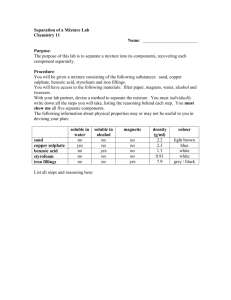

Name: Faatimah Hasan Date: 1/13/2025 CHM 252: Organic Chemistry II Nitration of Benzoic Acid Abstract The goal of this experiment is to synthesize 3-nitrobenzoic acid from benzoic acid and nitric acid. Thus, this reaction was an electrophilic aromatic substitution via nitration. Sulfuric acid was also used as a catalyst for this nitration. The nitration was performed at 4℃ and never went above 5℃ . The 3-nitrobenzoic acid was then vacuum filtered then washed for further purification. It was then weighed, and a percentage yield was measured. After the experiment, the amount of 3-nitrobenzoic acid synthesized was 8.13g and the percent yield was 197.93%. The high percent yield was most likely due to inadequate drying of the product. Introduction Electrophilic aromatic substitution is a method of synthesizing aromatic ring derivatives from aromatic substances. The aromatic compound grabs on to the electrophile in an electrophilenucleophile bond. Thus, creating a cyclohexadienyl cation (𝜎 complex). The nucleophile (or Lewis base in this case) bonds with the hydrogen to deprotonate the carbocation and its electrons restore the resonance of the aromatic compound. Electrophilic aromatic substitution reactions can occur with many different electrophiles. The main reactions with differing electrophiles are: nitration, sulfonation, halogenation, alkylation, acylation, and halogenation. In this experiment, nitration is performed on benzoic acid, a benzene derivative, to produce 3nitrobenzoic acid. In this reaction, sulfuric acid (𝐻2 𝑆𝑂4) is the catalyst. It is used to produce the electrophile from nitric acid (𝐻𝑁𝑂3). One hydrogen from the 𝐻2 𝑆𝑂4 is bonded to the nitric acid, and the water detaches for increased stability. What’s left is the nitronium ion as the electrophile, water, and a hydrogen sulfate ion (𝐻𝑆𝑂4− ). The nitronium bonds with a pi bond on the benzoic acid ring. When the sigma complex is formed, the Lewis base (water) bonds with the hydrogen local to the attached nitronium (deprotonates the carbocation), and resonance is restored. The catalyst is reformed by hydronium and the 𝐻𝑆𝑂4− reacting to form 𝐻2 𝑆𝑂4 . This experiment was done in 4℃ temperature and the reaction was never allowed to exceed 5℃ . Methods & Materials Materials: ❖ 50 mL Erlenmeyer flask ❖ 2mL concentrated 𝐻𝑁𝑂3 ❖ 100mL beaker ❖ 100g ice ❖ 400mL beaker ❖ 10mL D.I. water 10.5 mL concentrated 𝐻2 𝑆𝑂4 3.0g benzoic acid Ice bucket 100mL water Glass stir rod 10mL ethanol ❖ Vaccuum-filtration setup Methods: (A) Nitrating Mixture A nitrating mixture (NM) was first prepared. 3mL of concentrated sulfuric acid (𝐻2 𝑆𝑂4 ) and 2mL of concentrated nitric acid (𝐻𝑁𝑂3 ) were added in a cooled 50 mL Erlenmeyer flask (added whilst the flask was in an ice/water bath). (B) Reaction Mixture Next, a reaction mixture (RM) was prepared. In a 150mL beaker, 7.5mL of concentrated𝐻2 𝑆𝑂4 was added to a beaker and placed into an ice/water bath. After the 𝐻2 𝑆𝑂4 had cooled, 3.0g of benzoic acid crystals were added into the acid. The mixture was kept below 5℃ . (C) Nitration Once it was confirmed that the mixture was below 5℃ , the cold NM was slowly added into the cold RM. After they were fully mixed, the mixture was allowed to cool for another 10 minutes in the ice bath. An ice/water mixture was prepared in a 400mL beaker. 100g of ice were placed in the beaker followed by 100mL of water. The ice water was stirred constantly in a circular motion with a glass rod as the NM/RM was poured into the center. The product collected at the bottom of the beaker. To purify the product, it was placed into a vacuum filter mounted to a vacuum filtration setup. The product was washed twice with 5mL portions of cold DI water, and twice with 5.0mL portions of cold absolute ethanol. The product was then dried for approximately 10 minutes before being removed from the filter and weighed. Data & Results When making the reaction mixture, after mixing the 𝐻2 𝑆𝑂4 and benzoic acid, the solution became paste-like. After the addition of the nitrating mixture into the reaction mixture, the solution was clear but took on a light-yellow color. When poured into the ice bath, the solution became a white precipitate. Lastly, after drying the mixture, it was curd-like and scoopable. Percent Yield: Theoretical Yield: 3.0𝑔 𝐵𝑒𝑛𝑧𝑜𝑖𝑐 𝐴𝑐𝑖𝑑 122.12𝑔/𝑚𝑜𝑙 𝑎𝑐𝑡𝑢𝑎𝑙 𝑦𝑖𝑒𝑙𝑑 * 167.12𝑔/𝑚𝑜𝑙 =4.105g 8.125𝑔 Percent Yield: 𝑡ℎ𝑒𝑜𝑟𝑒𝑡𝑖𝑐𝑎𝑙 𝑦𝑖𝑒𝑙𝑑 ⋅ 100 = 4.105𝑔 ⋅ 100 = 197.93% Figure 1: Before adding Figure 2: After adding Figure 3: 3-nitrobenzoic acid nitrating mixture nitrating mixture product (8.125 g) Discussion The mechanism for nitration of benzoic acid results in a major product of 3-nitrobenzoic acid, a meta isomer. The meta isomer is the major product because when the electrophile reacts with the benzoic acid and forms a carbocation intermediate (sigma complex), the carbocation must be on a carbon that will help to stabilize the ring. Benzoic acid has a carboxyl group (-COOH) already attached to its carbon, making it a 3°carbon. If the -𝑁𝑂2 attached ortho/para, due to resonance, the carbocation would land on the tertiary carbon. It would destabilize the ring if the carbocation was on the tertiary carbon when an electron withdrawing carboxyl group is already attached to it. This also means -COOH is a deactivating group because it slows down the reaction due to its pulling of electron density (Carey, 2020). Since a meta product is preferred, the reaction was kept below 5℃ allow for as little ortho product as possible. Mechanism for the Nitration of Benzoic Acid Credits: Faatimah Hasan The percent yield calculated from the reaction was 197.93%. During the vacuum-filtration step, 10 minutes or less were used to dry the compound. Thus, this percent yield is mostly likely extremely high due to the mixture not being dried for long enough and having extra liquid still in it. References Carey, F. (2020). Organic Chemistry (11th ed.). McGraw-Hill.