DEP SPECIFICATION

Copyright Shell Group of Companies. No reproduction or networking permitted without license from Shell. Not for resale

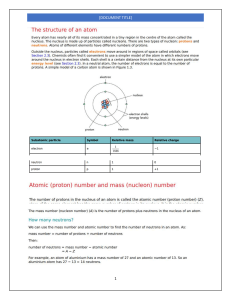

GAS/LIQUID, LIQUID/LIQUID AND GAS/LIQUID/LIQUID

SEPARATORS – TYPE SELECTION AND DESIGN RULES

DEP 31.22.05.12-Gen.

February 2021

DESIGN AND ENGINEERING PRACTICE

© 2021 Shell Group of companies

All rights reserved. No part of this document may be reproduced, stored in a retrieval system, published or transmitted, in any form or by any means, without the prior

written permission of the copyright owner or Shell Global Solutions International BV.

This document has been supplied under license by Shell to:

Wood Canada Limited m.thirunavukkarasu@woodplc.com 13/01/2022 08:33:57

DEP 31.22.05.12-Gen.

February 2021

Page 2

PREFACE

DEP (Design and Engineering Practice) publications reflect the views, at the time of publication, of Shell Global Solutions

International B.V. (Shell GSI) and, in some cases, of other Shell Companies.

These views are based on the experience acquired during involvement with the design, construction, operation and

maintenance of processing units and facilities. Where deemed appropriate DEPs are based on, or reference international,

regional, national and industry standards.

The objective is to set the standard for good design and engineering practice to be applied by Shell companies in oil and

gas production, oil refining, gas handling, gasification, chemical processing, or any other such facility, and thereby to help

achieve maximum technical and economic benefit from standardization.

The information set forth in these publications is provided to Shell companies for their consideration and decision to

implement. This is of particular importance where DEPs may not cover every requirement or diversity of condition at each

locality. The system of DEPs is expected to be sufficiently flexible to allow individual Operating Units to adapt the information

set forth in DEPs to their own environment and requirements.

When Contractors or Manufacturers/Suppliers use DEPs, they shall be solely respons ble for such use, including the quality

of their work and the attainment of the required design and engineering standards. In particular, for those requirements not

specifically covered, the Principal will typically expect them to follow those design and engineering practices that will achieve

at least the same level of integrity as reflected in the DEPs. If in doubt, the Contractor or Manufacturer/Supplier shall, without

detracting from his own responsibility, consult the Principal.

The right to obtain and to use DEPs is restricted, and is typically granted by Shell GSI (and in some cases by other Shell

Companies) under a Service Agreement or a License Agreement. This right is granted primarily to Shell companies and

other companies receiving technical advice and services from Shell GSI or another Shell Company. Consequently, three

categories of users of DEPs can be distinguished:

1)

Operating Units having a Service Agreement with Shell GSI or another Shell Company. The use of DEPs by these

Operating Units is subject in all respects to the terms and conditions of the relevant Service Agreement.

2)

Other parties who are authorised to use DEPs subject to appropriate contractual arrangements (whether as part of a

Service Agreement or otherwise).

3)

Contractors/subcontractors and Manufacturers/Suppliers under a contract with users referred to under 1) or 2) which

requires that tenders for projects, materials supplied or - generally - work performed on behalf of the said users comply

with the relevant standards.

Subject to any particular terms and conditions as may be set forth in specific agreements with users, Shell GSI disclaims

any liability of whatsoever nature for any damage (including injury or death) suffered by any company or person whomsoever

as a result of or in connection with the use, application or implementation of any DEP, combination of DEPs or any part

thereof, even if it is wholly or partly caused by negligence on the part of Shell GSI or other Shell Company. The benefit of

this disclaimer shall inure in all respects to Shell GSI and/or any Shell Company, or companies affiliated to these companies,

that may issue DEPs or advise or require the use of DEPs.

Without prejudice to any specific terms in respect of confidentiality under relevant contractual arrangements, DEPs shall not,

without the prior written consent of Shell GSI, be disclosed by users to any company or person whomsoever and the DEPs

shall be used exclusively for the purpose for which they have been provided to the user. They shall be returned after use,

including any copies which shall only be made by users with the express prior written consent of Shell GSI. The copyright of

DEPs vests in Shell Group of companies. Users shall arrange for DEPs to be held in safe custody and Shell GSI may at any

time require information satisfactory to them in order to ascertain how users implement this requirement.

All administrative queries should be directed to the DEP Administrator in Shell GSI.

This document has been supplied under license by Shell to:

Wood Canada Limited m.thirunavukkarasu@woodplc.com 13/01/2022 08:33:57

DEP 31.22.05.12-Gen.

February 2021

Page 3

2.1

2.2

2.3

2.4

3.

3.1

3.2

3.3

4.

4.1

4.2

4.3

4.4

4.5

4.6

5.

5.1

5.2

5.3

5.4

6.

6.1

6.2

6.3

7.

TABLE OF CONTENTS

INTRODUCTION ...............................................................................................4

SCOPE ..............................................................................................................4

DISTRIBUTION, INTENDED USE AND REGULATORY

CONSIDERATIONS...........................................................................................4

DEFINITIONS ....................................................................................................5

CROSS-REFERENCES ..................................................................................10

SUMMARY OF MAIN CHANGES....................................................................11

COMMENTS ON THIS DEP ............................................................................11

DUAL UNITS....................................................................................................11

NON NORMATIVE TEXT (COMMENTARY) ...................................................11

SELECTION CRITERIA FOR GAS/LIQUID, LIQUID/LIQUID AND

GAS/LIQUID/LIQUID (THREE-PHASE) SEPARATORS ................................12

GENERAL ........................................................................................................12

TYPICAL DESIGN MARGINS FOR UPSTREAM APPLICATIONS ................12

DESIGN MARGINS FOR REFINERIES AND CHEMICAL PLANTS ..............12

SELECTION CRITERIA AND STRATEGY .....................................................13

DESIGN RULES FOR NOZZLES ....................................................................16

PROCESS NOZZLES ......................................................................................16

MANWAYS ......................................................................................................17

INSTRUMENT NOZZLES ................................................................................17

DESIGN RULES FOR INTERNALS ................................................................17

GENERAL ........................................................................................................17

INLETS ............................................................................................................18

BAFFLES .........................................................................................................19

WEIRS .............................................................................................................20

GAS PHASE INTERNALS ...............................................................................20

LIQUID PHASE INTERNALS ..........................................................................28

DESIGN RULES FOR VESSEL SIZING .........................................................30

SEPARATION AREA(S) AND MAXIMUM FLOW RATES ..............................30

RESIDENCE TIMES, HOLD-UP TIMES, LEVELS AND WEIR HEIGHTS......35

VESSELS AND INTERNAL LAYOUT..............................................................37

OVERALL SIZE, L/D ........................................................................................46

OTHER SEPARATOR DESIGNS ....................................................................46

CYCLONE VESSELS ......................................................................................46

FILTER SEPARATOR .....................................................................................48

COALESCERS ................................................................................................50

REFERENCES ................................................................................................54

APPENDIX A.

APPENDICES

DEFINED PARAMETERS ...............................................................................55

1.

1.1

1.2

1.3

1.4

1.5

1.6

1.7

1.8

2.

This document has been supplied under license by Shell to:

Wood Canada Limited m.thirunavukkarasu@woodplc.com 13/01/2022 08:33:57

DEP 31.22.05.12-Gen.

February 2021

Page 4

1.

INTRODUCTION

1.1

SCOPE

This DEP specifies requirements and gives recommendations for the selection and design

of gas/liquid, liquid/liquid and three-phase (gas/liquid/liquid) separators.

Settling tanks, e.g., those used for the dewatering of crude, and basin-type settlers such as

the API interceptor used for de-oiling of oil-contaminated surface water, are excluded from

the scope of this DEP.

In this DEP two-phase and three-phase separators are also referred to as two-phase and

three-phase settlers, respectively. The term "settling" will also be used for the separation of

light-phase droplets in this DEP in order to be consistent with the term "settlers" which is

used both for the separation of light-phase and heavy-phase droplets.

Design rules are given for the following types of separators:

o

o

o

o

o

o

o

o

o

Knock-out drum

Vessel with mesh pad demister

Vessel with vane- type of demister

Separators of the SMS family (SMS, SVS, SMSM, SMMS)

Cyclone with tangential inlet (conventional cyclone)

Filter separator

Horizontal settler (for both L/L and G/L/L separation)

Plate pack settlers (both horizontal and vertical)

Coalescers (with either a coalescer bed, mat or cartridges)

Users of this DEP should first consult (2) to make an initial selection of a suitable type of

separator for a given duty. After selection of the desired separator, the design rules can be

obtained from (3), (4), (5) or (6).

This is a revision of the DEP of the same number dated February 2018, see (1.5) regarding

the changes.

1.2

DISTRIBUTION, INTENDED USE AND REGULATORY CONSIDERATIONS

Unless otherwise authorised by Shell GSI, the distribution of this DEP is confined to Shell

companies and, where necessary, to Contractors and Manufacturers/Suppliers nominated

by them. Any authorised access to DEPs does not for that reason constitute an

authorization to any documents, data or information to which the DEPs may refer.

This DEP is intended for use in facilities related to oil and gas production, gas handling, oil

refining, chemical processing, gasification, distribution and supply/marketing. This DEP may

also be applied in other similar facilities.

When DEPs are applied, a Management of Change (MOC) process shall be implemented;

this is of particular importance when existing facilities are to be modified.

If national and/or local regulations exist in which some of the requirements could be more

stringent than in this DEP, the Contractor shall determine by careful scrutiny which of the

requirements are the more stringent and which combination of requirements will be

acceptable with regards to the safety, environmental, economic and legal aspects. In all

cases the Contractor shall inform the Principal of any deviation from the requirements of

this DEP which is considered to be necessary in order to comply with national and/or local

regulations. The Principal may then negotiate with the Authorities concerned, the objective

being to obtain agreement to follow this DEP as closely as possible.

This document has been supplied under license by Shell to:

Wood Canada Limited m.thirunavukkarasu@woodplc.com 13/01/2022 08:33:57

DEP 31.22.05.12-Gen.

February 2021

Page 5

1.3

DEFINITIONS

1.3.1

General definitions

The Contractor is the party that carries out all or part of the design, engineering,

procurement, construction, commissioning or management of a project or operation of a

facility. The Principal may undertake all or part of the duties of the Contractor.

The Manufacturer/Supplier is the party that manufactures or supplies equipment and

services to perform the duties specified by the Contractor.

The Principal is the party that initiates the project and ultimately pays for it. The Principal

may also include an agent or consultant authorised to act for, and on behalf of, the

Principal.

The word shall indicates a requirement.

The word should indicates a recommendation.

The word may indicates a permitted option.

1.3.2

Specific definitions

See (1.3.4) and (1.3.5)

1.3.3

Abbreviations

The following abbreviations are specific to this DEP.

Term

Definition

conc

Local volumetric fraction of dispersed phase

GOR

Gas to Oil Ratio

GVF

Gas Volume Fraction

HAZOP

Hazard and Operability Study

HEMP

Hazards and Effects Management Process

HVU

Crude High Vacuum Units

ID

Inside Diameter

LOPA

Layer of Protection Analysis

NFA

Net Free Area (fraction)

PP

Polypropylene

SMMS

Schoepentoeter Mistmat1 Mistmat2 Swirldeck

SMS

Schoepentoeter Mistmat Swirldeck

SMSM

Schoepentoeter Mistmat Swirldeck Mistmat

SVS

Schoepentoeter Vane pack Swirldeck

TFC

Shell Twin-Flange Coalescer

TGU

Thermal Gasoil Units

TTL

Top Tangent Line

VBU

VisBreaker Units

This document has been supplied under license by Shell to:

Wood Canada Limited m.thirunavukkarasu@woodplc.com 13/01/2022 08:33:57

DEP 31.22.05.12-Gen.

February 2021

Page 6

1.3.4

List of Symbols

The symbols and terminology used in the DEP are summarised in Table 1.1 through

Table 1.5.

Symbol

A

Ar

C

D

d

Eff

Table 1.1

General symbols

Definition

Unit(SI)

Area

m2

Archimedes number, see (1.3.5)

Constant

Internal diameter of vessel, skirt, large

m

pipe, etc. (if no subscript, internal

diameter of vessel)

Diameter of small pipe, nozzle, bubble,

m

or droplet, plate distance (e.g., of plates

in plate pack)

QL ,out

Efficiency: Eff =

Unit(USC)

ft2

ft

ft

-

QL ,in

Fr

F

G

g

H

h

K

L

M

N

P

Q

Re

t

u

V

W

Froude number, see (1.3.5)

Derating factor

Gas

Acceleration due to gravity

m/s2

ft/s2

Height (total)

m

ft

Height (components)

m

ft

Friction loss factor

Length

m

ft

Mass flow rate

kg/s

lb/s

Number (number of vanes, number

of cyclones, etc.).

Pressure

Pa

psi

Volumetric flow rate

m3/s

ft3/s

Reynolds number see (1.3.5)

thickness

m

ft

Velocity

m/s

ft/s

Volume

m3

ft3

Width

m

ft

Table 1.2

Level terminology

Level

Definition

Unit(SI)

Unit(USC)

LA(H)

High level alarm

m

ft

LA(L)

Low level alarm

m

ft

LZA(HH)

High – High level trip

m

ft

LZA(LL)

Low – Low level trip

m

ft

NL

Normal level

m

ft

This document has been supplied under license by Shell to:

Wood Canada Limited m.thirunavukkarasu@woodplc.com 13/01/2022 08:33:57

DEP 31.22.05.12-Gen.

February 2021

Page 7

σ

φ

Table 1.3

Greek symbols

Definition

Unit(SI)

Difference (used in conjunction with

other symbols)

Porosity (of wiremesh, baffle plate)

Dynamic viscosity

Pas

Angle

°

Ratio of the specific heats (Cp/Cv)

Gas load factor, see (1.3.5)

m/s

Density

kg/m3

Gas/liquid interfacial tension

N/m

Flow parameter, see (1.3.5)

-

Φ

Phase fraction

Greek

∆

ε

η

θ

κ

λ

ρ

-

Unit(USC)

lb/(fts)

°

ft/s

lb/ft3

lb/s2

-

Table 1.4 Subscripts

Subscript

Definition

Ax

Axial

b

bulk

bed

Coalescer bed

c

Continuous Phase

Cf

Filter part of candle (in filter separators)

col

Collection compartment

coleff

Effective length of collection compartment

cont

Control requirements or specific control band

conc

Local volumetric fraction of dispersed phase

contot

Total control band

crit

Critical

crit50

Related to droplet with 50% chance of removal in G/L separator

crit99

Related to droplet with 99% chance of removal in G/L separator

Cs

Cross section or cross-sectional area

Ct

Candle tube (in filter separators)

Db

Dispersion band

D

Droplet

Dp

Drain pipe

F

Front

feed

Related to feed flow

Fp

Related to feed pipe

Fw

Front weir of a collection compartment

g

gas

This document has been supplied under license by Shell to:

Wood Canada Limited m.thirunavukkarasu@woodplc.com 13/01/2022 08:33:57

DEP 31.22.05.12-Gen.

February 2021

Page 8

Subscript

Definition

H

hydraulic diameter

heavy

heavy liquid phase

In

related to inlet

int

L/L interface

l,L

Liquid

light

Light liquid phase

Laminar

Laminar flow

Loss

Part of plate pack front face available for flow

low

Lower part

m

mixture

max

Maximum

min

Minimum

net

Effective area of plate pack

Noz

Nozzle

out

Outlet

out, l

At light phase outlet

ow

Overflow weir of a collection compartment in horizontal three-phase

settler with double weir

p

At constant pressure (as in Cp)

p

Droplet or particle

P

Related to physical properties of gas and liquid phases

perfpl

Perforated plate

pp

Plate pack for L/L separation

ret

Retention time

sch

Related to Schoepentoeter or vane inlet device

sd

Related to Swirl-deck

set

Settling compartment or settling process

sonic

Related to sonic velocity

spec

Specified

st

Swirltube

tl

Transition from turbulent to laminar flow

turb

Turbulent flow

This document has been supplied under license by Shell to:

Wood Canada Limited m.thirunavukkarasu@woodplc.com 13/01/2022 08:33:57

DEP 31.22.05.12-Gen.

February 2021

Page 9

Subscript

Definition

up

Underflow passage of front weir of heavy-phase compartment in

horizontal

three-phase settler with double weir

vp

Vane pack

v

At constant volume (as in Cv)

vb

Vane box

vfb

Related to distance between bottom plate and vortex finder in

cyclones

ves

Related to vessel

vo

Vane entrance opening (in Schoepentoeters)

w

weir

wi

Wire (of wiremesh)

wm

Wiremesh

ww

The two heavy-phase weirs in horizontal three-phase settler with

weir configuration

l

Related to feed inlet or number of constant

η

related to dynamic viscosity of liquid

ɸ

related to flow parameter

Table 1.5 Superscript

Superscript

Definition

*

Density correction

This document has been supplied under license by Shell to:

Wood Canada Limited m.thirunavukkarasu@woodplc.com 13/01/2022 08:33:57

DEP 31.22.05.12-Gen.

February 2021

Page 10

1.3.5

List of Formulae

Table 1.6

Term

Formula

Archimedes

number

Flow parameter

Froude number

σ3

g (ρ l − ρ g )

The Archimedes number is

used in vane pack

calculations

Ql

Qg

ρl

ρg

The flow parameter is used to

characterise the type of

gas/liquid feed into the vessel

or the relative importance of

the liquid load approaching

the separator internal

The Froude number is used

for liquid nozzles

Fr1 = u1

ρl

gL ρ 2 − ρ1

Qg

ρg

Ag

ρl − ρ g

Reynolds number

Re =

ρuD

η

Pressure drop

coefficient

Ck =

Gas Load Factor

1.4

ρl

η l2

Ar =

φ=

Formulae

Note

λ=

∆P

1 2

ρu

2

The gas load factor is also

referred to as K-factor or

Souders-Brown velocity. This

is a superficial gas velocity

modified with a gas density

scaling factor which accounts

to a large extent for the effect

of operating pressure

A ratio of momentum and

viscous forces, used to

determine flow regime in

plate packs

Constant coefficient varying

with geometry, for

momentum based pressure

drop

CROSS-REFERENCES

Where cross-references to other parts of this DEP are made, the referenced section or

clause number is shown in brackets ( ). Other documents referenced by this DEP are listed

in (7).

This document has been supplied under license by Shell to:

Wood Canada Limited m.thirunavukkarasu@woodplc.com 13/01/2022 08:33:57

DEP 31.22.05.12-Gen.

February 2021

Page 11

1.5

SUMMARY OF MAIN CHANGES

This DEP is a revision of the DEP of the same number dated February 2018. This is an

administrative update only to align the layout of this DEP to a new publishing application.

The February 2017 revision of this DEP represents the most recent major update, and the

following were the main non-editorial changes.

1.6

Section/Clause

Change

4.3

The requirements for calming baffles in L/L or G/L/L separators

changed from specific Net Free Area requirements to resistance

coefficient requirements for the baffles

4.5

The maximum gas load factor for horizontal KO vessels (with and

without demisters) is now calculated for the gas phase above

(LA(H) and not above LZA(HH)

4.5.3

Factors in Table 4.3 changed to match CK

COMMENTS ON THIS DEP

Comments on this DEP may be submitted to the Administrator using one of the following

options:

Shell DEPs Online

(Users with access to

Shell DEPs Online)

Enter the Shell DEPs Online system at

https://www.shelldeps.com

Select a DEP and then go to the details

screen for that DEP.

Click on the “Give feedback” link, fill in the

online form and submit.

DEP Feedback System

(Users with access to

Shell Wide Web)

Enter comments directly in the DEP

Feedback System which is accessible from

the Technical Standards Portal

http://sww.shell.com/standards.

Select “Submit DEP Feedback”, fill in the

online form and submit.

DEP Standard Form

(other users)

Use DEP Standard Form 00.00.05.80-Gen. to

record feedback and email the form to the

Administrator at standards@shell.com.

Feedback that has been registered in the DEP Feedback System by using one of the above

options will be reviewed by the DEP Custodian for potential improvements to the DEP.

1.7

DUAL UNITS

This DEP contains both the International System (SI) units, as well as the corresponding

US Customary (USC) units, which are given following the SI units in brackets. When agreed

by the Principal, the indicated USC values/units may be used.

1.8

NON NORMATIVE TEXT (COMMENTARY)

Text shown in italic style in this DEP indicates text that is non-normative and is provided as

explanation or background information only.

Non-normative text is normally indented slightly to the right of the relevant DEP

clause.

This document has been supplied under license by Shell to:

Wood Canada Limited m.thirunavukkarasu@woodplc.com 13/01/2022 08:33:57

DEP 31.22.05.12-Gen.

February 2021

Page 12

2.

SELECTION CRITERIA FOR GAS/LIQUID, LIQUID/LIQUID AND GAS/LIQUID/LIQUID

(THREE-PHASE) SEPARATORS

2.1

GENERAL

1.

The design shall be based on maximum gas, maximum liquid flow rates and slug

volume while taking into account a design margin or surge factor and consistent with

the control philosophy.

a.

The minimum design margin for any separator vessel shall be 1.1.

Typical design margins for primary separators are given in Table 2.1 and Table 2.2.

2.

2.2

Design margins may be reduced or eliminated (subject to the approval of the Principal)

based on more detailed knowledge of system behaviour and dynamics (e.g., pipeline

profile, pipeline holdup) and considerations of consequences of overload of separator

by slugs generated by transient conditions.

TYPICAL DESIGN MARGINS FOR UPSTREAM APPLICATIONS

Table 2.1 Offshore applications

1. Separator handling natural-flowing production from:

Design margin

Direct vertical access (DVA) wells on their own platform

1.2

another platform or well jacket in shallow water

1.3

another platform or well in deep water

1.4

2. Separator handling gas lifted production from:

DVA wells on their own platform

1.4

Wells on another platform, or well jacket

1.5

Subsea wells

1.5

Table 2.2 Onshore applications

1. Separator handling natural flowing production, or gas plant inlet

Design margin

separator in:

flat or low rolling country

1.2

hilly country

1.3

2. Separator handling gas lifted production from:

2.3

flat or low rolling country

1.2

hilly country

1.3

DESIGN MARGINS FOR REFINERIES AND CHEMICAL PLANTS

Typically design margins range from 1.15 to 1.25.

1.

If two immiscible liquids are present in the feed and the flow rate of the lower density

liquid is at least 5 % vol. of the total liquid flow rate, then the physical properties of the

lighter liquid shall be used in the gas handling calculations.

2.

Pressure drop calculations shall be based on maximum gas and liquid flow rates.

3.

When two immiscible liquids are present, the pressure drop calculations shall take into

account the apparent viscosity of the emulsion.

This document has been supplied under license by Shell to:

Wood Canada Limited m.thirunavukkarasu@woodplc.com 13/01/2022 08:33:57

DEP 31.22.05.12-Gen.

February 2021

Page 13

2.4

SELECTION CRITERIA AND STRATEGY

This section outlines various criteria and features which play a role in separator

performance and selection. For Upstream production separators, refer to

DEP 20.04.10.11‑Gen. for selection of the overall process line-up, then use the below

guidance for selection of individual separator types.

To facilitate the choice of a separator type for a given application, tables 2.3, 2.4 and 2.5

summarise the performance characteristics of various gas/liquid and liquid/liquid and

gas/liquid/liquid separators.

During selection, the separators are compared on the following points:

o

o

o

o

o

1.

Gas handling capacity:

Maximum capacity (gas load factor)

Turndown ratio (is ratio of design flow and minimum flow)

Liquid removal efficiency:

Overall

With respect to fine mist

With respect to the possible flooding above the maximal gas load factor

(flooding will cause a sharp decrease in efficiency)

Liquid handling capacity:

Slugs

Droplets (overloading of separation internal)

Liquid/liquid separation efficiency:

Overall

With respect to fine dispersed droplets

With respect to gas break out affecting liquid/liquid separation

With respect to the possible slugging which might cause a sharp decrease in

efficiency

Fouling tolerance:

Sand

Fouling material (e.g., wax and scale)

Pressure drop

The following selection strategy shall be used:

a.

Define the requirements for the separator.

With the aid of Table 2.3, Table 2.4 and Table 2.5, a number of separators can

then be ruled out. The tables use imprecise terms (e.g., fouling service, high

temperature) that for which it is impractical to define exact thresholds. They are

provided to suggest a framework for a competent designer to use when

evaluating the different options.

Typical outlet qualities of upstream equipment are included in

DEP 20.04.10.11‑Gen.

b.

Check whether there are limitations which will rule out horizontal or vertical

vessels.

c.

Check the appropriate design rules for each separator out of those remaining.

Based on these criteria, a final choice of separator can be made.

This document has been supplied under license by Shell to:

Wood Canada Limited m.thirunavukkarasu@woodplc.com 13/01/2022 08:33:57

DEP 31.22.05.12-Gen.

February 2021

Page 14

Table 2.3 Screening of two-phase liquid-liquid separators

Horz. settler

Horz. Settler w/

Coalescer w/

platepack

cartridges

Water cut > 0.05

good

good

Bulk separation

good

Improved separation

good

Fine droplets

poor

poor

good

Fouling service

good

poor

High temperature

poor

Table 2.4 Screening of three-phase gas-liquid-liquid separators

Horz.

settler

w/ boot

Horz.

settler

w/ weir

Horz. settler

w/ platepack

& weir

GVF < 0.9

GVF > 0.95

Slugging

Liquid quality

restrictions

good

good

good

good

good

good

good

Fouling service

good

good

good

Vert.

settler

Vert. settler

w/ platepack

good

good

poor

poor

good

This document has been supplied under license by Shell to:

Wood Canada Limited m.thirunavukkarasu@woodplc.com 13/01/2022 08:33:57

DEP 31.22.05.12-Gen.

February 2021

Page 15

Table 2.5 Comparison of various gas-liquid separators

VKO

HKO

VW

HW

VV1

VV2

HV

SMS

SMMS

SVS

CT

FS

Low

∞

Low

∞

Moderate

4

Moderate

4

High

3

High

3

High

3

Very high

10

Very high

4

Very high

2

Moderate

∞

0.9-0.95

Very low

N

0.9-0.95

Very low

N

> 0.98

Very high

Y

>0. 98

Very high

Y

> 0.96

> 0.96

> 0.96

Moderate Moderate Moderate

If double-pocket vanepack: N; for

single-pocket vane pack or in case

of straight vanes: Y

> 0.99

Very high

N

> 0.98

High

N

>0. 96

Low

N

50-80

Very high

Y

High

High

Very high

High

High

High

Very high

High

Very low

Low

High

High

High

High

High

High

Low

Very high

Very high

Low

Low

Low

Moderate

Very high

Low

sticky material

Very high

Very high

Very low

Very low

Very low

Moderate

Very high

Very low

Pressure drop

Very low

Very low

Low

Low

Moderate

Moderate

High

Moderate-Very high

(vs. loading)

Gas handling

max. capacity (λ)

turndown max . flow

min flow

Typical Liquid removal

efficiency

overall

wrt. fine mist

flooding above λmax

(Y/N)

Liquid handling capacity

as slugs

as droplets (QL,max)

Fouling tolerance

sand

VKO

HKO

VW

HW

VV1

VV2

HV

Vertical knock-out drum

Horizontal knock-out drum

Vertical flow wiremesh demister

Horizontal flow wiremesh demister

Vertical in-line separator with horizontal flow vane pack

Vertical two-stage separator with vertical flow vane pack

Horizontal vane-type demister

High

Moderate

Very high

Moderate

If double-pocket vanepack: very

low; if single-pocket vane pack: low,

if straight vanes: moderate

If double-pocket vanepack: very

low; if single-pocket vane pack: low,

if straight vanes: moderate

Low

Low

SVS

SMS

SMMS

CT

FS

Low

Schoepentoeter-vane pack-swirldeck separator

Schoepentoeter-mistmat-swirldeck separator

Schoepentoeter-mistmat-mistmat-swirldeck separator

Cyclone with tangential inlet (conventional cyclone)

Filter separator

This document has been supplied under license by Shell to:

Wood Canada Limited m.thirunavukkarasu@woodplc.com 13/01/2022 08:33:57

DEP 31.22.05.12-Gen.

February 2021

Page 16

3.

DESIGN RULES FOR NOZZLES

3.1

PROCESS NOZZLES

3.1.1

Feed nozzles and connected piping

All velocities and densities in this section refer to the inlet superficial mixture velocity and

mixture density.

1.

Valves, pipe expansions or contractions, bends, flow meters and other components

which generate a sudden pressure drop should be more than 10 pipe diameters from

the inlet nozzle.

a.

If a valve is less than 10 pipe diameters from the inlet nozzle, then a full-bore gate

or ball type valve should be used, fully open in normal operation.

b.

If a pressure reduction valve or flow control valve is needed it should be placed

downstream of the separator or a low-shear valve used.

c.

For vessels with normally no liquid in the feed, the requirement of a 10 diameters

length of straight pipe may be relaxed to 3 diameters length.

2.

For inlet devices with swirling flow (e.g., cyclones), bends shall be used in the

horizontal plane only, and only with curvature in the same direction as the swirl of the

inlet.

3.

For inlets devices without swirling flow, bends shall be used in the vertical plane only,

through the axis of the feed nozzle.

a.

If this results in a riser system just upstream of the vessel, transient flow (surging

or slugging) could occur in case of a high feed flow parameter φfeed and the vessel

should be designed to accommodate this.

4.

Piping layout and location/design of any reducer in multiphase flow shall be such that

no pockets exist where liquids can accumulate and generate surges or slugs.

5.

For horizontal vessels, the feed nozzle shall be located on the top or in the head of the

vessel.

Normally, the feed nozzle is elevated above the highest possible liquid level, see

Table 5.2 and Table 5.4.

6.

The feed nozzle shall have the same internal diameter as the upstream piping.

7.

The following momentum criteria shall be met as applicable to the type of inlet selected:

a.

No inlet, or deflector baffle: ρm um2 ≤ 1500 Pa (1000 lb/ft s2)

b.

Half-open pipe: ρm um2 ≤ 3000 Pa (2000 lb/ft s2)

c.

For the special case of an in-line vane separator see (4.5.2.3).

d.

Schoepentoeter (and Schoepentoeter Plus): ρm um2 ≤ 8000 Pa (5370 lb/ft s2)

e.

Inlet cyclone: ρm um2 ≤ 20000 Pa (13400 lb/ft s2)

f.

For higher inlet momentum than stated here, process and integrity checks shall be

made in consultation with the Principal.

8.

For feeds with normally no liquid, the design margin may be omitted from the inlet

momentum calculation.

9.

In units or separators where the inlet velocity can be very high (i.e., exceeding 40 m/s

(131 ft/s)), a Schoepentoeter shall be used as the feed inlet device with the following

velocity limits:

a.

To prevent erosion: ug ≤ 70m /s (230 ft /s)

b.

To prevent choking or damage due to vibrations: ug ≤ 0.8 usonic ,g

This document has been supplied under license by Shell to:

Wood Canada Limited m.thirunavukkarasu@woodplc.com 13/01/2022 08:33:57

DEP 31.22.05.12-Gen.

February 2021

Page 17

10. The Principal’s distillation specialists shall be consulted for proprietary requirements

beyond those stated in this DEP for feed inlet devices associated with Crude High

Vacuum Units (HVUs).

3.1.2

Gas outlet nozzle and connected piping

1.

The gas outlet nozzle should be fitted on the top of the vessel.

a.

3.1.3

2.

The gas outlet nozzle shall not be smaller than the downstream piping.

3.

The momentum through the gas outlet nozzle should satisfy ρgug2 ≤ 4500 Pa

(3000 lb/ft-s2).

4.

The piping leading from the gas outlet nozzle shall have the same diameter as the

nozzle for a distance of a minimum of 2 pipe diameters downstream of the nozzle

before any bends, reducers, valves or other components.

Liquid outlet nozzles and connected piping

1.

The diameter of liquid outlet nozzles should be chosen such that the liquid velocity

does not exceed 1 m/s (3.3 ft/s).

a.

3.2

Nozzle velocities up to 2.5 m/s (8 ft/s) may be accepted for revamps, if the nozzle

velocity and minimum liquid static height above the nozzle satisfies Frl<1.

2.

The diameter of a liquid outlet nozzle shall be at least DN 50 (NPS 2).

3.

Liquid outlet nozzles shall be equipped with a vortex breaker in accordance with

Standard Drawing S 10.010.

4.

The piping leading from a liquid outlet nozzle shall have the same diameter as the

nozzle for a distance of a minimum of 2 pipe diameters downstream of the nozzle

before any bends, reducers, valves or other components.

MANWAYS

1.

Manhole inner diameter should be designed as per the applicable pressure vessel

code.

a.

2.

3.3

In a vertical separator, it should be fitted in the middle of the top head.

For vessels with diameter 1.2 m (48 in) and below, body flanges should be

evaluated as an option.

For horizontal vessels with a weir, a minimum of one manhole shall be placed

upstream of the weir arrangement.

INSTRUMENT NOZZLES

1.

Instrument nozzles shall be a minimum of DN 50 (NPS 2).

2.

Instrument nozzle location and orientation should be evaluated versus plugging or

clogging by components in the feed stream (e.g., solids, wax, asphaltenes, scale).

3.

Level instrument nozzles, including nozzles for instrumented level process shutdown,

shall be located in the outlet section of the vessel so that no pressure drop from

internals can influence the measured level relative to the level near the outlets.

4.

Level instrument nozzles shall be mounted on the vessel wall, not on process nozzles.

5.

Level instrument nozzles should be mounted on the cylindrical part of the vessel, not in

the end caps.

4.

DESIGN RULES FOR INTERNALS

4.1

GENERAL

1.

All internals shall be removable through the manways.

2.

Internals should be fastened securely to the vessel by supporting lugs, and bolted to

these with double nuts.

This document has been supplied under license by Shell to:

Wood Canada Limited m.thirunavukkarasu@woodplc.com 13/01/2022 08:33:57

DEP 31.22.05.12-Gen.

February 2021

Page 18

4.2

INLETS

The choice between Schoepentoeter and half-open pipe will be a trade-off between the

required separation efficiency of the inlet internal and costs.

When a simple deflector plate arrangement is used as feed inlet device, then typical

dimensions for side feed inlet nozzle are provided in Figure 4.1.

Figure 4.1 Deflector plate arrangement for feed inlet of vertical knock-out drum

0.75d

0.75d

2d

d

1.5d

0.3D

Sides open

LZA(HH)

D=diameter vessel

Side view

Top view

1.

Mechanical vibrations due to the momentum of the flow should be considered when

determining the thickness of the deflector plates.

2.

For vertical vessels (G/L) with diameter less than 0.5 m (1 ft 8 in), the feed nozzle

should be fitted with a half-open pipe inlet device, with the opening directed downwards

3.

For vertical vessels (G/L) with diameter of 0.5 m (1ft 8 in) and larger and inlet nozzle

sizes of 0.15 m (6 in) and larger, either a half-open pipe or a Schoepentoeter inlet

device should be used.

4.

For horizontal vessels (G/L), a Schoepentoeter inlet device should be used.

5.

If a half-open pipe is used, its last section should be horizontal, pointing opposite to the

flow direction in the vessel and with its opening directed upwards.

6.

If the separation efficiencies of inlet devices are required for calculating the flow

parameter upstream of a wiremesh demister, φwm, the following formulae shall be used:

7.

a.

If a Schoepentoeter is used, φwm = 0.05 φfeed

b.

If a half-open pipe is used, assume φwm = φfeed

c.

If a simple deflector baffle or open nozzle is used, assume ϕwm=0.5 ϕfeed

For the design of Schoepentoeters, refer to DEP 31.20.20.31‑Gen.

This document has been supplied under license by Shell to:

Wood Canada Limited m.thirunavukkarasu@woodplc.com 13/01/2022 08:33:57

DEP 31.22.05.12-Gen.

February 2021

Page 19

8.

For L/L separators, one of the following options may be used for the inlet device:

a.

an elbowed pipe directed towards the vessel head;

i.

b.

9.

The inner diameter of the elbow shall be equal to that of the feed nozzle.

a vertical pipe with slots.

i.

The total area of the slots should be 3.3 times the cross-sectional area of the

feed nozzle.

ii.

The slots should be on each lateral side and on the upstream side (i.e., the

side facing the nearest vessel head)

For G/L/L(three-phase) separators, the choice of the feed inlet device should be based

on the GVF (gas volumetric fraction) as Table 4.1

Table 4.1

Gas Volumetric Fraction (GVF)

Feed Inlet Device Selection

Recommended Inlet Devices

GVF < 0.15

•

•

•

0.15 < GVF < 0.7

0.7 < GVF < 0.92

0.92 < GVF

4.3

•

•

•

•

•

Horizontal pipe section (elbow)

Deflector Plate

Horizontal half-open pipe with opening directed

upwards

Schoepentoeter

Inlet cyclone (liquid momentum dominated flows)

Schoepentoeter

Inlet cyclone (liquid momentum dominated flows)

Schoepentoeter

BAFFLES

1.

A calming baffle shall be installed before the settling compartment of horizontal

separators (double calming baffle is preferred) to prevent flow maldistribution in the

settling compartment.

2.

If double baffles are applied, the pressure drop coefficient Ck should be a minimum of

50 across the first baffle and a minimum of 25 across the second baffle, giving a

combined coefficient of a minimum of 75.

3.

a.

If only one baffle is installed, Ck should be a minimum of 75.

b.

If there is a pressure reducing internal immediately downstream of the baffle

plates, e.g. a plate pack, the pressure drop coefficient of the internal should be

combined with the coefficient of the baffle plates to give the minimum coefficient of

75.

c.

The total pressure drop coefficient over the baffles or over the baffles and the

pressure reducing internal downstream of the baffles should not be higher than

100.

d.

For inlet designs giving highly maldistributed flow (when peak liquid velocity is

150% higher than the average liquid velocity), the pressure drop coefficient should

be increased in consultation with the Principal.

The pressure drop coefficient shall be calculated as Eqn 4.1.

Ck = 2

1− ε

ε2

Equation 4.1

where ε is the net free area of the perforated plate

4.

The holes shall be evenly distributed over the plate.

5.

The hole size should be a minimum of 12 mm (0.5 in) and have minimum hole density

of 160 holes/m2 (15 holes/ft2).

This document has been supplied under license by Shell to:

Wood Canada Limited m.thirunavukkarasu@woodplc.com 13/01/2022 08:33:57

DEP 31.22.05.12-Gen.

February 2021

Page 20

6.

The baffle thickness should be a minimum of 3 mm (0.12 in).

7.

If the baffle is thinner than 3 mm (0.12 in), stiffeners shall be used and strength

calculations provided to demonstrate the integrity of the plate.

8.

For liquid/liquid settlers the calming baffles shall be mounted on a full perimeter support

ring occupying the whole vessel cross-section.

At the bottom, a small opening ( ≤ 0.15 m, (6 in)) is allowed for cleaning purposes.

9.

For three phase settler the baffles shall extend from the vessel bottom to the level of

the LZA (HH).

10. Baffle plates shall have manways incorporated.

4.4

WEIRS

1.

Weirs in separators should either have hand holes, removable weir panels or climbing

aids (weld-in steps) for cleaning.

Alternatively, manways can be applied on both sides of the weir.

2.

Weirs shall be at least 5 mm (0.2 in) thick.

3.

Weirs shall be installed leak tight, including the removable hand and manholes in the

weirs.

4.5

GAS PHASE INTERNALS

4.5.1

Wiremesh demisters

4.5.1.1

General

1.

Vertical flow wiremesh demisters should be used in vertical separators (Figure 4.2) in

the following services:

a.

for demisting with a moderate liquid load ( φwm ≤ 0.1) in the form of droplets.

b.

for compressor suction scrubbers, in non-fouling service, provided that

precautions are taken to prevent the disengagement of loose wire cuttings.

Figure 4.2

Vertical flow wiremesh demister

hwIre mesh

D

d1

TTL

hcont

This document has been supplied under license by Shell to:

Wood Canada Limited m.thirunavukkarasu@woodplc.com 13/01/2022 08:33:57

DEP 31.22.05.12-Gen.

February 2021

Page 21

2.

Horizontal flow wiremesh demisters should be used in horizontal separators in

Figure 4.3 in the following services:

a.

for demisting with a moderate liquid load, φwm ≤ 0.1

b.

for viscous liquids ( > 2 mPa s) where the liquid de-gassing requirement

determines the vessel diameter.

c.

for foaming liquids.

3.

Wiremesh demisters should not be used in fouling service (wax, asphaltenes, sand,

hydrates).

4.

Sizing of the wiremesh should be done on the actual wiremesh area excluding support

rings.

Figure 4.3 Horizontal flow wiremesh demister

L

d1

D

4.5.1.2

Wiremesh demister specification and installation

1.

The wiremesh demister should have the following characteristics:

a.

a free volume of at least 97 % ( ε ≥ 0.97).

b.

a wire thickness in the range 0.23–0 .28 mm (9–11 mils).

c.

a specific surface area of at least 350 m2/m3 (107 ft2/ft3).

d.

a bulk density of at least 190 kg/m3 (11.8 lb/ft3).

The thickness of a vertical flow wiremesh demister mat is normally 0.1 m. (4 in).

2.

For a vertical flow wiremesh demister in a vertical vessel, perforated plates shall not be

mounted upstream of the wiremesh demister mat.

3.

A horizontal flow wiremesh demister mat shall have a thickness of at least 10 % of the

vessel diameter with a minimum of 0.15 m (6 in).

4.

The path through a horizontal flow wiremesh demister mat shall be sealed by the liquid

level until the gas load factor becomes lower than 0.07 m/s (0.23 ft/s).

5.

In horizontal vessels with a gas outlet nozzle located at the top of the vessel, wire mesh

demisters may be applied horizontally in a box-like structure upstream of the gas outlet

nozzle.

6.

The wiremesh demister mat shall be made of knitted wire and formed to give the

correct shape.

7.

The demister mat shall be placed between two grids having a free area of at least

97 %.

This document has been supplied under license by Shell to:

Wood Canada Limited m.thirunavukkarasu@woodplc.com 13/01/2022 08:33:57

DEP 31.22.05.12-Gen.

February 2021

Page 22

8.

4.5.1.3

The demister mat shall be fastened in such a way that it cannot be compressed when

being mounted.

Wiremesh demister designs

1.

For a vertical flow wiremesh demister, the vessel (i.e., the mesh area Ag) shall satisfy

the gas handling capacity criterion as defined in Eqn 4.2 using the constants and

factors in Table 4.2.

a.

For calculating Q*max see (Appendix A)

*

Qmax

λmax =

= Cwm fη fφ f P

Ag , min

Eqn 4.2

Table 4.2 Parameters for Equation 4.2

Term

SI units

USC units

Cwm

0.105 m/s

0.344 ft/s

Cwm

0.09 m/s

0.30 ft/s

Cwm

0.12 m/s

0.39 ft/s

fη

1

1 + 10φwm

1

6

d

wi

σ

min 1, 23.5

ρ

∆

fP

2.

4.5.1.4

Constant term for vertical flow

in Eqn. 4.2.

Constant term for

horizontal flow at LA(H)

in Eqn . 4.2.

Constant term for

horizontal flow at

LZA(HH) in Eqn. 4.2.

6.71 × 10 − 4 0 04 Derating factor for liquid phase

,1 viscosity, mPa s or lb/ft.s,

min

ηl

maximum value 1.

1 0 04

min ,1

ηl

fφ

Note

1

6

d

wi

σ

min 1, 10.64

ρ

∆

Derating factor for the flow

parameter at the face of the

wire mesh, valid for

φwm ≤ 0.1.

De-rating factor for physical

fluid properties,

SI: d {m), σ (kg/s2), ρ (kg/m3),

USC: d (ft), σ (lb/s2), ρ (lb/ft3).

For horizontal flow wiremesh demisters, the vessel diameter shall be derived after

considering the requirements for both gas and liquid.

a.

The minimum vessel cross-sectional area for gas flow, Ag,min above the LA(H)

liquid level shall satisfy the gas handling capacity criterion of Eqn 4.2 using the

constants and factors given in Table 4.2.

b.

The minimum vessel cross-sectional area for gas flow, Ag,min above the LZA(HH)

liquid level shall satisfy the gas handling capacity criterion of Eqn. 4.2, using the

constants and factors in Table 4.2.

New developments

There are higher capacity mesh pad type of demisters on the market which are not covered

by this DEP.

1.

Application of new technologies for design shall be subject to the approval of the

Principal.

This document has been supplied under license by Shell to:

Wood Canada Limited m.thirunavukkarasu@woodplc.com 13/01/2022 08:33:57

DEP 31.22.05.12-Gen.

February 2021

Page 23

4.5.2

Vane packs

There are two classes of vane packs included in this DEP: vane pack demisters with

pockets for separation of liquid mist from gas, and vane packs coalescers without pockets

for coalescing purposes. The vane packs with pockets come in two categories: single

pocket and dual pocket.

Vane packs can be operated in two modes: horizontal flow, where the pockets containing

the separated liquid phase is drained with gravity perpendicularly to the flow direction, and

vertical flow where the pockets are drained parallel to the flow direction. For vertical flow

vane packs, single pocket designs are not allowed. The vane pack can be an element in a

multi-stage separation design, or it can be the only separating device; in the latter case the

vane pack is in an in-line configuration where it is mounted between the inlet and outlet

nozzle of the separator vessel, and the vessel is in this case vertically oriented.

4.5.2.1

General

1.

For feed φ < 0.01 in-line vane pack type demisters (with pockets) may be used.

2.

For feed φ≥0.01 and for slug conditions, in-line vane packs shall not be used.

3.

Vane type demisters should not be used in the following conditions:

4.

a.

in heavy fouling service (heavy wax, asphaltenes, sand, hydrates);

b.

for viscous liquids η > 2 mPa.s where degassing requirement determines vessel

diameter;

c.

for gas densities above 70 kg/m³ (4.4 lb/ft³).

For moderately fouling services, single pocket vanes should be used.

Double pocket vane packs are allowed in clean service only.

5.

6.

Vane packs shall be enclosed in a box and integrated in the separator vessel so that all

the gas passes through the vanes from the inlet to the outlet of the vane pack.

a.

The box shall extend 0.15 m (6 in) above and below the vanes, and 0.05 m (2 in)

to each side of the vanes.

b.

The box shall include 0.15 m (6 in) lip coverage of each side of the vane ends to

prevent internal gas bypassing, and similarly 0.05 m (2 in) on the sides parallel to

the vanes.

There should be a clearance of at least 0.1 m (4 in) between the vane pack box and the

surroundings to allow room for installation, removal, attachments and inspection.

a.

The distance between the top of the vane box and the top seam weld of a vertical

vessel should be at least 0.1 m (4 in).

7.

Sufficient height shall be available within the box to collect and drain away separated

liquid.

8.

For demisting vane packs, liquid shall be drained from the vane pack to the bottom

compartment of the vessel via drain pipes having a minimum diameter of DN 50

(NPS 2).

9.

a.

The drain exit shall be submerged below LZA(LL) by at least 0.1 m (4 in).

b.

One drain pipe shall be included for each meter of vane pack width, where width

is the direction perpendicular to the flow direction.

If perforated plates are included to enhance flow distribution across the vane pack,

there shall be at least 4dhole,baffle between the perforated plate and the respective vane

face.

10. For vane packs in vertical flow mode, perforated plates shall not be used upstream of

the vane pack.

This document has been supplied under license by Shell to:

Wood Canada Limited m.thirunavukkarasu@woodplc.com 13/01/2022 08:33:57

DEP 31.22.05.12-Gen.

February 2021

Page 24

11. Horizontal flow vane packs in vertical vessels shall not be used except for in-line

separators.

12. Vertical flow vane packs should not be used in horizontal vessels.

4.5.2.2

Vane pack face area for demisting vane packs

1.

The vane pack area Avp shall be calculated by Eqn 4.3

Avp =

*

Qmax

Eqn 4.3

λvp , max

Where:

λvp,max is the maximum allowable gas load factor into the vane pack based on the

face area of the vane pack.

2.

The vane height should be 0.3 ≤ hvane ≤ 1.5 m (1≤hvane ≤ 5 ft).

3.

The length and width of the vane pack should be balanced so that the inlet area

approaches a quadratic shape, to facilitate an even flow load to the vanes.

4.

For Ar > 225 (which is normally the case), the maximum allowed vane face gas load

factor shall be calculated by Eqn. 4.4.

gσ

λvp ,max = cvp

∆P

0 24

σ

ηl

0 04

1

1 + 25φ vp

Eqn 4.4

where:

For horizontal flow mode, cvp=1.75.

For vertical flow mode, cvp=0.95.

5.

For Ar≤225, the maximum allowed vane face gas load factor shall be calculated by

Eqn. 4.5.

σ

1

η 1 + 25φvp

l

λvp ,max = cvp

Eqn 4.5

where:

For horizontal flow mode, Cvp = 0.14.

For vertical flow mode, Cvp = 0.08.

4.5.2.3

In-line vane pack designs (vertical vessels)

See Figure 4.4.

1.

An in-line plate pack shall be mounted perpendicular to the centre lines of both the inlet

and outlet nozzle of the (vertical) vessel.

2.

The cross-section of the inlet nozzle shall be at least 15 % of Avp.

3.

The upstream piping shall maintain the same internal diameter as the inlet nozzle for a

minimum of 4 pipe diameters.

4.

The outlet nozzle shall be at least the same internal diameter as the inlet nozzle.

5.

A perforated plate shall be installed at the back of the vane pack.

a.

See (4.3) for details of baffle plate design.

This document has been supplied under license by Shell to:

Wood Canada Limited m.thirunavukkarasu@woodplc.com 13/01/2022 08:33:57

DEP 31.22.05.12-Gen.

February 2021

Page 25

6.

7.

The baffle plate should meet one of the following:

a.

net free area (NFA) of at least 20 %;

b.

the combined pressure drop coefficient of the vane pack and the baffle plate

Ck ≥ 75.

The vessel diameter shall be large enough to fit the vane box, and no less than 0.6 m

(2 ft).

a.

8.

It should also be large enough to allow disengagement of gas from the drained

liquids.

There shall be minimum 0.5 m (20 in) between the bottom of the vane box and LZA

(HH).

Figure 4.4

In-line vane separator

D

TTL

hcont

This document has been supplied under license by Shell to:

Wood Canada Limited m.thirunavukkarasu@woodplc.com 13/01/2022 08:33:57

DEP 31.22.05.12-Gen.

February 2021

Page 26

4.5.2.4

Demisting vane packs in vertical and horizontal flow mode

See Figure 4.5 and Figure 4.6.

Figure 4.5

Vertical flow vane separator

hvanebox

D

TTL

d1

hcont

Figure 4.6

Horizontal flow vane separator

L

d1

D

1.

The distance from the front of the vane pack to the nearest upstream internal (e.g., the

inlet) shall be at least DH of the gas phase cross-sectional area, calculated at NL.

2.

The distance from the back of the vane pack to the nearest downstream internal

(e.g., the gas outlet nozzle) shall be at least 0.5DH of the gas phase cross-sectional

area, calculated at NL.

This document has been supplied under license by Shell to:

Wood Canada Limited m.thirunavukkarasu@woodplc.com 13/01/2022 08:33:57

DEP 31.22.05.12-Gen.

February 2021

Page 27

3.

The available drainage height from the vane pack inlet to LZA(HH) shall be twice the

liquid static head in the drain pipe, using the properties of the liquid with the lowest

density in the design case in Equation 4.6.

h =2

∆P

ρl g

Eqn 4.6

This includes a margin of 100% and accounts for all pressure drops from the vane pack

assembly inlet (e.g., the liquid level surface) to the vane pack drain.

4.

4.5.2.5

4.5.3

The pressure drop across the vane pack assembly is geometry dependent and should

be requested from the manufacturer.

Coalescing vane packs in vertical and horizontal flow mode

1.

The vane pack size shall match the gas cross-sectional area as calculated for the

downstream demisting internal.

2.

There shall be at least 0.2DH distance, with a minimum of 0.3 m (1 ft) between the

coalescing vane and downstream demisting internals (e.g., demisting cyclones).

Demisting cyclones

Demister cyclones are conventionally used as a polishing stage for separating liquid from

gas. They are usually preceded by a coalescing stage: a mesh pad (or mist mat (4.5.1)) or

a coalescing vane pack (4.5.2) operated in a flooded condition. Applied in this manner the

combination can reach high efficiencies and turndowns.

Table 4.3

Pressure drop coefficients for Shell swirltube designs

Cyclone type

CK

Shell VersiSwirl

8.8

HPST

42.0

Standard

18.6

1.

For applications of multicyclone separator internals, SGSI should be contacted to

provide consulting advice regarding the technical adequacy of the particular product for

the envisaged operation on a case-by-case basis.

2.

The maximum gas load factor per swirl tube shall be in the range 0.7 - 1.5 m/s

(2.3 - 4.9 ft/s) and obey the relation in Equation 4.7.

λst ,max =

σ

g

C st

ρ

ρ

−

l

g

0.24

σ

ηl

1 + 75φ st

0.04

Eqn 4.7

Here, Cst is a geometry dependent variable which can be different between vendors

and products.

3.

The available drain height of the cyclones shall include for all pressure drops from the

inlet to the drain chamber of the cyclones (i.e. the sum of the pressure drop over the

inlet of the cyclone and the upstream coalescing mesh pads or vane packs).

This document has been supplied under license by Shell to:

Wood Canada Limited m.thirunavukkarasu@woodplc.com 13/01/2022 08:33:57

DEP 31.22.05.12-Gen.

February 2021

Page 28

4.

5.

The total pressure drop from the inlet of the demisting cyclone to the drain channel is

half the total pressure drop over the cyclones, and may be calculated using the

pressure drop coefficient.

a.

See Table 4.3 for pressure drop coefficients over the full cyclone for Shell

demisting cyclone designs.

b.

For other designs, the Manufacturer/Supplier should be contacted.

The available drainage height from the cyclone inlet to LZA(HH) shall be twice the

liquid static head in the drain pipe, using the properties of the liquid with the lowest

density in the design case in Equation 4.5.

This includes a margin of 100% and accounts for all pressure drops from the inlet

(e.g., the liquid level surface) to the cyclone drain.

4.6

LIQUID PHASE INTERNALS

This DEP only gives requirements for plate packs. Other liquid phase internals and internals

in other configurations are available on the market and can also be used. The Principal can

be consulted for more information.

4.6.1

Plate packs

Plate packs are used for efficient separation of primary oil-in-water dispersions.

This DEP only covers the requirements for cross flow plate packs, i.e., flow of separated

liquid is perpendicular to that of the main flow, which flows horizontally.

Plate packs can be installed in a horizontal (L/L, G/L/L) or in a vertical (G/L/L) separator.

4.6.1.1

General

1.

The distance from the calming baffle to the plate pack should be 0.15 m (6 in).

2.

Plate packs should be mounted in panels with a gutter between the panels.

3.

The minimum plate distance of the plate pack, dpp shall be as follows:

4.

a.

10 mm (0.4 in) for non-fouling services;

b.

40 mm (1.6 in) for fouling services.

The length of the plate pack shall be as follows:

a.

Minimum 0.3 m (1 ft);

b.

Maximum 1.5 m (5 ft).

5.

Bypassing of liquid shall be prevented by mounting closed plates before the gutters and

sealing clearances between plate pack and vessel wall.

6.

The platepack shall have the same length, plate spacing and plate inclination across

the full height of the platepack.

7.

A minimum of 0.5 m (1 ft 8 in) gap shall be present between the following as applicable:

a.

back of the plate pack and the outlet nozzles

b.

back of the plate pack and the weir (in case of weir arrangement)

8.

Plate packs should not be used if the dispersed phase droplets are smaller than 30 µm

(1.2 mils), or when the continuous phase viscosity is high (>10 mPa.s (0.007 lb/ft/s)).

9.

Plate packs should not be used in heavy fouling service.

10. If fouling is expected a cleaning system should be installed.

This document has been supplied under license by Shell to:

Wood Canada Limited m.thirunavukkarasu@woodplc.com 13/01/2022 08:33:57

DEP 31.22.05.12-Gen.

February 2021

Page 29

4.6.1.2

Plate pack area

1.

The cross-sectional area of the upper and lower zones in the plate pack shall ensure

that the flow is laminar (Re < 850) subject to the following:

a.

For corrugated plates the criteria for laminar flow is Re < 450.

b.

If a plate pack is to be retrofitted in an existing vessel where there is not sufficient

space to install a plate pack in which the flow is laminar, or if highly efficient

separation is not required, Re may be up to 1200.

The length scale for the Reynolds number is dpp.

2.

The actual plate pack area (App,net) shall include a correction for the presence of

constructional elements (e.g., risers).

3.

To fit the actual plate pack area into the vessel, a further correction should be made for

lost area between vessel wall and the plate pack modules.

4.

The length of the plate pack, Lpp, should be calculated from the mean superficial

velocity of the continuous phase through the plate pack, from the settling velocity of the

smallest droplet to be separated, up,set,lam (5.1.4.2) and from the angle of the plates with

the horizontal plane ( q ) using Equation 4.8.

LPP =

uc , ax , ppdpp

+ 8dpp

cosθup , set , lam

Eqn 4.8

The mean superficial velocity of the continuous phase through the plate pack section

to be sized can be calculated from the flow rate of the continuous phase and the net

area of the plate pack, A pp,net as Equation 4.9.

uc , ax , pp =

4.6.1.3

4.6.1.4

Qc

App , net

Eqn 4.9

Horizontal vessels with plate packs

1.

The height of the plate pack shall be at least equal to the maximum liquid level.

2.

The seal plate at the bottom of the plate pack shall have a small opening for cleaning

purposes (maximum of 0.1 m (4 in) height).

Vertical vessels with plate packs

1.

A bottom plate shall be installed in front of the plate pack, sloping down towards to the

plate pack at an angle of 10°.

2.

The width of the plate pack, Wpp, shall satisfy the criterion in Equation 4.10.

Wpp{m} <

(D - 0.2m )2 − (Lpp + 0.15m )

{SI}

Wpp{ft} <

(D - 0.67ft )2 − (Lpp + 0.5 ft )

{USC} Eqn 4.10b

Eqn 4.10a

3.

The maximum length of the plate pack, Lpp, shall be one third of the vessel diameter.

4.

The heights of the upper (light liquid) and lower (heavy liquid) separation sections of

the plate pack should be at least 0.3 m (1 ft).

a.

5.

The height/width ratio of both sections should be in the range 0.15–2.

The control heights shall only be based on the liquid flow rate of the heavy liquid phase.

This document has been supplied under license by Shell to:

Wood Canada Limited m.thirunavukkarasu@woodplc.com 13/01/2022 08:33:57

DEP 31.22.05.12-Gen.

February 2021

Page 30

5.

DESIGN RULES FOR VESSEL SIZING

5.1

SEPARATION AREA(S) AND MAXIMUM FLOW RATES

5.1.1

Degassing

1.

Where vapour carry-under is not allowed (i.e. <1 % v/v vapour is carried under with the

liquid), the vessel diameter shall satisfy the liquid de-gassing criterion (5.1.1, item 2).

a.

2.

It may be assumed that, if bubbles larger than 200 µm (8 mils) in size are able to

escape, the carry-under will be negligible. This will translate into a minimum

residence time/separator size for this criterion.

The gas area above the liquid phase, Ag, shall satisfy Equation 5.1:

Ag ≥ Cdeg ass

Ql , max ηl

Eqn 5.1.

ρl − ρ g

Where:

Ag is the vessel cross-sectional area for vertical vessels, and the G/L interface area

for horizontal vessels, assuming the vessel is 50% liquid-filled (Dvessel Lvessel).

Cdegass is 4.5 × 107 for SI units (Q in m3/s, ρ in kg/m3, η in Pa s) and 1.274 × 106 for

USC units (Q in ft3/s, ρ in lb/ft3, η in lb/ft s).

ηl is the liquid viscosity, which is the light liquid phase viscosity in case the light liquid

phase has negligible dispersed phase concentration (<5%vol heavy), but in all other

cases is the viscosity of the mixture.

5.1.2

Defoaming

1.

A height of 0.25 m (10 in) should be applied to allow for foaming liquids.

2.

When the liquid is flashing, Ag shall satisfy the criterion in Equation 5.2:

η l ,light

Ag ≥ CdefoamQl ,max

ρ

ρ

−

l

light

g

,

0 27

Eqn 5.2

Where:

Ag is the vessel cross-sectional area for vertical vessels, and the G/L interface area

for horizontal vessels, assuming the vessel is 50% liquid-filled (Dvessel Lvessel).

Cdefoam is 7000 for SI units (Q in m3/s, ρ in kg/m3, η in Pa s) and 1123 for USC units

(Q in ft3/s, ρ in lb/ft3, η in lb/ft s).

The defoaming criteria are based on the properties of the light liquid phase and the

total liquid flow rate.

5.1.3

Gas handling

1.

The available area for the gas shall satisfy the gas handling capacity in Equation 5.3.

a.

See (Appendix A) for information as how to calculate Q*max.

*

Qmax

λmax =

= Cb

Ag ,min

Eqn 5.3

This document has been supplied under license by Shell to:

Wood Canada Limited m.thirunavukkarasu@woodplc.com 13/01/2022 08:33:57

DEP 31.22.05.12-Gen.

February 2021

Page 31

5.1.3.1

Vessel without demisting internals

1.

For vessels without internals, Cb in Equation 5.3 shall be 0.07 m/s for SI units (Q* in

m3/s, A in m2) and 0.23 ft/s for USC units (Q* in ft3/s, A in ft2).

2.

The maximum allowable gas load factor should be derated if any of the following apply:

a.

the pressure is above 20 bara (290 psia);

b.

the surface tension, s ≤ 29 mN /m (0.064 lb /s2). :

λmax = min (C b , f bσ 0 3 ρ g−0 05 )

Eqn 5.4

Here, fb = 0.28 for SI units (σ in N/m, ρ in kg/m3) and 0.63 for USC units (σ in lb/s2,

ρ in lb/ft3).

5.1.3.2

Vessel with mesh pad demister

Vessels with mesh pad demisters can handle higher gas load factors than vessels without

demisting internals provided that the mesh pad is properly sized.

The vessel gas load factor results from the maximum mesh pad gas load factor.

1.

5.1.3.3

For vessels with mesh pads, the gas area shall be sized to accommodate a mesh pad

following the rules in (4.5.1).

Vessel with vane-type demister

1.

In-line separators in vertical vessel shall meet all of the following:

a.

b.

2.

dimensions for vane box as Equation 5.5.

D ≥ 0.2 + wvb2 + tvb2

{SI, m}

Eqn 5.5a

D ≥ 0.65 + wvb2 + tvb2

{USC, ft}

Eqn 5.5b

dimensions for vessel accessibility as D ≥ 0.6m or 2 ft.

The maximum gas handling capacity of a Horizontal vane-type demister and two-stage

separator with vertical vanepack depends on the actual liquid load to the vanepack and

therefore the maximum liquid load to the vanepack shall be limited to a feed flow

parameter f < 0.01, subject to the following:

a.

If a Schoepentoeter is used as the inlet device, the flow parameter may be higher,

provided that the separation efficiency of the Schoepentoeter is sufficient to

reduce f to < 0.01 just upstream of the vanepack.

b.

For hydrocarbon systems the vessel gas load factor should be limited to

Equation 5.6.

λmax =

*

Qmax

− 0 75

= 0.11 + 0.0095φ feed

{m/s}

Ag ,min

Eqn 5.6a

λmax =

*

Qmax

− 0 75

= 0.36 + 0.0312φ feed

{ft/s}

Ag ,min

Eqn 5.6b

This document has been supplied under license by Shell to:

Wood Canada Limited m.thirunavukkarasu@woodplc.com 13/01/2022 08:33:57

DEP 31.22.05.12-Gen.

February 2021

Page 32

c.

5.1.3.4

For aqueous systems the vessel gas load factor may be relaxed to meet

Equation 5.7.

λmax =

*

Qmax

− 0 75

= 0.11 + 0.0125φ feed

{m/s}

Ag ,min

Eqn 5.7a

λmax =

*

Qmax

− 0 75

= 0.36 + 0.0410φ feed

{ft/s}

Ag ,min

Eqn 5.7b

d.

If no slugs are expected, the vessel gas load factor shall not exceed

λmax = 0.15m/s (0.5 ft/s).

e.

If slugs are expected, to avoid flooding of the vane pack, the vessel gas load

factor shall not exceed λmax = 0.10m/s (0.33 ft/s).

Vessels with swirl tubes

The maximum vessel gas load factor for vessel with swirl tubes is typically determined by

the maximum swirl tube gas load factor (see sizing rules for swirl tubes, (4.5.3)).

Vessel with swirl tubes are generally combination of Schoepentoeter as feed inlet device, a

mesh pad or vane pack as coalescer and a swirl deck as liquid separator device.

This family of separators is knowns as SMS (Schoepentoeter-Mistmat-Swirldeck), SVS

(Schoepentoeter-Vanepack-Swirldeck), SMSM (Schoepentoeter-Mistmat-SwirldeckMistmat) and SMMS (Schoepentoeter-Mistmat-Mistmat-Swirldeck), see Figure 5.1.

5.1.3.4.1 Shell swirltube separators

1.

Shell swirltubes shall be installed vertically.

This complicates their installation in a horizontal vessel, because special precautions

are required to ensure an equal distribution of the gas over all swirltubes.

Furthermore, it minimises the head available for draining of the separated liquid.

2.

The use of Shell swirltubes in a horizontal vessel shall be subject to the approval of the

Principal.

This document has been supplied under license by Shell to:

Wood Canada Limited m.thirunavukkarasu@woodplc.com 13/01/2022 08:33:57

DEP 31.22.05.12-Gen.

February 2021

Page 33

Figure 5.1

SMS Separator (part of the SMS family: SMS, SVS, SMSM, SMMS)

D

hswirldeck

hcoalescer

d1

TTL

hcont

5.1.3.4.2 Other horizontal axial flow multicyclone separators