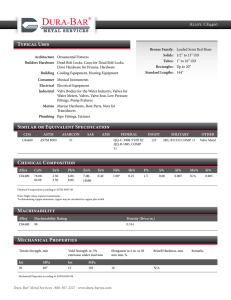

FABRICATION OF SOLID CRA PIPING SPEAKER: FULL NAME ABU DHABI NATIONAL OIL ONSHORE COMPANY ADNOC AGENDA • Common materials & welding consumables used ADNOC ONSHORE | FABRICATION OF CRA PIPING • Welding Process and Procedure Qualification - Special Requirements • Fabrication of solid CRA at Shop and Site 2 • NDT Inspections & acceptance criteria • Painting • Lesson Learned MATERIALS COVERED ● ● ● ● ADNOC ONSHORE | FABRICATION OF CRA PIPING ● 3 ● ● ● ● ● ● ● ● INCOLY (825) Piping components ASTM B423 UNS N08825 – Pipe ASTM B366 UNS N08825- Fitting ASTM B564 UNS N08825.- Flange INCONEL (625) Piping Components ASTM B444 UNS N06625 - Pipe ASTM B366 UNS N6625- Fitting ASTM B564 UNS N06625- Flange SDSS-Cr%25 ASTM A790 Gr. S32750 - Pipe ASTM A928 Gr. S32750 Welded Pipes Size 6” and greater-Pipe ASTM A182 F53- Flange ASTM A815 Gr. S32750 Cl. WP-S, ASTM A815 Gr. S32750 Cl. WP-WX- Fittings SS ASTM A312 TP316/316L- Pipe ASTM A403Gr.WP316/316L-WX - Fitting ASTM A182 Gr. F316/316L- Flange Joining of solid CRA Piping Components- Welding Consumables Predominantly we Go with ERNiCrMo-3 for Nickel alloy ADNOC ONSHORE | FABRICATION OF CRA PIPING (both 625 and 825 material). 4 ER2594/ E2594-15 for SDSS ER 316L/E316L-15 for SS PMI testing to be conducted as per AGES-GL-13-002 ADNOC ONSHORE | FABRICATION OF CRA PIPING WELDING PROCESS 5 ADNOC ONSHORE | FABRICATION OF CRA PIPING SPECIAL REQUIREMENTS FOR WPQ 6 • • • • ASTM G28 for 825 (IGC for Cr. Bearing alloy) ASTM G48 for 625 (Pitting and Crevice Corrosion Resistance test) ASTM G48 for SDSS (Pitting and Crevice Corrosion Resistance test) ASTM A262 for SS (Inter Granular Corrosion Test) ADNOC ONSHORE | FABRICATION OF CRA PIPING MATERIAL RECEIVING AND STORAGE 7 Materials are received and stored as per the Project specification Identified by PMI (if required), then color coded and stored or stacked on a wooden blocks / Racks with enough ground clearance. Pipes are arranged with a protected Bevel ends and covered from atmospheric exposure. Piping components as stored in Warehouse with this same identification and Bevel end protection. ADNOC ONSHORE | FABRICATION OF CRA PIPING FABRICATION OF SOLID CRA WELDING 8 •A dedicated Workshop to be assigned for SS and Nickel alloy fabrication isolated from other LTCS/CS materials. •Tools (Wire brush and grinding wheel to dedicated SS material) •Joints to be made matching the ID of the piping components •Prior to start of the welding Oxygen Level is ensured to below 0.05% •Purging Gas purity to be 99.9% •Rest Parameters are followed as per the WPS. •Inter pass Temperature is maintained 70-100 Degree Celsius for SDSS 150 Degree Celsius for SS and Nickel Alloy. •Heat input are also carefully monitored as per WPS 0.5 to 1.75KJ/mm max for SDSS 2KJ/mm max for Nickel Alloy. •Inert Gas Purging is maintained for Root and Cold Pass for SS/SDSS/ Nickel piping welding and upto a min. of 6mm deposit thickness. •Acceptable Level of Oxidation of Root if followed in process as said in DEP 30.10.60.31-Gen. Feb 2013 Unacceptable levels of Root Oxidation Acceptable levels of weld root oxidations NDE COVERAGE FOR WELDMENT ADNOC ONSHORE | FABRICATION OF CRA PIPING •Upon completion of the joint PMI, PT, hardness and other NDT Requirements Carried out as per Line class. 9 •In addition, Ferrite Content Test to be carried out for SS and SDSS weldment and HAZ 35%-65% for SDSS -100% (AGES-SP-07-007) 3-8 FN for SS-10% per WPS followed on the spool •NDT Coverage is as per piping material specification which in turn referred to Project Piping Class. POST WED ACTIVITIES Hydro Testing of the solid CRA Spools. ADNOC ONSHORE | FABRICATION OF CRA PIPING 10 Hydrotest is carried out as per the approved Project Specification with a condition of Chloride levels in water is less than 50ppm followed by immediate drain and drying. Painting of CRA Spools Upon completion of Hydro test the CRA spools is Blast and the Painted as per Project Painting Procedure. Painting Class LS1 for the Nickel alloy and SDSS and SS (AGES-SP-07-004) In any case painting material should be ZINC free Spools are identified and tagged throughout till Erection. LESSON LEARNED 1 Welding nickel alloy pipe to CRA clad pipe of two different thicknesses 11 ADNOC Classification: Internal Background in 2021 BIFP project BAB area 6 months after commissioning of the pump suction line of the water disposal tanks. Leakage was detected in the branches of the main header of this line. The main header was 6 reduced Tees CS with CRA lining (6 & 4 inches in diameter and 15 & 12 mm thickness). connected to 6 nickel alloy pipes (4 inches in diameter and 6 mm thickness). Leak location 12 ADNOC Classification: Internal Cause of the leak: During installation of the 4" joint,The contractor's pipe fitter had tapered the thick side of the joint to match the inside diameter of the thin pipe and this operation removed part of the clad area, exposing the CS to the corrosive fluid and initiating the corrosion mechanism which then leaked. 4” x 6 mm Area exposed to Corrosive fluid Tapering plan 6” x 15 mm 13 Ni Alloy material 4” x 12 mm CS/LTCS material ADNOC Classification: Internal How to correct: By using a transition spool (nickel alloy). This spool is a piece of pipe with the same diameter of the branch (4 inches) and equal to the thick part (12 mm) and weld it normally from the reduced tee side and make the taper from the other side to match the thin part. 4” x 12 mm transition spool Tapering plan 6” x 15 mm 14 Ni Alloy material 4” x 12 mm CS/LTCS material ADNOC Classification: Internal LESSON LEARNED 2 Nickel Branch connection to clad pipe 15 ADNOC Classification: Internal Background: In 2014, one year after the commissioning of the disposal water facility at BAB CDS (Project 1.8), it was noticed that there were some leaks coming from the connections between the nickel weld-O-lets and the clad pipes. After a detailed investigation, it was found that the contractor had not followed the correct installation procedure and that 365 similar branches would have to be replaced at an estimated cost of US$8 million. Leak location 16 ADNOC Classification: Internal Cause of leak: The contractor had drilled the hole without protecting the carbon steel surface with CRA material, and this surface was exposed to the corrosive fluid and the corrosion mechanism started and then leaked. Exposed CS surface Ni Alloy material 17 CS/LTCS material ADNOC Classification: Internal The following steps show the correct way to make such a branch (for 2 inch and below): Step No. 1 Drill a non-through hole, The non-through hole shall be drilled by using CNC machine. The diameter of the drilled hole shall be at least D+10mm, where D is the inside diameter of the weld-O-let (as shown in the figure). The outer carbon steel shall be completely peeled off and the cladding layer shall be fully exposed. To ensure it is free from iron contamination, the copper sulphate solution shall be applied with a brush to the nickel alloy area after removing CS. The hole shall be tapered 15 to 20 degrees. 15-20 deg Ni Alloy material D+10 mm 18 CS/LTCS material ADNOC Classification: Internal Step No. 2 Manual Weld Overlay After Step 1, a manual weld overlay shall be applied to the nickel alloy layer (as shown in the figure). Welding shall be carried out using the qualified WPS. Ni Alloy material 19 CS/LTCS material ADNOC Classification: Internal Step 3 Drill through hole Before drilling, the weld reinforcement on the outer surface of the CS pipe shall be ground flush. The through hole shall be drilled using a CNC machine. The diameter of the through hole shall match the ID of the weld-O-let and the minimum wall thickness of the cladding layer by manual welding overlay shall be 5mm (as shown in the figure). Ni Alloy material 20 CS/LTCS material ADNOC Classification: Internal Step No. 4 Fit up and welding The connection between the run pipe and the weld-O-let shall be nickel alloy only (as shown in the figure). Before fit up PT shall be carried out on the weld-O-let hole after cladding and machining. Thickness verification shall be performed with a clad gauge after cladding and machining to verify the remaining clad thickness. After fit up Welding shall be performed with the qualified WPS. Ni Alloy material 21 CS/LTCS material THANK YOU ADNOC ONSHORE