Concurrent Engineering Assignment: Product Life Cycle & R&D

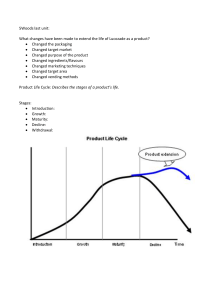

advertisement

NATIONAL UNIVERSITY OF SCIENCE AND TECHNOLOGY Faculty of Engineering Department of Industrial and Manufacturing Engineering Course: Concurrent Engineering Course Code: EIE 3222 Assignment 1 Due Date: 19 FEBRUARY 2025 Group 14 Student name Nkosilathi Moyo Walambuka Tafadzwa K Langalenkosi M Ncube Tatenda Madzimire Lovemore Mandebvu Anesu Chawira Student number N022216196N N02220662k N022219827H N02132660J N0222112R N02221269Y QUESTION 1 Considering the various stages of a product's life cycle (introduction, growth, maturity, and decline), what strategies can companies employ to extend the life of their products and maintain market relevance? How can understanding the product life cycle help businesses make informed decisions about product development, marketing, and innovation to stay ahead of the competition and respond to changing consumer preferences? ANSWER To prolong the lifespan of their products and stay relevant in the market, companies can implement strategies that are specifically suited to each phase of the Product Life Cycle (PLC). 1. Introduction Stage • • Strategies: o Focus on building brand awareness and educating consumers about the product’s benefits. o Use promotions, discounts, and trials to encourage early adoption and word-ofmouth marketing. o Establish strong distribution channels to make the product easily accessible. o Ensure the product is innovative and differentiates itself from competitors. Example: Companies may heavily invest in advertising and digital campaigns to attract early adopters and drive product awareness. 2. Growth Stage • • Strategies: o Broaden distribution to access additional regions or new target markets. o Improve product features or introduce complementary items to enhance its attractiveness. o Implement brand loyalty programs to retain existing customers and encourage repeat sales. o Maintain strong marketing efforts to surpass competitors and capture a larger share of the market. Example: A smartphone brand may introduce new features or accessories that enhance the original product, strengthening its position in the market. 3. Maturity Stage • Strategies: o • Launch product enhancements or new versions to distinguish it and spark renewed consumer interest. o Emphasize cost leadership with pricing strategies, like discounts or bundling, to stay competitive. o Explore new markets, either by expanding geographically or targeting different customer groups. o Focus on building brand loyalty through personalized marketing and customer engagement to retain current buyers. Example: Car manufacturers often release new models or limited-edition versions of popular vehicles to revitalize their product range during the maturity stage. 4. Decline Stage • Strategies: o Consider discontinuing or gradually phasing out the product, with a focus on cost reduction. o Target niche markets where the product may still have demand, or offer budgetfriendly alternatives. o Innovate and rebrand: Update or repurpose the product to spark renewed interest or introduce it in a new form. o Prioritize customer retention by offering loyalty programs or discounts to sustain sales during the final phase. Example: Technology companies often discontinue older product models, such as phones or computers, while launching more advanced versions, and may offer the older models at reduced prices. • How Understanding the Product Life Cycle Helps Businesses Make Informed Decisions: Understanding the PLC enables businesses to anticipate competitive pressures. Early stages may involve differentiating from competitors, while in maturity, companies may focus on retaining market share. In decline, businesses may consider consolidating or exiting markets that no longer provide growth opportunities. 1. Product Development: By understanding where a product is in its life cycle, businesses can determine when to innovate, improve, or create new versions of the product. For example, during the growth stage, companies might focus on enhancing features, while in the maturity stage, they may focus on incremental updates or variations to maintain interest. 2. Marketing Strategy: Recognizing the stage of a product allows businesses to tailor marketing efforts accordingly. In the introduction phase, heavy promotional activities are needed, while in the maturity phase, marketing may focus more on brand loyalty and differentiation. In the decline stage, marketing may shift to niche audiences or cost-driven strategies. 3. Resource Allocation: Knowing the PLC stage helps businesses allocate resources effectively. For instance, more investment in advertising is typically required in the introduction and growth stages, whereas in the maturity and decline stages, a focus on cost-efficiency and innovation might take priority. 4. Pricing Decisions: Pricing strategies can be adjusted based on the PLC stage. In the introduction stage, companies may use penetration pricing to attract customers, while in the maturity stage, competitive pricing and discounts may be more relevant. During the decline stage, businesses may lower prices to clear out inventory or introduce budget-friendly alternatives. 5. Product Innovation and Updates: The PLC informs when to make product updates or changes to keep the product relevant in the market. For example, as a product nears the decline phase, businesses may innovate or rebrand to extend its life or transition customers to newer products. 6. Competition Strategy: Understanding the PLC enables businesses to anticipate competitive pressures. Early stages may involve differentiating from competitors, while in maturity, companies may focus on retaining market share. In decline, businesses may consider consolidating or exiting markets that no longer provide growth opportunities. QUESTION 2 In the context of industrial engineering and manufacturing, how can companies balance the costs and risks of investing in Research and Development (R&D) with the potential benefits of innovation, improvement, and competitiveness? What strategies can organizations employ to ensure their R&D efforts yield valuable, practical outcomes that contribute to long-term success and sustainability? Answer In industrial engineering and manufacturing, companies must carefully balance the costs and risks associated with Research and Development (R&D) investments against the potential rewards of innovation, process improvement, and enhanced competitiveness. To strike this balance, companies can implement various strategies that maximize the returns on R&D and ensure valuable, practical outcomes: 1. Align R&D with Business Objectives: • • Strategy: Ensure that R&D initiatives align with the company’s long-term goals and market demands. By focusing on addressing key challenges or seizing opportunities in the manufacturing process, R&D can drive operational efficiency, cost reduction, or product differentiation. Example: A company may focus its R&D efforts on automation technologies to enhance production efficiency, reduce labor costs, and maintain market competitiveness. 2. Stage-Gate Process for R&D Projects: • • Strategy: Adopt a stage-gate or phase-gate methodology for R&D projects. This approach breaks the process into phases, with clear milestones to assess progress and decide whether to continue, modify, or cancel projects based on feasibility and expected return on investment (ROI). Example: A company may first develop a prototype of a new material or process and test its viability before moving forward with large-scale production. 3. Incremental vs. Radical Innovation: • Strategy: Companies should balance their R&D investments between incremental and radical innovations. While incremental innovations offer lower risk and quicker returns (such as small process improvements or product enhancements), radical innovations can • lead to transformative advancements that set the company apart, though they involve higher risk and longer timelines. Example: A manufacturer may focus on incremental improvements in supply chain efficiency while exploring disruptive innovations in materials science for future product offerings. 4. Collaborations and Partnerships: • • Strategy: Collaborating with external partners such as universities, research institutions, or other industry leaders can help distribute the financial and technical risks of R&D. These partnerships bring specialized expertise, accelerating innovation and reducing the costs tied to in-house research. Example: A manufacturing company might team up with an academic institution to explore new sustainable manufacturing materials, sharing both the financial burden and technical challenges. 5. Focus on Cost-Benefit Analysis: • • Strategy: Regularly conducting cost-benefit analyses ensures that R&D investments deliver measurable value. This analysis helps prioritize R&D initiatives that provide the highest returns and align with customer demand and market trends. Example: When developing a new energy-saving process, a cost-benefit analysis could help determine whether the energy savings justify the R&D investment. 6. Agile and Lean R&D Practices: • • Strategy: Embrace agile and lean methodologies in R&D to enhance efficiency and reduce waste. Agile practices focus on flexibility and fast iteration, while lean approaches aim to eliminate non-value-adding activities and optimize resource use. Example: A manufacturer could use lean R&D methods to rapidly prototype and test new technologies, such as additive manufacturing, and refine them based on production team feedback to reduce costs and improve practicality. 7. Customer-Centric R&D: • • Strategy: Involve customers early in the R&D process to ensure that innovations address their real needs and challenges. This reduces the risk of developing products or solutions that don’t meet market demands. Example: A company might gather feedback from customers through focus groups to refine a product prototype, ensuring the final version delivers tangible value and aligns with customer expectations. 8. Monitor Industry Trends and Competitors: • • Strategy: Stay abreast of industry trends, emerging technologies, and competitors’ R&D efforts. This provides insights into new opportunities and helps anticipate shifts in market needs or technological advancements. Example: A company might invest in R&D for integrating Industry 4.0 technologies, such as IoT or AI, into its manufacturing processes to stay competitive in the evolving market. 9. Long-Term Vision with Short-Term Gains: • • Strategy: Treat R&D as a long-term investment, setting both short-term and long-term goals. This approach ensures immediate returns while positioning the company for sustainable future growth. Example: A company may focus on a near-term innovation to lower production costs while simultaneously investing in a long-term R&D initiative aimed at developing a breakthrough technology for future market leadership. 10. Risk Management and Contingency Planning: • • Strategy: Implement robust risk management strategies to assess and mitigate the potential risks of R&D investments. This includes having contingency plans in place for unexpected setbacks, such as technological challenges or changes in market conditions. Example: A company working on a new robotics system for manufacturing could establish a contingency plan that allows them to scale back the project or pivot to alternative technologies if initial results are disappointing. By adopting the strategies listed above, industrial engineering and manufacturing companies can manage the costs and risks associated with R&D while maximizing innovation, improving operations, and sustaining competitiveness. With a focus on practical outcomes, collaboration, and customer-centered development, R&D investments can significantly contribute to long-term success and sustainability. REFERENCES ‘Concurrent Engineering Fundamentals’ Richard M. Crowson ‘’Product Design and Development’’ Karl T. Ulrich and Steven D. Eppinger The Principles of Product Development Flow: Second Generation Lean Product Development by Donald G. Reinertsen Engineering Design George E. Dieter Integrated Design and Manufacturing in Mechanical Engineering B. H. S. Lau