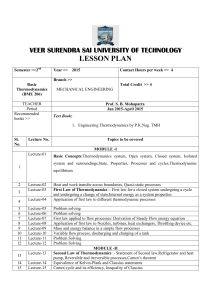

Exhaust gas economiser UNEX™ P The UNEX™ P multi-function exhaust gas economiser is a water tube, forced circulation boiler for steam or hot-water applications. Steam generating capacity: 0.5-5.0 t/h. Hot-water capacity: 400-2,800 kW. Standard design pressure: 10-24 bar (g). UNEX™ P Exhaust gas economiser Sketch of typical UNEX™ P economiser. Each boiler is tailor-made to suit the engine data. Description Vertical and straight exhaust gas ■ Built-in sound absorber UNEX™ P multi-function exhaust passages between the tube rows – ■ Built-in spark arrester gas economiser is a water tube, together with plain tube construc- forced circulation boiler for heat tion – decrease soot build-up on recovery from diesel engine ex- heating surfaces. This construction haust gas. runs without problems even in the The heat transfer surface consists of tions. The economiser is equipped vertical, concentric, parallel steel with a stationary water washing tube coils connected to inlet and and steam soot cleaning system. plete with connections, exhaust gas cones with counterflanges, lifting and fastening lugs and insulation with sheeting. ■ Valves and fittings for the boiler including manual steam soot- outlet manifold pipes. blowers and fixed water washing Features The rounded shape of the gas-tight ■ Compact system with plain tubes steel shell surrounding the tube ■ Easy and quick to install coils is ideal to withstand exhaust ■ User-friendly operation with inte- gas pulsations from the engine. ■ The economiser is supplied com- device. ■ Bolted hatches for maintenance and easy-access inspection doors. ■ Spare parts according to class. grated, continuous and fully automatic capacity control system Accessories (Optional) Sound absorber and by-pass duct ■ Built-in water trap ■ Silencer can be integrated are located inside the tube coils. ■ Built-in water washing device ■ Dumping condenser The sound absorption effect with and steam soot blowers as basic construction is approx. 20 dB(A). standard equipment Product centre: Aalborg Industries Oy, P O Box 9, Kaivopuistontie 33, FIN-26101 Rauma, Finland. Tel.: +358 2 838 3100, Fax: +358 2 823 1133, e-mail:rau@aalborg-industries.fi, website: www.aalborg-industries.com ■ Continuous automatic capacity control DATA SHEET series © Aalborg Industries 2001, August 2001 (Design data are subject to change without prior notice). most demanding operating condi- Scope of supply