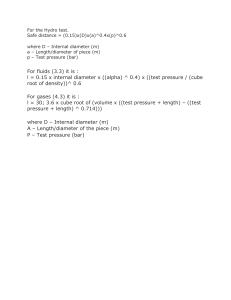

FINITE ELEMENT ANALYSIS REPORT OF CYLINDER LIFTER FOR FIUMETECH PVT. LTD. 01 18/06/202X Final Approval Rev Date Purpose Prepared by the Design Engineer Approved by Reviewed by X X TABLE OF CONTENTS REFERENCES...................................................................................................................... 3 EXECUTIVE SUMMARY................................................................................................... 4 1. INTRODUCTION ............................................................................................................ 5 2. SYSTEM DESCRIPTION ............................................................................................... 6 3. MATERIAL DESCRIPTION .......................................................................................... 7 4. LOADS AND FIXTURES ................................................................................................ 8 5. CONNECTOR DEFINITIONS ....................................................................................... 9 6. INTERACTION INFORMATION ............................................................................... 17 7. RESULTANT FORCES.................................................................................................. 22 8. F.E.A RESULT ................................................................................................................ 23 9. CONCLUSION AND RECOMMENDATION............................................................. 29 DISCLAIMER: ................................................................................................................... 30 REFERENCES [1] Material Properties: ASME BPVC 2021 Section II D (Metric).pdf EXECUTIVE SUMMARY ◼ This report summarizes a detailed engineering analysis conducted using SOLIDWORKS SIMULATION, a Finite Element (F.E.) analysis software. The analysis focused on the Static Elastic stress analysis of the Structural Validation, aiming to assess the part's performance characteristics under static loads. Threedimensional (3-D) and Two-dimensional (2-D) models were created, and the analysis provided insights into stress and deflection. The report includes methodology, references, conclusions, and recommendations for design modifications to improve the part's performance. The analysis findings serve as a foundation for enhancing the part's structural integrity under static loading conditions. 1 INTRODUCTION ◼ Detailed three-dimensional (3-D) solid and Two-dimensional (2-D) Shell, Finite Element (F.E.) computer models were constructed for Static Elastic stress analysis of the Seismic Validation. ◼ The analysis was performed to determine the structural integrity and performance characteristics of the Static Load Condition Validation under the specified design. ◼ This report documents in detail the technical approach, FE computer modelling, maximum stress at critical locations and maximum static stresses in the component. ◼ Tetrahedron elements are three-dimensional (3D) solid elements that are shaped like pyramids with four triangular faces. Tetrahedral elements are commonly used in finite element analysis (FEA) to mesh complex geometries, They have four nodes (for first-order elements) or ten nodes (for second-order elements). ◼ Triangular elements are 2D finite elements commonly used in finite element analysis (FEA) for meshing surfaces, especially in complex geometries. They come in different types, such as linear (3-node) and quadratic (6-node) elements, with higher-order variations for improved accuracy. While triangular elements are easier to use for irregular shapes and adaptive meshing, they generally require more elements to achieve the same accuracy as quadrilateral elements. They are widely applied in plane stress/strain problems, shell and plate structures, and fluid-structure interactions. 2 SYSTEM DESCRIPTION Figure 01 : Main loading frame of CYLINDER LIFTER 2.1 System Explanation ◼ CYLINDER LIFTER The segment was modeled for the analysis and run to check whether the lifting assembly can lift a cylinder of an average weight of 400 kg. the static step is run against the load of gravity and cylinder weight of 400 kg to identify the overall behavior of the assembly without having to analyze the entire assembly, which could be time-consuming or impractical. 3 MATERIAL DESCRIPTION MATERIAL NO.1 NAME: Plain Carbon Steel MODEL TYPE: Linear Elastic Isotropic FAILURE CRITERION: Max von Mises Stress YIELD STRENGTH: 2.20594e+08 N/m^2 TENSILE STRENGTH: 3.99826e+08 N/m^2 ELASTIC MODULUS: 2.1e+11 N/m^2 POISSON'S RATIO: 0.28 MASS DENSITY: 7,800 kg/m^3 MATERIAL No.02 NAME: ASTM A36 Steel MODEL TYPE: Linear Elastic Isotropic FAILURE CRITERION: Max von Mises Stress YIELD STRENGTH: 2.5e+08 N/m^2 TENSILE STRENGTH: 4e+08 N/m^2 ELASTIC MODULUS: 2e+11 N/m^2 POISSON'S RATIO: 0.26 MASS DENSITY: 7,850 kg/m^3 4 LOADS AND FIXTURES Loads and Fixtures Fixture name Fixture Image Fixture Details Entities: Typ: 3 face(s) Fixed Geometry Fixed-1 Resultant Forces Components Reaction force(N) Reaction Moment(N.m) Load name Gravity-1 Force-1 Remote Load/Mass (Rigid connection)-1 X -0.244591 0 Load Image Y 5,393.7 0 Z 0.927656 0 Resultant 5,393.7 1e-33 Load Details Reference: Values: Units: Top Plane 0 0 -9.81 m/s^2 Entities: Type: Value: 1 face(s) Apply normal force 4,000 N Entities: Connection Type: Coordinate System: Translational Components: Rotational Components: Reference coordinates: Remote Mass: Moment of Inertia: 1 face(s) Rigid Coordinate System1 ---,---,-----,---,--0 0 0 mm 5.2 kg 0,0,0,0,0,0 kg.m^2 5 CONNECTOR DEFINITIONS Bolt Connectors : Model Reference Connector Details Entities: Type: Counterbore with Nut-1 Connection Type: Head diameter: Nut diameter: Nominal shank diameter: Material name: Young's modulus: Poisson's ratio: Thread Count: Bolt Strength: Safety Factor: Preload (Torque): Friction Factor (K): Tight Fit: 2 edge(s), 3 face(s) Bolt(Head/Nut diameter)(Count erbore) Distributed 24.3 mm 24.3 mm 16.2 mm Strength Details Bolt Check: OK Calculated FOS: 2.401 63 Desired FOS: 2 ASTM A36 Steel 2e+11 N/m^2 0.26 6 threads/mm 2.5e+08 N/m^2 2 50 N.m 0.2 No Connector Forces Type Axial Force (N) Shear Force (N) Bending moment (N.m) X-Component 0 17.124 12.49 Y-Component 15,007 3.638e-12 -1.1308e-14 Entities: Type: Counterbore with Nut-2 Connection Type: Head diameter: Nut diameter: Nominal shank diameter: Material name: Young's modulus: Poisson's ratio: Thread Count: Bolt Strength: Safety Factor: Preload (Torque): Friction Factor (K): Tight Fit: 2 edge(s), 3 face(s) Bolt(Head/Nut diameter)(Count erbore) Distributed 24.3 mm 24.3 mm 16.2 mm ASTM A36 Steel 2e+11 N/m^2 0.26 6 threads/mm 2.5e+08 N/m^2 2 50 N.m 0.2 No Z-Component 1.7979e-10 -298.26 0.94383 Resultant 15,007 298.75 12.525 Bolt Check: OK Calculated FOS: 2.394 12 Desired FOS: 2 Connector Forces Type Axial Force (N) Shear Force (N) Bending moment (N.m) X-Component 0 -13.069 12.605 Y-Component 15,029 3.638e-12 5.9486e-15 Entities: Type: Counterbore with Nut-5 Connection Type: Head diameter: Nut diameter: Nominal shank diameter: Material name: Young's modulus: Poisson's ratio: Thread Count: Bolt Strength: Safety Factor: Preload (Torque): Friction Factor (K): Tight Fit: 2 edge(s), 3 face(s) Bolt(Head/Nut diameter)(Count erbore) Distributed 24.3 mm 24.3 mm 16.2 mm Z-Component 1.7965e-10 -302.14 -0.49766 Resultant 15,029 302.42 12.615 Bolt Check: OK Calculated FOS: 2.270 19 Desired FOS: 2 ASTM A36 Steel 2e+11 N/m^2 0.26 6 threads/mm 2.5e+08 N/m^2 2 50 N.m 0.2 No Connector Forces Type Axial Force (N) Shear Force (N) Bending moment (N.m) X-Component 0 -15.681 15.069 Y-Component 14,977 3.638e-12 1.1727e-14 Entities: Type: Counterbore with Nut-6 Connection Type: Head diameter: Nut diameter: Nominal shank diameter: Material name: Young's modulus: Poisson's ratio: Thread Count: Bolt Strength: Safety Factor: Preload (Torque): Friction Factor (K): Tight Fit: 2 edge(s), 3 face(s) Bolt(Head/Nut diameter)(Count erbore) Distributed 24.3 mm 24.3 mm 16.2 mm Z-Component 1.7861e-10 -373.19 -0.98332 Resultant 14,977 373.52 15.101 Bolt Check: OK Calculated FOS: 2.306 45 Desired FOS: 2 ASTM A36 Steel 2e+11 N/m^2 0.26 6 threads/mm 2.5e+08 N/m^2 2 50 N.m 0.2 No Connector Forces Type Axial Force (N) Shear Force (N) Bending moment (N.m) X-Component 0 44.835 14.321 Y-Component 14,936 3.638e-12 -2.0211e-14 Z-Component 1.4867e-10 -346.57 2.0304 Resultant 14,936 349.46 14.465 Entities: Type: Counterbore with Nut-7 Connection Type: Head diameter: Nut diameter: Nominal shank diameter: Material name: Young's modulus: Poisson's ratio: Thread Count: Bolt Strength: Safety Factor: Preload (Torque): Friction Factor (K): Tight Fit: 2 edge(s), 3 face(s) Bolt(Head/Nut diameter)(Count erbore) Distributed 24.3 mm 24.3 mm 16.2 mm Bolt Check: OK Calculated FOS: 2.394 58 Desired FOS: 2 ASTM A36 Steel 2e+11 N/m^2 0.26 6 threads/mm 2.5e+08 N/m^2 2 50 N.m 0.2 No Connector Forces Type Axial Force (N) Shear Force (N) Bending moment (N.m) X-Component 0 38.567 12.687 Y-Component 14,950 3.638e-12 -1.39e-14 Entities: Type: Counterbore with Nut-8 Connection Type: Head diameter: Nut diameter: Nominal shank diameter: Material name: Young's modulus: Poisson's ratio: Thread Count: Bolt Strength: Safety Factor: Preload (Torque): Friction Factor (K): Tight Fit: Z-Component 1.4259e-10 -302.98 1.4573 2 edge(s), 3 face(s) Bolt(Head/Nut diameter)(Count erbore) Distributed 24.3 mm 24.3 mm 16.2 mm Resultant 14,950 305.42 12.771 Bolt Check: OK Calculated FOS: 2.333 63 Desired FOS: 2 ASTM A36 Steel 2e+11 N/m^2 0.26 6 threads/mm 2.5e+08 N/m^2 2 50 N.m 0.2 No Connector Forces Type Axial Force (N) Shear Force (N) Bending moment (N.m) X-Component 0 15.138 14.03 Y-Component 14,889 3.638e-12 -2.5561e-15 Entities: Type: Counterbore with Nut-9 Connection Type: Head diameter: Nut diameter: Nominal shank diameter: Material name: Young's modulus: 2 edge(s) Bolt(Head/Nut diameter)(Count erbore) Distributed 24.3 mm 24.3 mm 16.2 mm ASTM A36 Steel 2e+11 N/m^2 Z-Component 1.3581e-10 -338.89 0.28022 Resultant 14,889 339.23 14.033 Bolt Check: OK Calculated FOS: 3.182 16 Desired FOS: 2 Poisson's ratio: Thread Count: Bolt Strength: Safety Factor: Preload (Torque): Friction Factor (K): Tight Fit: 0.26 6 threads/mm 2.5e+08 N/m^2 2 50 N.m 0.2 No Connector Forces Type Axial Force (N) Shear Force (N) Bending moment (N.m) X-Component 0 -13.706 0.7179 Y-Component 15,466 0 0 Entities: Type: Counterbore with Nut-10 Connection Type: Head diameter: Nut diameter: Nominal shank diameter: Material name: Young's modulus: Poisson's ratio: Thread Count: Bolt Strength: Safety Factor: Preload (Torque): Friction Factor (K): Tight Fit: 2 edge(s) Bolt(Head/Nut diameter)(Count erbore) Distributed 24.3 mm 24.3 mm 16.2 mm Z-Component 0 -29.397 0.58017 Resultant 15,466 32.435 0.92303 Bolt Check: OK Calculated FOS: 3.189 64 Desired FOS: 2 ASTM A36 Steel 2e+11 N/m^2 0.26 6 threads/mm 2.5e+08 N/m^2 2 50 N.m 0.2 No Connector Forces Type Axial Force (N) Shear Force (N) Bending moment (N.m) X-Component 290.99 -23.895 0.5789 Y-Component 15,408 0.45127 -0.010933 Entities: Type: Counterbore with Nut-11 Connection Type: Head diameter: Nut diameter: Nominal shank diameter: Material name: Young's modulus: Poisson's ratio: Thread Count: Bolt Strength: Safety Factor: Preload (Torque): Friction Factor (K): Tight Fit: 2 edge(s) Bolt(Head/Nut diameter)(Count erbore) Distributed 24.3 mm 24.3 mm 16.2 mm Z-Component 0 -32.678 -0.76506 Resultant 15,410 40.484 0.95946 Bolt Check: OK Calculated FOS: 2.835 19 Desired FOS: 2 ASTM A36 Steel 2e+11 N/m^2 0.26 6 threads/mm 2.5e+08 N/m^2 2 50 N.m 0.2 No Connector Forces Type Axial Force (N) X-Component 0 Y-Component 0 Z-Component -12,712 Resultant 12,712 Shear Force (N) Bending moment (N.m) -1,616 0.6056 -577.78 -10.462 Entities: Type: Counterbore with Nut-12 Connection Type: Head diameter: Nut diameter: Nominal shank diameter: Material name: Young's modulus: Poisson's ratio: Thread Count: Bolt Strength: Safety Factor: Preload (Torque): Friction Factor (K): Tight Fit: 2 edge(s) Bolt(Head/Nut diameter)(Count erbore) Distributed 24.3 mm 24.3 mm 16.2 mm 0 0 1,716.2 10.48 Bolt Check: OK Calculated FOS: 2.670 84 Desired FOS: 2 ASTM A36 Steel 2e+11 N/m^2 0.26 6 threads/mm 2.5e+08 N/m^2 2 50 N.m 0.2 No Connector Forces Type Axial Force (N) Shear Force (N) Bending moment (N.m) X-Component 0 2,491.2 -1.4055 Y-Component 0 66.568 14.856 Entities: Type: Counterbore with Nut-13 Connection Type: Head diameter: Nut diameter: Nominal shank diameter: Material name: Young's modulus: Poisson's ratio: Thread Count: Bolt Strength: Safety Factor: Preload (Torque): Friction Factor (K): Tight Fit: 2 edge(s) Bolt(Head/Nut diameter)(Count erbore) Distributed 24.3 mm 24.3 mm 16.2 mm Z-Component -11,545 0 0 Resultant 11,545 2,492.1 14.922 Bolt Check: OK Calculated FOS: 2.382 43 Desired FOS: 2 ASTM A36 Steel 2e+11 N/m^2 0.26 6 threads/mm 2.5e+08 N/m^2 2 50 N.m 0.2 No Connector Forces Type Axial Force (N) Shear Force (N) Bending moment (N.m) X-Component 0 -2,591 -0.54465 Y-Component 0 85.726 -19.677 Entities: Type: Counterbore with Nut-14 Connection Type: Head diameter: Nut diameter: 2 edge(s) Bolt(Head/Nut diameter)(Count erbore) Distributed 24.3 mm 24.3 mm Z-Component -11,548 0 0 Resultant 11,548 2,592.4 19.684 Bolt Check: OK Calculated FOS: 2.957 76 Desired FOS: 2 Nominal shank diameter: Material name: Young's modulus: Poisson's ratio: Thread Count: Bolt Strength: Safety Factor: Preload (Torque): Friction Factor (K): Tight Fit: 16.2 mm ASTM A36 Steel 2e+11 N/m^2 0.26 6 threads/mm 2.5e+08 N/m^2 2 50 N.m 0.2 No Connector Forces Type Axial Force (N) Shear Force (N) Bending moment (N.m) X-Component 0 1,748.3 2.5577 Y-Component 0 -715.63 9.0943 Entities: Type: Counterbore with Nut-15 Connection Type: Head diameter: Nut diameter: Nominal shank diameter: Material name: Young's modulus: Poisson's ratio: Thread Count: Bolt Strength: Safety Factor: Preload (Torque): Friction Factor (K): Tight Fit: Z-Component -12,444 0 0 2 edge(s) Bolt(Head/Nut diameter)(Count erbore) Distributed 24.3 mm 24.3 mm 16.2 mm ASTM A36 Steel 2e+11 N/m^2 0.26 6 threads/mm 2.5e+08 N/m^2 2 50 N.m 0.2 No Resultant 12,444 1,889.1 9.4471 Bolt Check: Need s attent ion Calculated FOS: 1.128 51 Desired FOS: 2 Connector Forces Type Axial Force (N) Shear Force (N) Bending moment (N.m) X-Component 2.6392e-10 0.045528 26.951 Y-Component 0 2,137.5 -11.123 Entities: Type: Counterbore with Nut-16 Connection Type: Head diameter: Nut diameter: Nominal shank diameter: Material name: Young's modulus: Poisson's ratio: Thread Count: Bolt Strength: Safety Factor: Preload (Torque): Friction Factor (K): Tight Fit: Z-Component -30,704 0 2.3166e-13 2 edge(s) Bolt(Head/Nut diameter)(Count erbore) Distributed 24.3 mm 24.3 mm 16.2 mm ASTM A36 Steel 2e+11 N/m^2 0.26 6 threads/mm 2.5e+08 N/m^2 2 50 N.m 0.2 No Resultant 30,704 2,137.5 29.156 Bolt Check: OK Calculated FOS: 5.321 1 Desired FOS: 2 Connector Forces Type Axial Force (N) Shear Force (N) Bending moment (N.m) X-Component 0 -0.044589 -12.24 Y-Component 0 2,434 0.92873 Entities: Type: Counterbore with Nut-18 Connection Type: Head diameter: Nut diameter: Nominal shank diameter: Material name: Young's modulus: Poisson's ratio: Thread Count: Bolt Strength: Safety Factor: Preload (Torque): Friction Factor (K): Tight Fit: Z-Component -0 -3.8327e-16 -1.0521e-13 2 edge(s) Bolt(Head/Nut diameter)(Count erbore) Distributed 24.3 mm 24.3 mm 16.2 mm Resultant 0 2,434 12.275 Bolt Check: OK Calculated FOS: 3.238 99 Desired FOS: 2 ASTM A36 Steel 2e+11 N/m^2 0.26 6 threads/mm 2.5e+08 N/m^2 2 50 N.m 0.2 No Connector Forces Type Axial Force (N) Shear Force (N) Bending moment (N.m) X-Component 0 -0.51996 0.24649 Y-Component 15,454 0 0 Entities: Type: Counterbore with Nut-19 Connection Type: Head diameter: Nut diameter: Nominal shank diameter: Material name: Young's modulus: Poisson's ratio: Thread Count: Bolt Strength: Safety Factor: Preload (Torque): Friction Factor (K): Tight Fit: Z-Component 0 -12.218 0.27684 2 edge(s) Bolt(Head/Nut diameter)(Count erbore) Distributed 24.3 mm 24.3 mm 16.2 mm Resultant 15,454 12.229 0.37067 Bolt Check: OK Calculated FOS: 3.199 23 Desired FOS: 2 ASTM A36 Steel 2e+11 N/m^2 0.26 6 threads/mm 2.5e+08 N/m^2 2 50 N.m 0.2 No Connector Forces Type Axial Force (N) Shear Force (N) Bending moment (N.m) X-Component 0 -25.107 -0.55546 Y-Component 15,554 0 0 Z-Component 0 -26.696 -0.11207 Resultant 15,554 36.648 0.56665 Entities: Type: Counterbore with Nut-20 Connection Type: Head diameter: Nut diameter: Nominal shank diameter: Material name: Young's modulus: Poisson's ratio: Thread Count: Bolt Strength: Safety Factor: Preload (Torque): Friction Factor (K): Tight Fit: 2 edge(s) Bolt(Head/Nut diameter)(Count erbore) Distributed 24.3 mm 24.3 mm 16.2 mm Bolt Check: OK Calculated FOS: 3.142 62 Desired FOS: 2 ASTM A36 Steel 2e+11 N/m^2 0.26 6 threads/mm 2.5e+08 N/m^2 2 50 N.m 0.2 No Connector Forces Type Axial Force (N) Shear Force (N) Bending moment (N.m) X-Component 0 -2.676 -1.062 Y-Component 15,579 0 0 Entities: Type: Counterbore with Nut-21 Connection Type: Head diameter: Nut diameter: Nominal shank diameter: Material name: Young's modulus: Poisson's ratio: Thread Count: Bolt Strength: Safety Factor: Preload (Torque): Friction Factor (K): Tight Fit: Z-Component 0 35.968 -0.29548 2 edge(s) Bolt(Head/Nut diameter)(Count erbore) Distributed 24.3 mm 24.3 mm 16.2 mm Resultant 15,579 36.067 1.1024 Bolt Check: OK Calculated FOS: 3.239 75 Desired FOS: 2 ASTM A36 Steel 2e+11 N/m^2 0.26 6 threads/mm 2.5e+08 N/m^2 2 50 N.m 0.2 No Connector Forces Type Axial Force (N) Shear Force (N) Bending moment (N.m) X-Component 0 20.487 0.1698 Y-Component 15,452 0 0 Z-Component 0 -54.155 -0.32658 Resultant 15,452 57.9 0.36808 Interaction Information Interaction Interaction Image Local Interaction-2 Interaction Properties Type: Contact interaction pair Entities: 2 face(s) Advanced: Surface to surface Contact/Friction force Components Contact Force(N) X 18.084 Y 163.36 Z -409.13 Resultant 440.91 Type: Contact interaction pair Entities: 2 face(s) Advanced: Surface to surface Local Interaction-3 Contact/Friction force Components Contact Force(N) X 0 Y -23,752 Z 0 Resultant 23,752 Type: Contact interaction pair Entities: 2 face(s) Advanced: Surface to surface Local Interaction-4 Contact/Friction force Components Contact Force(N) X 0 Y -24,376 Z 0 Resultant 24,376 Local Interaction-5 Type: Contact interaction pair Entities: 2 face(s) Advanced: Surface to surface Local Interaction-6 Type: Contact interaction pair Entities: 2 face(s) Advanced: Surface to surface Contact/Friction force Components X Y Z Resultant Contact Force(N) 0 0 -1.5865E-11 1.5865E-11 Type: Contact interaction pair Entities: 2 face(s) Advanced: Surface to surface Local Interaction-7 Contact/Friction force Components Contact Force(N) X 0 Y 0 Z 6.0329E-11 Resultant 6.0329E-11 Type: Contact interaction pair Entities: 2 face(s) Advanced: Surface to surface Local Interaction-9 Contact/Friction force Components Contact Force(N) X -37.523 Y 150.34 Z -301.8 Resultant 339.26 Type: Contact interaction pair Entities: 3 face(s) Advanced: Surface to surface Local Interaction-10 Contact/Friction force Components Contact Force(N) X 34.151 Y -1.1369E-13 Z -1.7053E-13 Resultant 34.151 Type: Contact interaction pair Entities: 3 face(s) Advanced: Surface to surface Local Interaction-11 Contact/Friction force Components Contact Force(N) Local Interaction-305 X -28.288 Y 1.8474E-13 Z 1.9895E-13 Resultant 28.288 Type: Bonded interaction pair Entities: 2 face(s) Local Interaction-306 Type: Bonded interaction pair Entities: 2 face(s) Local Interaction-307 Type: Bonded interaction pair Entities: 2 face(s) Local Interaction-308 Type: Bonded interaction pair Entities: 2 face(s) Local Interaction-309 Type: Bonded interaction pair Entities: 2 face(s) Local Interaction-452 Type: Bonded interaction pair Entities: 2 face(s) Local Interaction-453 Type: Bonded interaction pair Entities: 2 face(s) Local Interaction-734 Type: Bonded interaction pair Entities: 2 face(s) Local Interaction-735 Type: Bonded interaction pair Entities: 2 face(s) Local Interaction-1150 Type: Bonded interaction pair Entities: 2 face(s) Local Interaction-1805 Type: Bonded interaction pair Entities: 2 face(s) Local Interaction-1806 Type: Bonded interaction pair Entities: 2 face(s) Local Interaction-1807 Type: Bonded interaction pair Entities: 2 face(s) Local Interaction-2085 Type: Bonded interaction pair Entities: 2 face(s) Local Interaction-2086 Type: Bonded interaction pair Entities: 2 face(s) Local Interaction-2087 Type: Bonded interaction pair Entities: 2 face(s) Local Interaction-2088 Type: Bonded interaction pair Entities: 2 face(s) Local Interaction-2230 Type: Bonded interaction pair Entities: 2 face(s) Local Interaction-2231 Type: Bonded interaction pair Entities: 2 face(s) Local Interaction-2371 Type: Bonded interaction pair Entities: 2 face(s) Global Interaction Type: Bonded Components: 1 component(s) Options: Independent mesh 6 RESULTANT FORCES Resultant Forces : Reaction forces Selection set Units Sum X Sum Y Sum Z Resultant Entire Model N -0.244591 5,393.7 0.927656 5,393.7 Reaction Moments Selection set Units Sum X Sum Y Sum Z Resultant Entire Model N.m 0 0 0 1e-33 Free body forces Selection set Units Sum X Sum Y Sum Z Resultant Entire Model N -0.267581 19.3905 0.282709 19.3944 Free body moments Selection set Units Sum X Sum Y Sum Z Resultant Entire Model N.m 202.978 -85.826 26.8152 222.002 8 F.E.A RESULT Units:Unit system: SI (MKS) Length/Displacement mm Temperature Kelvin Angular velocity Rad/sec Pressure/Stress N/m^2 Study Results Resultant Displacement: Name Type Min Max Displacement1 URES: Resultant Displacement 0.000e+00mm Node: 12697 2.219e+01mm Node: 17434 LADDER STTLE-01MAIN ASSEMBLY-R1-LADDER STYLE-Displacement-Displacement1 Equivalent Strain: Name Type Min Max Strain1 ESTRN: Equivalent Strain 0.000e+00 Element: 31063 1.635e-03 Element: 44973 LADDER STTLE-01MAIN ASSEMBLY-R1-LADDER STYLE-Strain-Strain1 von Mises Stress: Name Type Min Max Stress2 VON: von Mises Stress 0.000e+00N/mm^2 (MPa) Node: 14967 4.023e+02N/mm^2 (MPa) Node: 18644 LADDER STTLE-01MAIN ASSEMBLY-R1-LADDER STYLE-Stress-Stress2 ISO Clipping : The Below plot shows that stress concentration in body is due to geometric and FEA limitations, the above plot contains the geometries that had stress of more than 140 MPA. Note: The gray coloured geometries are rigid bodies it is not the part of plot Legend. Stress probing at various locations of concerned part: VON MISES PROBE RESULTS AT DIFFERENT LOCATIONS The above Fig. shows the stress distribution under 400 kg & self-weight. The selected nodes are taken into account based on provided Interactions, Loads & Fixtures. The stress is concentrated above & in between of Frame & Piston cylinder arrangement and it needs to be addressed. Stress Trend (node: 18649): Highly concentrated area or components need to redesign. 8 CONCLUSION AND RECOMMENDATION ◼ The Static elastic analysis provided insights on the “Cylinder lifter assembly”, under the provided load and condition (DEAD WEIGHT + SELF-WEIGHT) at the maximum stroke length of 300 mm, with the assumption made of having rigid bodies such as a hydraulic cylinder in the simulation: ◼ As the initial provided CAD was unable to withstand high loading. Due to these overall changes in the frame structure and bucket were needed to address this condition the necessary modifications were made to the CAD assembly with the required approvals. The ladder pattern structure has been selected for further simulation. ◼ From the FEA results calculated maximum displacement is 2 cm at the bucket, overall Elastic strain is 1.365e-3, maximum Von Mises stress is 250 & 98.18 percent Von Mises stress under the allowable stress. ◼ The hydraulic cylinder to frame linkage part is subjected to high stress above the allowable stress and the same location the failure in the bolt connection is found, thus needs to be perform the necessary Design modification. ◼ The rest of the parts in the Cylinder lifter assembly are well under allowable stress according to the ASME BPVC 2021 Section II D for General structural steel (not pressure-rated). ◼ The recommended design changes are as stated below: The Bucket can be designed as the Skeleton structure to minimize the displacement further . The I or Rectangular beam can be utilised in the high-stress concentration area which is the hydraulic cylinder to frame linkage part. The double shear sheets can be utilized for the bolt connectors. The weld can be used at the piston linkage part rather than bolt may increase the structural integrity To discuss the above made Recommendations can reach out to us . Disclaimer: ◼ Finite Element is a mathematical technique of solving differential equation and the results predicted are subject to errors due to idealization, modelling, numerical solutions and error in predicting loads and boundary conditions. Due to this, and due to complexity of the project, the project may involve some amount of rework. Although utmost care is taken in ensuring the correctness of data and documents generated during the project, a chance of human error cannot be ruled out. In any such circumstances, when it is proven that, the error occurred in any of the data or documents generated attributed to us, our liability is restricted to redoing the same work again and resubmitting the same documents, at our sole discretion, without any further charge. No other expressed or implied liability is acceptable to us under any circumstances.