling point

liquid fed to

in the

of the

to a recirculating

driving force

the reboiler.

reboiler. For

the liquid

For mixtures,

driving

returned from

due to

from the

is enriched

re boiler, which

the reboiler,

which is

the addition

of the

elevated due

to the

reboiler is

the liquid returned

is elevated

addition of

enriched in

reboiler

boiling zone

components. As

mean temperature

higher boiling

result, the

temperature difference

zone of

the boiling

boiling components.

the mean

As aa result,

the higher

in the

difference in

the

some systems,

Recirculation can

in increased

systems, e.g.,

fouling in

exchanger is

can also

also result

reduced. Recirculation

is reduced.

in some

the exchanger

e.g.,

result in

increased fouling

the

results

polymerization.

exposure

high

decomposition

in

chemical

temperatures

or

to

when

when exposure to high temperatures results in chemical decomposition or polymerization.

_ _ . . . .

Level control

-4

i'

Bottoms

Bottoms

10.5 Typical

foran

Ref. [1]).

reboiler (Source:

internal reboiler

an internal

Typical configuration

configuration for

(Source: Ref.

Figure 10.5

[11).

Figure

Product

Product

Reboiler

Reboiler

Figure 10.6

Typicalconfiguration

Ref.[2]).

reboilersystem

10.6 Typical

configuration for

foraa once-through

once-through thermosyphon

thermosyphon reboiler

[21).

(Source:Ref.

system (Source:

Figure

10/

448

10

/ 448

RREBOILERS

EBOILERS

For reliable

reliable design

design and

and operation,

operation, the

the vapor

vapor weight

weight fraction

fraction in

in thermosyphon

thermosyphon reboilers

reboilers should

should

For

be limited

limited to

to about

about 25-30%

25--30% for

for organic

organic compounds

compounds and

and about

about 10%

10% for

for water

water and

and aqueous

aqueous solutions

solutions

be

[1,2]. IfIf these

these limits

limits cannot

cannot be

be attained

attained with

with once-through

once-through operation,

operation, then

then aa recirculating

recirculating system

system

[1,2].

should be

be used.

used.

should

10.2.7 Reboiler

Reboiler selection

selection

10.2.7

In some

some applications

applications the

the choice

choice of

of reboiler

reboiler type

type isis clear-cut.

clear-cut. For

For example,

example, severely

severely fouling

fouling or

or very

very

In

viscous liquids

liquids dictate

dictate aa forced

forced flow

flowreboiler.

reboiler. Similarly,

Similarly, aa dirty

dirty or

or corrosive

corrosive heating

heating medium

medium together

together

viscous

with aa moderately

moderately fouling

fouling process

process stream

stream favors

favors aa horizontal

horizontal thermosyphon

thermosyphon reboiler.

reboiler. In

In most

most appliappliwith

cations, however,

however, more

more than

than one

one type

type of

of reboiler

reboiler will

will be

be suitable.

suitable. In

In these

these situations

situations the

the selection

selection isis

cations,

usually based

based on

on considerations

considerations of

of economics,

economics, reliability,

reliability, controllability,

controllability, and

and experience

experience with

with simsimusually

ilar services.

services. The

The guidelines

guidelines presented

presented by

by Palen

Palen [1]

[1] and

and reproduced

reproduced in

in Table

Table 10.1

10.1 provide

provide useful

useful

ilar

information in

in this

this regard.

regard. Kister

Kister [3]

[3] also

also gives

gives aa good

good concise

concise comparison

comparison of

of reboiler

reboiler types

types and

and

information

the applications

applications in

in which

which each

each is

is preferred.

preferred.

the

Sloley [2]

[2] surveyed

surveyed the

the use

use ofvertical

of vertical versus

versus horizontal

horizontal thermosyphon

thermosyphon reboilers

reboilers in

in the

the petroleum

petroleum

Sloley

refining, petrochemical

petrochemical and

and chemical

chemical industries.

industries. Of

Ofthe

the thermosyphons

thermosyphons used

used in

in petroleum

petroleum refining,

refining,

refining,

95% are

are horizontal

horizontal units;

units; in

in the

the petrochemical

petrochemical industry,

industry, 70%

70% are

are vertical

vertical units;

units; and

and in

in the

the chemical

chemical

95%

industry, nearly

nearly 100%

100% are

are vertical

vertical units.

units. He

He attributes

attributes this

this distribution

distribution to

to two

two factors,

factors, size

size and

and

industry,

fouling tendency.

tendency. For

For the

the relatively

relatively small,

small, clean

clean services

services typical

typical of

of the

the chemical

chemical industry,

industry, vertical

vertical

fouling

thermosyphons are

are favored,

favored, whereas

whereas the

the large

large and

and relatively

relatively dirty

dirty services

services common

common in

in petroleum

petroleum

thermosyphons

refining dictate

dictate horizontal

horizontal thermosyphons.

thermosyphons. Services

Services in

in the

the petrochemical

petrochemical industry

industry also

also tend

tend to

to be

be

refining

Table 10.1

10.1 Guidelines

Guidelines for

for Reboiler

Reboiler Selection

Selection

Table

type

Reboiler type

Process conditions

conditions

Process

Operating pressure

Operating

Moderate

Near critical

vacuum

Deep vacuum

Design AT

Moderate

Large

Small (mixture)

Very small (pure component)

Fouling

Clean

Moderate

Heavy

Very heavy

Mixture boiling range

Pure component

Narrow

Wide

Very wide, with viscous liquid

Kettle or

Kettle

internal

internal

Horizontal

Horizontal

shell-side

thermosyphon

thermosyphon

Vertical

Vertical

tube-side

tube-side

thermosyphon

thermosyphon

Forced

flow

flow

E

B-E

B

G

R

R

R

B

Rd

Rd

E

E

E

E

B

F

B

G

R

F

F

B

G-Rd

Rd

Pp

E

E

Pp

Pp

G

Rd

Pp

Pp

G

G

Rd

Pp

G

B

B

Rd

E

E

G

B

G

G

F

F-P

G

G

G

G-Rd

G

B

B

Pp

E

E

E

B

abbreviations: B: best;

best; G:

G: good

operation; F: fair

fair operation,

operation, but better choice

choice is possible;

possible; Rd:

Rd: risky

risky unless

unless carefully

carefully

good operation;

Category abbreviations:

Category

could be best choice

choice in some

some cases;

cases; R:

R: risky

risky because

because of insufficient

insufficient data;

data; P:

P: poor

poor operation;

operation; and E: operable

operable

designed, but could

designed,

unnecessarily expensive.

expensive.

but unnecessarily

Source: Ref.

Ref. [[1)

Source:

1]

R E BBOOI I LLERS

ERS

10/

10 / 449

relatively large, but to a lesser extent than in petroleum refining, and they are generally cleaner as

well. Hence, the use of horizontal thermosyphons in petrochemical applications is less extensive

The above analysis

compared with petroleum refining, but greater than in the chemical industry. The

10.1 because size permitting, a vertical thermosyphon is

is somewhat contradictory with Table 10.1

indicated for moderate to heavy fouling on the boiling side. The reason is that in a vertical unit

the boiling fluid is on the tube side, which is relatively easy to clean, the vertical configuration

notwithstanding.

Overall, however, the vertical thermosyphon is the most frequently used type of reboiler [3]. Size

boiler type of choice unless the service is such that one of the

permitting, it will generally be the re

reboiler

other types offers distinct advantages, as discussed above.

10.3 Design of Kettle Reboilers

10.3.1 Design

Design strategy

10.3.1

A schematic representation of the circulation in a kettle reboiler is shown in Figure 10.7.

10.7. The

circulation rate through

through the tube bundle is determined by a balance between the static head of

liquid outside the bundle and the pressure

pressure drop across the bundle. A two-phase mixture exists in

the bundle and the vapor fraction varies with position. Therefore, the bundle hydraulics are coupled

with the heat transfer, and a computer model (such as that in the HTRI or HTFS software package)

is required to perform these calculations.

Since the circulation rate in a kettle reboiler is relatively low,

low, the pressure drop in the unit is

usually quite small. Therefore, a reasonable approximation is to neglect the pressure

pressure drop in the

unit and size the bundle using the heat-transfer correlations given in Section 9.3. Since kettles utilize

once-through operation, the feed rate is equal to the liquid flow rate from the bottom tray of the

distillation column. Hence, the feed and return lines can be sized to accommodate the required

liquid and vapor flows based on the available static head of liquid in the column sump. Because

the flow in each line is single phase (liquid feed and vapor return), the hydraulic calculations are

Vapor out

Vapor

\

[ Clear 1 { / " ~14~ I~;i ~ t ,~

! quid IY,

j XI

Clear ]

\\ t\ /Zr!'I't;II'I

IN

/ //

I __L-i [ FBuodlei [1 I I

i

\ \ \-I- ',i,l I l,l _J / / /

1

I Liquid feed

Figure 10.7

10. 7 Schematic representation

representation of the circulation in a kettle reboiler Source: Ref. [4}.

[4].

Figure

10/450

10/450

REBOILERS

EBOILERS

straightforward. Furthermore,

Furthermore,the

theheat-transfer

heat-transferand

andhydraulic

hydrauliccalculations

calculationsare

areindependent

independentofofone

one

straightforward.

another, making

making the

the entire

entire approximate

approximate design

design procedure

procedurerelatively

relativelysimple

simple and

and suitable

suitablefor

forhand

hand

another,

calculations.

calculations.

10.3.2 Mean

Mean temperature

difference

temperature difference

10.3.2

In exchangers

exchangers with

with boiling

boiling or

or condensing

condensing mixtures,

mixtures, the

the true

true mean

mean temperature

temperature difference

difference isisnot

not

In

generally equal

equal toto F(ATln)cf

because the

the stream

stream enthalpy

enthalpy varies

varies nonlinearly

nonlinearly with

with temperature

temperature

F(AT\~)r because

generally

over the

the boiling

boiling or

or condensing

condensing range,

range, violating

violating an

an underlying

underlying premise

premise of

of the

the F-factor

F-factor method.

method.

over

Computeralgorithms

algorithmshandle

handlethis

thissituation

situationby

byperforming

performingaazone

zoneanalysis

analysis (incremental

(incrementalcalculations)

calculations)

Computer

in which

which each

each zone

zone or

or section

section of

ofthe

the exchanger

exchanger isis such

such that

that the

the stream

stream enthalpy

enthalpy isis nearly

nearly linear

linear

in

withinthe

the zone.

zone. For

Forthe

the approximate

approximatedesign

designprocedure

procedureoutlined

outlinedabove,

above,however,

however, an

aneffective

effectivemean

mean

within

temperaturedifference

differencefor

forthe

thereboiler

reboilerisisrequired.

required.For

Forkettle

kettlereboilers,

re boilers,Palen

Palen[(1)

recommendsusing

using

temperature

1] recommends

the logarithmic

logarithmic mean

mean temperature

temperature difference

difference (LMTD)

(LMTD) based

based on

on the

the exit

exit vapor

vapor temperature

temperature as

as aa

the

conservative approximation

approximation for

forthe

the mean

mean temperature

temperature difference.

difference.That

Thatis,

is, the

the LMTD

LMTD isis calculated

calculated

conservative

assumingthat

thatthe

the shell-side

shell-sidefluid

fluidtemperature

temperatureisisconstant

constantand

andequal

equalto

tothe

thetemperature

temperatureof

ofthe

thevapor

vapor

assuming

leavingthe

the reboiler.

reboiler.

leaving

10.3.3 Fouling

factors

Fouling factors

10.3.3

Since heat-transfer

heat-transfer coefficients

coefficients are

are generally

generally high

high in

in reboilers,

reboilers, the

the specified

specified fouling

fouling allowance

allowance

Since

can account

account for

for aa substantial

substantial fraction

fraction of

ofthe

the total

total thermal

thermal resistance.

resistance. Therefore,

Therefore, itit isis important

important to

to

can

use realistic

realistic values

values for

for the

the fouling

fouling factors

factors in

in order

order to

to avoid

avoid gross

gross over-design

over-design that

that could

could result

result in

in

use

operational problems

problems as

as well

well as

as needless

needless expense.

expense. The

The recommendations

recommendations of

of Palen

Palen and

and Small

Small [5]

[5]

operational

are given

given in

in Table

Table 10.2.

10.2. TEMA

TEMA fouling

fouling factors

factors or

or those

those given

given in

in Table

Table 3.3

3.3 may

may also

also be

be useful

useful for

for

are

some applications.

applications. As

As always,

always, however,

however, the

the best

best source

source for

for fouling

fouling factors

factors isis prior

prior experience

experience with

with

some

the same

same or

or similar

similar application.

application.

the

10.3.4 NNumber

of nozzles

nozzles

10.3.4

u m b e r of

In order

order to

to obtain

obtain aa reasonably

reasonably uniform

uniform flow

flow distribution

distribution along

along the

the length

length of

of the

the tube

tube bundle,

bundle, an

an

In

adequate number

number of

of feed

feed and

and vapor

vapor return

return nozzles

nozzles should

should be

be used.

used. For

For aa tube

tube bundle

bundle of

of length

length LL

adequate

and diameter

diameterDb,

the number,

number, Nn,

N,,, of

ofnozzle

nozzle pairs

pairs (feed

(feed and

and return)

return) isis determined

determinedfrom

fromthe

the following

following

D,, the

and

empirical equation

equation [1,6]"

(1,6):

empirical

L

N,, = L

N,-

(10.1)

(10.1)

5Db

5D,

The calculated

calculated value

value is

is rounded

rounded upward

upward to

to the

the next

next largest

largest integer.

integer.

The

Table 10.2

10.2 Recommended

Recommended Fouling

Factors for

for Reboiler

Reboiler Design

Design

Fouling Factors

Table

Boiling-side stream

stream

Boiling-side

factor (h.

(h.f?

.·F/Btu)

Fouling factor

Fouling

ft2 .oF/Btu)

C--Cs normal hydrocarbons

C1-C8

normal hydrocarbons

Heavier normal

polymerizing hydrocarbons

hydrocarbons

Diolefins and polymefizing

0-0.001

0-0.001

0.001-0.003

0.001-0.003

0.003-0.005

0.003-0.005

Heating-side stream

stream

Heating-side

Condensing steam

Condensing organic

organic

Condensing

Organic liquid

Source: Ref.

Ref. [5]

[5]

Source:

0-0.0005

0.0005-0.001

0.0005-0.002

REBOILERS

REBOILERS

10/451

10

/ 451

10.3.5 Shell

Shell ddiameter

10.3.5

iameter

chosen to

provide adequate

The diameter

to provide

above the

of the

surface of

diameter of the

adequate space

the surface

space above

the K-shell is chosen

boiling

the boiling

The

A rule

the distance

distance from

rule of thumb

that the

uppermost

is that

vapor-liquid disengagement.

thumb is

the uppermost

disengagement. A

from the

for vapor-liquid

liquid for

liquid

of the

shell diameter.

to the

more rigorous

tube to

the shell

be at

least 40% of the

somewhat more

at least

the shell

should be

A somewhat

shell should

diameter. A

the top

rigorous

top of

tube

based on

the vapor

vapor loading

for the

the following empirical

on the

is based

loading [5,6]:

empirical equation

equation for

(5,6]:

procedure is

sizing procedure

(

(7° )0.5

)0.5

2290p,

VL -= 2290

V/.,

pv ~

Do

PL -- Pv

PL

(10.2)

(10.2)

where

where

VL == vapor

vapor loading

loading 0(lbm/h.ft)

VL

b m / h . ft3)

(Ibm/ft?)

and liquid

densities 0bm/ft

liquid densities

vapor and

pPy,pL

v , PL =

= vapor

3)

surface tension

tension (dyne/cm)

(dyne/cm)

aa == surface

divided by

vapor space.

the mass

of the

volume of

vapor divided

is the

rate of

by the

loading is

the vapor

The

space. The

mass flow

flow rate

the volume

The vapor

of vapor

vapor loading

The

to

vapor

is

velocity

to

by

value

low

allow

Equation

(10.2)

provide

given

intended

a

sufficiently

value given by Equation (10.2) is intended to provide a sufficiently low vapor velocity to allow

from

segment area,

calculated from

is calculated

The dome

entrained liquid

area, SSA,

dome segment

droplets. The

liquid droplets.

of entrained

settling of

gravitational settling

gravitational

A , is

loading as

the vapor

as follows:

vapor loading

follows:

the

SSA

A -_

y

mv

LL •X VL

VL

(10.3)

(10.3)

where

where

vapor mass

flow rate

(lbm/h)

mass flow

my ==vapor

rate 0bin/h)

rhv

length of

tube bundle

oftube

(ft)

bundle (ft)

LL ==length

albm/h,

lbm/h.ft

VL cx

VL

ft3

SSA

A ~aftft?

2

cross-section shown

area isis the

the dome

area

Considering the

K-shell cross-section

the area

the K-shell

Figure 10.7,

segment area

shown inin Figure

10.7, the

dome segment

Considering

above the

liquid surface.

that lies

For known

surface. For

ofthe

the liquid

diameter and

known bundle

segment that

circular segment

bundle diameter

lies above

and dome

dome

the circular

of

can be

area, the

circular

(bytrial

trial and

be determined

table of

the shell

determined (by

error) from

segment area,

ofcircular

fromthe

diametercan

anderror)

thetable

shell diameter

segment

level isis usually

10.A. Since

Since the

above the

areas inin Appendix

maintained slightly

segment areas

Appendix 10.A.

the liquid

liquid level

slightly above

usually maintained

the

segment

of

the

approximately

height

the

row

shell

equal

liquid

top

the

in

diameter

of

tubes,

bundle

to

is

top row of tubes, the height of liquid in the shell is approximately equal to the bundle diameter

bottom of

the clearance

between the

the

plus the

accountfor

and the

bundle and

the shell.

shell. However,

the bottom

forthe

the bundle

ofthe

However, toto account

clearance between

plus

purposeof

thisheight

andfroth

offoaming

foamingand

3-5in.

maybe

beincremented

by3-5

incrementedby

frothformation,

of

forthe

formation,this

heightmay

thepurpose

in.for

effectof

effect

vaporoutlet

diameter [6].

thevapor

theshell

Demisterpads

padscan

outletnozzles

shelldiameter

alsobe

canalso

installedininthe

[ 6]. Demister

calculatingthe

nozzlestoto

beinstalled

calculating

furtherreduce

reduceentrainment.

entrainment.

further

EExample

x a m p l e 110.1

0.1

requiresaadome

5.5ftft2.2•The

plusclearance

kettle reboiler

areaofof5.5

reboilerrequires

clearanceisis

diameterplus

Thebundle

segmentarea

dome segment

bundlediameter

AAkettle

diameterisisrequired?

shelldiameter

Whatshell

22.4in.

approximately22.4

in.What

required?

approximately

Solution

Solution

liquid height

for foaming

4 in. toto the

effective liquid

height ofof

height toto account

gives an

account for

an effective

Adding 4in.

the liquid

foaming gives

liquid height

Adding

approximately60%

heightisisapproximately

2.2ft.ft. For

liquidheight

firsttrial,

the first

effectiveliquid

trial, assume

Forthe

theeffective

the

60%ofofthe

assumethe

26.4i in.

26.4

n . -=2.2

Then,

diameter.Then,

shelldiameter.

shell

D,==22/0.6

Ds

2.2/0.6 ==3.67ft

3.67 ft

Further,the

(shell)diameter

40%,i.e.,

circle(shell)

height,h,h,totocircle

theratio

sectorheight,

ratioofofsector

diameterisis40%,

i.e.,

Further,

0.4

hh/D

/ D ==11-0.6

- 0.6 ==0.4

10// 452

452

10

REEBBO

R

O I I LLEERRSS

From the

the table

table in

in Appendix

Appendix 10.A

10.A with

with h/D

h/D == 0.4,

0.4, the

the sector

sector area

area factor

factor isis A

A=

0.29337. This

This value

value

From

= 0.29337.

must be

be multiplied

multiplied by

by the

the square

square of

of the

the shell

shell diameter

diameter to

to obtain

obtain the

the actual

actual segment

segment area.

area. Thus,

Thus,

must

SA == 0.29337

0.29337 (3.67)

(3.67)2 == 3.95

3.95 ftft?2

SA

Since this

this isis less

less than

than the

the required

required dome

dome segment

segment area,

area, aa larger

larger shell

shell diameter

diameter is

is needed.

needed. For

For the

the

Since

second trial,

trial, assume

assume the

the effective

effective liquid

liquid height

height is

is 55%

55% of

of the

the shell

shell diameter.

diameter. Then,

Then,

second

2.2

2.2

D.0gs

Ds

= 0.55 ==4.0f

4.0 ft

h/D ==1--0.55

0.45

h/D

1 - 0.55 == 0.45

A == 0.34278

0.34278 (Appendix

(Appendix 10.A)

10.A)

A

SA

ft 2

SA == 0.34278(4.0)

0.34278(4.0)2 == 5.48

5.48 -~

2 5.5

5.5°

Therefore, aa shell

shell diameter

diameter of

of approximately

approximately 44 ftft is

is required.

required.

Therefore,

10.3.6 Liquid

Liquid ooverflow

10.3.6

v e r f l o w rreservoir

eservoir

With aa kettle

kettle reboiler,

reboiler, surge

surge capacity

capacity is

is provided

provided by

by the

the liquid

liquid overflow

overflow reservoir

reservoir in

in the

the kettle,

kettle,

With

as opposed

opposed to

to the

the column

column sump

sump when

when a thermosyphon

thermosyphon reboiler

reboiler is

is used.

used. The

The liquid

liquid holdup

holdup time

time

as

in the

the overflow

overflow reservoir

reservoir is

is usually

usually significantly less

less than

than in

in the

the column

column sump

sump due

due to

to the

the cost

cost of

of

in

extending the

the length

length of

of the

the K-shell, of

of which

which only

only the

the bottom

bottom portion

portion is

is useable.

useable. The

The small size

size and

and

extending

limited holdup

holdup time

time can

can make

make the

the liquid

liquid level in

in the

the reservoir

reservoir difficult

difficult to

to control,

control, and

and can

can lead

lead to

to

limited

relatively large

large fluctuations

fluctuations in

in the

the bottom

bottom product

product flow rate.

rate. These

These fluctuations

fluctuations can

can adversely

adversely affect

affect

relatively

the operation

operation of

of downstream

downstream units

units unless

unless aa separate

separate surge

surge vessel

vessel is provided

provided downstream

downstream of

of the

the

the

reboiler, or

or the

the bottom

bottom product

product flows

flows to

to storage.

storage. These

These problems

problems can

can be

be avoided

avoided by

by eliminating

eliminating the

the

reboiler,

overflow weir

weir in

in the

the kettle

kettle [7]. However,

However, a drawback

drawback of

of this

this strategy

strategy is

is that

that incomplete

incomplete separation

separation

overflow

reboiler feed

feed and reboiled

reboiled liquid

liquid results

results in the

the (partial)

(partial) loss

loss of one

one theoretical

theoretical distillation

distillation stage.

stage.

of reboiler

10.3.7 Finned tubing

10.3.7

Radial low-fin tubes

tubes and

and tubes

tubes with surface

surface enhancements

enhancements designed

designed to improve

improve nucleate

nucleate boiling

boiling

characteristics can be

be used

used in reboilers

reboilers and

and vaporizers.

vaporizers. They

They are

are particularly

particularly effective

effective when

when the

the

characteristics

temperature driving

driving force

force is small, and

and hence

hence they

they are

are widely

widely used

used in refrigeration

refrigeration systems. In additemperature

to providing

providing a large

large heat-transfer

heat-transfer surface

surface per

per unit

unit volume,

volume, finned tubes

tubes can result

result in significantly

tion to

higher boiling

boiling heat-transfer

heat-transfer coefficients

coefficients compared

compared with plain tubes

tubes due

due to the

the convective

convective effect of

higher

two-phase flow between

between the

the fins [1]. As the

the temperature

temperature driving force increases,

increases, the

the boiling-side

boiling-side

two-phase

resistance tends

tends to become

become small compared

compared with the

the thermal

thermal resistances

resistances of the

the tube

tube wall and

and heatheatresistance

medium, and

and the

the advantage

advantage of finned tubes

tubes is substantially diminished.

diminished. A quantitative

quantitative treatment

treatment

ing medium,

and enhanced

enhanced surfaces

surfaces is beyond

beyond the

the scope

scope of this

this book.

book.

of boiling on finned and

10.3.8 Steam

Steam as heating medium

10.3.8

When condensing

condensing steam is used

used as a heating

heating medium, it is common practice

practice to use

use an approxWhen

heat-transfer coefficient on the

the heating

heating side for design

design purposes.

purposes. Typically, a value of

imate heat-transfer

1500Btu/h

W/m? ·K

This value is referred

referred to the

the external

external tube

tube surface

surface and

1500

Btu/h. .ft?

ft2..·F(8500

~

K)) is used. This

includes a fouling allowance. Thus,

Thus, for steam condensing

condensing inside plain tubes

tubes we have:

includes

1500Btu/hf·F

8500 W/m?·K

[(Do/Di)(1/hi

D i ) ] - 1 ~ 1500Btu/h.

ft 2 .~ F ~ 8500W/m

2. K

[(D,/DD) (/h, ++ eRo)]'=

condensate nozzles are

are presented

presented in Table

Table 10.3.

10.3. The

The data

guidelines for sizing steam and condensate

Some guidelines

Ref. [8] and are for vertical thermosyphon reboilers.

reboilers. However, they can be

be used

used as

are taken from Ref.

reboilers of similar size.

general guidelines for all types of reboilers

REBOILERS

REBOILERS

10/453

10 / 453

Table 10.3 Guidelines for Sizing Steam and Condensate Nozzles

Shell OD ((in.)

in.)

16

2O

20

24

30

36

42

Heat-transfer

area (ft)

(ft2)

130

215

330-450

525-1065

735-1520

1400-2180

Nominal nozzle

nozzle diameter (in.)

(in.)

Steam

Condensate

4

4

6

6-8

6--8

88

88

1.5

1.5

22

33

3-4

44

4

Source: Ref.

Ref. [8]

[8]

10.3.9 Two-phase

Two-phase density

calculation

density calculation

In order

order to calculate the static head in the reboiler, the density of the two-phase mixture in the

boiling region must

must be determined. For cross flow over tube bundles, this calculation is usually

made

methods for separated

made using

using either the homogeneous

homogeneous model, Equation (9.51), or one of the methods

flow in tubes, such as the Chisholm correlation, Equation (9.63). Experimental data indicate that

neither approach

neither

approach is particularly accurate [9], but there is no entirely satisfactory alternative. The

homogeneous model is somewhat

homogeneous

somewhat easier to use, but the Chisholm correlation will generally give a

more conservative

conservative (larger) result for the static head.

The following example illustrates the design procedure

The

procedure for kettle reboilers.

Example 110.2

0.2

lb/h of a distillation bottoms

96,000 lb/h

bottoms having the following composition will be partially vaporized in

a reboiler:

Component

Mole%

Mole

%

Critical

Critical pressure (psia)

(psia)

Propane

i-butane

/-butane

n-butane

15

15

25

60

616.3

529.0

551.1

The

enter the re

boiler as a (nearly) saturated liquid at 250 psia. The dew-point temThe stream

stream will enter

reboiler

perature of the stream at 250

psia is 205.6F.

psia will

perature

250psia

205.6~ Saturated steam at a design pressure

pressure of 20

20psia

be used

used as the heating

heating medium. The reboiler is to supply 48,0001b/h

48,000 lb/h of vapor to the distillation

column. The

The reboiler

reboiler feed line will be approximately 23 ft long, while the vapor return line will have

a total length of approximately 20 ft. The

The available elevation difference between the liquid level in

re boiler inlet is 9 ft. Physical property data are given in the following table.

the column sump and the reboiler

Design a kettle reboiler for this service.

Property

Reboiler feed

Liquidoverflow

overflow Vapor

Vaporreturn

Liquid

T (oF)

(F

H(Btu/lbm)

H

(Btu/lbm)

C

Cp(Btu/Ibm.F)

(Btu/lbm. ~

k(Btu/h·ft.·F)

k(Btu/h,

ft. oF)

u(cp)

# (cp)

p(lbm/ft)

p(lbm/ft 3)

o (dyne/cm)

a(dyne/cm)

Molecular weight

197.6

106.7

106.7

0.805

0.046

0.074

28.4

3.64

56.02

56.02

202.4

109.9

0.811

0.046

0.074

28.4

3.59

56.57

202.4

216.4

216.4

0.576

0.014

0.0095

2.76

55.48

10/454

10

/ 454

RREBOILERS

EBOI LERS

Solution

Solution

(a) Make

Makeinitial

initial specifications.

specifications.

(a)

(i) Fluid

Fluidplacement

placement

(i)

There isis no

no choice

choice here;

here; the

the boiling

boilingfluid

fluid must

mustbe

be placed

placed inin the

the shell

shell and

and the

the heating

heating

There

mediumininthe

thetubes.

tubes.

medium

(ii) Tubing

Tubing

(ii)

One-inch, 14

14BWG,

BWG,U-tubes

U-tubeswith

withaalength

lengthof

of16

16ftare

specified.AAtubing

tubingdiameter

diameterofof¾

in.

One-inch,

ft are specified.

3/~in.

could also

also be

beused.

used.

could

(iii) Shell

Shell and

andhead

head types

types

(iii)

TEMA K-shell

K-shell isis chosen

chosen for

for aa kettle

kettle reboiler,

reboiler, and

and aa type

type BB head

head isis chosen

chosen since

since the

the

AATEMA

tube-sidefluid

fluid (steam)

(steam) isis clean.

clean.Thus,

Thus, aaBKU

BKUconfiguration

configurationisisspecified.

specified.

tube-side

(iv) Tube

Tube layout

layout

(iv)

square layout

layoutwith

with aatube

tubepitch

pitch of

of1.25

1.25in.

in. isisspecified

specifiedtotopermit

permitmechanical

mechanicalcleaning

cleaningof

of

AAsquare

the external

external tube

tube surfaces.

surfaces.Although

Althoughthis

this service

service should

shouldbe

bequite

quiteclean,

clean, contaminants

contaminantsinin

the

distillation feed

feed streams

streamstend

tend totoconcentrate

concentrateininthe

thebottoms,

bottoms, and

andkettle

kettlereboilers

reboilersare

arevery

very

distillation

prone toto fouling.

fouling.

prone

(v) Baffles

Baffles and

and sealing

sealing strips

strips

(v)

Noneare

arespecified

specifiedfor

foraakettle

kettlereboiler.

re boiler. Support

Supportplates

plateswill

willbe

beused

usedtotoprovide

providetube

tubesupport

support

None

and vibration

vibration suppression.

suppression. Four

Four plates

plates are

are specified

specified toto give

give an

an unsupported

unsupported tube

tubelength

length

and

that isis safely

safely below

belowthe

the maximum

maximum of

of74

74in.

in. listed

listed in

inTable

Table 5.C1.

5.Cl.

that

(vi) Construction

Construction materials

materials

(vi)

Since neither

neither stream

stream isis corrosive,

corrosive, plain

plain carbon

carbon steel

steel isis specified

specified for

for all

all components.

components.

Since

(b) Energy

Energy balance

balance and

and steam

steam flow

flow rate.

rate.

(b)

The reboiler

reboiler duty

duty isis obtained

obtained from

from an

an energy

energy balance

balance on

on the

the process

process stream

stream (boiling

(boiling fluid):

fluid):

The

q -- b'lvHv

4- m L H L

-- b ' I F H F

where the

the subscripts

subscripts F,

F, L,

L, and

and VV refer

refer to

to the

the reboiler

reboiler feed,

feed, liquid

liquid overflow,

overflow, and

and vapor

vapor return

return

where

streams, respectively.

respectively. Substituting

Substituting the

the appropriate

appropriate enthalpies

enthalpies and

and flow

flow rates

rates gives:

gives:

streams,

= 48,

48,000

48,000

000 xX 2216.4

1 6 . 4 ++ 48,

000 xX 1109.9-96,000

0 9 . 9 - 96, 0 0 0 xX 1106.7

06.7

qQ =

25.42

10 Btu/h

Btu/h

q0 -~

5.42 x 106

From Table

Table A.8,

A.8, the

the latent

latent heat

heat of

of condensation

condensation for

for steam

steam at

at 20psia

20 psia isis 960.1Btu/lbm.

960.1 Btu/lbm.

From

Therefore,

the

steam

flow

rate

will

be:

Therefore, the steam flow rate will be:

=

= 5.42

5.42 • 106/960.1

10/960.1 -= 56451bm/h

5645 lbm/h

mnstean - - q/~.steam

0/stea - blsteam

(c) Mean

Mean temperature

temperature difference.

difference.

The effective

effective mean

mean temperature

temperature difference

difference is

is computed

computed as

as ififthe

the boiling-side

boiling-side temperature

temperature were

were

The

constant at

at the

the vapor

vapor exit

exit temperature,

temperature, which

which in

in this

this case

case isis 202.4

202.4F.

The temperature

temperature of

of the

the

constant

~ The

condensing steam

steam is

is also

also constant

constant at

at the

the saturation

saturation temperature,

temperature, which

which isis 228.0~

228.0F at

at 20

20 psia

psia

condensing

from Table

Table A.8.

A8. Therefore,

Therefore, the

the effective

effective mean

mean temperature

temperature difference

difference is:

is:

from

AT% == 2228.0

202.4 == 25.6~

25.6F

ATm

2 8 . 0 -- 202.4

Approximate overall coefficient.

coefficient.

(d) Approximate

Referring to Table

Table 3.5, it is

is seen

seen that

that for

for light

light hydrocarbons

hydrocarbons boiling

boiling on

on the

the shell

shell side

side with

with

Referring

steam on the

the tube

tube side, 200 _<

< UD

Up <_

_< 300 Btu/h

Btu/h -.ft?

Taking the

the mid-range

mid-range value

value

condensing steam

condensing

ft2-.PF

~ Taking

Up == 250

250Btu/h..ft?

.·F for

for preliminary

preliminary design

design purposes.

purposes.

gives UD

Btu/h.. ft2 .~

REBOILERS

R

EBOI LERS

(e)

10/455

10

/ 455

number of tubes.

area and

Heat-transfer area

and number

tubes.

Heat-transfer

54210"

q

_ 5.42

• 106 ~_

__g7?

847 ft 2

U AAT%

UD

Tm

250 •25.6

25.6

A

847

n;=

t - - -=

=

202

-}()}

nD,L

n(/12) • 16

zrDoL

zr(1/12)

16

A

A

represents the

that nnt represents

bundle, i.e., the

the bundle,

the

sections of tubing

Note that

number of straight

the number

straight sections

tubing in the

Note

U-tubes, this

For U-tubes,

number of tube

this is twice

number of tubes.

actual number

tube holes

tubes.

tubesheet. For

twice the

holes in the

the actual

the tubesheet.

number

the value

tables, and

and so

value listed

corresponds to the

listed in the

be referred

so will be

referred to

the tube-count

tube-count tables,

However, it corresponds

of tubes.

tubes.

the number

number of

as the

as

passes.

Number of tube

tube passes.

(f) Number

For condensing

are sufficient.

sufficient.

condensing steam,

steam, two passes

passes are

For

Actual tube

tube count

and bundle

diameter.

count and

bundle diameter.

(g) Actual

This shell

the closest

size is

count is 212 tubes

closest tube

tubes in aa 23.25 in. shell.

is

From Table

Table C.5, the

shell. This

tube count

shell size

From

The bundle

the tubesheet.

at the

course, be

be

the smaller

K-shell at

of course,

diameter of the

the K-shell

bundle diameter

tubesheet. The

diameter will, of

smaller diameter

the

but a value

smaller, but

calculations.

be sufficiently

design calculations.

sufficiently accurate

for design

somewhat smaller,

accurate for

value of 23 in. will be

somewhat

Required overall coefficient.

coefficient.

(h) Required

The required

the usual

usual manner:

heat-transfer coefficient

calculated in the

manner:

required overall

overall heat-transfer

coefficient is

is calculated

The

q

==

nan Do

DL

nt:r

L AAT

Tm

Vreq

Ua --

5.42 x 10 6

5.42 10°

238Btu/h

== 238

Btu/h 9.f

ft 2?.·F

9~

25.6

16 x 25.6

(1/12) x 16

n x (1/12)

212 x Jr

coefficient, hh;.

() Inside

Inside coefficient,

(i)

i.

take:

For condensing

we take:

steam we

condensing steam

For

1500Btu/h.f.·F

Ro)] '2

+ eDi)]-1

[(/DD) (1~hi

(/h, +

[(Do/Di)

~ 1500

Btu/h 9ft 2. ~

h, -= hb.

coefficient, ho

Outside coefficient,

h.

(j) Outside

(j)

in order

which was

safe

presented in

was presented

used in

to ensure

Palen's [1]

Chapter 9, will

[1] method,

be used

will be

in Chapter

method, which

ensure aa safe

order to

Palen's

the Mostinski

on the

conservative) design.

design. It

based on

correlation for

nucleate boiling

the nucleate

It is

Mostinski correlation

for the

(i.e., conservative)

is based

boiling

(i.e.,

to which

account for

applied to

factors are

coefficient, to

for mixture

which correction

effects

mixture effects

correction factors

heat-transfer coefficient,

to account

are applied

heat-transfer

tube bundle.

and convection

bundle.

in the

convection in

the tube

and

coefficient, hh,

boiling coefficient,

Nucleate boiling

(i) Nucleate

(i)

nb

for the

pseudo-critical and

compute the

and pseudo-reduced

the pseudo-critical

pseudo-reduced pressures

The first

the

to compute

step is

first step

is to

pressures for

The

of the

which will

will be

place of

used in

Mostinski correlation:

in place

in the

mixture, which

the Mostinski

be used

the true

true values

values in

correlation:

mixture,

psi

555.4 psi

529.0 ++ 0.60

0.60

551.1 -= 555.4

epc

- ~ x i Pa,

ec,i =015x616.3

- 0.15 x 616.3 ++0.25

0.25 x 529.0

• 551.1

P=}

0.45

P, -=PIP,

P/epc

-= 2250/555.4

5 0 / 5 5 5 . 4 -= 0.45

Ppr

mixture

Equation (9.2a),

with the

the mixture

given in

Mostinski correlation

in Equation

The Mostinski

is used

as given

used as

correlation is

(9.2a), along

along with

The

since Ppr

Also, since

is

given by

by Equation

(9.17a). Also,

correction factor

Equation (9.17a).

as given

factor as

(9.18) is

0.2, Equation

Equation (9.18)

P, >> 0.2,

correction

pressure correction

factor. Thus,

calculate the

the pressure

Thus,

correction factor.

used to

to calculate

used

hnb

0.00622 P~176

# Fm

, --=0.00622P!"F,F%

Fp

1 . 8 p- ~- r 1.8(0.45)0

1-8(0-45) 0 1 7 - 1.5715

1.5715

F, -=1.8PP

- (+0.0176208R07°(1 + 0.0176 0~176

-1

F»=

Fm

To --Th

BBR

R - = TD

T B -=

- 205.6

2 0 5 . 6 -- 1197.6

9 7 . 6 =8.0F

- 8.0 ~

10/456

REBOILERS

Since the actual heat flux is unknown, it is approximated using the required

required duty:

• _

0q

'%DL

ntrcDoL

_

54210°

5.42 x 106

- 6103 Btu/h. ft .22

212/2

212zr(1/12) x %

16 = 6103Bt/h.ft

F%»=

Fm = [1+0.0176(6103)1(9)05][1 + 0.0176(6103)~176

-1 0.7636

= 0.7636

hnb

= 0.00622(555.4)~

0.7 x 1.5715

1.5715 x 0.7636

ha =0.00622(555.4)°"(6103)

hnb =261

= 261 Btu/hf?

Btu/h. ft 2 ·F

.o F

h),

(ii)

(ii)

Bundle boiling coefficient, h

hb

The

The boiling heat-transfer coefficient for the tube bundle is given by Equation (9.19):

hb = hnb Fb + hnc

Although the tube

tube wall temperature

temperature is unknown, with an overall temperature

temperature difference

of 25.6°F,

25.6~ the heat transfer

transfer by natural convection should be small compared to the boiling

Therefore, hp

component. Therefore,

hnc is roughly estimated as 44 Btu/h.ft.F

Btu/h. ft2. ~

component.

The bundle

Db ~ 23in.:

23 in.:

The

bundle convection factor is computed using Equation (9.20) with D,

Ic(Pb.)?D, \

_ 1.0]]0·75

o.75

0.785Db

F=10+01

Fb

= 1.0 + 0.1 C1 (PT/Do)2Do

[

-o±[ «ig.,]"

_ 1.0] 0.75

0.785 x 23

= 1.0 + 0.1 1.0(1.25/1.0

1.0(1.25/1.0)2 xx 1.0

1.0

Fb

= 1.5856

F, =

The outside coefficient is then:

The

h,=h,

+ 44 2

F

ho = hb =261

- - 261 x 1.5856 +

= 458Btu/h

458 Btu/h .ft?

9f t 2 .~

(k)

Overall coefficient.

UD -- [ (1~hi + RDi) (Do/Di) +

Do In (Do~DO + 1/ho + Rno1-13

2 ktube

J

Based on the values in Table 10.2, a boiling-side fouling allowance of 0.0005 h

h.- ft22.- °F

~ /Btu is

deemed

deemed appropriate for this service. For 1-in.

1-in. 14 BWG tubes, D;

Di =

= 0.834in.

0.834 in. from Table B.1.

Taking ktuae

26 Btu/h.

ft. ~ for carbon steel, we obtain:

kn. ~==26

Btu/h ·ft.·F

+ 1.0/458 0.0005] -1

UD-[a»o».

= [ (1/1500) + "e,yy,94,rs-oo

os]

»

2•

(1.0/12) In (1.0/0.834)

+

Up

= 275 Btu/h

Btu/h .f?

9ft 2 .~

F

Un =

F

(1) Check

heat flux and iterate if necessary.

Check heat

0)

A new estimate of the heat flux can be obtained using the overall coefficient

coefficient:

¢~t = Un

UD AT,,

b Tm =

- 275

275 •x25.6

2 5 . 6=

- 7040Btu/h

7040 Btu/h- .f?

ft 2

REBOI

R

E B O I L LEAS

ERS

457

10 / 457

calculate hnb,

previous estimate

estimate used

used to calculate

the previous

this value differs significantly from

steps

from the

h,, steps

Since this

and (k) should

and UD

until consistent

consistent values

Due to the

values for ~@ and

are obtained.

Up are

the

obtained. Due

be repeated

should be

repeated until

(j) and

exact

heat-transfer coefficient

the mean

both the

temperature difference,

mean temperature

the heat-transfer

difference, exact

uncertainty in both

coefficient and

and the

uncertainty

are obtained

obtained after

The following values

not required.

after several

several more

values are

iterations:

required. The

more iterations:

convergence is not

convergence

=

hb

Btu/h 9.f?

ft 2 .o

F

PF

h,, ~ 523

523Btu/h

=

ft2

Btu/h.9ft

@ ~= 7600 Btu/h

UD

Btu/h. .f

ft ?2 .o

F

·F

U, ~ 297

297Btu/h

coefficient exceeds

exceeds the

Btu/h • ft22 .~

required coefficient

coefficient of

• °F by

overall coefficient

significant

The overall

the required

by aa significant

of 238 Btu/h.

The

indicating that

over-sized.

that the

amount (over-design(over-design = 25%), indicating

the reboiler

reboiler is over-sized.

amount

heat flux.

(m) Critical heat

the Mosfinski

boiling on

Mostinski

nucleate boiling

for nucleate

The critical

heat flux for

on a single

tube is calculated

critical heat

calculated using

single tube

using the

The

correlation, Equation

(9.23a):

Equation (9.23a)"

correlation,

~.

qc -= 803

P

" C 'p0.35

r (

Pr) 0"9

9 (1 --P,)99