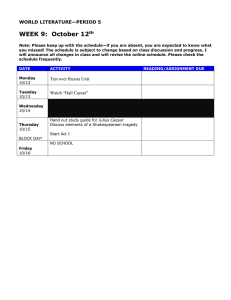

CAESAR II® Online Video Training Series CAESAR II® Statics One Written by David Diehl Director of Training, Intergraph® ICAS Division Training when you need it - anywhere in the world SM CAESAR II® Statics One David Diehl, Course Author Produced and Edited by Anthony W. Horn First Edition - February 2015 ©2015 CAD Training Technologies, LLC Houston, TX USA http://www.pipingdesignonline.com No duplication permitted without express written consent i Welcome to these Special Videos for Learning CAESAR II® Statics! These CAESAR II Statics One training videos are the second in our video training series for CAESAR II software. These lessons were developed by David Diehl, the Director of Training at the Intergraph® Corporation, and are designed to teach you CAESAR II in the easiest, fastest way possible. As you watch the videos and follow along doing the exercises you'll learn many of the commands, features, and techniques that will make you more productive and accurate in your work. It won't take long before using CAESAR II becomes automatic and you'll master its intricacies as you explore the world's leading pipe stress analysis system! So thank you for your commitment to training, and let's get started! Anthony W. Horn, Editor 2015 ii Trademark Information The material, applications, and routines presented in this book have been included for their instructional value. They have been tested for accuracy, but are not guaranteed for any particular purpose. The author and copyright holders do not offer any representations or warranties, nor do they accept any liabilities with respect to this video and written material, instructions, software applications, or routines. This material in these documents and accompanying videos is solely owned and copyrighted ©2015 by CAD Training Technologies, LLC, Houston, Texas, USA. Duplication in any manner is strictly prohibited without express written consent. All pipe stress analysis should be done according to the appropriate piping codes and under the direct supervision of a professional engineer. Trademarks Intergraph®, the Intergraph logo®, PDS®, SmartPlant®, SmartMarine, FrameWorks®, SmartSketch®, I-Route, I-Export, ISOGEN®, SPOOLGEN, SupportManager®, SupportModeler®, TANK, PV-Elite, CADWorx®, CADWorx DraftPro®, GT STRUDL® and CAESAR II® are trademarks or registered trademarks of Intergraph Corporation or its subsidiaries in the United States and other countries. Microsoft® and Windows® are registered trademarks of Microsoft Corporation. MicroStation® is a registered trademark of Bentley Systems, Inc. AutoCAD® is registered in the U.S. Patent and Trademark office by Autodesk, Inc. Other brands and product names are trademarks of their respective owners. Intergraph® provides the programs, CAESAR II®, PV Elite, GT STRUDL and CADWorx® Plant Professional, “as is” and with all fault. Intergraph® specifically disclaims any implied warranty of merchantability or fitness for a particular use. Intergraph® Corporation does not warrant that the operation of the program will be uninterrupted or error free. iii About the Author and Editor Drawing from over 30 years of engineering, technical support, and training experience, David Diehl has created an outstanding course in CAESAR II Statics One. Serving as the Director of Training at the Intergraph® Corporation, Mr. Diehl is recognized as one of the top CAESAR II trainers in the world. Now you can benefit from his experience as he shares with you his knowledge of using CAESAR II software in a powerful, yet easy to understand course. Anthony Horn, the Editor of this video training series and author of the CAESAR II Fundamentals Course is the owner and creator of PipingDesignOnline.com. Launched in 2011, PipingDesignOnline.com has issued over 1700 certificates in CADWorx and CAESAR II software in more than 40 countries, and is the largest Intergraph CADWorx and Analysis Solutions software training organization in the world. iv CAESAR II Statics One Table of Contents LESSON 1 Video 1 Starting the "Simple" model ........................................................................... 1 Video 2 Using the Interface, Adding Restraints and Tees, Viewing the Model ........... 6 Video 3 Using the List Feature, Analyzing and Viewing Results................................. 9 LESSON 2 Video 1 Using the Simple Model, Viewing Deflected Shape, Modifying Display ......... 18 Video 2 Expansion Stress Formula, Types of Stresses Considered ........................... 31 Video 3 Stress Cube, Morh's Circle, Expansion Stress Formula Examined ............... 36 Video 4 Axial Stress, Stress Intensification Factors .................................................... 41 Video 5 Torsional Stress, Flexibility and Stress Intensification Factors ...................... 44 Video 6 Calculating Expansion Stresses using Mathcad, Comparing to CAESAR II .. 49 Video 7 Calculating other Stresses using Mathcad, Comparing to CAESAR II .......... 57 Video 8 Operating Load Case and Stresses, Code Stresses ..................................... 65 LESSON 3 Video 1 When Spring Supports are Needed ............................................................... 72 Video 2 Calculating Dead Weight in the Hot Position, Load Variation ........................ 77 Video 3 How the Anvil® Catalog Works ...................................................................... 81 Video 4 Hanger Load Cases ....................................................................................... 85 Video 5 Example Selection, the CAESAR II Hanger Report ...................................... 88 Video 6 Hanger Report, Hanger Design Data, Actual Installed Load ......................... 93 Video 7 Hanger Selection Problem ............................................................................. 97 Video 8 Evaluating the Hanger Selection.................................................................... 103 Video 9 Modifying the Design to Improve Results ...................................................... 109 LESSON 4 Video 1 Review of Hanger Design ............................................................................. 114 Video 2 Hanger Control Settings in the Configuration and Piping Input Areas ........... 117 Video 3 3 Hanger Control Settings in the Input Spreadsheet .................................. 126 v Video 4 Additional Hanger Control Settings in the Input Spreadsheet........................ 131 Video 5 Hanger Control Settings in the Load Case Editor .......................................... 135 Video 6 A Detailed Review of the Hanger Reports ..................................................... 138 Video 7 Verifying and Modifying Hanger Selections ................................................... 143 Video 8 Things to Watch For in Hanger Selection ..................................................... 149 Video 9 When to Design Using Actual Cold Loads ..................................................... 154 LESSON 5 Video 1 Starting the Turbine Model............................................................................. 158 Video 2 Completing the Model, Including the Intake Section of the Model ................. 167 Video 3 Analyzing and Viewing the Deflected Shape ................................................. 174 Video 4 Adding CNodes, Filtering Results for Viewing ............................................... 184 Video 5 Analyzing the Turbine using NEMA SM23 ..................................................... 192 Video 6 Adding a +Y Support to Improve the Results ................................................. 203 Video 7 Changing the +Y Support to a Spring Can to Improve Results...................... 209 Video 8 Modifying the Piping Geometry to Increase Flexibility ................................... 217 Video 9 Verifying the Turbine Design Results............................................................. 228 vi PipingDesignOnline Video Training CAESAR II Statics - Building the "Simple" Model CAESAR II Statics - Building the Simple Model, Video One (Reference Video: C2_S_L1_V1A) 1. Here's the system that we're going to build for our exercises in the beginning of this section. It's a very simple system going from an anchor, a horizontal run, and to an elbow. It's 8-inch pipe. From the elbow it travels down to another anchor. The line has a reduced tee in it. The outlet will be a 6-inch branch coming off of an 8-inch header. We see the symbol for the CAESAR II coordinate system in the lower right area of the screen. This model will give us all the basic components we need to talk about stress. We'll have an elbow and a tee with their stress intensification factors. We'll heat the line up to get some load in the system and, from that load, we can calculate stress. So this is the model we're going to build right now. 1 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Building the "Simple" Model 2. The basis of this model is to develop the terms involved in calculating code-defined stresses and then, evaluating those stresses. It's a very simple model. So we'll start a brand a job. 3. Click New. For the file name, enter "Simple." Place it in the CAESAR II Models folder (located in the files you downloaded for you course files). \CAESAR_II_Statics_Support_Files\CAESAR II Models We’ll use this same folder for the models we build in this course. This folder has a configuration file in it which it will use for jobs in this folder, and it sets our units. 4. Yes, we are running metric units here in this course. The temperatures are in centigrade. The length, OD and wall thickness of a pipe will be in millimeters. Note that we'll have the Nominals setting turned ON. This will let us call out 8-inch pipe by name (8), and it will put in the proper actual OD. We can enter S for standard wall, and the system will give us true wall thickness at that condition. 2 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Building the "Simple" Model 5. Click OK and the system start the input processor. 6. The display shows the first element, 10 to 20. Now we'll model the line. 7. In the DX field, Type: 3000 <Enter>. In the Diameter field, Type: 8 <Enter>. Notice the system puts in 219 in the diameter field (219 mm). Also the system sends a message in the Status field that it converted the nominal size (8") to the size in millimeters (219.0750). 3 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Building the "Simple" Model 8. If you hover the pointer over the Wt/Sch field you'll see the system shows mm for the units. Type: S <Enter> (for a Standard Schedule). The system will enter in the proper wall thickness. If you have any question on what value to put in there, Click in the field and press the Function 1, or question mark key, and it will open up the help file. It shows help on entering wall thickness, and it gives examples. There's the S that was just entered, standard wall. 9. Corrosion-- we don't have any corrosion here, leave this field blank. 10. Pipe density will come in when I've specified the material. 11. Fluid density-- This line will be filled with water. Type: 1sg <Enter> in the Fluid Density field. Make sure to enter the sg (for Specific Gravity) or your values will be much too large. 12. In the Temp 1 field, Type: 250 <Enter> (for 250 degrees centigrade). 13. In the Temp 2 field, Type: 21 <Enter> (for 21 degrees centigrade, our ambient temperature). You can find the ambient temperature used in this configuration by clicking the Special execution options button. The system defaults to 70 degrees Fahrenheit, and when using metric units converts that to 21.114 degrees centigrade. 4 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Building the "Simple" Model 14. In the Pressure 1 field, Type: 25 <Enter>. 15. Double click the Bend check box. You'll see Long in the field under Radius (you may have to expand your input screen to the right to see this field). The system puts in a Long Radius by default. The system displays nodes 18 and 19. Node 18 will be on the weld line for the elbow on the horizontal run. Node 19 is at the midpoint of the elbow. Node 20 is at the weld line for the elbow at the end (in the vertical leg down). The system will calculate stress at three points around the bend. 16. Double click the Restraints check box. Click Anchor and verify it is on node 10. 17. In the Material field, Click in the field and Type: a106 <Enter>. The system displays several choices (grades) for A106. Double click on the row - Grade B. This material has an index value of 106. So if you type 106 in the Materials field in the future the system will use this material. You can see the system fills out other fields it can derive from the material selection. 18. The system has now filled out the values for Pipe Density, Young's modulus, and Poisson ratio. 19. To see the strain associated with this pipe, Double-click on the Chevron by the Temp1 field. The system displays the value for the thermal expansion rate, 0.002877 millimeters per millimeter. 20. We see also that the system has displayed values for the allowable stress. We have B31.3 selected for the default piping code. CAESAR II has many piping codes in the program, but we'll use 31.3 for this example. The Cold Allowable Stress (SC), or basic design stress ambient condition is 138 MPa. When the system is at 250 centigrade, it drops down to 132 MPa (SH). That came all in with the selection of material. Get you model to this point and we'll continue after that! 5 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Building the "Simple" Model CAESAR II Statics - Building the Simple Model, Video Two (Reference Video: C2_S_L1_V1B) 1. Continuing on, you'll notice that in almost every job, this first element usually takes more time than any others because that's where a lot of these items are initialized. Most of this information will be carried on throughout the rest of the model, and we won't have to spend too much time resetting many of these values. 2. Click the Continue button. The next element will be from 20 to 30. In the DY field, Type: -2000 <Enter>. (You don't have to type mm) Note that the program automatically is incrementing the node numbers by 10. Because the program's doing that, I'm assuming that as well. You have a choice in any kind of increment on these node numbers that you wish. 3. To display the node numbers, Click the Node Numbers button on the toolbar. 4. Now why did we stop at node 30? That's where our welding tee is. 5. Double click the SIFs & Tees button. 6. Verify node 30 is displayed in the field. For Type, select Welding. This sets a welding tee at node 30. 7. Click Continue. In the DY field, Type: -2000 <Enter>. 6 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Building the "Simple" Model 8. Double click Restraints. Select Anchor (for node 40). 9. The program assumes that once you start a model, that you're specifying a restraint at the end node (the to node). So that's why node 40 was displayed in the field automatically when you were ready to select an Anchor. If you recall in the very first element, the system displayed node 10 in the field. That's because with the first element, the system figures you're starting from a boundary condition like an anchor. 10. All right, now we're going to put our branch in from node 30 to node 50 in the Z direction. 11. Click Continue. In the From field, where it says 40, delete that value and put in 30. In the DZ field, Type: 1500 <Enter>. If I had the wrong direction-- I don't, but if I had the wrong direction-- I could type a negative here and the model would display the branch going in the negative Z direction. We won't do that. We'll have it modeling in the positive Z direction. 12. The branch off the tee we just modeled will be a 6-inch pipe (it will be a reducing tee). In the Diameter field, Type: 6 <Enter>. The system converts the nominal 6" size to millimeters (168.2750 mm). In the Wt/Sch field, Type: s <Enter>. This resets the wall thickness for the 6" line (7.1120 mm). 7 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Building the "Simple" Model 13. Our last component is our anchor at the end. Double click the Restraints check box. The system displays node 50 in the field. Select Anchor. 14. So we've completed the model. That's what we're going to be running in CAESAR II today. It's a very simple model, but again, we do have an elbow in play and also a welding tee. The temperature in the line will give us thermal strain. We also have dead weight which will put its own stress on the line as well. 15. Click the Orbit button to view the line from different angles. 16. There are several tools in the program that allow you to manipulate the plot so you can see the important data in the model, which we'll use as we progress through the course. OK, so we have our model complete now. You duplicate these steps yourself and build this model. Then we'll take some time to follow on through the process of running CAESAR II, building our Load Cases, and then viewing our results. 8 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Building the "Simple" Model CAESAR II Statics - Building the Simple Model, Video Three (Reference Video: C2_S_L1_V1C) 1. OK, we're going to analyze this model now. We'll review it, analyze it, and then start taking a look at some of the results and try to get a sense for the type of numbers that we're calculating out of CAESAR II and how they're presented to you. Before I actually do the error check, I'm going to take a look at a few items here. We see the OD of the line is 8-inch and 6-inch pipe. Click the Diameters button. This displays the pipe diameters in the model. That's confirmed. Click the Show Temperatures button. The system is at 250 degrees centigrade. 9 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Lesson One Video One (C) Click the Show Pressures button. The system shows the pressure is at 25 bars of pressure. Click the Show Pressures button again to turn off this view. We can see the anchors are displayed, showing our boundary conditions 2. If I wanted to check the lengths of my pipe, I could go to the Element list and review them. Click on the List button. Select Elements. This gives us a list of information about each element in the model. This is a simple system, but when I view the list I see 3 meters, 2 meters, 2, meters, 1 and 1/2 meters. This looks fine. I'm ready to do my error check on this model. Close the Element List. 3. Click the Start Run button to run the Error Check. The program reviews the data. 10 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Lesson One Video One (C) There are no errors in this model. There are no warnings from reviewing the data. But there is one note. In any model we run, this note will be the center of gravity report. 4. The system shows the total dead weight of this system is 5,700 N. The center of gravity report is based on the origin being at node 10. It shows me where the center of gravity is located. 5. Click the Load Case Editor button. There are other, faster ways to the analysis, but I believe that on the first run of any model, you should review all the Load Cases, all the data. So let's go look at those Load Cases. 6. Here's what the program recommends that we run. The program will recommend Load Cases to do hanger sizing, which we don't have here. It will also recommend Load Cases to do sustained and expansion stress calculations, according with the piping code. You might have other Load Cases to run as well, but as far as recommended cases, these are recommended cases here. 7. Here we see the operating Load Case (OPE). That will be analyzing the system when it's in operation. It's got dead weight, the thermal properties and also pressure terms. 11 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Lesson One Video One (C) 8. The second Load Case is for the installed position and includes weight plus pressure. I say installed, here it says sustained (SUS). That is a collapse check performed by the piping codes. 9. The third Load Case (highlighted above) is the fatigue check-- Load Case 1 minus Load Case 2-- that's the expansion stress range between installation and operation expansion (EXP). So the stress type will tell us how to calculate the stress using the code equations and also what the limit for that stress is, and compare the calculated stress to that code limit. 10. Highlight the L3 Load Case (as shown in the previous figure). 11. Click the Run the Analysis button. 12. The next stop will be the output processor. We see there are basically three columns of data here, or three columns to my menu. 12 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Lesson One Video One (C) 13. The three columns include the Load Cases that were analyzed, different reports for these Load Cases, and then some general data belonging to the entire model, not associated with any specific Load Case-- our Input Echo, our intermediate results like stress intensification factors and flexibility factors, coefficient of expansion, dead weight of pipe-- are all in these miscellaneous data reports. 14. Normally, the first thing I would do in looking at an output is to confirm that the model is more correct. You might notice that Load Case 3 is in red. That's an indicator that the program has calculated an overstress in the expansion case. 15. OK, so we have three different Load Cases that were analyzed, and we have these different reports for those three Load Cases. We're going to bring these reports to the screen for these exercises. 16. Click Load Case One to highlight it. 17. Click Displacements for the report type we wish to display. 18. Click the View Reports button to display the report on the screen. 19. We could also send it out to a file. We could send it out to Microsoft Word. We could send it out to Microsoft Excel. We could send it out directly to the printer as well, or build up a booklet. We'll leave that for a later assignment. 13 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Lesson One Video One (C) 20. This report shows where the system moves to when it goes into operation. So the anchors at 10, 40, and 50 do not move at all. They're anchors. But the piping in between those anchors, does move around-- and quite a bit, as we see here. At node 19, the system moves almost 12 millimeters in the Y direction. 21. So each report that we see here is associated with a Load Case. I selected the operating case, Displacements. Close this report. 22. I could look at the installed, Displacements. Click the Sustained Load Case (SUS). Click View Reports. 14 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Lesson One Video One (C) In this report we see much smaller numbers; there's no thermal strain in here. Close this report. 23. We could also look at the operating Restraint report. This is how the piping system talks to the outside world in the operating case. Click the Operating Load Case (OPE). Click Restraints report. Here are the loads on these restraints, in N and Nm. We see some rather large loads here. Close this report. 24. The way the program works is we find the position of each node in space for each Load Case. Then we calculate the internal forces and moments, which then can be oriented with respect to the pipe. From there, we can calculate stress. That's going to be our first focus when we look at where these numbers come from. How is that stress calculated in accordance with the piping code in play? 25. Let's take a quick look at the sustained stresses. 15 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Lesson One Video One (C) 26. Click the Sustained Load Case (SUS). Click Stresses (for the stresses report). Click View Reports. 27. We see in the report, it says "CODE STRESS CHECK PASSED." We'll take a look at all the numbers later. Close this report. 16 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Lesson One Video One (C) 28. Click the Expansion Load Case (EXP). It is displayed in red. Click Stresses. Click View Reports. We see in this report that the system failed since the stresses in this Load Case exceed the allowable values in the piping code. It looks like we're 30% over the allowable stress at a node 30. 29. Now you build your model to this point, do the error check and run the analysis of your model. Verify you have similar results to what we show here. Your numbers may vary because of the version of the program that you're using or maybe some small difference in the input, but you should be pretty close to these numbers when done. Then we'll continue on from there. 17 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Calculating Stresses CAESAR II Statics - Lesson One Video One 1. Welcome to the CAESAR II training classes video courses online. This is the second in the CAESAR II Video Training Series. The first one was on the fundamental operation of the program. Now we're going to talk about static analysis of piping systems using CAESAR II. Our first focus will be on the stresses that we calculate in the program. Many people call CAESAR II a pipe stress analysis program. CAESAR II does more than just calculating stress, but as the major portion of the program, we'll take a close look in this set of videos on the stresses that we calculate. 2. The stresses are a measure of the mechanical demand on the piping material, and a safe piping system is one where the calculated stresses throughout the system are kept below the code defined allowable limit. Now, when we say code, we mean the piping code. In the United States, for example, that is ASME B31.3, the process piping code. There are over 30 different piping codes in CAESAR II, and they all have their own specific rules for evaluating stress in the piping system. We'll be looking at things such as what is that stress that we're calculating? What is its limit? How do you design the piping system to meet those limits? 3. When the program displays its results, it will indicate a failure in the stress calculation by the red line in the Load Case. In this example, I'm in the static output processor and Load Case 3, and the expansion stress range case is in red. This indicates to me that if I look at that report, the stress report, the stresses will exceed the allowable stresses at one or more points in the piping system. 18 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Calculating Stresses 4. Let's take a look at the model. I'm in the CAESAR II input processor now and we're using the model we built previously, called SIMPLE. I will go into the input processor and we're going to review it. 5. We can see that the element from 10 to 20 was the horizontal run, with an elbow at 20. The next element, 20 to 30, is the riser. The tee is at 30. Nodes 30 to 40 ends the vertical run at the anchor and the reduced pipe size is on the branch off the tee from node 30 to node 50. This is the model that we built earlier. 6. We are now going to error check this model by clicking on the Start Run button. 7. We see we have no errors; we can run this model. There are no warnings issued by the program. 8. The only item we have here is the note, which is our standard Center of Gravity Report. It tells us the center of gravity of just the pipe or the whole system together, the total dead weight. After that the report will show the position of that center of gravity. 19 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Calculating Stresses 9. Usually when I run a job for the first time, I always click on each of these independently: Start Run, then the Load Cases, and then the Batch Run. Many users, when they build their model, will click on the Batch Run. Using this procedure causes the system to do this error check and use the default Load Cases. This might cause you to overlook some warning from the program. So I suggest for the first pass, you always click on the Start Run button first and look at the messages. 10. Let's take a look at our Load Cases for this model. And yes, this is what we expect, the operating state of the system, the installed state (OPE), the sustained stress calculations, code stress calculations (SUS), and then the range calculation, the displacement range between the operating and installed positions (EXP). That is useful for the expansion stress calculations. 11. Those are the recommended Load Cases. I will click the Batch Run button now. This is that same Running Man, at this point, that we saw earlier. This will run the analysis. 12. The next stop will be the output processor. So here we are with the output processor of CAESAR II. Again, this is the job Simple. We see that we had three Load Cases defined, operating, installed or sustained, and expansion stress range. We have these different reports available for those three Load Cases. 20 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Calculating Stresses 13. We're going to first focus on just the overstressed case (Load Case 3, EXP). When we see a Load Case that is in red, that indicates to me that the program has calculated stress above the allowable in that Load Case. 14. I'll select Load Case 3, EXP, then I'll click on Stresses. Next, I want to generate a report, so we'll click on View Reports. This will display the report on the screen. I can also send it out to a file, send it out to a printer, or send it to Microsoft Word or Microsoft Excel. We'll display it on the screen. 15. So here I am in the output processor. This is the stress report, Load Case 3 stresses. This is the expansion case, Load Case 3. So we are, again, repeating the Load Case that we were looking at. Now I have a series of disconnected column headings. Column Headings 21 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Calculating Stresses 16. As I mentioned before, the columns are disconnected by this stress summary. Below the summary are the node numbers. If I scroll down, the rows in the table shift up and the table looks complete. There's a column for node, bending stress, torsion stress, code stress, and so on. 17. Let's take another look at the summary section of the report. The summary begins by showing us what piping code we're using, ASME B31.3 - 2012. Again, we see the message that the code stress check failed for the expansion Load Case. Now, the highest stress in the system, and maybe not the only overstressed point, is listed in this summary. Code stress at node 30 is 423.6 MPa. The allowable stress is 324 MPa. It is 30% over the allowable limit defined by B31.3 - 2012. There are some other stresses listed as well, axial stress, bending stress, torsion, hoop, maximum stress intensity. We'll talk about those later. 22 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Calculating Stresses 18. If we look at the list of numbers below, we see every node in the system, 10, 20, 30, 40, 50, is shown here. We also see some other nodes here, 18, 19. These are for the elbows. st 1 Element nd 2 Element rd 3 Element We have one elbow in the system. This is the beginning of the elbow (node 18), midpoint of the elbow (node 19), and end of the elbow (node 20). The beginning and end could be the same as our weld points on that elbow, and we also see they are in pairs. These are element by element pairs. Scanning through the numbers, here is that node 30 (near the bottom in the figure above). Again, the summary said this node was stressed 30% over the allowable. The Ratio column here shows it at 130 (130% of the allowable). So the row displayed in red-- and if you can't see red, perhaps you'll notice the * star shown-- is the overstressed point. Any stress that exceeds 100% of the allowed value from the piping code will also be displayed in red and with an asterisk. So our code stress is calculated as 423 MPa, and our limit was 324 MPa. We'll talk more about these numbers later. 19. If we look back at the summary section again, these are the different types of stresses that we didn't talk about earlier. The report columns only list values for the bending stress, torsion stress, and the code stress. However, the summary includes axial stress, hoop stress, max stress intensity. Those numbers are available as well, but not through this report. Let's look for more information on those stresses. 23 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Calculating Stresses 20. Go back to the Output menu, and instead of selecting Stresses, I will click on the Stresses Extended report. This will give me an extended width of the display and put in more columns in our table. View that report. 21. This is Stresses Extended report, stresses on each element and, yes, axial stress, bending, torsion, hoop, maximum stress intensity are displayed in this report. As I scroll down the columns now line up with data, and if I was interested in any of these, I would have values to use. 24 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Calculating Stresses 22. Now the piping code does not offer an allowable stress for these columns. Frankly I'm only interested in the code stress and its allowable. But if you do have an interest in other calculations or, if you want, you could use these to diagnose problems elsewhere. For example here, our code stress is 423 MPa. It's almost all bending stress (396.09), so we can relate it like that. Now we'll move onto a graphic representation of this data. We'll start by closing out this report. 23. From the toolbar, I can see this elbow here. This is the 3D Plot display button. I can click on this 3D Plot display button and it will open up the plot processor. 24. Along the top is the same toolbar that we saw earlier in the Input Processor, but there's another toolbar here as well for the Output Processor. We are looking at the expansion case here. Usually when I look at the model for the first time, I'll go to the operating case, when it's hot and in operation, with all the weight on it. 25. Then I'll click on this first button here, Deflected Shape. 25 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Calculating Stresses The system displays the deflected pipe in a bronze color, which shows the deflected shape. The display is not to scale, but it does give us an idea of where the system is moving to when it goes into operation. 26. If we click the Orbit button we can start to view the system. 26 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Calculating Stresses I can see how the branch pipe pushes out to the riser, and I can see how the elbow grows away, and the bending on these legs. This is probably what we would expect to see. The anchors are acting like anchors. So this visual check is a good way to confirm your boundary conditions, and see if they're working properly. 27. Now let's take a look at some other things here as well. I'm going to go back to our expansion case, because that's what we were looking at in terms of stress. The change in position is now shown. This is not a true state of the piping system, because it's the change in the piping system, but we can display numbers on the screen as well. 28. We have this Show Element Grid button, or we can just click on a piece of pipe to do the same thing. Let's click on this piece of pipe, and now we have this grid. 27 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Calculating Stresses 29. Hold down the mouse button in the orange header area of the grid window. Drag it up and over to the left and snap it to the side. The grid contains all the numbers for this model. 30. Click on Stresses for the Expansion case. We can see on the element 30 to 50 the code stress, which is 30% over the allowable. So we can easily review numbers while looking at the plot at the same time. This is a very good way to diagnose problems in your piping system. 28 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Calculating Stresses 31. We also have another way we can review this data graphically. Instead of looking at the deflected shape, look at the overstressed points. We can use Stress colors by percent, Overstress, Maximum Stress, Stress by colors by value. I want to look at Stress colors by percent. 32. Click on the Stress colors by percent button. Reset the plot to the Southeast view. 33. If we see red, that is greater than 100%. If the pipe is burgundy, it is between 80 and 100%. So we see some burgundy colored pipe in this display. 34. The pipe displayed in red near the branch. To make it a little easier to see, let's get rid of these other colors, and change them to white. 35. When the colors are set to white, and when we exit the job, these settings will be stored on the machine. So the next time we come into this file, our updated colors will appear. Changing the colors like this makes it easier to see that the branch off of the tee is what is overstressed. 29 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Calculating Stresses 36. To change the colors click on one of the colors you want to change. Click the button with the dots (browse button), select the color white, and then click OK. Do this for each color except red. 37. Now you can see the overstressed areas of the line more easily. OK, get your model to this point. Review what we've covered and repeat these steps. Make sure you can do this much and that you understand what's been covered to now. We will pick up on the stress analysis after that. 30 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Calculating Stresses CAESAR II Statics - Lesson One Video Two 1. We're back in our model and now we'll go to the report and review the data on that report. This report is the stress report and includes the name of the job, and to whom the software is licensed to. It's best to take a look at the header bar to see what the report is that you're looking at, and it will define the load case that comes out of CAESAR II. 2. We see here many different columns. Fortunately for us, we're viewing the entire model's report (minus the stress summary which we'll talk about later). This is the entire model from 10 to 40 and 30 to 50. 31 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Calculating Stresses 3. The report is listed by elements. So we see here focusing first on the node numbers, each element is listed in this report as basically the free body diagram of the element. The forces and moments to keep that free body in equilibrium are then used to calculate stresses on the elements. We see a number of stresses listed. We have Bending Stress, Torsion Stress, Code Stress, and Allowable Stress. Which is the stress we have to look at? Which one's important to us? 4. Well, in my opinion, the code stress is the money stress as far as I would call it. We want to compare the calculated code stress to the allowable stress defined by the piping code. The line in red indicates that the branch at node 30 exceeds the allowable. The calculated stress is 423 MPa, and the allowable stress is calculated as 324 MPa. We are 30% over the allowable stress. 5. So the system is overstressed in accordance with B31.3. Now, what does this actually mean that we are overstressed in the expansion case? Well, according to code, we may fail this Tee over time through fatigue. A through the wall crack might develop at that point. We really can't say when, but assuming a certain number of cycles for this plant, it is not an initial failure, but a failure that will happen sometime in the future. 6. In order to assure a safe design, we'll have to redesign the system in order to drop that code stress below the code defined allowable stress. Now, what is that code stress equation? The following figure shows what B31.3 gives us in paragraph 319.4.4(a). 32 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Calculating Stresses 7. It says the expansion stress range equals the square root of the absolute value of the axial stress due to displace strains (that's our thermal strain), plus the bending stress at that point, also due to displacement strains That squared plus two times the shear stress squared to that. So we need the square root of the sum of the squares. What can we learn from this formula? Well, let's talk about evaluating stress. 8. Basically, if node 10 and node 20 are on each end of the pipe element below, we're going to calculate stress on each end. We need some kind of accounting system for all the terms that we have to consider. We're going to relate our stresses to a local coordinate system. The local coordinate system being the longitudinal stress term (stress along the pipe), the hoop stress (or circumferential stress around the circumference), and the radial stress through the wall of the pipe. 33 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Calculating Stresses 9. If I would create a little stress element on the wall of the pipe here, it would look like the stress cube shown here. We have the longitudinal stress (shown pointing to the right), and a shear stress (normal to the tail of the longitudinal stress vector). The shear stress is caused by torsion on the line. On the near surface we have hoop stress, in the hoop direction, and the shear stress. On the outside wall, we have the radial stress. Hoop Stress Shear Stress Longitudinal Stress 10. We will use this stress cube to get back to that equation we saw earlier. Here are all the terms that we're going to work with. What we're going to do is ask, are longitudinal stress caused by thermal strain? We're looking at expansion stress calculation. We'll have the axial term; the axial force due to stress. Axial Term Bending Term The axial force is divided by the cross section of the metal, and the bending moment will be divided by the section modulus of the pipe. Now, this will be changing through the wall of the pipe, so we want the maximum longitudinal bending stress, and that would be at the outside of the wall, the surface of the pipe. 34 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Calculating Stresses 11. We have very low stress in the hoop direction caused by thermal strain. Typically, hoop stress is considered when we're talking about pressure stress. We'll talk about that later. But right now we've basically got what's required as far as the code is concerned. We're heating up this piping system without any regard for pressure or dead weight. It's like we're in outer space and we're heating up this piping system. There's no dead weight here. Radial stress is also zero. 12. So we have a longitudinal stress. We have no hoop stress caused by thermal strain, and no radial stress caused by thermal strain. Shear stress is caused by the torsion. So the base equation, torsion divided by two times that same section modulus is the shear stress on the stress element. We might have a direct shear as well, but on the outside wall, where we have our maximum bending stress that would be zero. So we're going to exclude that from our calculation. So we only have the axial load, the bending term, and the torsion term remaining in our calculation, by code. 13. If I go back to my cube, the radial term is zero, the hoop term is zero, and I have just the shear term, and the longitudinal stress term, how does that look? If I look down from the top of that cube, I have a longitudinal stress and the shear terms. Do I have a limit for longitudinal? Do I have a limit for shear? No. What the codes do is they take this stress element, and rotate it in the space, to get a maximum principle stress or a maximum shearing stress. In our next video, we'll explore how we can convert this combination of stresses into a simplified evaluation of the total stress on the stress element. 35 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Calculating Stresses CAESAR II Statics - Lesson One Video Three 1. OK, now let's convert these general stresses into stresses that are used by the piping code. Remember that if I have a stress cube, and we are looking at a static analysis, that system is in equilibrium. It's not moving. It's stable. All the forces and moments are balanced. So if I look at my stress cube, this surface back here has a shear term on it. Shear times area is a load. Here's a direct stress. Direct stress times area is a load. So I've got loads in the vertical and horizontal directions shown here on the illustration. 2. Let's cut a new surface here. The force on this new surface must balance out the remaining forces on the other surfaces. So if I have forces I can calculate stress. I have a direct stress and a shear stress on this new diagonal face. We have an existing shear stress on the horizontal face, and both shear and direct stresses on the vertical face. 3. I can, with some work, calculate the stress on this new (diagonal) face. A convenient tool that we have to do this transformation for the stresses on the new face is Mohr's Circle. Given the stress, direct stress and shear stress, on the original faces, I can develop a new set of numbers for the new face based on the angle and those loads. So let's look at Mohr's Circle. Here's an example. 36 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Calculating Stresses On the horizontal axis, we have our direct term. On the vertical axis, we have our shear stress term. On this face we have SL and -τ. I'm going to say shear is positive clockwise. So there's SL negative tau (-τ). The other face has only shear stress and no direct stress, so direct stress is zero, shear stress is tau. Here's the other point. 4. These two points now establish this circle called Mohr's Circle. This is a locus of points that will have the direct stress and shear stress on the new face. 37 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Calculating Stresses If I plot it this way, then I rotate for the new face in this direction, angle phi, then based on this rotation, here are my new stresses on that new face. Given the two points I can develop the circle, and that will allow me to calculate the stresses on any angle phi. So here's my new stress on that face. 5. Now I don't really care about any general angle; I'm most interested in the limits of this circle. Generally speaking, in Mohr's Circle, we will have, on a 3-D surface, three principals stresses. A principal stress is a stress where there is no shear term. It's the orientation of that face of that cube where there is no shear. We have that at three places here. We have the S1 defined as the largest principal stress. S3 is the smallest principal stress. Remember that we had a 0 term in the radial direction, that 0 stress, which will be S2. So we have the tension stress S1, compression stress S3, and then the radial term, the third surface which will be 0. 6. We have three stresses on our stress cube, and we've rotated in space. We have three surfaces here. If I use Mohr's circle, I can rotate this cube in space to a position where I get purely normal stresses on those three faces. Where does that happen? It happens at these three points. So S1, reorient the cube to get the maximum principal stress, principal stress is normal to the face and no shear exists. The minimum here is out here at S3 by definition, which is in compression. It's on the negative side. Then again, S2, our radial term, is 0. 38 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Calculating Stresses 7. The piping code theory of failure is maximum sheer stress. If the sheer stress exceeds a certain value, we assume that causes the failure of the material. There are many different theories of failure. Maximum shearing stress is a quite useful one for us. The maximum shearing stress is this value here. We're also going to be able to relate that to the radius of Mohr's Circle, which is also then related to the diameter Mohr's Circle. We could also talk about S1 minus S3, the diameter of Mohr's Circle. This is twice the maximum shearing stress. 8. So we're going to use the maximum shearing stress theory of failure. We want to know what the maximum shearing stress on this piece of pipe is. So I have a complex state of stress; I have longitudinal stress and shear stress. How does that relate to this maximum shearing term? Well the nice thing about it is that now I don't have to worry about what is the magnitude of SL and what is two times the shear term. Instead I'll just get you one number, maximum shearing stress, and use that to compare with the failure. 39 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Calculating Stresses What is the maximum shearing stress here? Well I'll draw this triangle. There's my vertical run (that's two times tau): positive tau and negative tau. The horizontal run here is SL minus 0, or the longitudinal stress or bending term. So with those two sides of the right triangle given, I can calculate the diameter of Mohr's Circle here. For this calculation, just take the hypotenuse and divide by 2. So this is our equation for the calculated stress in our expansion case. 9. Of course we're interested in the maximum shearing stress, but what the code will do in terms of simplification is basically get rid of that 2 that we're dividing by. So instead of dividing by 2 here, multiply both sides by 2. So 2 times the maximum shearing stress equals this equation. 10. Compare that now to the code equation. Well it has the same format exactly. Here's a longitudinal term, which is a direct axial load. There's our bending term. Square it. That's SL2, and here's our 2 times the shear term. So we have bending stress and shear stress caused by torsion on the element and also any direct axial load. The direct axial load is taken absolutely. T he code simplifies and gets rid of the sign. We want to acknowledge that there might be some additional direct axial stress on the line as well. 11. Like most piping codes, B31.3 will use this maximum shearing stress theory of failure to evaluate the strength of the piping system. So this is our equation from the code for the expansion stress range calculation, and what we'll do in our next video is go from that equation, to the output report in CAESAR II. 40 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Calculating Stresses CAESAR II Statics - Lesson One Video Four 1. Now we're going to see how we can tie this calculated stress into an overstress at node 30 in our piping system. We're going to be reviewing the expansion stress range, the code defines the case that we're looking at (see the following figure) as the expansion stress calculation, and the code says, here's our equation for the expansion stress range, and that's the equation we just developed. This is equation 17 in the B31.3, 2012 Edition. It is found in paragraph 319.4.4 Flexibility Stresses in the code. They define these terms, SE is the computed displacement stress range. 2. There is no dead weight in this; there is no pressure. It's just displacement stress range. Sa is the axial stress range due to displacement strains. Sb is the resultant bending stress, again, due to displacement strains, and St is torsional stresses, due to displacement strains. The code goes on the state, in paragraph 302.3.5(d) that this calculated stress shall not exceed SA. So all the piping codes that we use in CAESAR II have a similar type of calculation. A calculated stress must be less than some allowable stress. In doing this evaluation, if every point is below that allowable stress, the system is considered reliable for operation. So here's our equation again, SE equals the absolute value of the axial stress, plus the bending stress, that quantity squared, plus two times the torsion stress, that quantity squared, square root. Sa is the axial stressed range of displacement. 41 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Calculating Stresses 3. The code defines the axial stress range as an intensification factor times a direct axial load caused by displacement strains divided by the area of the pipe (the cross section area of the pipe). 4. This is a rather new equation for B31.3, the expansion stress range, and in fact, this term ia appears for the first time in the 2012 Edition. This intensification factor changes our calculation from a true calculated stress to an effective stress. It's an adjustment factor. This i is an adjustment factor, to relate the relative weakness of a component. You will see that elbows and tees have higher values of ia, and for all the intensification factors. Straight pipe does not have a value; it's just equal to one. 5. So the piping codes use this intensification factor to adjust the stress calculation to reflect the weakness of the component under evaluation. An elbow is weaker than a butt weld in a straight pipe. This would mean that the elbow has a higher stress intensification factor than a butt weld. A welding tee, or an unreinforced fabricated tee, also has its own stress intensification factor reflecting the weakness of that component compared to a butt weld. If I have, for example, a girth butt weld and expose it to cyclic stresses, let's say a range of stress of 200 MPa that fails after 5,000 cycles. But an elbow, being a weaker component, would fail at 5,000 cycles with only 100 MPa. So the elbow it has less stress level to reach the same failure point. The piping codes generally calculate a nominal stress, force over area, or moment divided by section modulus, and then increases that nominal stress to account for the weakness of the component being evaluated. This increase in the calculated stress is the stress intensification factor. In the program you'll see it termed as SIF, for stress intensification factor, or italic lowercase i, stress intensification factor. 6. So a larger SIF indicates a weaker component; weakness in terms of the fatigue strength that we're talking about here in the expansion stress range, or weakness in terms of collapse, which we'll talk about later. By increasing the calculated stress, the stress limit is now independent of component shape. I don't care if you're talking about a tee, or an elbow, or a butt weld, or a socket weld. If I assign the right stress intensification factor, my measure of failure is based on the piping material itself, and not on the component shape. 42 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Calculating Stresses 7. Here's an example, so let's have a girth butt weld on a cantilevered piece of pipe and I cycle that cantilever up and down until it fails. Let's say I can get the failure exactly at 10,000 cycles with a stress range (fatigue calculations), a stress range of 260 MPa. I pull it up, get a positive 130 MPa, then I push it down to get negative 130 MPa, and it fails after 10,000 cycles. Now let's say I set up an elbow in the same test stand, and I miraculously have it fail at the same 10,000 cycles. But I can get the elbow to fail at 10,000 cycles, not with 260 MPa stress range, but instead let's say it is 130 MPa instead; it has half the stress range allowable. Well, instead of using a lower allowable stress for the elbow, what the piping codes do is they increase the calculated stress. 8. So if the elbow fails at the same time but with half the stress, its stress intensification factor then will be two. So we'll calculate the same stress level, we'll double to calculated stress from 130 to 260, and then I can base my allowable stress on the piping material itself, low carbon steel, for example. It has a certain stress allowable and we compare to that allowable stress. This was looking at one stress intensification factor for the axial term. There are intensification factors for most terms of load in the piping codes. We'll pick up in the next session looking at some of those other terms. 43 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Calculating Stresses CAESAR II Statics - Lesson One Video Five 1. Now let's take a look at some of these other terms that we have in our expansion stress range calculations. Here's the bending term. Sb is the resultant bending stress range due to displacement strains. B31.3 provides equation 18 to define Sb, the bending stress range. There is our intensification factor, i but its ii. That's the in-plane stress intensification factor. There is also an in-plane bending moment and out-plane bending moment, and it's associated out-plane stress intensification factors. That is all divided by the section modulus for the pipe. 2. Section modulus is a common piping term. It is basically the moment of inertia, I, divided by the radius of the pipe. Of course in bending stress calculation, the bending stress is Mc/I where c is the point through the cross section where we wish to calculate the stress. Our highest stress is on the outer wall, so c equals the outer wall or the radius of the pipe. 3. So the Z term is just I/r. So instead of talking about Mc/I like other mechanical engineers might use it, we're going to say for pipers, it's M/Z. The same term. We can see that we might have a different stress intensification factor for an in-plane bending moment than we would for an out-plane bending; whether it's a tee or an elbow or any other planar component in a piping system. 44 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Calculating Stresses 4. Let's define in-plane and out-of-plane bending. If I have an elbow and I throw it on the floor, it lies in the plane of the floor. Suppose I put a bending moment on one end or the other end of that elbow, and that bending moment is not torsion. If I pull the elbow out of the floor plane, that's an out-plane bending moment. If I put a bending moment on the elbow and it remains in the plane to the floor, that's an in-plane bending moment. So the vector for this bending term for in-plane bending is perpendicular to the plane of the component. The same is true with a tee. If I have a tee and I put it on the floor, the bending moment that pulls it off the floor, one end or any of the three elements framing the tee - that would be an out-of-plane bending. 5. Let's go back to our elbow stress intensification factors. There are different stress levels required to develop a through the wall crack for in-plane and out-of-plane bending. Stress intensification factors are different for different directions. We already saw one for the axial term. Here we see two common terms for elbows and tees, for in-plane bending. We have a certain level where we reach failure for this, versus an out-plane bending, which will be at a different level. So the piping codes have defined different terms for in and out-of-plane bending. 6. The last component of our calculated stress is our torsion stress. B31.3 gives us an equation for that. Torsion stress is an intensification factor, but this for the torque term, times the torsion in the line (the torsion bending moment) divided by 2 times the section modulus. Again, these terms are defined in the piping code. 7. Where do we get the stress intensification factors? We've seen several of them. We saw an it , an ii , and an io. Where do those values come from? 45 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Calculating Stresses 8. If we take a look at appendix D of B31.3 entitled Flexibility and Stress Intensification Factors, we can see they have values defined for stress intensification factors, both out-plane and inplane. We have illustrations shown for an elbow, a closely mitered joint, a widely spaced joint, a welding tee, and reinforced fabricated tee. These values are based on the geometry of the component. 46 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Calculating Stresses 9. On this page, we also wee the unreinforced fabricated tee, the extruded welding tee, the welded in contour insert (Sweep-o-let), and the branch welded on fitting (Weld-o-let). There also SIF's for other joints in a piping system. The other piping codes have similar tables. The tables may not be exactly the same, but they will also be used to define the intensification factor for these piping components in those respective codes. 10. These SIFs, or stress intensification factors, are based on testing done back in the late 1940s by A. R. C. Markl, who was the chief engineer at Tube Turns, a piping component manufacturing company. He and his team developed these stress specification factors based on testing. If you wish to reference these papers, they are still very good documents in terms of pipe stress. The ASME papers that Markl developed are still available from the company Tube Turns in the US. 47 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Calculating Stresses 11. So what are the stress intensification factors in and out-of-plane for a welding tee? Well, first we see a calculation in Appendix D will be for a flexibility character h. It defines h as 3.1 times the nominal thickness of the matching pipe for the tee divided by the mean radius of the matching pipe for the tee. So it uses the size the pipe that is connected to the tee. 12. Basically it's the nominal thickness divided by the radius of the pipe times 3.1. This came from testing. The out-plane SIF defined in the piping code is 0.9 divided by h to the 2/3. The inplane is 3/4 of the out-plane plus a quarter. What the program will do for you is based on your geometry, calculate ii and io and the other terms ia and it, and apply them to your piping system calculations. OK, let's put these terms back into our example models in our next presentation! 48 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Calculating Stresses CAESAR II Statics - Lesson One Video Six 1. So let's put these back into our example. In the figure below, we can see the pipe data for our system and below that is the stress intensification factor calculations. The pipe data contains information on the OD, wall thickness, OD and wall thickness with a header pipe, or the run pipe-- this is our branch pipe. Radius of the branch pipe, ID of the branch pipe, area of the branch pipe, moment of inertia and section modulus of the branch. And then again, the SIF's for the intersection itself. These are ii and io. We also will develop from there some other terms before we can do our calculation. 49 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Calculating Stresses 2. We also have some additional terms, shown in the figure which follows. 3. One comment in B31.3 is that when you have a reduced branch on a tee, you will adjust the strength of the intersection by not changing the SIF. The way B 31.3 developed this was to reduce the section modulus calculation to increase the calculated stress for the branch. So we will need that term as well. Again, the program takes care of all these calculations. For the axial term's intensification factor, the code says it equals the outplane SIF for a tee. The torsion term's intensification factor is equal to 1; in other words, there's no value to increase the calculated stress. 4. In the following figure are the loads on our tee. We will use these loads with these terms, and also the terms on the previous page in order to calculate the code defined stress for the branch pipe on our tee. Where do these numbers come from? Well, they're developed by CAESAR II. It's a preliminary calculation before we get the stress. 50 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Calculating Stresses 5. So what are these terms? Well, the first one listed is the axial load on the branch. It's the load pulling this branch off the tee. Next is the torsion term twisting this run of pipe, twisting the branch. Following that is in-plane bending—this is the bending moment that keeps the tee in its existing plane. If this anchor was not at node 50, I could pull this free end up and down in the plane of the tee. That means in this case, in-plane bending is about the X axis. The last one is out-plane bending will occur if I take node 50 and pull it towards me; I'm pulling the branch out of its plane. That would be bending about the Y axis, globally. That's my out of plane bending moment. CAESAR II produces these numbers for us as well in reports as part of the output. Let's look at them. 6. Here's my report from CAESAR II. I'm looking at node 30 going to node 50. The axial term is in the Z direction. So let’s look at the global force in the Z direction. 51 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Calculating Stresses Here's a little free-body diagram of 30 to 50. It shows it's in the positive Z direction. Well, positive Z is to the left; it's an axial term here. That is actually considered compression in CAESAR II, which is why we have a negative sign in the computed value. So the program is keeping track of the orientation locally of the element with the loads on that element. The red arrows indicate the local forces and moments on node 30, and the magnitudes come from the results in the next table below. 7. So we have our axial term in the Z direction. MZ is a torsion term. Next is the in-plane bending again, which would be a vector bending about the X axis pointing out to us. This would mean bending node 50 straight up and down. That would be the in-plane bending. Inplane bending is the MX term, the moment around X. 8. The out-plane bending is the bending moment on the branch that pulls the branch out of the plane of the tee. That's bending about the Y axis. So if node 50 was not anchored, it would be the bending moment associated with bringing node 50 towards us or pushing it away from us, pulling it out of the plane. This is how we'll determine in- and out-of-plane bending of that tee. With these loads in the system geometry, CAESAR II will proceed to calculate the code stresses we reviewed earlier. 52 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Calculating Stresses 9. Here's an illustration of these calculations using the MathCAD application. We can use this program to manually calculate, by equation, those same stresses. 10. We see in the following figure the pipe OD and wall thickness, both for the branch and the header pipe. The derived values, the radius of the pipe, the value h is a flexibility characteristic defined in Appendix D of the B31.3 piping code. We also see values for the in- and out-ofplane stress intensification factors from the appendix. Also shown is the moment of inertia section modulus and so on. 53 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Calculating Stresses 11. Scrolling down through this report we see the same forces and moments for our stress calculations as shown as calculated using MathCAD. In this analysis for the expansion case, pressure is set to 0 because we're not looking at pressure in this analysis. If I look at the calculations performed by MathCAD, here they are: axial stress, bending stress, torsion stress, and the expansion stress range. 54 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Calculating Stresses 12. Now let's look at the CAESAR report. Here we see in the extended report the list for Axial Stress, Bending Stress, Torsion Stress, Hoop Stress, Max Stress Intensity, and finally, Code Stress. Our focus here is on the Code Stress calculation. 13. So here's the expansion stress range, MathCAD calculated 423.59 and CAESAR II calculated showing 423.60. That's a match. That's the value for stress, and it's made up of these three components. 14. An interesting thing with CAESAR II is that we list Axial Stress, Bending Stress, Torsion Stress, but these are basic textbook calculations that may not vary between piping codes. The stresses shown in the previous figure (Sa, Sb, and St) are quite specific for B31.3. 55 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Calculating Stresses 15. If I look at my axial stress that I calculate for my expansion stress range, I get minus 26.79 MPa. What does CAESAR II show? It shows 11.51 MPa. So CAESAR II is returning the pure structural load, axial load, divided by the area of the pipe, giving me 11.5. So this is a generic axial stress without regard for this new stress intensification factor we have in B31.3. 16. The bending term does match up. I got 396, and there's my 396. So in this column of CAESAR II we do use SIF's, or stress intensification factors, for the bending term. 17. In the torsion column, my calculation from the code appears to be minus 12 MPa. If I look at my listing here, it says minus 10. This difference is from a note in the code which states that if I have a reduced outlet on the branch connection at a tee, I shall use an effective section modulus calculation. So here in this column, the torsion stress, it is the effective section modulus calculation. When I add up all these terms together, I get my calculated stress of 423.59 MPa. So now you can see how detailed some of these calculations are. These decisions made by the software in using SIF's, in using effective section modulus versus actual section modulus are illustrated in this section of the course. 56 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Calculating Stresses CAESAR II Statics - Lesson One Video Seven 1. OK, in our previous video we were reviewing the expansion stress calculations. Let's move on and look at a few more calculations in the output report. 2. Sustained calculations will be reviewed next. Before we start looking at the stress report, let's collect our terms that we need to work with. First, here is a listing of the sustained stress indices, the capital I. We also call it the SSI, or Sustained Stress Index. This is new to 31.3, and the SSI for sustained stresses is a function of the stress intensification factor that we had from the expansion case. 3. Our in-plane SSI is 1.5, out-plane is 1.75, torsion and axial are set at 1 flat. Again, we're looking at the outlet on the tee, node 30. So we also collect-- these are the SSIs for the branch. Here are the local forces and moments for our stress calculations, the axial load, in-plane bending moment, out-plane bending moment, and torsion. 57 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Calculating Stresses 4. So we assign those values. We also have the pressure term as well. These will all be used to calculate the sustained stress in accordance with B 31.3. 5. Here's our calculation. We have our axial stress calculation, our bending stress and our torsion stress. These terms are combined in order to calculate the longitudinal stress due to sustained loads. Our calculated value using MathCAD is 13.33, and yes, we have 13.33 in our CAESAR II output report. The allowable stress for those collapse loads or the collapse stresses are 132.12 MPa. That's the hot allowable stress for this node in the piping system. 58 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Calculating Stresses 6. Other stresses that we have in the program are the calculations for the Axial, Bending, Torsion and Hoop stress that we see in extended report. Again this is for node 30. There are 12.93, and you can then review all the rest of these. And yes, we're calculating these stresses in CAESAR II using these equations. 7. Note here that on the bending stress, it is not the capital I that we saw in the stress calculation. Again, we consider these more the textbook calculations of stress, and our interest is mainly on the code stress calculation. 8. Now what of this other calculation, Maximum Stress Intensity that appears in the CAESAR II output report shown earlier? Well, there's a little more to talk about in that one. This is a stress that is calculated at four points across the cross section. 59 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Calculating Stresses If I take my resultant bending moment and lay it on the pipe, I have, and using the right-hand rule, the side of this pipe at points 1 and 2 is in tension, due to this bending moment, and the side at points 3 and 4 is in compression. We're pulling out towards us, in 1 and 2. We're pushing in, in 3 and 4. 9. We're going to calculate stresses on the outside surface, inside surface, on both the tension and compression side. Also, it's not just with the bending term, but with all three directionsaxial, hoop, and the radial term. 10. So here are the terms, these four points. Each row represents a point. The first point is the first row in this vector. The second point is the second row, and so forth. We're calculating longitudinal stress at point one, two, three, four. Hoop stress is calculated at one, two, three, four. The hoop stress calculation is the Lamē equation for hoop stress, based on the inside and outside radius of the pipe. 11. Longitudinal stress should be familiar. It's the axial term, and the bending term, outside radius, inside radius. Radial stress is 0 on the outside surfaces, but negative P (it's the compressive radial stress on the inside surface of the pipe). The shear stresses are the basic shear term, outside radius, inside radius based on torsion. 60 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Calculating Stresses 12. We're going to calculate these four stresses at these four points through the cross section. We will then take them to Mohr's Circle, and then calculate the three principle stresses based on these four terms. 13. This will give us the center of Mohr's Circle, in longitudinal hoop's term. This is the radius of Mohr's Circle. So when I add the radius to the center, I get one of the three principal stresses. I subtract the radius from Mohr's Circle, and I get the second of the principal stresses. The third term will just be the radial term. So these are our three stresses on Mohr's Circle, where there is no shear term. 61 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Calculating Stresses 14. Well, I can't tell you which one is the maximum in order to get S1 minus S3. Again, stress intensity is the diameter of the largest Mohr's Circle, S1 minus S3. But I don't know which one's which. So I can sort these three different stresses at the four points, and here they are. Here's the Sa at 1, Sa at 2, and Sa at 3. 15. This is on the outside surface in the tension side (1), inside surface tension (2), inside surface compression (3), outside surface compression (4). Then we sort these terms so that we get them in order, and then calculate the largest difference between 1 and 3. 62 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Calculating Stresses Then we sort them again, and our maximum stress intensity, which comes out to 30.88 when calculated using MathCAD. Looking again at our CAESAR II report we see we get the same value. 63 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Calculating Stresses 16. There is another switch you can set in the program, in the configuration file to use either the octahedral shearing stress calculation, or the equivalent stress calculation. In CAESAR II, what we do is run the octahedral shearing stress calculation to calculate this octahedral stress calculation. S1 minus S2, the quantity squared; S2 minus S3, the quantity squared; S3 minus S1, the quantity squared. We then take the square root of that, multiplied by one third, and that's going to be our octahedral shearing stress. 17. So that value is 12.61. Again, we don't offer any allowable limits for that; it's more of a textbook calculation. That pretty much covers the stress calculations in CAESAR II. We'll move onto one final section in the next video to conclude this discussion. 64 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Calculating Stresses CAESAR II Statics - Lesson One Video Eight 1. All right, we're about ready to wrap up the discussion on stress calculations in CAESAR II. If you recall, I made several comments on code stresses or textbook stresses. I want to go back to one more point on this code stress. 2. Again, in CAESAR II, we calculate code-defined stresses and we compare them to the codedefined limits. If you have an overstress, the stress case is shown in red in the output processor that clearly indicates that the code stress check failed. But what about the operating case? 3. If I look at the operating case in the output section of CAESAR II for 31.3 or 31.1, I'm going to get to a report like this. Here's the stress report, and it says, NO CODE STRESS CHECK PROCESSED for the operating case, B31.3. If I look at the allowable stress, it says 0. 4. Again, the way that the 31.3 and 31.1 piping codes, and many other piping codes, establish criteria for safe design is not based on the state of stress in the piping system, but on two specific modes of failure-- collapse and fatigue. They have their own stress calculations and their own limits. However, in these piping codes, we do not combine them to calculate the stress. So this state of stress, we still list it as a code stress in the column here, but this is not a code-defined stress calculation here. So if you see no allowable stress and you have allowable stresses specified, it's probably in this type of situation where the code does not provide a calculation or an evaluation of a stress in such a state. 65 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Calculating Stresses 5. Now, if you're not running 31.3 or you're not familiar with the terms that are used in the piping code, you could go back to our Quick Reference Guide from the Main Menu. It's here, in the Main Menu of CAESAR II, on the ribbon, Help, Quick Reference Guide. 6. Here's the Quick Reference Guide, right from the program. 66 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Calculating Stresses 7. I'm going to go to Code Stresses. Here is a quick review of all the code-defined stresses that are found in CAESAR II. Here are some of the terms used in this section of the reference guide. 67 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Calculating Stresses Here are some general terms used in the US codes: Longitudinal Pressure Stress, and the Operating Stress equation. Here's a section for B31.1. You can see that it's broken down into the equation for stress that we calculate, the limit that we establish for that stress case, and the stress category. Again, when you define a stress category, you're defining the equation used to calculate the stress and the limit for that stress. So this is how we set up our evaluation for 31.1, Sustained (SUS), Expansion (EXP), and Occasional (OCC). 68 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Calculating Stresses In 31.3 it's also Sustained, Expansion, and Occasional. 69 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Calculating Stresses 8. Here are some other codes: nuclear code, older power codes, here's the transportation code 31.4, liquids transmission code. 70 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Calculating Stresses Here are 31.4, chapter IX (that's the offshore code); we see different calculations are used. We see there is hoop stress, longitudinal stress, and equivalent stress, which is von Mises stress. These results are compared to yield limits, percentages of yield. 9. Other codes are included as well: 31.5, 31.8, and so on. So here's all the US codes. 10. Then we get involved with the international codes. The Dutch Stoomwezen code, the French power code, Canadian transmission codes, and so on. So review this document if you have any questions about the calculated stresses that we have in CAESAR II, and make sure these conform to your understanding of what the program should be doing. So there you have it. We've completed our review of the stress calculations in CAESAR II! 71 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Selecting Hangers CAESAR II Statics - Selecting Hangers Video One (Reference Video: C2_S_H_V1) 1. In this series of discussions, we'll talk about the hanger selection procedure in CAESAR II. There will be a second set of videos on manipulating the CAESAR II selection, so at this level, we're just concerned about how the program selects springs and installs them with your piping system. 2. Designers can locate dead weight supports quite easily. There are a number of tables and charts for that. So it's easy to locate hard supports for carrying dead weight. Unfortunately, because of the vertical growth of the piping system, that differential thermal growth between the support structure and the piping complicates the actual support that is installed in the system. The choice must be made between a rigid support (or a resting support) -- or a rod hanger-- a variable load hanger, or what we'll call a spring hanger, or can, and also, finally, the constant effort restraint. 3. The choice here is quite important in several respects, not just in engineering, but also in cost. A typical support for an 8-inch pipeline at high temperature, a simple rod hanger including all the hardware might right up to $600.00. A spring hanger might be almost twice that, over $1,000.00. A constant effort, over $3,500.00, so yes, there is a cost associated with these supports, as well. 4. Now if I have a piping system that only has to support dead weight, I could easily put a +Y support in the CAESAR II, where we see the simple support location right here, and I could run a dead weight analysis, and the program will show a load on that support. I'll call that load dead weight-- whenever that value might be. I will take that number, go to a catalog, and select the proper rod size, and install it in the piping system. 72 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Selecting Hangers 5. Now this rod is stiff enough so that it can support the dead weight without any deflection. So in CAESAR II, it's a rigid support. Now initially, I had it as a +Y, this illustration would be a double-acting Y support. Unfortunately, if this vertical riser gets hot, the piping system will grow vertically, and we will have some issues with what is the load on that support. 6. There could be other issues as well. Number one might be the pipe might lift off the support, and dead weight travels elsewhere. Or the support could actually hold down the pipe, as shown here, in which case, we'll end up getting more bending in this elbow, and we might overstress that elbow. Also, this load down at the bottom of the pipe is going to be quite different, as well. It could be larger than the dead weight, because now we have the thermal load pushing down, as well. So this hard support, while the cheapest of the three selections that I mentioned earlier, will not be a proper selection for a thermal analysis. 7. Now if I could possibly replace that hard support, which can carry dead weight on its own, with some kind of force-- so that when the piping system is cold, it's carrying dead weight, and when it moves to its hot position, it is again carrying dead weight-that would be a perfect support, if you've got the load right. So that no matter where the pipe moves to, the support is always giving the same load, and it can carry the dead weight. 73 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Selecting Hangers 8. Can you do that? Well, yes. Here's a device that can do that, a counterweight. In fact the piping code 31.3 talks about counterbalance supports. Now theirs are basically levers, but this pulley system would do the same thing, so that no matter where the pipe wants to move vertically, the system will always supply the proper dead weight load to that node. 9. However, that might not be practical, because the structure above the system now has to carry two times the dead weight-- the dead weight of the connection to the pipe, and the dead weight from the connection to the counter balance itself. Also pulleys like this might be trouble in terms of maintenance over the years. 10. Here's another choice. This is a very compact choice, which is a constant effort hanger-- you can actually read Grinnell® on this support, but these would be ANVIL® springs now. This is a typical layout (there are several other layouts). The support connection is on top, and the piping system is down below, and the pipe moves up and down. 74 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Selecting Hangers 11. Now we see a spring in the hanger. So if the piping connection point moves up and down, it will pivot about a point in the hanger, which will pull the spring in and out. So how can we call this a constant effort support, if this spring is moving, which is changing load? Well, that's why "Constant" is in quotes. It is effectively constant. A typical constant effort support has a load variation-- we'll describe the term later-- of no more than 6%. That means that the load change on this spring changes no more than 6% from its minimum to its maximum position. 12. So if the minimum load is 1,000 pounds, the maximum load would be 1,060 pounds. Let me note that in this presentation, I will be using US units rather than metric units. However, when we run the actual model in CAESAR II, we'll be using metric units. 13. The reason why this is called a constant effort hanger is that the spring itself compresses a short amount, and that because of the pivot and the links, we will get a lot larger deflection on the free end. So a short deflection in the spring causes a much larger deflection at the free end on our hanger. That softens the entire set-up, and gives it more travel for the same load range. So this is a simple way to get more flexibility out of this connection. 14. What's wrong with that constant effort hanger? Well primarily, they're not cheap. We saw that in the initial overview. This type of hanger costs three or four times the cost of a rod hanger, and they can also allow position drift. 15. When these sorts of supports are used in high temperature systems, or piping systems in the creep range, if you don't get the load correct, the piping system will carry some of the load away from the spring, and as it goes into the creep mode. It will start to drop, and you could bottom out all these constant effort hangers. So you have to get the load right. 16. Finally, internal friction in these components, at the pivot points, could cause some stickiness when it starts to move it. If its load changes, it'll have to change more than the required load in order to pop that free. So there is a matter of maintenance. 75 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Selecting Hangers 17. Is there a compromise between that rigid restraint, that rod we had earlier, and that simple applied force that we talked about earlier to carry that dead weight through a thermal travel? Well, think of it this way. The rigid support has a very high stiffness. A constant force has no stiffness at all. Is there anything in between these two ranges? 18. Yes there is. A regular spring can hanger, with its finite stiffness, might serve the purpose, and that's what CAESAR II does when we do hanger sizing. We'll select a spring from the catalog that can handle the load range that's required for that node in the piping system. So here's a simple spring can. When we start our next session, we'll talk about the contents of the spring catalogs that we are using in CAESAR II. 76 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Selecting Hangers CAESAR II Statics - Selecting Hangers Video Two (Reference Video: C2_S_H_V2) 1. So here we have the insides of a spring hanger. We have the connection to earth on the top side of the hanger, and the pipe is down below, represented by the circle. As the pipe wants to move up or down, it pulls the rod, which then compresses or un-compresses the spring. So the load path is from the pipe, through the rod, to the plate, through the spring, to the can, and then up to the support. So as the pipe moves up and down, it's just basically working against the stiffness of the spring. 2. On the outside of the can, there is some sort of marker, shown by the arrow on the face that is tied to the plate. As the spring moves up and down, it will display, or point to, the current load of that spring. When they build these spring cans, they set the plate here marked with these loads on it, based on the actual load in the spring. So there will be a minimum load in the spring and a maximum load in the spring. The loads don't start at zero-- there is some preload on the spring, even at its top-most position. 3. Let me add to that that these springs can move up or down, the spring could be underneath the pipe or above the pipe. There are a lot of different arrangements for this spring to work properly. 4. When we look at this spring, it can only be balanced at one point. Because there's a spring involved, the load changes as the pipe moves up or down. So we're going to say that we wish to balance that dead weight term that I calculated earlier-- the dead weight of the piping system at a point. Let's say the load type is for the cold piping system. The amount of load on that hard support, where we pick the rod, will be the load that we want to carry with this spring as well. Again, it can only be balanced at one position. 5. Every other position-- as it grows vertically, as temperature changes, or valves open or close-will have a different position on this spring, and the load will be a little different on the piping system. This imbalance is usually acceptable. 77 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Selecting Hangers Now if we take a look at a piping system, the same piping system we were looking at earlier, and we install the spring so that it is preset to carry dead weight in the cold position, this point's not going to sag at all, it's got the right load on it. But then, when we heat up the piping system, the piping will move up this capital ∆. And now the load is going to change on the spring, the load will now be dead weight, minus K∆. The question is, is that close enough? 6. Wouldn't it be nicer, or more appropriate, to get the target load in the operating position? That's the position where the piping system is hot and active, providing the service it's supposed to supply. Since we're interested in the loads on equipment, loads on flange pairs and the like, we probably want to balance it out in the operating position, rather than in the installed position. To do that, we would have to increase (in this situation) the spring load in the cold position to anticipate the vertical growth, so that when it gets to the hot position, it's carrying the dead weight. And that's what we're normally going to do in hanger sizing in CAESAR II. We balance the calculated dead weight in the hot position. 7. While we're talking about changing loads-- and we're going to talk about hot load and cold load in the piping system, let me add that a more correct terminology would be operating load and installed load. If we think of a regular piping system that gets hot when it goes into operation, then saying cold load (installed) and hot load (operating) is appropriate. However, in cryogenic lines, or when you have lines that are growing down from an anchor above, they're going to move in the negative Y direction as they go into operation. 78 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Selecting Hangers 8. For these examples, I'm going to say that the hot load is the target load. We're going to size this spring to carry that hot load, in the operating position. We use the cold position to start our calculations for the hot load, and we're going to apply it in the operating position. 9. The cold load is a calculated value that will be intentionally incorrect in order to account for the travel to get to the hot position. So that cold load will be the calculated hot load, plus the calculated displacement times the selected spring rate. So what we're going to do is find a spring can from a catalog that can carry both the hot load and the cold load. If that spring handles both of those, then we know we have the proper spring rate. 10. A term that we have to discuss also with these springs, in terms of how far out of balance they are in other positions-- is this term called load variation. It is the change in a load between the hot load and cold load, divided by the design load (or the hot load, in our case). If we go back to our mathematics here, we could replace cold load with this term here. When we subtract this out, we end up with the spring rate times the deflection (thermal deflection at that point), divided by the design load (hot load). This is shown circled in the figure below. 11. Oftentimes it's limited by specification to about 10% to 25%. Certain manufacturers will say the spring load variation should be less than 25%. If the hot load is 1,000 N, the change in the load between hot and cold should be 250, 750 to 1,000, or 1,250 to 1,000, and it will still be within the 25% variation. 12. When you get close to equipment like pumps, that are very sensitive to loads, you will probably reduce the load variation to make sure that there isn't too much change to keep that variation below, let's say, 10%. But now we're getting close to the constant effort hanger range of no more than 6%. So load variation is another item that we will be concerned about when we select springs in CAESAR II. 13. Now how do we select the right spring? Well there are basically two terms that we were working with-- the dead weight load, and the ∆ (movement from cold to hot). If we have an idea of what we expect from our piping system (our demand on our spring), we can go into the catalog with these two terms, and select a spring that can satisfy those two criteria. In the ANVIL® catalog, the catalog we'll use today, they talk about spring size. 79 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Selecting Hangers 14. Spring size indicates the range of loads that can be carried by a specific spring. The higher the size number, the more load it can carry. The spring figure number (as ANVIL calls it), relates to the amount of travel for that specific spring. So we'll look at both size and figure number when we order it from the catalog. In the next session, we'll talk about the data that we get from the catalog. 80 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Selecting Hangers CAESAR II Statics - Selecting Hangers Video Three (Reference Video: C2_S_H_V3) 1. Let's take a look at the ANVIL® catalog. Here's the ANVIL Spring Table. It's an unusual but very useful format, a throwback to using your finger as a computer where you can just point to different values on this table and select your support. You just need to know what the load is that you have to carry and also the travel, then you can make the spring selection. For this table here, we see that there is a varying capacity. 2. We see there's a size 0 spring on the left and on the right is a size 22 spring. Different manufacturers have different ranges, but basically they try to cover all that an engineer needs. If I look at this number here, it says 43. That's 43 pounds. This one carries 2,500 pounds. So the minimum load of the size zero spring is 43 pounds. The minimum load of a size 22 is 25,000 pounds. That quite a variety of capacity; you have to pick the right one. 3. If I go from top to bottom, that size zero spring has a range of 43 to 95 pounds, which is quite a load variation. You could say the load variation is 100% or over that. 4. So we're not going to be able to use the entire range of any spring, but just a little segment of that range. We can see the size 22 spring goes from 25,000 to 54,000 pounds. So hopefully you can find a spring somewhere in this table that suits your requirements. 81 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Selecting Hangers 5. Now if I lay the spring can on top of this table, and let's say I'm using this size 18 spring, this point right here would be labeled 8,000 pounds. Then, if I pull this rod all the way down to the bottom where the indicator is pointing down here, it would then be carrying about 17,000 pounds. So the range is about 8,000 pounds to 17,000 pounds. 6. Manufacturers, for the most part, do not wish that we work in the range above or below the range marked "Recommended Travel" in the previous figure. Most manufacturers give a recommended minimum load and a recommended maximum load on the spring. These recommended limits are shown with solid lines on the chart. 7. If I'm off of my load calculation, perhaps a little lighter than calculated, I might start to drift up in the range above the recommended value. So we should consider the recommended travel and load limits to be more like a safety factor, to avoid unloading the spring completely or bottoming out the spring. While there is a maximum travel range, by default CAESAR II sets it to use the recommended travel range. 82 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Selecting Hangers 8. Now, this spring table has three different size springs on it, the short range spring, the midrange spring, and the long range spring. The term short, middle, long deal with the amount of travel, or the slot length that is actually in the spring can. We see here that if I use my recommended minimum line here, they all start at zero. And at the other end, at the high end, it says 1.25, 2.5, and 5. 9. So the short range spring recommended travel is 1.25 inches, mid-range is double that, 2.5, and the long range recommended travel is double that again, or 5 inches. So that's why we show the ratio of 1:2:4. On the overall travel, note that the short range goes from zero to 1.75. 10. So if I recommend using only 1.25 of a total of 1.75, I have a quarter inch unused at the top and bottom of the short range spring. That increases by the time you to get to the long range spring. On the long range spring I'm surrendering a full inch on the low end and a full inch on the high again. Again, that's the difference between recommended travel, shown as the "Working Range" on the left of the chart and the maximum travel on the right of the chart. 11. So those are the three types of springs that I can select. Some manufacturers have a fourth spring, in fact, ANVIL has an extra long spring available. CAESAR II has some of these catalogs that have that fourth category ring in the selection procedure. 83 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Selecting Hangers 12. The three sizes short, middle, long have different spring rates. We see down at the bottom of the screen, it says spring rate and shows the short range spring rate, mid-range, and long. 13. The size zero spring has a spring rate of 30 pounds per inch for the short range, 15 pounds per inch for the mid-range, and 7 pounds per inch for the long range. As we go further down the table, these springs get very, very stiff. The size 22 spring has a spring rage of 16,000 pounds per inch on the size 22 short. The way this table is built then is that the short range spring wraps down and around as shown in the previous figure. Mid-range springs wrap around matching travel with spring rate in a similar fashion, and the long does as well. 14. Now, how can different travel limits provide the same load limits? We just change the spring rate. 15. Whether I'm a short, mid, or long range spring, I get the same working range. How can I do that with different spring rates and different travels? Well, they balance each other, F=kx. As the spring rate increases, the travel decreases. 16. If I look at my lengths or travels, I get the 4:2:1 (long, mid, short). If I look at my spring rates from long, mid to short, it goes 1:2:4. Since they get multiplied by one another, they give you the exact same range. So we have the exact same load data for three different types of springs: short, mid, and long. Now, how do I select the proper spring among these many choices? We'll pick that up in our next session. 84 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Selecting Hangers CAESAR II Statics - Selecting Hangers Video Four (Reference Video: C2_S_H_V4) 1. So how do we select the proper spring, or proper support, for a piping system that grows thermally in the vertical direction? Or maybe better asked, "How does CAESAR II select the proper spring?" Well, it's a matter of load and deflection. Those are the two terms that are in play here. How much load you want to carry in the operating position, and then, what is the travel from the installed position to the operating position? Two basic input pieces, the load, and the vertical travel. CAESAR II will run load cases to collect that information, and then go to the catalog and find a spring that can carry the load in the operating position, and then still carry the installed load for that same spring, by testing different spring rates. 2. When you locate a spring to be sized by the program in your model, the program will have to calculate the dead weight to be carried by that location. So here we see, in the load case editor, that load case number one is weight alone and there is a stress type called hanger (HGR). What the program will do is put a +Y support in the model at your hanger point, and run this weight case. That's going to be the load case that calculates the dead weight to be carried by that point in the piping system. It will estimate the natural load carried by the support for each selected location. We can adjust that number to suit the design, and we'll come back to that later, but we're going to call that our hot load. So the first load case that the program runs for hanger sizing will be to calculate the hot load of that future spring. 85 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Selecting Hangers 3. The program then has to calculate how much travel is expected at that point, going between cold and hot. So the program will run load case number two, which is now an operating load case, but it will remove that +Y restraint that was used at the hanger points, and replace it with a vertical force equal to that dead weight load, and run that operating case. This will then simulate the action of an ideal spring, by carrying that dead weight load through that travel. So now, if I then look at the results for deflection from load case two, that vertical deflection must be less than what is allowed by that spring-- whether long, mid, or short. So if a pipe moves more than two inches, and the short range spring can only move one and a quarter inches, well, you can't install a short range spring at that point. 4. The program will then use the weight that was calculated in load case number one with the deflection from load case number two, and then take that to the hanger table to select a spring rate, and then back calculate what the proposed cold level will be. So it tests different spring rates until they fit the load limits for a specific spring. 5. The program will go to the hanger table. It knows what the load is that has to be carried in the hot position, and it knows the distance between hot and cold. It will locate the first spring-- the smallest spring-- that can carry that operating load. Once the spring load is set-- the hot load-- there is a set of spring stiffness values associated with that spring size. It will test the spring rate for the short range spring by estimating what the cold load in the spring is. Again, it's estimating that k. The dead weight is defined. The travel is defined, and we're just going to test different spring stiffness values to see if this installed load is also in the range for the spring that we're looking at. 6. Now, if both the operating load (dead weight) and the installed load (dead weight plus k∆) are within the recommended range, that workable spring is identified and that spring is selected. If, however, the cold load does not sit within that range, it will move from the short range spring to the mid-range spring. Basically, all we're doing is dividing our spring rate by two, and then test to see if the cold load fits. If that doesn't fit, then we go to a long range spring internally. The long range spring is, again, the stiffness divided by two, and the procedure will continue. In certain catalogs, we also then go to the extended range spring. This would be the fourth set. The program could also, if it doesn't work, go to two springs at the same point, making a trapeze out of it. 86 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Selecting Hangers 7. If the first spring size doesn't fit, it moves up the next larger figure to see if that one works. Again, if it can't find a single spring, it will then try to size two springs at that same point. If the whole procedure fails to find a spring that suits, the program will recommend a constant support hanger, where you can dial in the load. CAESAR II doesn't select one from the catalog. You will take that load to be carried directly to the catalog, and select your constant effort spring by hand. 8. Now, this works whether the pipe grows up or down. In our example, we're growing up. In this case here, we're showing where the pipe grows negative-where the install load is above. The math works the same; it's just that now the ∆ is a negative number, and the cold load is now less than the hot load. It also works when you use cold load design. Typically, we want the operating position to carry just dead weight, but you can have CAESAR II say, well, I want to balance it in the cold position, and let it go out of balance in the hot position. People working around rotating equipment sometimes want to get it balanced in the cold case first, and then reset the springs. Once the equipment is all lined up, they can reset them so that they will get the operating position carrying just the dead weight. So it's a way that you can manipulate the springs to work-- and again, the math works whether you move up or down. 9. Let's take a look at an example. Let's use the ANVIL table and select a spring that will carry the balancing load in the operating position. That's typical work with CAESAR II. I'm going to say that we will run a weight analysis, and the program will automatically put a rigid plus Y restraint at the hanger point. Once the weight analysis has been run we see that the load in that hard support is 900 pounds. We then take that number, and we remove the vertical restraint and replace it with that support load, 900 pounds, and we run an operating case to see how much that point moves between cold and hot. We record that thermal growth-- in our case it is 1.2 inches. So now we have the two numbers that are required to go to the table. We know how much load we have to carry in the hot position-- or the operating position-- and we know the travel from installed to operation. We take those two numbers to the catalog. Here's an illustration of the catalog. In the next session we'll select a spring for this example. 87 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Selecting Hangers CAESAR II Statics - Selecting Hangers Video Five (Reference Video: C2_S_H_V5) 1. So, here we are viewing our catalog to select a spring. We have two numbers we are taking to this table with, the load we have to carry in the operating position, 900 pounds, and the travel upwards from installed to operation, a positive 1.2 inches. 2. If I look at this table, the first spring that can carry 900 pounds. I'm going to go from solid line to solid line here (circled in the figure below), a size 8 spring. I see 900 pounds but it is at the limit of its load. Now, that's going to be the hot load, 900 pounds, and will grow back down to the cold load, a bigger number. We see that we can't use a size 8 spring because there's not enough room below that. So, it will need to go to size 9. 88 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Selecting Hangers 3. This is how it would work by hand. In this figure, in the right column we see 900 pounds. It's listed in the size nine column. I start on 900 and move across the row to the left. In the column for the short range spring, I'm already down one half inch through the allowed travel for that spring. The spring we end up choosing will have to compress 1.2" as it goes down to the cold position, 1.2 inches lower. As I move down from 0.5" I can go down to 0.75", 1", then 1.25" and that's it (a movement of 3/4"). I can't use the short-range spring, because there is not enough room for the spring to to move 1.2 inches down from the starting position at 0.5". 4. Next let's try the midrange spring. The total slot length available on the mid-range spring useful is 2 and 1/2 inches. When we're at 900 pounds we're already down one inch, so I go down further from here a half inch, full inch, 1.2, then I come back to the right under the 9 column. Somewhere in this part of the table would be my cold load. So, it looks to me like a size nine spring might work well for us here going from 900 pounds, our design load, back to the cold load of about 1,130 pounds or so. There are other checks as well, but again, we're using a computer to do this work, so there are no fingers to drag across a catalog page like we just did in this example. 89 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Selecting Hangers 5. Let's go through it with CAESAR II. The program knows the minimum and maximum load for each spring size, and I'm going to bypass trying the size eight. We'll go right into size nine, which can carry 900 pounds. What's important here are the spring rates associated with size nine springs. What the program will do is say, OK, test, first, 400 pounds per inch; that's the short-range spring size nine. 6. We'll replace these terms. The operating load is the dead weight; that's our 900 pounds. The installed is dead weight plus k delta, so we're testing a k here; we're testing 400. If I substitute the other numbers, the 900 and the 1.2 inches, it will give us a cold load or, installed load, of 1,380 pounds. Again, this is a shortrange spring. 7. The program records what the minimum and maximum recommended loads are for these springs, and it will fail this test, because the maximum recommend load on a shortrange spring is 1,200 pounds. So, 1,380 exceeds 1,200. We cannot select a shortrange, size nine, spring. Also, there's only 3/4 of an inch of travel remaining in that can once we get our operating load set. 90 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Selecting Hangers 8. So, short-range didn't work. The program then moves on to the mid-range spring and the test goes on with that one. Again, we're going to now use the same dead weight and delta and replace it with a different stiffness. This time, the stiffness is not 400, but 200 pounds per inch. As we go from short to mid to long, we keep on dividing our spring rates by two. 9. As we do that math, now it's 900 plus 200 times 1.2, and our installed load, is estimated at 1,140 pounds. Well, according to our check so far, that would work, because that is less than the 1,200 pound limit that we are using as the maximum load recommended for a size nine spring. But we still have to check that load variation; that's also another important qualification of the spring that we select. 10. So, we'll check the load variation. Again, the load variation is the change in the load divided by the hot load, or the k delta divided by the dead weight. So, once again, the deflection is set and the load is set. The only thing we're qualifying is that stiffness that we just selected, 200 pounds per inch. Acceptable. Plug in the numbers and we'll see that when we put in the 200 here, we're excessive. We get a change of 27%. Our limit, by default in CAESAR II, is 25%. 11. If I know that the only thing I'm changing is my stiffness and I'm currently looking at a mid-range spring, if I move from a mid-range to a longrange spring, it'll automatically cut my load variation in half. So, right away I know if my midrange spring is 27%, my long-range spring is going to be 13 and 1/2%. So yes, the program will select a long-range spring for this point in the piping system. 91 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Selecting Hangers 12. The program will select a long-range spring which Anvil calls Fig. 98, size nine spring. The operating load will be 900 pounds and the installed load will be 1,020. That's just a simple calculation of the hot load plus k times delta. As we see, the load variation here, if you do the math, is 13-1/2%. What CAESAR II will show in the output processor is this table. 13. The table first lists the node number, where the spring will be installed. Next is the number required-- we only require one in this case, the figure number, 98, which is the Anvil term for a long-range spring. It's also a size nine long-range spring with a spring rate of 100 pounds per inch. 14. The two numbers that were used to select this spring are the numbers listed as the Vertical Movement (travel) at that point, positive or negative, and the load that we wish to carry in the operating position. The load next to it is that other cold load. We call it the theoretical installed load, because it's a simple, mathematical formula, dead weight plus k delta. We also see another term is labeled zero. That means we did not do that calculation. We'll talk about that a little more later. Also we can see that our load variation, 13%. Another nice thing in our report here is that we show the minimum and maximum recommended load for that spring. Comparing these numbers, 700 to 1,200, that's the working range of that spring, and we're going between 900 and 1,000. So, we're sitting pretty much right in the middle of that recommended range, and that's what you wish to have. You don't want to be near the top or the bottom of the range of the spring you select; it's best to be in the middle, so it's easily adjusted and changed. We'll continue on with a few more screens in our next session regarding actual installed load, and then we'll run an example. 92 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Selecting Hangers CAESAR II Statics - Selecting Hangers Video Six (Reference Video: C2_S_H_V6) 1. When you have the program select a spring for you, it is wise to check the working range of the spring compared to what the demand on the spring is. We see in this example that the available range is about 500 pounds, starting from 712 pounds. We're running at 900 to 1,000 pounds, so we're sitting right in the middle of that table. That's a good spring. 2. Now what about that actual installed load? Well remember that the spring is designed to balance the operating load? We're calling it the hot load. When we look at the installed load, that dead weight plus K delta may pull the system out of balance. This extra load at the point in the cold position may cause the pipe to move. 3. If that's the case, and if you're using the pipe position to set or adjust the spring so it is properly aligned in the cold position, we might have to accommodate that variation in position, in the cold position. The actual install load case will do that for you. It's another analysis performed by CAESAR II in order to count for the flexibility of the piping system and the stiffness and preload on the spring. 93 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Selecting Hangers 4. Now many springs that you size will have very little difference between the theoretical installed load, the hard number we calculate, and the true actual install load, which accounts for system flexibility. Where will these be different? Well if your piping system is very flexible in the vertical direction compared to the spring rate of the spring itself, you could get some differential between the theoretical the actual install load. Or if you're using a very large load variation in spring, that means there's a large change in load at that point, the extra load in the cold position could misalign the indicator on the spring can. So you're not sure what load is actually in the system in the operating position because you can't line up the marker in the cold position. Also, if you are unblocking and aligning your springs without a fluid in the line (in a fluid filled line), then that lack of dead weight will pull the cold load out of alignment. When I say Alignment I'm talking about the vertical position, the spring with respect to the pipe. 5. If you wish to examine the effect of this difference you can always look at the output of CEASAR II. Look at the installed load and any deflection in the installed position. You could actually have the program calculate that installed load as part of the hangars design. To do that, you would activate the hanger design control criteria. I'm showing you the menu item. Here is a toolbar icon that you would click to get this. That will open up the hanger design control data, and this check box is usually empty. Check this check box and it will create another analysis in order to calculate the installed position. 6. Finally, when you have that check box indicated here, you will have an additional hanger design load case developed. In this case it is weight, no content, plus hangers. This is also a hanger load case. 94 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Selecting Hangers So then if I have the box checked, I would have another number in this field right here. 7. In the input screen I'll just check the hanger box and the system will open up this auxiliary data. There are three areas here. The node and Cnode pair for that node is where you have to identify where you want the springs to be installed. CAESAR II does not select the best place to install a spring or support; it only selects the proper spring for the location you choose. 8. The mid-part of the screen here is used to design the spring itself. 9. We also have another area at the bottom of the screen for predefined hangar data. Here you are asked to specify your spring rate and you're theoretical cold load. Not the actual load, but the theoretical cold load. That's what's loading the system and the system moves from that point. If I specify these two terms, then the program will not do any design for us; it will use the spring that we installed. 95 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Selecting Hangers 10. A nice little item here is that if you specify just the spring rate, and you don't specify an installation load, the program will try to size your spring rate in the system by changing the preload so it works properly. Only if this spring rate does not serve its purpose in your new design, it well then override it with the one that it will pick from the table. So, you have a nice little design criteria here where you can try to use existing springs. Let's say you're updating your existing line and you have a spring out there now, maybe that old spring will still work. Just specify the K and the problem will calculate the preload for you. 11. Finally, we offer another choice here. If you leave these two blank, and you just specify the load, this is the constant effort support. There is no spring rate associated with it; it's all just load. You might say, well I could specify this load as a positive Y-force in my input. This is a better way do it, though. Call it a hangar and put it here, and now this will appear as a restraint in your model. Then, when you look at your restraint report, you'll see your constant effort hangers in the restraint report. If you specify this load as a external force, a +Y force, the program will not put it in the restraint table. So it's a good way to associate constant effort hangers with you our piping system. On our next video we'll take a look at this simple model. We would have to design springs at these three points here, and the purpose of these springs is to unload these pump nozzles below them. So we're going to run CAESAR II to size these three springs. We'll start that on our next video. 96 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Selecting Hangers CAESAR II Statics - Selecting Hangers Video Seven (Reference Video: C2_S_H_V7) 1. This is the model we're going to run to demonstrate some of the capabilities of hanger sizing in CAESAR II. You will have this model on your machine almost complete. You'll be at the same state that I have here. 2. Here is my model. We have piping system node 10 up here, coming around, coming down to three anchors or three displacement sets. A, B, and C, these are those three nozzle connections. We see the symbol for the hangers at these elbows, node 270 and node 170, but there's none yet at node 70. We're going to place this hanger on that elbow at node 70. 3. This model is four-inch pipe, standard wall, A106. We're not that hot, 120 degrees centigrade. Let's go to one of those pump nozzles at the bottom. We see that we end at node 300, which is also called node A. 97 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Selecting Hangers 4. The nozzle has this displacement set. It moves up 3/4 of a millimeter going from cold to hot. So this pump connection is growing thermally and then the risers also growing. Our task is to support the piping system at the elbow at the top. The spring has to carry that load through some vertical travel. We'll have the program select that spring. 5. Let's take a look at the hanger on the end. Here's the hanger, check box for hangers, and here's the hanger display data. Notice it's at node 268, not at 270. We're coding down the riser, so node 270 is the far end of that elbow and node 268 is the near end of the elbow. That's where I'm sizing the spring. There's no connecting node (CNode) specified. 6. We will select a spring from the ANVIL catalog, and CAESAR II has quite a few catalogs in it available for use. We see here several different items and we can define. The following lesson on Hanger Controls will discuss controlling this analysis. Right now I just want to talk about standard sizing in CAESAR II. 7. The only other items that are checked here, short range springs will be used. If you unselect this, it will pick a mid-range instead first. We have a 25% load variation defined by default for this spring. These are also controlled in the configuration file or in the hangar control data over here. So a very simple spring. 8. Now I want to go to my point my piping system over at node 68. 98 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Selecting Hangers 9. Click on that piece of pipe to select it. Double Click Hangers. Change the node 68. 10. It is set to ANVIL, 25% variation, short range spring. That's my data for this model. 11. The program will size a spring, or three springs for this model. It will run a weight analysis with +Y supports at these three locations, and determine how much weight will be carried by those three points. Then it will remove those +Y restraints and replace them with a positive Y force equal to the load that it just calculated. Then the program will run an operating case to see how much these three points move as the system changes from cold to hot. 12. With that load and that travel, then the program can go into the ANVIL catalog and select springs and install them. After that, the program will go on and complete the other analyses requested by the user. That's our model. 13. Click the error check. Start run. 14. The program has two messages tied directly to hanger sizing. The first note says there are three hangars in the job and all of them have to be designed by the program. No spring is defined completely in this model. 99 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Selecting Hangers It goes on to say in note two, that if you wish to size springs, you must do these load cases: a weight alone analysis with the +Y supports, and operating case with the forces. After case number two, then the program will select the springs and then install them in the model for any other analyses that you request. I'm going to look at the load cases that the program has set for me. 15. Click on Load case editor button. Here are the load cases. Click Recommend. Here are the recommended load cases by the program. The first two cases are for hanger sizing, stress type hanger. After load case number two, the hangers have been installed in the model. So load case three includes the stiffness of the springs. Also the pre load is included. It is called H. H stands for hanger pre loads. 16. Then load case four, which would be the sustained stress case for the installed position. All the force based loads are here, weight, pressure, and the hanger pre loads. Load case five is the standard expansion stress range between three and four. 17. Click Yes. 100 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Selecting Hangers 18. These are the load cases I'm going to run. Click the Load Case Options tab. Here we see that load case one is weight for hangar loads, and load case two is operating for hanger travel. 19. Note that in both cases it says suppress. The program doesn't list by default the output for these load cases other than the load in travel, because these two locations are not configured with the proper supports at this time. Only load case three and on have the springs installed in system, so there's really no data for you to review in the output processor for these two load cases. 20. Also note that under hanger stiffness, if there were any hangers in the job, they would all be made rigid to get the proper load distribution. If you're looking at the hanger travel, the hanger stiffness would be ignored completely. This is an ideal travel case, so we don't see other spring rates playing a role in here. After that, it's all as designed. So they're your designed springs. 21. Click the Run the Analysis button (running man). 101 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Selecting Hangers The output screen will show up and show us the standard reports that you might expect. 22. Note how the first two load cases are grayed out; I can't access any of this data. If I try, let's say, show me the restraints from load case one, there is no response from the machine. There is no data, so we're not going to do that. Turn those off if you've selected them (Do a Control-Click to de-select them). At this point, get your model to this state, and then we'll take a look at the output for the model in the next session. 102 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Selecting Hangers CAESAR II Statics - Selecting Hangers Video Eight (Reference Video: C2_S_H_V8) 1. If your model's at this state too, then we can review our results together. We are going to take a look at the hangers that were selected. Hangers aren't associated with any specific Load Cases, so they're going to be over here in the column called General Computer Results. 2. We see that we have two hanger-related reports. One is Hanger Table and the other, Hanger Table with Text; the difference is the text, of course. 3. Select them both. We'll review the differences between these two reports. Click the View Reports button. 4. We have two reports: Hanger Table and Hanger Table with Text. You can tear these apart by just dragging the tab away, and I can have them side-by-side. 5. Here is the simple Hanger Table, and here's the Hanger Table with Text. This data here is the text. So we can view the output with just the two lines (Hanger Table) or this sixline approach (Hanger Table with Text). 103 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Selecting Hangers 6. Close out the Hanger Table. I prefer the Hanger Table with Text because there's more information. The machine says that we have these three springs selected. At node 68 is the one that I put in, that is on the far right side of the model. It's a size 5 spring. At the midpoint of the model the system has selected a size 4 spring, and the spring on the left side of the model is a size 4 spring. 7. That system looked symmetric and I'm kind of surprised that it's picking different-sized springs. Let's look at the basic data we started with. 8. First of all, vertical movement, about 3 millimeters, 3.2 millimeters. Yes, we get the same motion from each of these three springs. 9. But notice that the load is changing a little bit. We see 1,200 N. 1,100 N. 1,150 N. 104 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Selecting Hangers I can see that when we get over approximately 1,250 N, the size 4 spring no longer works. I have to go to a size 5. 10. We see that the size 4 goes up to 1,254. On node 68, when you go to the cold position the load gets higher, and that's 1,275. 11. So even here I could say, yes, 1,254 N was my maximum load on a size 4, and if we get higher than that we need the size 5. Of course, the spring rates are changing as well, but this is looking at why this one's different. 12. But still, I'm kind of concerned why this one has come out different from these other two. Well, simply because CAESAR II selected it, doesn't necessarily mean it is the best spring for the job. Let's take a quick look at the data, then we'll look at how these springs work with the rest of the system. 13. Again at node 68, we have one spring required. It's a figure 82, which is ANVIL's short-range spring, a size 5 spring. 14. This theoretical installed load is a calculated value, which is using this spring rate (221 N per cm), times the vertical motion (3.2 mm), plus the hot load. This totals out to 1,275 N. The program also lists the horizontal motion at that point. If you have a lot of horizontal motion, you might have to put a longer rod on the spring so the horizontal travel doesn't cause a large angle of rotation for the hanger rod. 15. Several catalogs say the angle in rods should change less than 4 degrees between installed and operation. So if your rod is swinging too far, you have to use a longer rod to reduce the effect of that lateral deflection of that node. 105 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Selecting Hangers 16. Load variations are small. 6%. Again, that's the difference between these two loads divided by the hot load. We have 6%, 5%, and 4%. The added data shows you what type of spring it is, short, mid, or long, and then we see the min and max loads. So, yes, we're going from 1,000 to 1,700. This is 1,200, and we're sitting on the high side, but it doesn't change much. That's a fine spring. 17. As you look at the other two, though, we are getting close to our limit of 1254. One is 1,135 and here's 1,206. So at 1,206, we've got about 50 N, and the spring rate is 165 N per centimeter. So we're about one third of a centimeter away from the maximum recommended load on that spring. These are kind of at the high side, but they work mathematically. 18. Those are the three springs that were selected by the program. Are they appropriate for our system? We don't know that yet. Close this report. 106 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Selecting Hangers 19. Now let's take a look at another report. Select Operating and Installed positions of this piping system, Select Restraint Summary. Select View this report. (Note: You can use Control-Click to de-select the previous reports.) 20. This will show us all the boundary conditions of our system. We have several in our model. We have the existing supports, and now the three springs that we designed. 21. Node 10 is the anchor at the top of the model. Node 40 is supporting the main run of pipe. We see these pairs of numbers, the spring at node 68 above the anchor at node 100. This is the right-side pair. Spring and anchor, or spring and pump nozzle. Then we have node 168 and node 200. That's the middle pair. Spring, programdesigned variable support hanger and there's our pump nozzle B. Then finally, at node 268 and node 300, will be the left-hand pair, spring and anchor (pump nozzle A). 107 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Selecting Hangers 22. Now, what we want to focus your attention on are the anchor (pump nozzle) loads. Let's just use this pair right here, nodes 268 and 300. We have a spring above the anchor at node 300, and the purpose of that spring is to unload the pump. If we look at the loads in the pump, though, we see what the pump is carrying-- it's a negative number. The system is pushing down on the pump nozzle about 700 N cold. Then, when we go into operation, it increases the pushing down to over 1,000 N. 23. So we are pushing down cold, and pushing down even more as it gets hot. What's happening? As the spring grows vertically, its load-carrying capability is reduced because you are allowing the spring to relax a little. So cold, it's 1,200. Hot, it's 1,154. That accounts for the difference down here, at least a lot of it, anyway. 24. However, the big problem for me with this system is that, when the pipe is sitting there cold, it's already carrying 700 N. If I could pick a bigger spring up above it (carrying more weight), I could get this number to zero, or even maybe a positive number. This is not a good spring to work with that support. So the program picks springs, but not necessarily the best springs. We're going to have to modify this model a little, or modify our selection criteria in order to drop the load on the anchor at the bottom and allow it to be carried by the spring up above. We'll do that in the next session. 108 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Selecting Hangers CAESAR II Statics - Selecting Hangers Video Nine (Reference Video: C2_S_H_V9) 1. Our issue with the selection, at this point, is that the hanger is not interacting well with the pump below it. We want the hanger to carry the load. If I pick up a bigger spring (a heavier spring), it will reduce the load on the pump nozzle, and which will increase the life of that pump. 2. Let's go back to our model and take a look at what the program is doing for hanger sizing. Remember that the program does two load cases initially, in order to size the springs. First, we calculate the dead weight. Let's say we're doing a weight analysis. What does the program do? First it puts a +Y support at each one of these three points. It then does a weight analysis using these 3 new supports plus all the other supports in the system. These supports include the pump nozzles as well, which are also supporting the piping system. So some weight is going to be resting here, at each one of these three new support points, and then the numbers that we saw in CAESAR II output for the hangers is the load that we read from these three points. 3. But you must remember that some of the dead weight is also being supported by these points down here at the bottom. The distribution of dead weight between the hanger point and the anchors (pump nozzles) is a function of the stiffness of the piping, and the dead weight of the piping. So our problem is that these anchors are taking up too much load in this initial weight analysis. 4. We have a way of fixing, or changing that. What we can do in CAESAR II is tell the program that we don't want to treat these nodes at the bottom as anchors. Instead, allow them to drop vertically if they want. 109 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Selecting Hangers So for this case only, in this initial dead weight analysis, we're going to disconnect the vertical direction on these three points. That will then drive a lot more dead weight up to these three points (hangers). That will results in a better operation of the system. 5. One piece of advice, though, is that if you're going to release an anchor, be sure you have a hanger above the anchor below. It should be close - no more than three (some say five) pipe diameters away from the riser. We are at the near end of these elbows, about 1-1/2 ODs away from the end of these weld points on these elbows. Let's do that in CAESAR II. I want to release these three anchors, only for this first dead weight analysis, so that the hangers will carry more load. 6. Going back to my CAESAR II output, I'm just going to keep an eye on this pair on the left side. The hangers carrying installed 1,200 N, while the pump is carrying 700 N. You add those two numbers and you've got 1,900 N. I want to see almost all that 1,900 come up here to the support at the top, while the nozzles carry less. Let's have the program do that. 7. Close the report. Go back to the Input Processor. Select that piece of pipe, which contains node 268. Use the cell, Free the restraint or the displacement at node blank. Enter 300 for the node to free. That's the pump nozzle below this hangar. 8. This piece of data alone is insufficient to activate this command. We also have to specify a free code. If you recall the way I drew it, I said I only want to release it in the Y direction-that's typical for these types of supports. Click Free in the Y direction only. You have several choices here. If you free it in other directions, you will get shear or bending moment terms playing a role as well. Personally, I almost always use just the Y direction only. 110 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Selecting Hangers 9. We have to do that for all three of these hangers. Repeat for the hanger at node 200, also in the Y direction. Again, repeat for the hanger at node 100 in the Y direction. Click the running man button again (Batch Run button). This set of changes only frees these nodes in the initial dead weight analysis. 10. We see the output results. Select the Hanger Table with Text. View the report. 11. We see now that the program is picking a size six spring at all three locations, which I believe is a better solution. We have similar translations, vertical motion of 3.2 millimeters, which is what we saw before. 12. Look at the loads on our hangers-- operating loads (hot loads): 1,953, 1,952, and 1,948. These are all about the same spring; they're essentially identical springs which do reflect the layout of the piping system. 111 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Selecting Hangers Checking the maximum and minimum: 1,307 to 2,241, 1953 to 2,050. We're still on the high side of the ranges, but not so close to the limit. We're still about a centimeter away. These look like three good springs to install in the piping system. 13. How did I confirm them before? Well I went to the restraint report. Control-click (hold down the Control key and click) on the Hanger Table with Text report to de-select it. Click the Operating and Sustained load case. Click the Restraint Summary. Click View the report. Now let's take a look at the pair, the hanger on node 68, with the anchor at node 100. 112 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Selecting Hangers 14. In the installed case, the pump is positive, so I'm actually pulling up a little on that nozzle in the cold position. Then it goes negative when it goes in the hot position. You recall before that the maximum load on the nozzle in the hot case was well over 1,000N. We have now reduced the maximum load on the pump accordingly. We start with a little positive, cold, and then go negative, hot. 15. I think this is a better designed pump nozzle anyway. We put the load up on the hanger instead, and we have a similar pattern at the other two hanger points as well. So this is important. You don't want to say "CAESAR II told me to buy this spring." You, as the engineer, are responsible for the piping system. So the tool gives us a way to quickly select a spring from the catalog, but you should be confirming all the selections in a manner similar to this one here. 16. What we did is modified the load on the spring by shifting it to existing supports. Another way that you can do that is to type in by hand the number that you want to see on the hanger. This will override the calculation of the program. If you want to do some further manipulation of the pump load, now that you have some idea of what the load on that hanger is, you can modify the hanger load right here, and re-run this model until you get the pump's loads proper, and the spring selections proper as well. 113 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Hanger Design Controls CAESAR II Statics - Hanger Controls Video One (Reference Video: C2_S_H2_V1) 1. This set of presentations will further develop the hanger-sizing capabilities of CAESAR II by describing the other controls we have over hanger-sizing and hanger-selection in the program. CAESAR II will select springs from a catalog. It also can in some cases select rigid rods or constant effort hangers. 2. But why are variable supports required in piping systems? Well, a spring support can carry the dead weight at a node in a piping system through a range of travel, and that's unique to that sort of a spring support. Now before we get into these other controls, let's review some of the requirements for hanger selection. The program must contain two components before it can select a spring from the catalog. It has to know how much dead weight has to be carried at that point, and that could be then used as the operating load on the support. As an option, you could also call it the installed load. 3. We also must have the travel of that node as it moves from its cold to its hot position. We will use the operating travel to do that and we will exclude any dead weight sag when we calculate that travel. What is the actual procedure we use in CAESAR II? Well, first we have to collect those loads. We will run an analysis that will calculate what we're calling here the balancing load at each hanger location. We do that by putting a +Y support at every hanger location and running a weight analysis. 4. Whatever load we have on that +Y support will be considered the balancing load for hanger selection. Then we remove those +Y supports that we put at every hanger point and replace them with the load that we calculated from the first load case-- an upwards load to simulate the effect of that spring can. Then we run an operating analysis. The change in position from 0 to that operating position will be the vertical travel, which will then also be used along with the dead weight to select the spring from a catalog. 5. Then those forces that we added are removed from the analysis, the springs are selected, they are installed with preloads, and then any additional load cases are analyzed. So now we have two numbers to work with in the catalog. In my example here (in US units) I'm going to say we want to carry 600 pounds of force after the pipe moves up to its operating position, and it's moving up 1/3 of an inch. 114 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Hanger Design Controls 6. So if I go to the ANVIL® catalog, I would first locate that load-- 600 pounds-- in the catalog, and then find the relative position for, let's say, the short range spring. In the picture here it says 1/4 of an inch. Then move it back down to the installed position. So again, when the pipe is hot, it is moved up to within 1/4 inch of the top of the range of the short range spring. Now we are basically cooling the pipe down back to the cold position, and the pipe is now dropping down 1/3 of an inch. So we now are 1/3 plus 1/4 of an inch from the minimum load on that spring. 7. Then we can read back into the table and find out what is the load on that spring in the cold position. These two numbers then will be used to select a spring, and we're going to say the change in the load is about 100 pounds. It is around 694, maybe 700 pounds, then back to 600 pounds. The operating load is 600, so 100 divided by 600 is 16% variation. So that would be an acceptable spring if the maximum load variation was set to 25%. 8. So which spring is that? Well, we'd go back to the catalog and say, this is a size 8 spring. It is a short range spring with a spring rate of 300 pounds per inch. The operating load in that spring is 600 pounds and the change in the load is 300 pounds per inch times the 1/3 of an inch, or 100 pounds. That means the installed load is 600 plus 100, or 700 pounds, and that's how we would select the spring. You could then order that spring from the manufacturer with that data. The program goes on after that and installs that spring into the model; it will insert the stiffness. In my example, it was a spring support. If the program picks a rigid restraint or constant effort support, it will have different impact on the model, but in every case, the program will install the appropriate restraint into the model, and if necessary, a preload. 115 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Hanger Design Controls 9. If it's a rigid, it's just a stiff restraint in the vertical direction. If it's a spring can, it is the spring stiffness in the vertical direction, and a preload (the installed load). If it's a constant effort support, it will just be a force, but a force that would also be listed in the restraint report. So it's pretty simple. But how do we make CAESAR II do that? That's all the controls that we have that we will discuss in this presentation. So here are several illustrations of similar manufacturers that we have in CAESAR II. How do we pick the right spring? That's going to be the purpose of this session. 116 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Hanger Design Controls CAESAR II Statics - Hanger Controls Video Two (Reference Video: C2_S_H2_V2) 1. CAESAR II provides four different locations where you can control your hangar design procedure; one is in the configuration file, two is in the hangar design control data, three is on the input screen itself, and finally, in the load case processor. We're going to review each of these four different steps. 2. Follow along with each step as we go through these options. 3. Now for the first one in the configuration file, we will look at several sections in this configuration file. Just to show you where I am right now, if I go to the main menu of the program, I can click on Configuration File. It's also available in input processor. It'll bring up this processor here, where I can set general options for this folder while we're running CAESAR II. Several of these branches on this tree will be directly related to hangar sizing. 117 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Hanger Design Controls On this screen, we will be able to change the default hangar stiffness. Our current default setting is 1E to the 12th pounds per inch as the default, just like any other restraint stiffness. I see no reason to modify this, but it is another switch you have available to you. 4. We have 33 different hangar tables included in the CAESAR II hangar database, so if you wish to use any one of these springs here, you could set it globally in the configuration file. Then, whenever you open up a new spring in the program to size by the program, it will use your table selected here by default. You can also change different colors for your hangars and restraints. 5. Here's the default hanger restraint stiffness, 1.75E 12th. It's bolded here because I'm now in metric units in this model. 118 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Hanger Design Controls On the other items, spring hangar table, that's in our database definitions. Here by default is the ANVIL® table. I could have selected any one of these tables as the default selection table. 6. In terms of colors, that will be under Graphic settings and here we see hangars, and also hangers with CNodes. We'll talk more about CNodes later, but that's the other end of the hangar, (the connecting end). The hangar node is the pipe node, the hangar CNode is the other end of that restraint. We would suggest that for CNodes you would give it a separate color so you can see if it is connected to what I would call earth or connected to some other point in the system. 7. There are a couple of other switches that are available. One is Ignore Spring Hangar Stiffness in the Analysis. This is usually used only if you wish to match hand calculations or older programs which did not put stiffness into the thermal analyses. For purposes of simplicity, those stiffness’s were ignored. 119 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Hanger Design Controls I would not recommend that you reset that switch, but it is available in Computational Control, Ignore Spring Hangar Stiffness. 8. Another setting is Include Spring Hangar Stiffness in the Hangar Operating Travel Case. This is useful at times. It can reduce the travel demand on the hangar. What it will do in the analysis is change the system stiffness when it is calculating the operating load for hangar travel. So the program would propose a spring and include the spring stiffness in this hangar travel calculation. This could reduce the overall travel and maybe select for you a shorter spring. 120 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Hanger Design Controls If you do so, you'll note that in the output it's going to change the listing from “Theoretical Cold Load” to “Field Installed Load”. Also, be careful when you use this to confirm the data. We have this note at the end of our hangar table saying that verify the as-assigned stiffness’s when you start up your piping system. So that was the Control File settings. Now we're going to talk about the Hangar Input Data. 9. To do that, I'll return to CAESAR II and we will take a look at the input for a model piping input. And there's two ways to get to this switch. One is to click on the toolbar button Hangar Design Criteria or in the menu from Model Hangar Design Control Data. These are the switches we're talking about here, and here they are on the screen. 10. Again – follow along on your system as we go through these settings. 121 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Hanger Design Controls From this switch, we can set general control and initial settings for the current job. Here is where we can select it from the toolbar, and here's our view. The things that are only found here on this screen are the number of design operating load cases, and many times you're using just a single operating case to size all the springs. However, if you have hot pump cold pump operations or other situations where the travel at any one spring could change between load cases, you might want to use more than one load case to select a spring. By default, it is set to one. If you do have more than one operating case to size supports for, you will then also specify the default design option. This would then set the default for every spring used in this model. And finally, the other general control on this screen is calculating actual cold loads. In the previous session, we talked about calculating cold loads to get a better setting for your springs or better way to check the installed loads on your spring, so we can be more certain that they're going to operate properly. It is this switch here that does the analysis after the springs are installed and before any other load cases that you wish to have run are analyzed. 11. On the number of hangar design operating load cases, you can specify any one of up to nine different operating load cases to select a spring by default. We also have other choices here: maximum load at that point or average load at that point, maximum travel at that point, average travel at that point. This entry will determine how many different load cases are used to select a spring. Where there is more than one operating case for the piping system, this will allow you to set the default load case used to set each spring in the analysis. 122 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Hanger Design Controls 12. We have several switches here, and we can use any one of up to nine operating load cases to set that travel. We could (on all the load cases used) use the maximum operating load, maximum travel, average load average travel, or maximum load and maximum travel. 13. Here's a good example. We have a two pump system where the red line is cold and the purple line is hot. So we see here for the system Operating Case One, the left leg is hot, and Operating Case 2, the right leg is hot. So I would want to design the spring on the left using Load Case 1, but when I'm designing the spring for the right side, I'll be using Load Case Number 2. You can set the program to use that. So if I'm designing the piping system, I would say number of hangar design operating load cases equals two and I will set the multiple load case design option to Load Case Number One. Then when I enter these springs in my model, they'll both be set to using Number One, but I would then change the right spring to using Load Case Number Two. So Load Case Number One or Operating Case One sets the left spring and Operating Case Number Two sets the right spring. 14. The other switch on this general control for hangar sizing is Calculate Actual Cold Loads. This was, again, discussed in the last session, and is a good way to verify that the cold position is accurate in the analysis. The program will then include the analysis of the cold position. So if the system is very flexible with respect to the spring rate or if there's a large travel or a large load variation of the node, the pipe might spring up a little with the unbalanced cold load and it may affect the adjustment of the spring can. 123 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Hanger Design Controls 15. Also, if you are unblocking your springs in the cold position with no fluid in the line, you would run a weight no content analysis in order to see how much that changes the spring load in the cold position. 16. There are other items on this control data screen, and we talked about three of them: Number of Hangar Design Operating Load Cases, how many operating cases you have in the analysis, and the Multiple Load Case Design Options. That selects which travel to use, and the actual cold loads. 17. The other items that we have on this screen are Allow Short range springs. By default, it's checked. This can be useful to turn off if you're short range springs are more difficult to acquire or if they might be more expensive than the mid-range springs. 18. Allowable load variation is another term we have here. By default it's 25%., by specification B31.1 and MSS SB-69. However, you could change that to a smaller number if you're very close to sensitive equipment. Also remember that the program will use this as a limit check in the selection of the spring. If you have too much load variation for a short range spring, the program would automatically shift to a mid range spring of that same size to cut the load variation in half and so on. 19. We also have on this screen a few other items that were not mentioned in the initial hangar presentation. Here’s the Rigid Support Displacement Criteria. This is a value in length units, let's say a tenth of an inch if I'm in US units. If the pipe thermal travel is less than this value that you enter here, the program will pick a rigid rod. The item right below it, Maximum Allowed Travel Limit, is similar. If the pipe travels more than the value specified here, the program will not pick a spring. It will instead take a constant effort support. This would happen automatically as you extend beyond the travel limits of the hangar table that you select. So you can force the program to pick a constant support, let's say close the rotating equipment, if you specify a low number at this point. The numbers that we're specifying here, act for every new spring you enter into the model. These settings here, do not affect existing springs. 124 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Hanger Design Controls 20. Here you can also specify the Hangar Table. Now again, the hangar table is specified in the configuration file. What we're talking about here is a local change to the specific input file. So you could re-specify it here. 21. There are also three checkboxes in this screen. Let me open that screen again here. We see check boxes for Extended Range, Cold Load, and Hot Load Centered. One, two, or all three could be checked at the same time. Again, these would be useful if I'm entering a new spring. The current settings at these three locations would also then be used on any new spring that you define, but they're also available on the individual spring definitions. The extended range will go beyond the recommended range defined by the manufacturer. Cold load design will balance the supports in the cold position, not the hot position. This might be useful in aligning your equipment. For the last item here, cold load centered, the program will attempt to move to the next largest spring, even though a smaller spring would work. This is to center the hot and cold loads. We'll talk about that again later when we talk about the individual spring selections. We'll go on to the other places where you can control hangar sizing in the next session. 125 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Hanger Design Controls CAESAR II Statics - Hanger Controls Video Three (Reference Video: C2_S_H2_V3) 1. The third area where you can specify or control your hanger sizing is in the actual input spreadsheet. I'm going to pull up the CAESAR II input spreadsheet here, and we see at node 268, we have a spring to be sized. So we will review now the settings for this spring selection. 2. When you double-click the check box for hangers, the system displays the auxiliary area on the right. Here is where you will define the controls for the hanger selection at this specific node. Note: This illustration is for an example using Node 30 for the spring location. Once again, we see there's the node number (Node 30 in this illustration) that we're sizing the spring at, with a Cnode (Connecting node); general data to select a spring; and finally, at the bottom of the page, an area where, if filled out, the program will not select a spring for you. It will instead, use an existing support. 3. What's the difference between a restraint and a hanger? While a restraint is pure stiffness, a hanger allows you to define stiffness and a preload, or just a constant effort hanger by itself. The first specification for the hanger data would be the node number for the hanger. 126 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Hanger Design Controls 4. You also have, as an option, the ability to define a connecting node. Normally, this is left blank, meaning you're connected to earth, an immovable object. A Cnode can be used if the connecting point of the hanger is to a structure which also moves vertically. 5. In this example here, we have a vessel, a hot vessel that grows vertically. The pipe is supported using a spring with this moving end, and then I could specify a Cnode on the connecting end. Let's call it node 31, for example, and I could specify a vertical deflection of node 31. Then, when the spring is to be selected, it will be based on the relative thermal growth, not the absolute thermal growth of just this node alone. 6. In the hanger design data area, we have many options. We see some that we've already seen before, certainly the hanger table itself. We have, again, in CAESAR II, 33 different hanger tables, and I expect the list of available tables will continue to grow. 7. Each one of these tables has three different sizes: short, mid, and long. Several of them also have a fourth size as well; we'll call it extra long. So it depends on which table you use, whether you have this extra spring can size to work with. 127 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Hanger Design Controls We also have those three check boxes we saw earlier, for the Extended Range, Cold Load, and Hot Load Centered. 8. The extended range again will use the entire range, rather than eliminating the high and low end to allow you adjustment in the field. The cold load will set the spring to be balanced in the cold position rather than the hot position. This is useful in the aligning equipment, and then changing load after the equipment is lined up. The hot load centered, again, will check the next size higher. If the design load on the spring is very close to a limit, the program will go to the next size. 9. Available Space is another item here. We mentioned this before. If you specify a number here, the program will use this number against the length of the spring can itself. If the spring can is too big to fit in the available space, the program will not be able to select that spring. CAESARII does not specify any length for hardware. The program has in its database the lengths for a spring can above the pipe or a spring can below the pipe. The program has these two lengths shown in the following figure. We do not have all the leftover hardware length like these nuts, connecting rods, and the like. So while CAESAR II would be watching this spring can length as the available space, in many cases, your requirement in the field is much greater, because of all the extra hardware. 128 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Hanger Design Controls 10. One minor point about that is if you actually put a negative number in your input in the Available Space field, the program will show you a picture of the support underneath the pipe, rather above the pipe. 11. A few other items here-- Allowed Load Variation. We saw that earlier under hanger control data usually set to 25%. You could reduce it to a smaller number to reduce load variation around rotating equipment, for example, or make it even larger if you don't want to buy springs and get away with perhaps stiffer springs rather than more flexible springs. 12. Rigid Support Displacement Criteria-- we saw that also in the hanger control data. If you are out in the middle of a run of pipe where there's really no reason to put a spring-- if it's a very rugged system-- you could have this setting to select a rigid rod if the vertical growth is less than the entered value, let's say less than a tenth of an inch. In the middle of a pipe rack, a tenth of an inch is certainly not excessive when we talk about using a hard support, not allowing it to move at all. But when you're close to rotating equipment, there a tenth of an inch means a lot, so you want to pick a spring in that case. So this setting is going to allow you to decide which type of support to use around sensitive areas. 13. Maximum Allowed Travel Limit-- we saw in the control data, if you exceed this limit, the program will automatically select a constant effort support. 14. Some of the other items on this screen, the Number of Hangers at Location, Hanger Hardware Weight, and so on are also useful in that they allow you to select two springs or have the program select two springs. Let's say you're on a riser where you really can't use just one spring. You'd have to probably trapeze two springs on either side of the clamp that is holding up the piping system. And each spring would then be sized for half the load. So it's important to get this number right. When you say you have two springs at a location, the program will divide the total design load by half, and design two springs, each carrying half the load. 15. Allow Short Range Springs-- we saw that check earlier as well. By default the system is set to allow short range springs. If you don't have access to short range springs, you can turn that off. 129 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Hanger Design Controls 16. Operating Load-- this is a very good tool in fine-tuning your springs. Once you have an analysis done, if you wanted to tweak that spring, increase a load or decrease a load, you could use a number here to override the calculated dead weight at that point. This is a way to do some more precise work around rotating equipment where you want to tune up your piping system. 130 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Hanger Design Controls CAESAR II Statics - Hanger Controls Video Four (Reference Video: C2_S_H2_V4) 1. So, continuing on with the hanger control data on the input spreadsheet, we also have Hanger Hardware Weight. This is kind of interesting-- the program will allow you to specify additional weight. Now this would be the weight that is added into the piping system, between the spring and the pipe itself. You recall earlier, in this illustration (left), where the program will have the shorter length here in its analysis, but the true length is a little bit longer. 2. If this is a very light spring, and there's a lot of hardware weight, this hardware weight will also affect the spring settings. So if it is appreciable, you might want to turn on or add this additional weight to your hanger selection. The entered value will be added to the design load, but it will not be shown in the restraint reports, because we're showing the load on the restraint from the piping, and not with this added hardware weight. 3. We looked at the Multiple Load Case Design Option earlier in the general control settings for hanger sizing, but this allows you to change it for each individual spring. You can choose whether you want to use operating load case one, two, or the maximum travel or the average travel for that point. 4. The final items on this screen, the Free Restraint at Node listed twice and a Free Code is useful in sizing the spring as we saw in the previous sessions. The ability that we get here is that dead weight can be removed from these anchors, and pushed up to a nearby spring, so that the anchor doesn't carry the load, like at the pump nozzle. It says free restraint at node blank, where you type in the node number. It is not limited only to restraints-- displacement sets are also considered part of these boundary conditions. So if I have an anchor that grows thermally, I can define it as a set of displacements, and I could also use that as a node to free up for the dead weight distribution. 131 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Hanger Design Controls 5. Along with the setting of the node number, you also have to specify a direction (Free Code) which you are freeing the support. We have several choices. If up is Y, you can release it in the Y direction, Y and X, or Y and Z-- or X, Y, and Z all together and finally all six degrees of freedom. We suggest that you only release these anchors if the hanger that you wish to size is above that restraint, or nearly vertical in line with that restraint. That way there's no bending moment that gets built up as you button up this bigger spring. The bottom of the input screen for hangers, again, allows you to define existing springs, or existing constant effort supports. 6. You can specify the Spring Rate, and the Theoretical Cold (Installation) Load (the expected cold load) at that point. Or, if it's a constant effort hanger, you can specify the Constant Effort Support Load that the support provides the piping system. If you specify both a spring rate and a theoretical installation load, the program will use that one directly. You could also just specify the spring rate by itself, and the program will use the hanger design algorithm to estimate that installed load, and perhaps reuse an existing spring that has to just be reset for the new piping system layout. 7. One other item here-- the hanger display, how we display it on the plot. In CAESAR II, you can turn on or off items on the plot. Here we see three springs at these three locations. I'm going to turn off the display of those, and now they're gone. I unselected, or deselected the display for the hangers. 132 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Hanger Design Controls 8. We also have the ability to increase their size, so you we can really see them, or reduce the size. So there are certain things you can do in here to get more information into the plot about our springs. 9. If you put a negative value in the Available Space field for the spring, the program will show it as a support underneath the pipe, rather than above. One caution on using this, if you want to see that kind of interesting display of a can support, be sure that you provide a large enough negative length here, so that it does not impact the selection of the spring itself. So don't type minus 1, to get this symbol, but type in perhaps minus 1,000 to make sure that any can that is less than 1,000 millimeters, or 1,000 inches, will be still selected. 10. Now, once your data is complete in a model that has hangers to be sized, and you select error check in the CAESAR II program, you'll see some extra notes in the error check processor that will indicate how many springs are to be sized in the model, and also recommend load cases, that should be analyzed. Now, what we see here is load case number one, to calculate the dead load that will be carried by the spring, and load case number two will calculate the thermal travel, or the strained travel expected out of that spring. 11. After those two load cases, the program will select a spring from the catalog that you specify, install it in the model with preload, and then do any other additional load cases that you request. 133 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Hanger Design Controls 12. Now, if you ask the program to calculate the actual cold loads in the system, you will see, instead, a third load case, which will install the spring in the model, and preload it, and then run a weight case-- as you define it, weight, or weight, no content-- in order to find out what the actual installed load is, as opposed to that theoretical installed load. So that wraps up the Piping Input options for the spring selection. In the next video, we will talk about load case modifications that you can make for hanger sizing. 134 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Hanger Design Controls CAESAR II Statics - Hanger Controls Video Five (Reference Video: C2_S_H2_V5) 1. There's one more area where you can specify data for your hangers, and that is in the load case processor. Here we see the load cases that are used for a hanger selection in this model. We have three extra load cases that are labeled hanger for stress type. These are not used to evaluate the piping system, but instead collect the data required to properly select a spring and install it in the piping system. 2. The first case is the weight analysis. And by the way, this is the only case where we say we release an anchor. It will be only in this weight case where we release the anchor to size a spring. We'll talk more of that later. This weight case is used to calculate the design load for the spring. 3. Then case number two is pretty much an operating analysis. Here we remove that rigid restraint we put in the first case, the collected dead load at the point, and replace it with a force that we calculated to replicate the action of the spring, pull out the dead weight sag, and see how much the pipe wants to move up going in the operation or down. 4. Then, the third case we show here in this analysis is used for calculating the actual installed load on the spring. This is the optional case that you can turn on or turn off. Then after that we have all the regular load cases you would expect out of CAESAR II. Also note that in this model here, we have another load case component called H. That's the hanger preload. That will appear if you have existing springs that are preloaded in the model or if you are using the hanger sizing procedures that we're talking about here. 135 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Hanger Design Controls 5. When you go to load case options for these same set of load cases, you're going to see there are two areas where you can affect the results out of CAESAR II. One of them is in the output status. 6. Now by default, we do not show you any output for-- in this case-- the two load cases that were built to size the spring. The dead weight analysis, what we'll call the restraint weight case, and the free thermal growth case. This says suppress here. These are not final analyses of your piping system. We suggest you do not turn these to keep because the restraints that are used in the output processor may not match the same restraint organizations that you had for these two load cases. 7. You can also adjust the stiffness’s that are used in the analysis for different load cases with these springs. We see three different choices for hanger stiffness, Rigid, Ignore, and As Designed. Of course, once we get past the initial spring selection, you should be using the As Designed springs in the model. 8. In the very first case, where there will be springs selected, we have it set to Rigid. So every spring is going to be replaced with basically a rigid rod or a +Y restraint to calculate the dead weight at all these points. In the second load case where we want to have the spring travel calculation, we have to allow it to move, so we switch it to Ignore. So there are three switches again. Rigid, Ignore, and As Designed. 136 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Hanger Design Controls 9. Now what would happen if you had a system that has more than one operating load case? You're going to find that if you specify multiple load case design options, the program will have- as you see here-- more than one operating case. So in this example, operating case one would be the left leg is in operation while the right leg is on standby. And operating case two is the opposite, where the right leg is hot and the left leg is cold. So the error check will show you have more than one thermal load case designed for it, and also in the Load Case Editor you will see the same replication of the free thermal load case. That wraps up the hanger input and control. In the next video, we'll talk about looking at the results from the hanger's design algorithm. 137 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Hanger Design Controls CAESAR II Statics - Hanger Controls Video Six (Reference Video: C2_S_H2_V6) 1. So let's take a look at the output that we get from CAESAR II when you have hangers selected in your CAESAR II analysis. The output processor will have two items in the right column, in the menu discussing hanger data-- what is hanger table and hanger table with text, the difference being the text. We see here in this screen, this is the general hanger data. If I would select instead hanger table with text, I would see this data. 138 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Hanger Design Controls 2. So what is different between hanger data and hanger your data with text? Well, here they are side by side. We see there's a lot of common information, like through the name of the spring. But the actual text that we're talking about here is this additional data down at the bottom. This is quite useful, and in fact I would always recommend selecting hanger table with text, rather than hanger table when I'm confirming the springs that were selected. If you just wanted a list of all the springs once you have verified all of them, then hanger table would be fine. 3. Now, whether it's hanger table or hanger table with text, we have this common information. First, again, the program will calculate the dead load at that hanger. That's listed under the hot load. Now really, I should say operating load, because I shouldn't say hot or cold, but just the operating load. This is the design load for the spring, by default. That comes from load case number one. 4. The second item on the screen that is initial input for hanger selection is the vertical movement at that spring location. That's from load case number two. 139 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Hanger Design Controls When I say load case two, I'm talking about only one operating load case. If I had more than one operating load case to size a spring for, I could have more than two load cases to select this value. But these are the two numbers, the load and the travel to get to that hot position that are used by CAESAR II to select the spring and install it in the system. 5. The spring that is selected is listed here as a spring rate. So this is how the stiffness matrix gets updated. The program will put this spring rate in the model at that hanger point. The other item that is calculated based on the travel and the load is this theoretical installed load. 6. Again, in the hanger selection, you know what the hot load is, or the desired hot load for the hanger is. You will then test different spring rates to make sure you can carry the proper cold load on that same spring. So again, this theoretical cold load equals the hot load plus the travel times of spring rate. 7. Cold load equals hot load plus travel time spring rate. That spring corresponding to this 224 pounds per inch is an ANVIL® spring, because we used the ANVIL catalog. It is a Figure 82, which indicates the size of the spring-- short, middle, long-- and it's a size number seven spring. 8. This will be installed at node 68. So I have the node number, the figure number, and the size of the spring. Here, it says we need a single Anvil spring. Be sensitive to that number. 140 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Hanger Design Controls 9. The other items that we see on this hanger table or hanger table with text is a load variation. Again, one of the criteria for selecting the spring is to maintain a load variation perhaps below 25%. That's the default in CAESAR II. In other words, the difference between these two numbers is less than 25%. Well, the program displays what the load variation is, and we have a 9% load variation, 9% is the change between 498 and 543. 10. Now in this analysis, there was no load case setup for calculating the actual installed load. If I did throw that switch in the input processor to calculate actual cold loads, I would have another number here, but the program would have performed an additional analysis to calculate that load. 11. If the system is relatively stiff, this actual installed load is usually very similar to the theoretical installed load. Or if you have a low load variation, these two numbers would be the same. There are certain circumstances where it might be wise to calculate the actual installed load, rather than using the theoretical installed load. 12. We also show how much lateral motion is at that spring location. So node 68, when it goes into operation, might move up 2/10 of an inch, but it also slides over-- I'm not sure how much in what direction, but the total lateral deflection is less than a tenth of an inch. Keep an eye on this number. If this gets to be a large number, you might have to be concerned about how much angulation you get on the rod. Some would say that the rod should not swing more than four degrees. So if this starts to get large, you might need a larger rod length in order to make sure that the angulation stays low. 141 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Hanger Design Controls 13. Now if you select hanger table with text, rather than hanger table, you get this extra text. What do we see here? Well, here it'll say that this is a short range spring, as opposed to a mid or a long range spring. So a Figure 82 is ANVIL nomenclature for short range spring. 14. We also show the maximum and minimum recommended load or maximum load, depending on your selection in the input for this spring. This is a very good set of numbers to examine to qualify the spring that was selected. Here, this size seven spring’s recommended load ranges between 392 pounds and 672 pounds. So that's the recommended load range for that spring, and we're going between 500 and 540. So we're sitting right in the middle of that table, and this is a very good selection. Recall that we are calculating a load based on your input. If you have valves, for example, in your piping system that was selected from the CAESAR II valve flange database, those valve weights might be off. 15. They probably are not exactly the same weights as you have in your built system. So if you would be wrong in these loads here, you might get too close to these limits. You want to have your spring to be in the middle of this range, and we have a good selection right here. 16. Finally, this spring can, the size seven spring is about nine and a quarter inches long, just the can itself. Of course, there's other hardware included with this spring. But if I only have, let's say, 12 inches of clearance between the top of the pipe and the support above the spring, I might have difficulty. Check this number. Of course, this was also some input that was used for selecting the spring in the first place, the clearance space or allowed space to install the spring. So that's the spring that was selected in this situation, but we should examine the output to make sure this is a proper spring to be used for this application. So in our next video, we'll talk about verifying that spring selection. 142 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Hanger Design Controls CAESAR II Statics - Hanger Controls Video Seven (Reference Video: C2_S_H2_V7) 1. So now we have a spring selected by CAESAR II and it's installed in the system for use in any other analysis required for this piping system. It is up to you to verify that that spring is proper, not only initially in the design condition, but also for any load case that you are using with this spring in the system. 2. So again. In the Hangar Report, you can verify whether or not the spring is close to its minimum or maximum load. Also, when you look at the output for other load cases, you can also check to see that the spring is carrying proper load near equipment. We'll take a closer look at that later. 3. The spring is there not just to carry load of the pipe, but also to perhaps change the load throughout the system. You can unbalance the spring to carry more load or less load to unload equipment nearby this spring selection. Also, in these other load cases that you may analyze, those load cases should be checked as well to make sure that you are within the working range for the spring. 4. Also, be concerned about horizontal deflection at these hangar locations. The B31.1 Piping Code says the change in angle of a rod hanger shall not exceed four degrees, for example. In your hangar supports, you do not want so excessive angulations at these hanger points. So you could check your horizontal deflection and compare that to the rod length associated with your hangers and make sure they are within their required values. 5. Perhaps you can do better. Don't restrict yourself to work only with the program selection. I wouldn't want to hear anybody say “CAESAR II told me to buy that spring.” You are the engineer, and it is your responsibility to ensure that the spring is correct. 143 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Hanger Design Controls 6. So let's take a look at a piping system. Here's a simple layout where we have a spring selection above a pump anchor, and I'm showing the input for the hangar design criteria for the spring. So at node 68 we have the hangar location. We’re using default data here: spring table, allowable load variation, and if a short range spring works we're going to use it. I highlight here that we are not specifying any node release for the dead weight distribution. Well, let's take a look at the output. 144 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Hanger Design Controls 7. Here's the restraint report for the Hangar Point Node 68 and the anchor below Node 100. We're looking at the operating case and installed cases three and four. In the operating case in the Y direction, the hangar has been designed to carry 390 pounds and in installed case, 423 pounds. 8. So it goes from 423 cold to 390 hot. That's the spring that was selected by the program. I have no complaint with that, but when I looked down at my anchor at 100, I notice that the anchor is carrying, in the hot case, minus 282 pounds and, in the cold case, minus 127 pounds. So again, we designed this spring to carry the dead weight load in the hot case, but that was ignoring the dead weight load in the hot case on the pump below it. 9. So the low distribution is basically shared on the riser between the hangar above and the pump below: 390 and 282. Well, I'm buying a spring here to reduce the load and the load change on the pump below. Now, a spring will reduce the load change, but I should take a closer look at the balance load on the pump. Maybe I should have that be lower so that I don't have such a large load on the pump, and I can do that with CAESAR II. 10. Is this a good spring? I'll say no. If I get a bigger spring, I could take more of the load off of the pump, and that's what we're going to do. We have a size 6 Figure 82 ANVIL® spring, which is a short range spring. The hot load is 390, and the spring rate chosen for the spring is 168 pounds per inch. We can back calculate what the installed load will be. 145 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Hanger Design Controls 11. Well, because I reviewed the output, I realized that maybe I should carry more load on the spring, and one way you can do that in CAESAR II is to release this anchor in the Y direction. We’ll release the anchor at 100 in the Y direction only when you do the dead weight distribution for the spring selection only for that dead weight distribution. 12. So in Load Case One of CAESAR II for this hangar design case, we'll have an anchor up at the top end of the line. I'm going to talk just about the Y direction. The Y support at the start of the line, the Y support near the middle of the line, and the Y support simulating this hangar. 13. The lower end (connected to the pump) will be dangling free. That will then drive a lot of the dead weight load up to the point at our hanger connection on top. One caution though is that if your hangar point is not close to the center line of the released anchor, you're going to develop a bending moment as well and it won't work as well. So we would suggest that you get off the riser by no more than three ODs of the pipe to release this and have the load come up directly. 14. Is that a better one? Well, here are the results for that analysis. That was the only change between the two. We see that now the pump is now carrying only 124 pounds downward and the cold load is positive 41. This is a much better balanced pump. Recall previously they were larger numbers. To get this to happen this way, we had to have more load on the hangar. So we see this is a much better report in that all the load is coming up onto the hangar and not down to the pump. So now instead of having a size 6 spring, we have a size 7 spring. It's still a short range spring; it's just a stiffer spring. 146 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Hanger Design Controls 15. Now we could even tune this further. If I know that right now my pump is going between 41 pounds up-- we're pulling up on the pump in the cold position and pushing down 124 pounds hot-- I can work off of that change and split the difference. So instead of going between 41 and negative 124, if that spring carried an additional 42 pounds above, I could split this pretty much evenly between 83 and 82 pounds. Now, I'm not going to say that's a better design; I'm just illustrating how you could fine tune the hangar selection. Let's do that now in CAESAR II. 16. So I want my hot load in the spring, instead of being 558 which we saw before, I'm going to add that additional 42 pounds. That will make the cold load and hot load on the pump nozzles more balanced. 147 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Hanger Design Controls 17. What we do in CAESAR II to do that is type in the actual operating load. This will control what load will be used at that spring point. When I run that analysis, I told the machine make it 601. That's the spring load, and we see that the pump below is now carrying this balanced load. Again, I'm not saying that this is a better design than the previous, but you can see that you can fine tune the hangar selection and use that information from the pump to pick a, perhaps better, spring. It ended up being the same spring, but with just a different load set. 148 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Hanger Design Controls CAESAR II Statics - Hanger Controls Video Eight (Reference Video: C2_S_H2_V8) 1. Let's take a look at a few other hanger control features we have in CAESAR II, or items that should be of concern to you in using hanger sizing. One is CAESAR II will, at times, say there is zero load being carried by one of your hanger selection points. You'll encounter that at two times. 2. One is during solution. The program will say, during the solver, Mode (1) is the dead weight calculation for every hanger. It will say some designed hangers may be supporting zero weight loads. That indicates that perhaps that hanger point should be located somewhere else, because in the operating case, it wouldn't be carrying any load. 3. Also in the hanger table output, the program will say, yes, constant effort spring selected operating load did not fall within the allowed working range. And what is the load on that constant? It's zero. So when I would see that in my output, I will say, maybe I shouldn't have put a spring at 20, or a support at 20, and maybe it should be located elsewhere. 149 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Hanger Design Controls 4. Now what does that really mean? One way you could investigate that problem, since the program just ignored that weight there, is to build a model by hand. So here's that model that we were looking at just a minute ago. I have a hangar at 20 and 30, and I want to size the spring. 5. Now we have a valve on the end, which is a dead weight. When the dead weight sags on the end, it's going to rest on this +Y support at node 30, and lift off the support at node 20. This is why the program said node 20 is not carrying the proper load; it's not carrying any load. 6. Looking at the results for the operating load case, yes, node 20 is not carrying any load on the +Y support. Again, I'm replicating what we call the restraint weight case for hanger sizing. On Node 20, the +Y is not carrying any load. 7. It's moving up a very little bit, about one hundredth of an inch. We probably couldn't even see it, but all the load that doesn't go to the anchor goes out to node 30. So this would be an indication that maybe you should remove that restraint, or maybe move it somewhere else along the line. 150 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Hanger Design Controls 8. Now, one other point is that we have a check box in the hanger selection procedure is to center the hot load. Now, I said earlier that a better spring is one that sits in the middle of its table. You want to be close to the upper limit of that table, so the program would normally just stop as soon as it finds a good spring. However, you can push the program to look at the next higher spring selection, to see if it fits better in the range. 9. Now, in order for the program to go to Hot Load Centered, the calculated hot load must be within 10% of the maximum range for that spring. If it is within 10%, and you select hot load centered, it well then try the next spring, as well. Here's a CAESAR II output report for the spring, without considering centering the hot load. The hot load in this model shows 653 pounds, and the maximum allowed single spring load is 672 pounds. 10. These two numbers are within 10% of one another, so this is a candidate for that hot load centered switch. Right now we have a size seven spring. 151 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Hanger Design Controls 11. If I go to the table, I can see that the design spring has a hot load of 653, and it goes back to its installed position, back to 574 pounds. 12. Now, again, the vertical growth is negative. If I look at my next spring, I can see that I can carry my 653 pounds, and unload it down to 548 pounds-- again, the same minus one third of an inch. This might be a more useful spring in this selection. 13. So, for hot load centered to work, we have to have an operating load within 10% of the limit. If so then the program would go on and look at the next size spring. 152 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Hanger Design Controls 14. Now, running the model again with the check box hot load centered, I see the program selects a size eight spring. It still moves 1/3" down, going from installed to operating. The hot load is still 653 pounds, but it picked a size eight spring, and we are farther away from the maximum load of 653 to 900-- lots of room. This would be a better spring; it’s a size eight, rather than size nine. 15. A few other items, be aware that the program will at times select two springs, rather than one spring, in your system. If you get through the table and one spring doesn't work, the program will cut the load in half, and then select two springs, certainly by two springs. Be aware of that number (NO. REQD). Also, in your input, you have the option to say, I want two or three springs; an example might be in a riser situation. 153 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Hanger Design Controls CAESAR II Statics - Hanger Controls Video Nine (Reference Video: C2_S_H2_V9) 1. One final issue here in hanger selection is the term "Actual Cold Loads." You will see in CAESAR II a check box that you can say "Provide Actual Cold Loads." This will have CAESAR II calculate one more load case where the springs are installed in the system and loaded with weight, or maybe weight no content depending on when you set your springs. This will then be the load on that spring when you are putting it into service-- cutting the straps off and letting it carry load on its own. 2. Now remember that we are balancing our piping system for the operating load, so at any other position-- up or down, let's say in the installed position-- there will be either more or less load on that spring. If you used a theoretical cold load, it may actually put more load on the piping system in the installed position than is required because the pipe itself might deflect when you put the unbalanced load in. It might be better if you use the hot load and the actual cold load when ordering a spring, rather than the hot load and the theoretical cold load. 3. Again, it's one more analysis. The difference between the theoretical cold load and the actual cold load is caused by the relative stiffness to the piping system with respect to the spring. If you have a very, very flexible line and a large load variation on the line-- again, the load variation is the difference between this theoretical cold load and the designed hot load-- you will have a large imbalance. With a flexible piping system, it might actually pull the piping system up rather than pulling the spring down. 4. One way of further adjusting the load on the spring-- related to this actual cold load-- is to have the program include the spring stiffness in the operating load and calculate the operating travel. If you throw this switch in the configuration file, the program then will change the status of the hanger stiffness in the load case used to select the spring travel. Here it says "As Designed." Usually it is free. Free thermal growth would be used to set the travel of the spring. Here though the spring stiffness may reduce the travel of the spring going from cold to hot. 154 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Hanger Design Controls 5. Here is an example of that. We have a rather large motion of one inch at a hanger, and we're to carry 629 pounds in the hot case. Well, the system picks a spring that is almost 24% load variation. The difference between these two numbers (629 and 779) is 24% of 629. The load variation is the difference between installed load and hot load divided by the hot load. Here the actual spring installation load (710) was shown. So here is our regular spring selection, and the actual load was calculated. It's only 710 pounds. The theoretical load is 779 pounds. 6. So there's a drop of 10% for the actual load. Well, some would say that this spring will never get compressed to this load, so we are basically wasting some travel here in selecting a spring that can move a full inch. If I throw that switch in the program-- this one we saw earlier-- to say, yes, include spring hanger stiffness in the operating case, then I get the result shown in the lower half of the previous figure. Note that we still have the same hot load, but the vertical movement has been cut almost in half. This was a very flexible system, so this imbalance caused a lot of deflection. 155 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Hanger Design Controls 7. But since we said include the proposed hanger stiffness in the vertical travel, it reduces that travel, and our field installation load matches the actual installed load. We do make a note when you throw the switch in the program-- the title of this column changes from "Theoretical Installed Load" to "Field Installed Load." We also add a note at the bottom of the hanger report to be sure to walk down these lines and check all these springs when you put them in operation. 8. Here's another example of using that kind of a switch. Here is a very, very long run of pipe-- a very flexible run. The user has selected springs at every location. Well, this system, because of all the differences between the installed and operating loads, the preloads and the spring are going to pull up the system even more. So this would be a poor selection. One way you could fix that is to include spring hanger stiffness in the operating case. 9. We could also ask, why put a spring in the middle of this run? Call that a rigid restraint; the system is flexible enough. That will drive down the travel of all these other springs. 10. Here's the model, again, and here's the default selection where you do not include the stiffness of the springs in that vertical motion. In both cases, we have the exact same dead weight at every spring, but notice the difference in the travels. For example, at node 150, all that extra pull from the load being greater than the balance load-- we got a two inch pull on this line vertically. 156 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Hanger Design Controls 11. However, the actual thermal growth is much less. When we include the spring stiffness, it moves a little over 1/500 of an inch. That has a great impact on the springs that are actually selected. Here, we're picking two triple springs-- that's the pretty expensive stuff-- when in fact one short range spring will do the job. So if you see this kind of action in CAESAR II, you might want to throw that switch to include the hanger stiffness in the operating travel case. So again, when you size springs in CAESAR II, there's only one balanced position for that spring, and typically, we're going to call that a "Design Load," and that's going to be the "Hot Load." 12. But you can also change it to use that as the installed cold load design. Since we designed it for the hot position, any other position will be out of balance. However, based on your operating travel, we will limit that by the load variation setting that you have in CAESAR II. By default, it's 25%, which limits the amount of out of balance, and that will usually make it acceptable. However, other load cases that you might want to run in CAESAR II after the hangers are selected might cause a greater imbalance in the system. But back to the hanger sizing-- this imbalance will cause a spring deflection in the installed position in order to balance the right load in the hot position. So there you have the video series on controlling the hanger design algorithm in CAESAR II. It's easy to just select a few spring points, but it comes down to you reviewing your work and assuring that's a proper spring for the job. So when it comes down to it, you buy the spring, and you design the spring. CAESAR II is just a tool that helps you select a good spring in your analysis. 157 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Turbine Design Problem CAESAR II Statics - Turbine Design Video One (Reference Video: C2_S_Turbo_V1) 1. In this session we're going to gain a little more experience in using CAESAR II in working a problem that has a turbine it. We will build a model in CAESAR II, and then evaluate the nozzle loads and, if necessary, redesign the piping system to satisfy those load limits on that turbine. Here's a picture of the system we're going to run. We have a 12-inch header (the large line on the right) supplying steam to this turbine, and then an exhaust line (on the left) taking exhaust away. 2. So we have a 12-inch header with the four-inch branch to the turbine, six-inch nozzle on the exhaust-- reducing out to an eight-inch line, back to an 8-inch header. Now, if you look at our boundary conditions for this model, we have the 12-inch header on the inlet side with an anchor on one side (the left end). We do not have to code beyond that anchor to have a good model on our side of the anchor, because no information goes through the anchor. On the other side, there is a Y support and a guide at the end of the line (shown at the far right end of the figure). This is controlling the displacement of the 12-inch line. 3. Now, the 12-inch line might sag a little more than normal, because we don't have the connected pipe beyond the ends, but I doubt that pipe is going to move much. Our main interest is in the inlet and exhaust lines, not the header in that sense, so I think we have a pretty good boundary condition here at the branch connection. I'm going to ignore any numbers we get of this support. 4. Likewise, on the exhaust line, one end is anchored, and that's driving the position of our exhaust tee. At the other end, again, there is a Y support and a guide on that line. So we get a pretty well controlled system here. 158 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Turbine Design Problem 5. The issue also then is to model this turbine. The turbine has got an anchor at the base of it, and we have our two nozzles-- the fourinch suction and the six-inch discharge. There are some limits to that load, and these equipment loads are a lot lower than the allowable stress in the piping system. So in many cases, it's the rotating equipment that will control the final design of the piping system. 6. Here's a closer look at that turbine. We can see we have the valve coming into the line with a flange connection to the turbine. Exiting the turbine is a six-inch flange, a six by eight reducer, right to an elbow, right into a flange gate valve assembly-- then up to the rest of the system. 7. Now, fortunately for us, we don't have to build the entire system. The inlet part of the system (on the right) is saved as a model on the computer. It's called TURBO_IN. Again, there's an anchor at the base of our turbine, so this inlet system is independent (as far as structural response) from our system that we're going to model. 159 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Turbine Design Problem 8. But I want to evaluate that turbine, and in evaluating the turbine, you must evaluate all the loads on the turbine assembly. So we will need both the inlet and outlet, or inlet and exhaust piping together. In this exercise we're going to build the exhaust side, and then we're going to bring in the inlet side so we won't have to model it. 9. Our sequence of node numbers that we're going to use, starting with the anchor, will be node number 10. Node 20 will be the face of the flange on the turbine. Node 30 will be the end of the flange and the beginning of the reducer, and node 40 will be the end of the reducer. 50 will be the elbow node; 60 will be the end of the elbow. 70 and then node 80 will take us to the elbow-- then 90, 100, 110, and 120. That's all we're going to have to model here today. The rest will come in when we bring in the rest of the model, called TURBO_IN. 10. Start up CAESAR II. All right, so we have CAESAR II open. Let's build a brand new file. Click New. 160 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Turbine Design Problem Type: Turbo for the file name. It will be located in the Turbo folder, in your course files. The program displays the units. These are the units that are in the Turbo folder we supplied with this course, called Training Units. You will use these units for this model. Our pressure is in Bars, and the stresses will be in MPa. Click OK. That opens up the Input Processor. 161 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Turbine Design Problem 11. The first element is from 10 to 20. This is the body of the turbine. We're going to go from the anchor point in the turbine to the nozzle of the turbine. The dimensions are shown in the drawing. 12. Since we're going from the base to the nozzle, For the DX field, Type: -100 For the DY field, Type: 300. For the DZ field, Type: 450. Note: When you enter data into a CAESAR II data field you must press <Enter> or click in another field to complete the entry. For the Diameter field, Type: 6 (for 6" diameter). The system will convert it to millimeters. For the Wt/Sch field, Type: 40. We will not specify any corrosion for this model. The fluid density is steam. I'll ignore it. 13. For the Temp1 field, Type: 150. For the Pressure 1 field, Type: 5 (it is 5 bars). 162 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Turbine Design Problem 14. This element, from node 10 to node 20 will be a rigid element. This is a construction element. Click Node Numbers (to display the node numbers). Double Click Rigid. This will make it a rigid, construction element; we want it to be very stiff. This will allow the rigid element to grow thermally, but not allow the casing to deflect at all. Double Click Anchor, to put an anchor at node 10. 15. What else do we have to specify here? Material. In the Material field, Type: 106 <Enter>. The system sets the material to (106)A106 B. 16. The Code field defaults to B31.3. If you want to be complete here, you can specify cyclic factor F of one in the F1 field. You can also leave it blank, it defaults to one anyway. 163 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Turbine Design Problem 17. In the Insulation field, Type: 50 <Enter>. In the Insulation Density field, Select Calcium Silicate. If you didn't define a density, but you had a thickness, it would default to Calcium Silicate anyway. In the Line Number field (in the lower right area of the screen), Type: Exhaust <Enter>. That completes the first element. 18. We'll go on to the next element. Click Continue. The next element, 20 to 30. This is the flange of the exhaust piping. Click on the Valve flange Database. Select the Single Flange, 150 pound class. Click OK. 164 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Turbine Design Problem 19. The program continues the same vector as the previous element when you use the valve flange database. 20. In this model, the flange is in the true z direction, not on this skewed angle like the construction element for the body of the turbine. How can I quickly change it? In this model, the flange is in the true z direction, not on this skewed angle like the construction element for the body of the turbine. How can I quickly change it? Click on this chevron. It will open up the entire field for the delta dimensions. Be sure to pull it open so you can see the entire screen if it's partially hidden. We see the length of the flange is displayed (92.075 mm). All we need to do here is just change the Direction Cosines. Set the three fields to 0, 0, 1. Click in one of the other fields (the DX, DY, or DZ). When that is done, the flange will reorient to that new vector. We see the entire length, 92, is in the right direction. 165 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Turbine Design Problem 21. Click Continue. 22. This next element is going to be the reducer. On the drawing, it says its 152 millimeters long. In the DZ field, Type: 152 <Enter>. 23. Double Click Reducer. In the Diameter 2 field (the exiting diameter), Type: 8 <Enter>. In the Wall Thickness field, Type: 40 <Enter>. As you type Enter, the system converts the diameter and wall thickness to millimeters. 24. We can see that the plot displays the conic shape for the reducer. 25. Save your work at this point. We'll continue on with this model in our next video. 166 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Turbine Design Problem CAESAR II Statics - Turbine Design Video Two (Reference Video: C2_S_Turbo_V2) 1. OK, we have our model built through the reducer. Let's continue on. Click Continue. In the DZ field, Type: 305 <Enter>. This is the length of the elbow (from end to corner). Double-click Bend. By entering in the virtually exact length of the elbow from endpoint to corner the system does add the midpoint node, but it does not add the value for Angle 2 (the zero angle node number). It always puts in this value if you don't put in the "fitting to fitting" types of measurements. The system doesn't call it out as nodes 48, 49, and 50. Node 40 is the near weld point of the elbow. Click Continue. In the DY field, Type: 305 <Enter>. Since we may not be precise on the elbow length, the system could have a tiny length of pipe at the end of the elbow. We're basically connecting the next component (a flange) to the end of the elbow, fitting-to-fitting. 167 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Turbine Design Problem 2. Click Continue. This is the gate valve assembly. Click the Valve flange database button. Select a Gate valve, with the mating flanges attached, 150-pound class. Click OK. 3. Click Continue. This will be from node 70 to node 80. In the DY field, Type: 2500 <Enter>. Double-click Bend. 4. Click Continue. In the DX field, Type: -1500 <Enter>. Double-click Bend 5. Click Continue In the DZ field, Type: 2500 <Enter>. Double-click SIF's & Tees Select a Welding Tee. 168 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Turbine Design Problem Now we'll continue the model from node 100 to node 110. 6. Click Continue In the DX field, Type: -4000 <Enter>. Double-click Restraints At node 110, Select a +Y restraint. Add a second restraint at node 110 Select a Guide. We will not fill in a value for a Gap on this guide. 7. Click the Last Element button (to go to the end of the model). Click Continue. Change the From node to 100. You'll be modeling from node 100 to node 120. In the DX field, Type: 2000 <Enter>. Double-click Restraints. Select an Anchor for node 120. This completes the model for the exhaust side of the turbine. 169 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Turbine Design Problem 8. Let's take a closer look at the model. We have an anchor down there at 10, the construction element to get the thermal growth of our turbine, through our assembly to a tee, and an anchor on one end of the header. So we've got clean boundaries at the first node and on one end of the header. The questionable boundary condition is the one is where we have the +Y and the Guide, but as far as our connection point here at the tee, it's probably going to be fine. OK, that's the model. Let's bring in the rest of the model. To bring in the rest of the model, we're going to use a feature that has not been discussed before in this series. It's the Include File button. The button illustration is a folder with a piece of pipe by it. Next to it is another button showing a folder with a piece of steel by it. These buttons allow us to include piping files and structural steel files. 170 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Turbine Design Problem Another option to use this command is under the Environment drop-down list, Include Piping Input Files. So we'll use this one here. 9. Click Environment Click Include Piping Input files. This brings up a dialog box. The first field is for the name of the file we wish to bring in. Next is an option to link it or embed it (we'll talk more about this later). Next is an option to rotate that model about the Y-axis. For example, if my orientation of my other model was different, I could realign them here. The last field allows us to add an increment to all the node numbers for the model that we're bringing in. This is used to avoid having a mismatch with my existing node numbers. For example, if this old job that I'm going to bring in also started at node 10 and used 10/20/30, I would need to increment these so they don't sit on top of each other. 10. Click the Browse button. The system looks initially in the same folder as your current model. Select TURBO_IN.C2. Click Open. 171 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Turbine Design Problem TURBO_IN_C2 is the model that we will ship with this training series. Once we click Open, the model drops it into the data set automatically. For this example, we're going to link the model now, rather than embedding it. For the field Readnow?, Leave that set to N (no). This doesn't make it part of the model file. We're not going to rotate it, and we're not going to change any node numbers. Click OK. 172 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Turbine Design Problem The system displays our model (TURBO), plus the model we just linked (TURBO_IN). So we can save some time in building our models. If I have common subsets, I can build them once, and then use them in several models. Since both models had a common node 10, they both ended up with the same connection point. 11. It's kind of interesting that we see two anchors at 10. We'll talk about that more later on. So get your model to this point. Then we'll talk more about it in the next video. 173 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Turbine Design Problem CAESAR II Statics - Turbine Design Video Three (Reference Video: C2_S_Turbo_V3) 1. OK, I believe we're ready to run this model now. We have our inlet side from the other file on the right, and we built the exhaust side, that is the portion of the model on the left. 2. What happens if I select (click on) the element from 1010 to 1020? Here's the input for it. However, it's all grayed out; I can't edit it. 3. This is the difference between linking a file and embedding it. When we link a file, it is not part of this model. It shows up in the model and it shows up in the analysis. It also shows up in the output. But we can't modify it. 4. Let's fix our model here so that we can modify it. Click Environment. Click Include Piping Input Files. 174 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Turbine Design Problem We see the same data in the dialog box as before. 5. Click on TURBO_IN. The system displays a line above the current line where we can make changes to our settings. 6. In the ReadNow? field, Highlight the N and Type: Y <Enter>. Click the Replace button. This updates the settings for this file we're including in our model. Click OK. 175 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Turbine Design Problem 7. Now nothing changed as far as appearance; it still looks the same. 8. Click on a couple of elements in the file we included in our model. We can see that now they are part of the model, and we can edit them. 9. Click on Environment, Include Piping Input Files again. The dialog box is now empty. That's because what we brought in before is now part of the model. It's no longer itemized in this list anymore. 10. Let's run this model. Click on the Start Run button. This will run the Error Checker. 11. Since this is the first time we're going to run this model, we should look at all the warnings that come out of the program; we might want to heed them. 176 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Turbine Design Problem 12. I have two weightless rigid elements. Those are the two elements that are modeling the body of the turbine, starting from node 10. We have a reducer in the model, and there was not a specification of the slope of the reducer (that's the alpha value). For this piping code we don't have to worry about it. It tells us its 15 degrees, and that's fine. The system says we have one hanger already in the model. We didn't look at, but on the inlet side, there's a hanger or base support (a can underneath the pipe). Then we see the Center of Gravity report. They look fine. Let's look at our static load cases. 13. Click the Edit Static Load Cases button. The program is recommending that we look at the Operating case, the Installed or Sustained case, and the Expansion Stress Range case. 177 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Turbine Design Problem 14. Click the Run the Analysis button (the Running Man button). 15. Here's the output menu with the three load case we analyzed, the different reports for those load cases, and then some general data. 16. The hangar in this model was already completely defined; there was no reason to size it. Click on the Operating Load Case to highlight it. Click on the 3D plot button. Click on the Deflected Shape button. 178 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Turbine Design Problem 17. We can see how the line expands out from the Anchors. It slides out axially from the guides on both headers. So we have pretty good results for our two tee connections. 18. Our main point of interest in the turbine. As we zoom in, we can see that it expands from the anchor located at node 10. 19. Let's take a look at some of the output for this model. Close the 3D Plot. Click on the Sustained and Expansion Load Cases. Click Stresses. Click View Reports. 179 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Turbine Design Problem 20. I selected two reports, so I have two tabs along the bottom. The Sustained Stresses (2) and the Expansion Stress Range (3). In the Sustained case, our highest stress ratio is 15% of the allowable and it's on the inlet side, not the exhaust side. So I'm not going to worry about that. On the expansion stress range case, we're using 8% of the allowable stress at node 100. That's on our side; it's the tee connection on the exhaust header. The stress is quite low, and that sounds good for our turbine. Usually, when you get near equipment, you have to have low stresses in the line in order to save the equipment. I'm really not interested in reviewing other results here now; we just needed that overview. Close this report. 21. Our main focus in this example is working on the loads on the turbine. So I'll look at the Operating and Sustained, Restraint Summary report. Click on the Operating and Sustained Load Cases. Click Restraint Summary Click View Reports. 180 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Turbine Design Problem 22. Node 10 is on the base of the turbine. It says the load is 477 in the X direction. But really the two nozzles are our main point of interest. If we scroll down, we can see node 190 that is on the inlet side. But where is node 20? Node 20 is where I have my nozzle connection. It is not in the restraint report; there is no restraint at node 20. 23. Let's look at just the Operating Load case. Close this report. Click the Operating Load Case. Click the Restraints report. Click View Reports. We don't see node 20, but we do see node 10 twice. If your recall before, the load at node 10 in the restraint summary was two times 238. Actually, we have two anchors at 10. 181 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Turbine Design Problem It's structurally correct. But I think we'd all rather see just one node 10 here. So I'm going to go to tune up my model a little bit to show these data correctly. 24. Close the report. We'll go back to the input processor. Click the Back to Input button. 25. Verify you're at node 10. When we looked at it earlier, we had two anchors in the plot. Double click Restraints. Click OK to delete the anchor in our model at node 10. We'll leave the anchor in the inlet side in the file we imported. But that node 10-- there's still an anchor. Run this batch. This is just cleaning up. 26. Click the Batch Run button to re-run the analysis. Click on the Operating Load Case. Click on the Restraints report. Click View Reports. 182 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Turbine Design Problem 27. Now when we look at Load Case One, restraints, there's online one node 10 and it shows 477 N under the FX column. The model didn't change at all; it's just the way it's reporting these values. 28. Our focus from now on will be on the turbine. Let's look in the Global Element Forces report. Close this report. Select the Global Element Forces report. Click View Reports. The element 10 to 20 is the body of the turbine on the exhaust side. These numbers shown on that row represent the load on the turbine. That's what I'm interested in. Now, I could write these numbers down and work with them, but we're going to do a little trick with the program in order to get these numbers here to show up in the restraint report. So get your model to here, and in the next session we'll tune up or model a little bit more to make it ready for load checking. 183 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Turbine Design Problem CAESAR II Statics - Turbine Design Video Four (Reference Video: C2_S_Turbo_V4) 1. I'd like to point out one more thing in the analysis before we go back to the input. Let's take a look at the restraints report. Select the Operating Load Case. Select the Restraints report, View Reports. Many times when I look at the model for the first time, I try to make sure the numbers make sense. One of things that we have in the static analysis of this operating load case is that the system must be the equilibrium. In other words, all the internal loads are balanced by external loads. We have dead weight, that's an external load, but everything else is internal to the system. So if I add up my FY column, gravity is a negative Y, and this should add up to be the dead weight of the system. If I add up all the loads of the X direction, I should see zero sum, and in the Z direction as well. 2. Well, I don't know what the dead weight is, but if I look at the X column-- it's the simpler column here, and this system doesn't look like it's in equilibrium. One of these anchors (the one at node 1090) is not an absolute anchor. It's not connected to earth; it's connected to another node. We have a Node/CNode pair in this model. 184 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Turbine Design Problem 3. Let's take a look at that in the plot. Close this report. Click the 3D Plot button. The anchor here is not an absolute anchor. You notice it's a different color. The anchors that are absolute-- or as I'm calling absolute, are the anchors that are connected to earth. They are displayed in red. This gold color means that this is a relative anchor. It's a Node/CNode pair. It's a nice trick to get the flange loads showing up in the output restraint report. That's a nice feature that we're going to replicate in our inlet side. 4. I said we have to be in equilibrium. We have a filter in the program. Let's go back to that report. Select the Operating Case. Select the Restraints report. Click on the View Reports button. Again, I'm claiming that 1090 is a relative anchor. If I pull this restraint at node 1090 from this list (it has a value in X of -434), all the others do add up to zero. We have a filter in our output processor, it can be quite useful. Close this report. Click on Filters. Click on the Restraints tab. Click the button for None w/CNODEs. Click Apply. 185 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Turbine Design Problem 5. View the same report (OPE, Restraints). Node 1090 is not displayed in this report. Only the absolute anchors are included, and the FX column now adds up to zero. If we add up the column under FZ it will equal zero as well. If we add up the column under FY that equals the dead weight of the piping system. We're going to leave that filter on for now, and later we'll change it. There are other filters that are quite useful as well. Let's go create that relative anchor at node 20, now. 6. Close this report. Go the Back to Input button. 7. Here's that node pair 1090 and 1091. Remember that we had node 1090 in our output report. Node 1090 is the node that has the restraint on it. The connecting node (CNode) is 1091, and that's why we have that anchor symbol at that point. We're going to do the same thing on the exhaust side. We will have a node pair 20 and 21. Node 20 is the turbine node. Right now we have 10 to 20 in our model. We're going to change this element (this is currently 20 to 30). We're going to make it 21 to 30, and we're going to put the anchor between them. Let's do that. 186 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Turbine Design Problem 8. Click on the element 20 to 30. Change it to be 21 to 30. When you press <Enter> or click in another field the model breaks apart. Since node 21 was not defined previously, the system puts it at the origin. 9. To correct this, Double click Restraints. Set the restraint node to be node 21. Select Anchor. We don't want this to be an absolute anchor, connected to "earth". We want it to be connected to another part of the piping system. We'll add a connecting node (a CNode). In the CNode field, Type: 30 <Enter>. So we are saying node 21 is connected to node 20. Instead of being connected to earth, it's connected to turbine. So when I look at the restraint report for the restraint at node 21, it will give me the loads, with the proper signs, on the turbine. Just like our restraint report shows forces and moments on the anchors and restraints, we'll see node 21 acting on node 20. It's important that you get the sense right. We didn't want to say 20 is connected to 21, because that would mean you'd be looking at turbine loads on the pipe. Now that we done this, the color of the anchor changes and matches the one of the inlet side. 187 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Turbine Design Problem We're going to also, at node 21, give that node a name. 10. Double click Name. In the From node field, Type: Exhaust <Enter>. We didn't change the model; the system is still going to move at the same place, and we'll get the same load, and the same stresses. But we are going to have the information in a format that will be quite useful later on. 11. Click the Start Run button. We see the same messages as before. Click on the Batch button to start the analysis. 12. Select the Operating Case. Select the Restraints report. Click on the View Reports button. Node 21 does not appear in the report (remember we have the CNodes filter on). Close this report. Click on Filters. 188 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Turbine Design Problem Click on the Restraints tab. Click the button for All w/CNODEs. Click Apply. This will isolate the items I wish to see. 13. Rerun the report. If you recall, we put a label called Exhaust on node 21. Let's turn that feature on. Close this report. 189 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Turbine Design Problem 14. Click the Options tab. Select Node Name. Let's have the system display the node name, with the node number in parentheses behind it. In the dialog box, Click the Name button. Click OK. 15. Rerun the report. We now have the nozzles labeled on the report. Close this report. 190 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Turbine Design Problem 16. Close this report. Click on Filters. Click the button for Reset all Filters. Click Apply. 17. Rerun the report. Now I know that these two named nodes are my restraints with CNodes. I can easily isolate those from the rest of the numbers, and now I've got a good report. We'll use this format throughout the rest of this analysis. All right, you get your numbers looking like this, and we're ready to go on to the next video. 191 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Turbine Design Problem CAESAR II Statics - Turbine Design Video Five (Reference Video: C2_S_Turbo_V5) 1. You might be familiar with some of the equipment checks that we have in CAESAR II. We have the inline checks that we can use for API 610 pumps, or different vessel connections. In this problem we have a turbine here, and the turbine is not that simple. There are individual checks on each individual nozzle connection, but a big part of the turbine evaluation is based on the resolution of all the forces and moments about a single point in the turbine. For that, we will have to go to the Outboard Processor, or the standalone equipment checks that we have in CAESAR II. I want to evaluate those two loads on the turbine. I will leave CAESAR II output processor, and get back to the main menu. 2. Click the Analysis tab. 192 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Turbine Design Problem The National Equipment Manufacturing Association sets the standards for turbines, including the maximum loads on individual turbine nozzles. Checking turbines requires that all the loads must be resolved about a resolution point in the turbine. You can read this document to learn more about it. 3. Click on NEMA SM23. In the File name field, Type: Turbo_Demo. Click Open. Click Yes, to create a new file. In the Equipment Description field, Type: Example. 4. Click on the NEMA Input Data tab. 193 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Turbine Design Problem 5. Our turbine has some specific data requirements. If I go back to my illustration, here's the definition of the dimensions of the inlet and exhaust with respect to that base point. If I look at it here, I'm saying that shaft is in the X direction. In the following figure, the upper drawing represents a view looking into the turbine from the front. The lower view represents the plan view (top view) of the turbine. The shaft is in the global X direction. That's an important criteria for the definition of the resolution point. Eventually, all the forces and moments will be defined at the inlet and exhaust node numbers. We will also then relate them to this resolution point. Now, the resolution point is the intersection of the exhaust nozzle with the shaft, or equipment center line. It is indicated with the figure showing two concentric circles. 194 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Turbine Design Problem 6. I'm going to have to then relate both my nozzles to that resolution point. The shaft is in the X direction. In the Cos X field, Type: 1 <Enter>. Click the Add Nozzle button. 7. We will have two nozzles: the inlet and exhaust. For the Nozzle Type field, Select INLET. In the Node Number field, Type: 1090 <Enter>. That's the node number that's appearing in the restraint report. The key here-- and this is why I put those nodes and CNODEs in the model-- so I can pull the numbers directly from the CAESAR II output file with a button on this form (we'll do that soon), but we do have to have the correct node numbers here. So the pipe node is 1090, the CNODE is 1091. It's this 1090 loading up the turbine. In the Nominal Diameter field, Select 4". Now we'll fill out the area for specifying the location of the Resolution point. 195 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Turbine Design Problem 8. We'll use this figure to get the distances from the turbine nozzles to the resolution point. Looking at the inlet side, in the X direction-- this is from the resolution point to the nozzle-- I'm going in the negative X direction. Each one of the marks in the figure is 50mm, so that's going to be minus 50 in the X. (Enter this value in the form). In the Y direction, 250 above (positive 250). In the Z direction, from the resolution point to the nozzle, it is minus 250. So we have minus 50, positive 250, and minus 250. In the Factor for Allowable Increase field, Type: 1 <Enter>. If you're doing API 617 compressors it's basically some factor of the NEMA report, you can put that factor in here. But I'm not allowing an increase. 196 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Turbine Design Problem 9. Now we'll do the the last item needed in this dialog box. Click the Select Loads by Job/Load Case button. Click on the TURBO._P Click Open. This is the output file for the model we've run so far. The system recognizes that we have three load cases there. I want to evaluate the turbine when it's in operation, that's when it's got load, and it's when it's spinning. Click CASE I (OPE). Click OK. 10. CAESAR II displays the numbers from the output file. 197 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Turbine Design Problem 11. Let's add the other nozzle. Click Add Nozzle. In the Nozzle Type field, Select Exhaust. In the Node Number field, Type: 21 <Enter>. In the Nozzle Diameter field, Select 6". 12. Now for the resolution point, we enter the distances from the resolution point to the nozzle. In the DX field, Type: 0 <Enter>. You will always have a 0 here. The help files kind of interesting here, it says that there's some kind of ambiguity in this definition, so we give you a couple choices here. In the DY field, Type: 50 <Enter>. In the DZ field, Type: 250 <Enter>. 198 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Turbine Design Problem 13. Click Refresh Loads from Current Job. The system displays the loads on this second nozzle. We have other nozzles you can add, extraction nozzles and the like, but basically, one and one out, this will be all we need. 14. Click the Analyze button. 15. We'll review the report. 199 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Turbine Design Problem We have a third tab here called Equipment Report The report starts out with our input data. Here's my inlet nozzle, and loads, exhaust nozzle and loads. 200 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Turbine Design Problem 16. Next we see the report for the inlet nozzle alone. The system collects individual loads, and then it converts the resultant force into US units, forces and moments. This is because the allowable limit is three times the force, plus the moment must be less than 500 times the diameter used (3F + M < 500*D), where D is the exhaust diameter. This has to be in US units, so we convert our metric units into English units and then use that to satisfy this equation. Well 3F + M = 1,253, and 500 * D = 2,000. Therefore, it says, we're only at 60% of the allowable, which is great. That's on the inlet side alone; it's based on the inlet nozzle here-four inch. Next we'll review the results for the exhaust nozzle. 201 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Turbine Design Problem We see some red ink here-- we are almost two times the allowable on the exhaust nozzle. When we go through our equation (3F + M = 5909) we're almost to 6,000, and the limit is 3,000. That's the exhaust nozzle. Then we will look at it resolution about the center point, or the resolution point of this turbine, and that fails as well. All right, when we start our next session, we will diagnose this problem, and attempt to fix it. 202 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Turbine Design Problem CAESAR II Statics - Turbine Design Video Six (Reference Video: C2_S_Turbo_V6) 1. OK, let's work on getting the turbine loads within acceptable limits. We know we fail on the exhaust nozzle and on the total evaluation of the turbine. Let's look at just the exhaust nozzle right now. Knowing more about what NEMA is requesting, we're taking three times the resultant force plus the moment, and that must be less than 3,000. Well at this point we're almost twice that. Since we're multiplying the forces by three, I think we should look first at lowering the forces. In looking at the forces, the force in the global Y direction is -7,000. If we could drop that number down, we might be able to get this to pass. Well, now we have something to look at. We are going to focus our attention on 7213, which is in metric units, in the Y direction at node 21. 2. Let's go back to CAESAR II. Click on the Home tab Click on the Static button to open the Output Processor. 203 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Turbine Design Problem 3. I'm going to look at the Operating and Sustain. I don't want to look at just the Operating because I want to be able to determine whether the load is caused by dead weight or caused by thermal strain. If the load is caused by dead weight, I'll probably want to add some kind of support to carry that dead weight. However, if it's caused by thermal strain, I'll want to add flexibility, rather than stiffness. So it's important to be able to identify the cause of our big number. Click on Load Case 1 and Load Case 2. Click on Select the Restraint Summary. Click on the Filters tab. 4. We want to see only the two nozzles. These are connected with CNodes. Click the Restraints tab. Click the Only w/CNODEs button. Click Apply. 204 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Turbine Design Problem 5. Click View Reports. Here is the report. If it doesn't fit your screen you can zoom in or zoom out using this toolbar. Here's the information for node, 21, and there is that number 7,213 that we would like to reduce. That's the number that's way too big. Of course, Z is pretty big also, but this is much bigger. Now, if I look at the installed load, it's 4,500. The forces gets larger when the system goes into operation, but the majority of the load is associated with dead weight in the sustained case. So before the system heats up, it's already got 4,500 pounds pushing down. It is negative Y on the turbine, so I want to add a restraint to carry off that load. 205 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Turbine Design Problem 6. Let's take a look at the plot. Close the report. Select only Load Case 1. Click 3D Plot. 7. Here's our overloaded nozzle. Why don't we put a +Y support at the junction of the elbow and reducer? This might be a quick fix to take the load off of the turbine. Close out the Output Processor completely and Go back to the Input Processor. 8. Click on the reducer to select it. Double click Restraints. On node 40, Select a +Y restraint. 9. Click the Batch Run button. It's a simple change. I expect no errors from the program-- running man. 10. Select the same two load cases, Operating and Sustained. Select the Restraint Summary. Click the View Reports button. 206 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Turbine Design Problem 11. Well, it's not what was expected, is it? If we look at the operating case, it's still 7,213 N. The sustained load has changed, but what happened here? One way we could see a little more information here is look at the Restraint Summary Extended. These extended reports give us a little more information. There are more columns of data. Close this report. Select the Restraint Summary Extended report. Click View Reports. 207 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Turbine Design Problem We see we not only have the forces and moments, but also the position, the translation, of those nodes. Let's go down to our node 21. There's a 7,000. We have a +Y support there at node 40. Look what happens at 40; it lifts off the support! When it's sitting there cold, it's carrying 6,000 N, so we actually have a positive load on our exhaust flange. Then when it heats up, it lifts off that support. It actually moves up almost a half a millimeter at that point, and it's basically just the thermal growth of the casing itself. So we lift off the support when it goes into operation. Therefore a hard support will not do here, and that's often the case when you get around equipment connections. Even though it might not move that much, you have to be able to support the hot load more so than the cold load. That's the important load case to consider when it's hot. So this +Y support is not going to work for us. In the next session, we'll replace it with a spring, so get your model to this point and we'll continue on. 208 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Turbine Design Problem CAESAR II Statics - Turbine Design Video Seven (Reference Video: C2_S_Turbo_V7) 1. OK, so we know that the +Y alone, the resting support, will not be sufficient in carrying the load of that nozzle as the casing grows vertically. So what we're going to do is we're going to go ahead and replace that +Y support with a spring. In the output menu, I'm going to go right back to the input processor. Click the Back to Input button. 2. Select the reducer. The +Y is defined on this element. Double click Restraints to delete it (Click OK when prompted). Double click Hangers. Notice that the program shows a spring above the pipe. The program does have a different set of data for base supports. The actual spring coil can itself is different for a hanger and a can. If we enter a negative number in this field, Allowable Space, the system will convert the symbol to a can symbol (underneath the pipe). In the Allowable Space (neg. for can) field, Type: -1000 <Enter>. Note: You have to enter enough room in this field for the system install the support. Entering -1 will change the symbol, but not enough room for the can installation. 209 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC to give PipingDesignOnline Video Training CAESAR II Statics - Turbine Design Problem 3. Click the Batch Run button to start the analysis. The program will try to use the existing load cases to run the analysis, but the existing load cases are insufficient. Here's the message that comes up on the screen-insufficient hanger cases. So what do we do? Click OK to return to load case definitions. 4. The system displays the load cases. We need some additional load cases to design the new spring hanger. Click Recommend. 5. The system recommends load cases based on the current conditions in this model. Here are two Load Cases for Hanger sizing, and after that, then we can do the Operating, Sustained, and Expansion Stress Load Cases. Another load case component here we haven't seen is H, for hangers. That represents the preload on the spring. Click Yes to use these recommended load cases. 210 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Turbine Design Problem 6. Click the Batch Run button to start the analysis. We're now at the output menu. The first two Hanger Load Cases aren't available to look at. The data from those locations are found in the Hanger Table With Text. Select Hanger Table W/Text. Here's information on our springs. The spring listed at node 1065 (at the bottom of the report) is in the inlet side that was defined by the user. The spring for node 40 is he one that the program picked for us. It's an ANVIL Size 10, Figure 82, that's a short range spring. The reports show the load and vertical movement. We see it's only moving at a half a millimeter, but it is carrying some load. So now we can carry about 6,000 N in both the hot and cold position, which is what we're after. Let's see how that affects our numbers. 211 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Turbine Design Problem 7. Close this report. Deselect the report (do a control-click on it to deselect it). Select the Operating and Sustained Load Cases. Select Restraint Summary. Click on View Reports. We have the filter turned on in this report and we're only showing nodes 21 and 1090, or the exhaust and inlet nozzles. Now, remember that we had about 7,000 N before, when it's in operation. Now it's down to 900 N. We might have some complaints about the load in the cold case; that's when they're going to align that piece of equipment. Well let's not worry about that right now; let's see if we can get this to pass. So we dropped this from about 7,000. We see the Z load is still pretty high, but let's see if this will pass the turbine checks. This is a nice illustration of how CAESAR II can use the node numbers and share data between the NEMA SM23 and CAESAR II calculations. 212 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Turbine Design Problem 8. Close this report. Close the Output processor and return to the Main Menu. Click on the Analysis tab. Click on NEMA SM23. Since we have a job already established in this folder, it's going to open that one up again. Click on the NEMA Input Data tab. The Inlet nozzle didn't change; we didn't change any of that piping on that side. So we don't even have to modify these numbers. If we just click on Refresh Loads from the current job, it's going to stay with Load Case 1. However, remember we now have hanger sizing in this model, so I now want to point to Load Case 3. So I can't use the existing, 9. Click Select Loads by Job/Load Case. The system opens up a dialog box for you to select the model again. Click on TURBO_P. Click Open. 213 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Turbine Design Problem Select CASE 3. Click OK. But the numbers didn't change. Let's go to the second nozzle, nozzle number 2. It's the exhaust nozzle. 10. Click the Up Arrow by the Nozzle field. It sets the Nozzle to 2. Now this one did change and it's set for Load Case 3, as well. Click the Refresh Loads button. We see 900 (approx) in the FY field. That's what we want. Click the Analyze button. The input echo data for the inlet nozzle didn't change; it looks good. Reviewing the output for the exhaust nozzle, it looks good as well. 214 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Turbine Design Problem On the individual exhaust nozzle, that was sufficient to bring down the total. When we take three times the force in the US units, plus the moment in US units, we get about 2,500. Since the limit for this nozzle alone is 3,000, we are within the allowable. 11. We have one more report to check. Scrolling down, when we resolve everything about that resolution point, we fail. It's a different set of calculations, but we will get all the forces have almost resolved about the resolution point, and we see that the equation we're running now (the last equation listed) is two times the resultant in forces, plus the resultant moments, equals (in US units) 2,000. Based on our allowables, we're only allowed 1,800, so we fail here. So the individual nozzle is OK, but we can't continue with this in this fashion, because we still have too much load. Now once again, we're just going to work with the numbers here. It's 2 times the force plus the moment. Well the resultant forces is 431, resultant moment is 1,100. If I reduce these forces, I'm going to have twice the effect as the change in the bending moment. So I need to drop it by about 200. Looking at the forces in the model we see that the force in the Z direction is the biggest force, 1,500. 215 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Turbine Design Problem 12. Looking again at the Exhaust Nozzle, that force in the Z direction is 2,000 from the exhaust nozzle. And that get summed with the inlet nozzle, a positive number. So if I can get this number smaller, this force in the Z direction, I'll drop the load on the nozzle. That might be one way to get this to get pass. All right, where we are right now is we will have to examine how we can possibly reduce the Z load, that's the largest number that we see up here, to get this turbine to pass. Verify these results in your system. We'll continue to work on this in the next session. 216 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Turbine Design Problem CAESAR II Statics - Turbine Design Video Eight (Reference Video: C2_S_Turbo_V8) 1. OK. Our goal now is to reduce the force in the Z direction (FZ). That's the biggest number we see anywhere on the exhaust nozzle and that's what we're going to try to change now. The suction nozzle looks pretty good, so my attention will be on the force in the Z. 2. Close this report (if it's open). Return back to CAESAR II. Click the Home tab. Click Static. 217 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Turbine Design Problem 3. Select the Operating and Sustained Load Cases. Select the Restraints Summary. Click on View Reports. 4. The program still have the filters are turned on and we see only the restraints with CNodes. There system displays nodes 21 and 1090. This is the number that we're after. 2,000. We have to get that lower. Well, look at the load in the installed position, it's only minus 142. So if that 2,000 Newton load is a sum of sustained effects and expansion effects, the greatest share is handled by the expansion affects, because the sustained effects are only 142. So, we now can say that this is an expansion issue; thermal strain is causing that force in the Z direction. 218 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Turbine Design Problem 5. Let's look at the plot for that. Close this report. Select the Operating Case. Select the 3D Plot button. 6. Click the Deflected Shape button. We see the plot in the operating condition. Expanding Absorbing and Loading the Nozzle We have an excessive load (in the negative Z direction) on the nozzle. Well, there's only two pieces of pipes that are actually growing in the Z direction. We have the short segment at the bottom, connecting to the nozzle. We also have one branching out of the exhaust header at the top. It's a longer segment and has more thermal growth. So this thermal strain has to be absorbed by the pipe and transmitted into that nozzle. The leg that can flex in order to absorb that thermal growth is labeled in the previous figure. If this horizontal leg was longer, it would make it a lot more flexible. It could then accept the more deflection up on top and cause less response down below it. Our goal is going to be to add flexibility by adding length to this leg, which is absorbing the load. If we can connect into the header line with the tee moved further away from the anchor (for instance one meter further down), leaving everything else the same, that might be the best way to satisfy this issue. 219 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Turbine Design Problem 7. Let's go back to the input processor now, and modify the model. Close the 3D Plot view. This returns you to the Output Processor. Click on Back to Input. Reduce the Input Spreadsheet Screen by clicking on the pin in the upper right corner. This maximizes the plot view of the model. I reduced the input screen, so all I have is the plot. So anything I type in, will be acting on the plot. Type: Y <Enter>. This causes the system to view the plot from the top. 220 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Turbine Design Problem 8. The exhaust side of our model is at the bottom of the display, and the inlet side is displayed at the top portion of the plot. I want to make this leg and segment of the exhaust header longer. Shorter Longer 9. The Distance command has been updated in the recent version of CAESAR II to work with graphics. Before, you had to key in node numbers into a dialog box. Note: If your system does not support these new features you can just view the videos. Click Distance. We'll use the Snap feature of the program. Check the box as shown if needed. As you move the mouse around the model, Snap points (circles) appear. If we click my mouse button now, it will snap a point in the piping system (indicated by a circle). However, the Snap symbols are big, so we're going to change the size. 221 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Turbine Design Problem 10. Right click on the plot, Select Properties, then Display Options. And you note there's a symbol there. You can also find that symbol on one of the tool bars. Scroll down to the bottom of the list. For Symbol Information, Click in the Type field. Click Circle (filled center). Set the Size to Smallest. Click Apply. Click the X in the corner of the Plot Settings dialog box to close it. Now, we have a more compact symbol to work with. 11. Also - let's change the font size too. Right click on the screen, Properties, Display Options. Under the Fonts section, Click Annotations. Change the font size to 20. Change the font color to Black. Leave the font type as Arial. Click OK. 222 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Turbine Design Problem 12. We should recall that the length of the line we want to lengthen is 1,500 mm and I want to make it 2,500. This tee in the exhaust header will also be repositioned 1000 mm further down the line. Now, if your version of CAESAR II does not support the new Distance command features we are about to us, you can go into the input processor and change the lengths of the piping elements as needed. 13. Zoom in to the lower area of the model if needed. Click Distance (if it's not already open). We'll click some points to check our distances. The pipe we want to change is 1500 mm. Click the Select Element button. This will turn off the Distance command. Click the Move Geometry button. This activates the other 3 buttons. Click Move Geometry (X-Axis). The system displays red circles at the nodes. Using the mouse, Click two points to window the line you want to move. 223 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Turbine Design Problem 14. Click on the top snap point. Let go of the mouse button. Drag the mouse to the left and Type: -1000 <Enter>. The system changes the geometry of the model. 15. To verify it's correct, Click Distance. Click the 2 nodes on the line to measure between them. The distance has been increased by 1000mm. The lower elements updated as well. 224 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Turbine Design Problem 16. Click SE Isometric to reset the view of our plot. Click File. Click Save As. Type: Rerun <Enter> for the file name. 17. Click the Batch Run button to start the analysis. The system takes us to the Output Processor. Click the Operating and Sustained Load Cases. Click the Restraint Summary report. Click View Reports. We're trying to see a smaller FZ. It was about 2,000 before; now, it's about 1,000. 225 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Turbine Design Problem 18. Let's check the turbine again and see if this has improved the analysis results. Close this report. Close the Output Processor. We're back to the main menu of CAESAR II. Click the Analysis tab. Click NEMA SM23. Click on the NEMA Input Data tab. 19. We saved our model under a new name (Rerun) so we need to use that file in this analysis. Click Select Loads by Job/Load Case. Select RERUN_P. Click OK. Select the Operating Load Case. Click OK. Click the up arrow by the Nozzle field to go to the 2nd nozzle. Click Refresh 226 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Turbine Design Problem The system displays the new loads. Click the Analyze button. Let's review the results. Well, we're not done yet, but we are meeting the standard values for turbine nozzle loads for our size range. We're going to look at one more analysis after this, and then we'll be done with this model. 227 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Turbine Design Problem CAESAR II Statics - Turbine Design Video Nine (Reference Video: C2_S_Turbo_V9) 1. OK. Our turbine is in good shape now from the standard point of view. Let's review some of our other output for this model. Close the NEMA report. We're back at the CAESAR II main menu. Click the Output tab. Click Static. Our focus is going to be on that spring that we selected. Select the Operating and Sustained Load Cases. Select View Reports. 2. We've been modifying piping around node 21, and we put the spring. Let's take another look at that node. 228 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Turbine Design Problem 3. You recall that we used to have a very, very large load here in the vertical direction. That's why we had to put the spring in there, to carry load in a hot position. But look at the load in the cold position; it's a very large load in a cold case. This load might be difficult to carry when you're trying to align this equipment, so I would like to have a lower load here. What's kind of interesting too, it's a big positive number. If we would disconnect this flange, it would drift up away from the turbine nozzle. We can readjust the spring load automatically in the program, and that's what we're going to do here. You can do a lot of fine tuning in CAESAR II, and let's just take a look at making that number smaller. 4. Close this report. Click Back to Input. We have two different ways you can change the spring selection procedure. Click in the "To" field. Roll your mouse wheel until you to node 40. That's where the hanger is. We can specify our own operating load by hand, and that will override what the program calculates. Another option is to free up one of the connections when it calculates the hot load at that point. Let me rephrase that. We can have the program reallocate dead weight to other supports by releasing an anchor or two in our model. Now what anchor would I want to release? Well, if when I'm sizing the spring at node 40, if I disconnect the nozzle close by (node 21), then all of the load will come back onto the hanger, and I might have a better load distribution between the hangar and nozzle. 5. So we're going to give that a try. Let's tell the system to free the restraint at node 21-- that's where the restraint is defined-- in the Y direction. In the Free Restraint at Node field, Type: 21 <Enter>. In the Free Code field, Select 1-Y. These two cells work together. I usually release it only in the Y direction. The system releases it only for that very first weight load case; everything else is buttoned up properly. 229 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Turbine Design Problem 6. Click the Batch Run button. We want to see if the installed (Sustained) load is reduced without getting an excessively large operating load. Select Load Case 3 (OPE) and Load Case 4 (SUS). Select Restraint Summary. Click View Reports. Let's review the report. Now, this looks a lot nicer to me. The installed load is only 34, which is very low. We see it goes negative in the Operating case. The value earlier was about 2,000, and now it's around 1,100 positive. This is a much better installed load. 230 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Turbine Design Problem 7. Let's run this through NEMA SM23 again and see how this change affects it. Close this report. Close the Output Processor. We're back to the CAESAR II main menu. Click on the Analysis tab. Click on NEMA SM23. Click the NEMA Input Data tab. Click Refresh Loads from Current Job. Set the Nozzle to 2. Click Refresh Loads from Current Job. Click the Analyze button. 231 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Turbine Design Problem Our exhaust nozzle comes in at 67% of the allowable, and this is better. This is a better spring overall in its installation and also in the resulting load on the turbine. Let's go look at that spring directly. 8. Close this report. Click the Output tab. Click Static. 232 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline Video Training CAESAR II Statics - Turbine Design Problem Click Hanger Table W/Text. Click View Reports. We're now using an ANVIL size nine spring. If I recall, the other spring was a size 10; so it went to a lighter spring, and it suits this installation much better. So there you go. We've used the program to model part of the system, and used the Include feature to bring in other subsets of our model. Most of our attention was on the turbine, but we worked on both satisfying sustained load problems and expansion load problems to meet the NEMA allowable load requirements for this turbine. 233 Copyright© 2015 All Rights Reserved CAD Training Technologies, LLC