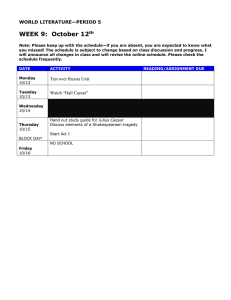

CAESAR II® Training & Development Online Video Training Series Training when you need it - anywhere in the world SM Model geometry, run the analysis, review results Fundamentals Anthony W. Horn Guide CAESAR II® Fundamentals Anthony W. Horn First Edition - January 2014 ©2014 CAD Training Technologies, LLC Houston, TX USA http://www.pipingdesignonline.com i Welcome to these Special Videos for Learning CAESAR II® Fundamentals! This is exciting! When I first started learning CAESAR II I said to myself, "I hope there are some training videos available for me to look at." I had discovered that watching a video and then following along with an instructor made it much easier for me to learn a subject quickly. If I could just see how to do something, I seemed to catch on faster. I think this is especially true for a more advanced type of software. So fast forward, a few years, and we now have this type of training available! This course is designed to introduce you to the fundamentals of CAESAR II, Intergraph's® premier pipe stress analysis system. Our goal here is not to teach you pipe stress analysis (we already assume you know that), but we want you to get started in CAESAR II and quickly begin to solve problems. You'll see how to navigate the software, model piping geometry, and analyze your results. We'll also look for opportunities to explore and use a number of the commands and features in CAESAR II as we go through the process of solving the course examples. So thank you for taking this course and let's get started! Anthony W. Horn 2014 ii Trademark Information The material, applications, and routines presented in this book have been included for their instructional value. They have been tested for accuracy, but are not guaranteed for any particular purpose. The author and copyright holders do not offer any representations or warranties, nor do they accept any liabilities with respect to this video and written material, instructions, software applications, or routines. This material in these documents and accompanying videos is solely owned and copyrighted ©2014 by CAD Training Technologies, LLC, Houston, Texas, USA. Duplication in any manner is strictly prohibited without express written consent. Trademarks AutoCAD® is registered in the U.S. Patent and Trademark office by Autodesk, Inc. CAESAR II®, CADWorx Plant Professional®, and Isogen® are registered in the U.S. Patent and Trademark office by Intergraph® Corporation. Intergraph® provides the programs, CAESAR II®, and CADWorx® Plant Professional, “as is” and with all fault. Intergraph® specifically disclaims any implied warranty of merchantability or fitness for a particular use. Intergraph® Corporation does not warrant that the operation of the program will be uninterrupted or error free. Autodesk® provides the program, AutoCAD®, “as is” and with all fault. Autodesk® specifically disclaims any implied warranty of merchantability or fitness for a particular use. Autodesk®, Inc. does not warrant that the operation of the program will be uninterrupted or error free. iii About the Author Anthony Horn is the owner and creator of PipingDesignOnline.com, the largest CADWorx training organization in the world. PipingDesignOnline.com, launched in 2011, contains over 300 specialized CAD training videos, and has served over 1500 subscribers in more than 45 countries. In 2008 he authored the Intergraph® video training DVD titled Mastering CADWorx Plant Professional Software which became the industry standard for CADWorx training. His private school, the Horn Drafting & CAD Center has trained over 3500 CAD operators and pipe drafters for Houston industries since 1968. He holds degrees in both engineering and architecture, and was a contributing author to The CAD/CAM Handbook (McGraw Hill, 1985) and Pipe Drafting and Design (Gulf Publishing, 1996). In 2012 he published Mastering CADWorx Plant Professional Software, available from Amazon.com. iv Acknowledgements Special thanks are due to David Diehl, PE., Director of Training, at CADWorx and Analysis Solutions, Intergraph Process Power and Marine. His support and great knowledge of CAESAR II were instrumental in helping me produce this work. The author also wishes to thank the American Society of Mechanical Engineers for allowing me to include a copy of their ASME, B31.3 Piping Code, Appendix S as part of these course materials. v CAESAR II FUNDAMENTALS Table of Contents EXAMPLE 1 Video 1 Introduction and Course Overview................................................................. 1 Video 2 Starting a New File, Using the Interface, Entering Parameters ..................... 11 Video 3 Modeling Geometry, Adding Bends and Restraints, Viewing Options ............................................................................................. 16 Video 4 Selection and Viewing Options, Orbit, Walkthrough, Display Options ........... 22 Video 5 Error Checking, Running the Analysis, Load Cases, Reviewing Results ...... 30 Video 6 Creating a Custom Report, Comparing Results to Code Results .................. 34 Video 7 Reviewing Sustained Load Case Results, Comparing Stress Results .......... 38 Video 8 Creating a New Load Case and Custom Report, Comparing Results ........... 43 Video 9 Viewing Plotted Results, Showing Deflected Shape, Forces, Moments, Element Viewer, Animating Results ............................................................... 49 Video 10 Configuration, Outboard Processors, Interfaces, Utilities ............................... 56 EXAMPLE 2 Video 1 Inputting Parameters, Modeling Geometry .................................................... 63 Video 2 Display Options (Materials, Temperature, etc.), Additional Input Options ..... 71 Video 3 Using Lists, Block Operations ........................................................................ 77 Video 4 Running the Analysis, Comparing Results with Code, Animating Results ..... 84 Video 5 Designing a Hanger, Reviewing Load Cases ................................................ 90 Video 6 Generating a Stress Isometric ....................................................................... 98 Video 7 Modeling a Wind Load, Inputting the Wind Profile Parameters ..................... 104 Video 8 Developing Wind Load Cases, Snubbers, Analysis, Reviewing Results ....... 110 EXAMPLE 3 Video 1 Inputting Parameters, Multiple Temperatures and Pressures, Modeling ....... 120 Video 2 Completing the Model, Viewing Different Temperatures and Pressures ....... 128 Video 3 Analyzing Results, Comparing Results with the Code Results ...................... 136 vi EXAMPLE 4 Video 1 Exporting a CAESAR II Input File from a 3D CAD System ............................ 140 Video 2 Opening the File, Adjusting Restraints, Adjusting Parameters ...................... 143 Video 3 Calculating and Modeling the Nozzle Displacements .................................... 147 Video 4 Adjusting the Model, Entering Nozzle Limit Check Information ..................... 153 Video 5 Analyzing Results, Finding Excessive Loads on the Pump Nozzles ............. 158 Video 6 Analyzing Alternate Geometry, Looking for More Flexibility .......................... 165 Video 7 Modeling a Dummy Leg ................................................................................. 170 Video 8 Adding a Restraint, Offset, and Single Flange, Running the Analysis ........... 176 Video 9 Modifying Geometry to Increase Flexibility, Deleting Elements ..................... 185 Video 10 Modeling New Geometry, Using the Flange and Valve Database ................. 191 Video 11 Duplicating using Mirror/Copy, Changing Sequence, Renumbering Nodes .. 203 Video 12 Running the Analysis, Conclusion ................................................................. 211 ASME B31.3, Appendix S vii CAESAR II® Fundamentals - Example One Video 1 1. Welcome to the CAESAR II Fundamentals Course! In this course, we're going to explore a lot of the features and topics in CAESAR II software. Our goal in this course is for you to be able to create models analyze them and review your results, as well as navigate the various parts of the software when you're finished with this course. 2. In this course we're not going to spend much time talking about the theory behind pipe stress analysis. We're going to assume you're already familiar with that. So our goal here is to learn how to use the software. 3. The figure above shows a typical screen in CAESAR II. On the left area, we have what's called the input spreadsheet. This area is where we set up the dimensions of the model, and we have the pipe size and schedule. Lower down in here are the pressures and temperatures, and there's an area to specify the materials for the model. 1 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example One Video One 4. So this is where it all happens. As we build the model, we'll start seeing an image of it appear in the right area of the screen. This area is called the plot. This is where we can view it from different directions, and we have a number of viewing options. 5. In this example, we have temperatures displayed. So we see we have a higher temperature in one leg than the other. So this interface is what we'll use to view our model as it develops. 6. There are four main areas that we're going to explore in this course. We'll be building the geometry and modeling with the software. We'll also learn how to run the analysis and the error checker and produce reports and view our results. 2 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example One Video One 7. We'll learn how to create custom reports so that you can get your information to come out exactly like you want. We'll also see how to import a model in from a 3D CAD system and work with that. In CADWorx Plant Professional software and Smart Plant 3D, designers have the ability to export out a CAESAR II model. Then the stress analysts can just open it right up in CAESAR II, and it's just quick and easy. This way the pipe stress engineer doesn't have to recreate all the model geometry. So we're going to see how that happens. 8. Most of the examples in this course will come out of Appendix S in the ASME B 31.3 piping code. ASME has allowed me to include a copy of appendix S in your workbook. So this where we're going to be getting the first three problems that we'll analyze in this course. 9. If you want more information about the theory behind these first three examples, you can find it here in this appendix S. It's explained in detail and they discuss the formulas and information that forms the basis of these problems. We'll model and solve these problems ourselves, and also use them as a means to explore a number of features in CAESAR II. 3 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example One Video One 10. This is what the lessons are going to look like. This first one is just a simple model. It's example one in Appendix S. Next we'll work with a liftoff model, and then we'll do this moment reversal model. So we'll be building these models and comparing our results to what the code shows. 11. This last model is the one I mentioned earlier. This is the 3D model that came out of the CADWorx Plant Professional system. We'll open the input file that CADWorx created for us in CAESAR II and analyze it. We'll be able to use this model as an opportunity to look at the nozzle limit checks on these pumps, and we'll find that we're going to have to modify the geometry some to get within the recommended allowable values on these nozzle loads. 4 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example One Video One 12. As we do these lessons, we'll also explore other features in CAESAR II. For instance, in the liftoff model, we'll take the +Y restraint out, and we'll have CAESAR II model a hangar for us. In the illustration we can see the hangar installed in the proper position. 13. Also we have a report that shows what's going on here in the model. We'll see that when you put a hangar in using CAESAR II, it's an easy process. CAESAR II automates so much of that, and the software includes over 30 manufacturers' catalogs built right into it. 5 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example One Video One 14. Here are some other topics we'll look at. We'll create new load cases for our models. We'll do some nozzle limit checks. We'll animate the displacements in our models, and we'll add a wind load (an occasional load) to one the examples. 15. When we work with the imported CAD model we'll modify it to pass the nozzle limit checks. We'll learn some CAESAR II editing tools that are really nice, and we'll take a part of the geometry, and mirror/copy it around the center line in the YZ axis. We'll also see how to work with block operations, to rearrange and renumber a group of elements in a single step. 6 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example One Video One 16. We'll be working in a folder called CAESAR II Fundamentals Course Files. In the course itself, there's a link you can click to download the workbook and also the set of background files. So you must start and save your files in this folder because it will set the CAESAR II units automatically and avoid early problems. 17. This course will be in Imperial Units. Later, if you want to do this in metric, those dimensions are included in the first three examples in the code, so you can recreate these later in metric if you'd like to do so . But at first, follow along with the course and do them as shown in Imperial. 18. Here's how the course is going to work. Here's a typical video player, with different videos along the bottom. The best way to go about this is to start playing the video and watch it for just a few minutes. Let it show you one or two specific things, and then you can pause it. 19. While you're watching the video, if you like, there is a full screen toggle along the bottom. So if you can't see it real well, you just click that, and then it displays larger, and you can see it in detail. After you've seen something specific, pause the video, and then toggle over to CAESAR II. Then you will recreate the steps you just saw in the software. The videos will just lead you through everything step-by-step, and you just recreate what they've shown you. 7 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example One Video One 20. Also your workbook will be very useful. Just have your workbook open up to the right page as you work, and it will follow right along with the video very closely. So you'll see it and hear it in the video, and then you'll use your workbook and recreate it. Learning this way works really well. What's good about a video is if something is shown, and you don't quite understand it, you can just click back a little bit and rewind it, and you can see it again. So nobody's going to get left behind, and everybody can work at their own pace here. 21. Now, certification and PDH hours in this course are optional. If you want to earn a certificate and PDH hours, all you have to do is just work through the lessons, pass the quizzes, complete the survey, and the system will produce a certificate automatically for you. If you don't want to pass quizzes or get involved in that, you don't have to do that. The certification is just optional. 22. If you decide you don't want to get a certificate, everything is still available. You can look at all the videos and have access to all the workbooks and all the information. It's just that the system is not going to create a certificate automatically unless the quizzes are passed and the survey has been completed. 8 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example One Video One 23. All right, we're just about ready to get started now. This is the first example in appendix S, and this is the line we're going to model. You can see it's a pretty simple line. We have the measurements given, and we have the restraints positioned in the figure. So this is the information we're going to be keying in. When we're done, the completed model will look like this. 9 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example One Video One 24. Here are the design and operating conditions that we'll be working with. We have the size of the pipe given and its schedule. We have other information, like the specific gravity of the fluid, the insulation thickness, and the material, which will in turn give us the pipe's density. So we have everything here that we need. So great!. Let's just go on now to the next video, and we can start our course and begin learning CAESAR II! 10 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC CAESAR II® Fundamentals - Example One Video 2 1. In this example, we're going to input the values shown in the ASME B31.3 piping code for our problem set up. Once we have those input into CAESAR II and everything set the way we want, we'll begin to model the geometry of the line. So I'm going to toggle over to CAESAR II, and this is how the program looks when it first starts up. If you haven't started CAESAR II yet, Double click on the CAESAR II icon, and let's get it started. 2. Depending on the version you're running, your screen may look like mine or be slightly different. If it's a little different, it's going to be pretty straightforward to figure things out and follow what we’re doing. We'll be able to do the work no matter which version you're running. 3. Now we'll start a new file. Click New. If your screen looks different, you can find File and New on your system and get it started. 4. For the course files, you'll use the CAESAR II Fundamentals Course Files you downloaded from the course website. Make sure you use this folder for your work. That way the units will be set and you can find all the files you'll need as you go through the course. You can see on this screen that we're going to be putting in some input for piping calculations, but CAESAR II also has the ability to do some structural steel stress analysis as well. So we have Piping Input checked, and then I'm going to click up in this space for the name and call this, Example_1, then click OK. 5. The system will start up, and it will bring us into the Input Piping screen. First it displays the current units. In this example, we'll be working in Imperial units, so our length is going to be in inches, forces will be in pounds, densities-- insulation density, for instance-- will be in pounds per cubic inch. 11 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example One Video Two 6. For this example, work in the same units. Then later, you can go back and do this in metric units if you'd like. Click OK to close the units dialog box and get started. 7. The system will display the Input Piping screen. It's in a spreadsheet form and is designed for inputting settings, distances, and other things, like restraints, bends, etc. Also on the right of the spreadsheet, you'll see a window where the CAESAR II model displays as it progresses. 8. The spreadsheet can be moved and docked as needed. Depending on how your input screen is set when it first appears, it may be displayed slightly different than mine. For instance, it might be docked along the top. If that's the case, you can drag it down with the mouse and move it as needed (it may take a click to activate it). 9. Also, there are some other things you can do with this spreadsheet area. I'll drag and push it up and it will dock. Notice the Auto-hide button in the upper right area of the screen. When that is clicked, the Input spreadsheet will turn into a tab, and the model display area will be much larger. 12 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example One Video Two 10. Hovering over the spreadsheet tab and clicking it will reopen the input spreadsheet. It's locked right now, but if you click the auto-hide button again, it unlocks, and then you can drag it and reposition it using the mouse. 11. A good way to set up the screen is to hold down the mouse button in the spreadsheet title bar area, then drag it over to the left so that the mouse pointer touches the edge of the left window. Then the input spreadsheet will snap into a docked position, which works well because you can input values and see the model in the right window. What's nice about this set up is the model resizes automatically as it's changed within the window. 12. As you watch the video, you will notice my Input screen is compressed. This is because I'm recording using a fairly low resolution, thinking users might play this material on a mobile device. 13. Now we'll begin to input some of our design parameters. The Input screen has node 10 to 20 displayed. Later, we'll start inputting pipe lengths as the piping geometry gets modeled. However, the first step is to specify the pipe diameter, schedule, material, and other parameters. 13 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example One Video Two 14. Click in the Diameter field. If the exact diameter is known, we could type it in. In this example we know it's a 16-inch nominal pipe size. Type: 16 <Enter>, and the system will input the correct pipe diameter. Note: If you hear a beep from your system, that means that a conversion has taken place (in this example 16 was changed to 16.000). Also, you'll see a message appear near the bottom of the input spreadsheet about what is taking place. 15. Click in the Weight/Schedule field. Type: 30 <Enter>. The system will update the field with the pipe's wall thickness. 16. Leave the mill tolerance set as shown to 12-1/2%. Click in the Corrosion field. Type: 0.063 <Enter>. 17. Click in the Material field. Type: 106 <Enter>. CAESAR II will update the material to ASTM A106 grade B pipe. Also note how the system fills out additional fields based on the material selected. 18. Click in the Fluid Density field. Type: 1SG <Enter>. Note: It is very important to include the SG as part of this field's value. This represents a Specific Gravity of 1. for this field. Failure to include the SG term will result in large values being input, and you'll get errors later because the results will be larger than expected. 14 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example One Video Two 19. Click in the Temperature 1 field. Type: 500 <Enter>. 20. Click in the Temperature 2 field. Type: 30 <Enter>. 21. Click in the Pressure 1 field. Type: 500 <Enter>. 22. Click in the Insulation Thickness field. Type: 5 <Enter>. 23. Click in the Insulation Density field. Type: 11/1728 <Enter>. We'll enter it this way since 11 is in pounds per cubic foot, and CAESAR II uses density in pounds per cubic inch (1 cubic foot = 12x12x12 inches = 1728 cubic inches). Our system is now set up and we're ready to start modeling. Why don't you get your system set up at this point, and then we'll carry on after this? 15 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC CAESAR II® Fundamentals - Example One Video 3 1. All right. We've got our CAESAR II file opened up and now we'll begin to model the geometry of this line. Let's check our sketch first for measurements. I'm going to hold the Alt key down and press the Tab key, to take a look at the sketch in Appendix S in the B31.3 Piping Code. We'll be building their Example One. 2. We can see on the model that we're given nodes which identify points along the line. The line goes from node 10 to 20, on around 30, then 40, and down to node 50. We can see that on node 10 and also on node 50, we have some anchors. On node 20 we have what's called a Y restraint. This restrains the line and prevents it from moving up or down on the Y direction (the vertical direction). 3. In Appendix S, there's a chart that lists the distances on some of these nodes. The chart shows the distance from node 10 to node 15 is 20 feet. So using the values listed, we'll begin to build the model. 4. CAESAR II is set to increment its node count by 10. Click in the "To Node" field. Type: 15 <Enter>. Click in the Dx field. Type: 20- <Enter> The hyphen tells the system to use 20 feet for this value. If you just type 20 it will enter it as inches. 16 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example One Video Three 5. On node 10 will be an anchor. Double-click the Restraints box. Verify node 10 is set. Click the down arrow, and select Anchor. You can then click on another field or press <Enter>. 6. Use the Alt_Tab keys to view the model sketch shown in the code. Node 15 is an extra node which give us more information about the stresses and forces in this line. The next node is node 20, which is 20 feet over in the X direction. 7. Use the Alt_Tab keys to return to CAESAR II. What we want to do is tell the system to continue on to the next point. There's a toolbar in CAESAR II that is used to navigate between nodes and add or delete nodes as needed. The buttons on the toolbar will go to the Next, or Previous nodes, as well as the beginning or end of the line. 8. Click the Continue button. The system will increment the node count. Click in the "To Node" field and Type: 20 <Enter>. 17 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example One Video Three 9. Click in the Dx field and Type: 20- <Enter> (for a distance of 20 feet.) 10. Double click Restraints Verify the restraint will be on node 20. Click Y (for Y restraint). 11. Checking the sketch, we'll model a 10 foot segment over to node 30. 12. Click Continue Click in the Dx field. Type: 10- <Enter>. 13. At this point (node 30) we'll have a bend. The line will elbow and turn up at this point. 14. Double-click on Bend. 18 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example One Video Three 15. Click Continue. Notice the nodes are from 30 to 40. Click in the Dy field. Type: 20- <Enter> and the line extends 20 feet up in the vertical direction. 16. Double click Bend. You can see it's set for a long radius bend. 17. Click Continue. Click in the To Node field. Type: 45 <Enter>. Use the Alt_Tab keys to view the sketch. The segment we're working is from node 40 to node 45, which will be a distance of 10 feet. The last segment (node 45 to node 50) will be a distance of 20 feet, with an anchor on the end of the line. 18. Click in the Dx field. Type: 10- <Enter> (for 10 feet in the X direction.) 19. Click Continue. Click in the To Node field. Type: 50 <Enter>. Click in the Dx field. Type: 20- <Enter>. 20. Double-click Restraints. Click Anchor (verify it's on node 50). Press <Enter> or click in a different field. 19 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example One Video Three 21. Click on the small button in the upper right corner of the input spreadsheet. The spreadsheet will shrink and display as a tab. Now you'll change some display settings. 22. Click on the Node Numbers tool button. This displays the node numbers in the model. 23. Click on the Anchors tool button. Click the down arrow and change their size to Larger. Do the same for the restraints. Click on the Restraints tool button. Select Larger for these. Along the toolbar is a button to display lengths. Click on it to have the system will display lengths for the segments. 24. Move the pointer into an open area of the screen and right click on the mouse. Select Properties. Select Display options. Here you can change a variety of display settings, background colors, text size, etc. 20 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example One Video Three 25. Scroll down to fonts. Change the font size for the nodes to 24. Click OK when done. Click the Apply button (near the top of the dialog box). Close the dialog box. 26. Click File and Save. Great! We're at a good stopping point for this video. Why don't you get your model to this point, and in the next video, we'll take a look at some other display options that we have available on the toolbars. 21 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC CAESAR II® Fundamentals - Example One Video 4 1. We're back at our model. Now let's take a look at some of the viewing options that we have view the model. I'm in the Southeast Isometric View. If you click this down arrow, and you click on the Southeast Isometric, it'll reset the screen to this view. 2. I've also clicked on the Select button. What this does is it lets me click on an object in the model, and the object gets highlighted. If we hover over the selected item the system will display information about it. 3. Click on the Zoom Window button. Click a point, hold down the mouse button, and drag it and release. The system will zoom into that part of the model. 4. The button next to that is Zoom Extents. Click Zoom Extents to zoom out and show the entire line. Also there is a Zoom to Selection button. We have a segment selected, so if we click on the Zoom to Selection button, the system will automatically zoom into that area for us. So CAESAR II has a variety of ways to zoom to areas of the model. 22 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example One Video Four 5. Another option we have is an Orbit command. Click Orbit, and hold down the mouse button, and the model will rotate (your view is orbiting around the model). Depending upon where you click on the model, you will move around that point. An easier orbit option to control is Orbit with Vertical. Click that button, then hold down the mouse button and drag it. The vertical line in this will stay vertical, and your view of the model will not tilt over to the side. So I think this command is a little easier to control. 6. Here are buttons for Pan and Zoom. We can also pan and zoom just using the mouse itself. Click the Select button to disable Orbit. Roll the mouse wheel in or out to zoom in or out. Hold down the wheel of the mouse and move it left or right to pan. You can see when the wheel of the mouse is held down, the Pan button highlights. 7. This Walkthrough is an interesting feature. Click Walkthrough. The system displays a pallet to use for the command. You can move the palette where you like on the screen. As you hover the mouse over the walkthrough palette, the pointer displays as two little feet. Position the mouse so that lead foot is in the upper arrow area, and hold down the left mouse button. The view will change as you walk forward into the model. You're position is moving into the model - the model is stationary and you are moving into it. If you place the lead (left) foot in the lower arrow area and click, you will move back out. 23 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example One Video Four Also you can move to the left or right. 8. You can also move up and down. Position the lead foot in the small up arrow on the left. When you click the left mouse button, you will move up. Down works the same way. Put the lead foot in the down area, click and hold down the mouse button and you'll move down. The Walkthrough also has a rotational movement option. Place the lead foot where you want it, in the left or right curving arrow. As you can begin to click there the system takes you in and around through the model. This takes a few clicks to practice, but will be useful in a large model. Close the Walkthrough palette. 9. Click on the Southeast Isometric view button to reset the view. Click on the Select Element button to turn off the Walkthrough options. We're currently in the shaded view. Click the Zoom Window button to zoom in. Click the Hidden Line Wire Frame button. This displays the model in wire frame with the hidden lines removed. We don't see the far sides or back surfaces of the pipe. Also this display mode does not show restraints. 24 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example One Video Four 10. The button next to it displays the model as a normal wire frame. If we click that button, we see all the circles and the lines on the graphics behind, on both sides of the model. It's like it's transparent. In this mode, it does show the restraints and the anchors. 11. Next to that is a two line display button, similar to a double line plot. Click on the Two Line Plot button. 12. Next to that is a translucent display. Click on the Translucent Objects button. Click on the Rendering (shade) button if needed. Now we have a translucent model. We can see the curvature of the elbows back on the far side of the pipe. 25 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example One Video Four 13. Click on the Single Line button. So you can have options to display the model in single or double line, wire frame, or rendered. Click on the Rendering button, and Click Off the Translucent button if needed. This will get you back to the normal rendered view. 14. This toolbar sets the display to front view, back view, top, bottom, left, right. These buttons produce the various orthographic and isometric views in the display. 15. Along the top toolbar that we've already looked at, we turned on the restraints and the anchors. One button will show hangers if they are in the model. Other buttons will show displacements and nozzles, flanges, nozzle limits, expansion joints, and Tees. So CAESAR II has options to display these elements as well. 16. Click the Lengths button. When it is active the system displays the lengths of the segments of the model. The Range button displays a range of nodes. If we enter some range, for example from 10 to 30, it would just show that part of the model. 26 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example One Video Four 17. The Find Node button will zoom to a particular node, or group of nodes, in the model. If you click that, and enter in some node numbers, then select zoom in, the system will zoom to that area of the model. 18. Click the Plot Properties button. This does the same as right clicking, and selecting Properties. Here you can change a number of display settings. If you change one of the settings, you must also click the Apply button to activate the changes. Click the X in the upper right corner and exit this dialog box. 19. Click Prospective Mode display button. The button next to is is the Orthographic Mode button. The Perspective Mode will look like it tapers as it moves away from you. This Orthographic Mode display will look more like an isometric display. A line will appear the same width as it moves from near in the screen to further back. 27 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example One Video Four 20. Click on the Viewports button. This button allows you to divide up the screen into multiple viewports. Notice the crosshairs appear across the full screen. If you move the mouse across the screen you can divide it into four viewports. Depending upon where the crosshairs are positioned, you can set the size of the viewports as you like. Get the crosshairs approximately centered and then click. Now, instead of a single viewport, the system creates four different views. Next we can set each of these views as we'd like. Activate the upper left viewport (click in it once). Then click the Top View button. That view will display as the top view. Do the same in the other viewports. Set the Lower Right to the Right View. Set the upper right to the Southeast Isometric View. 28 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example One Video Four 21. The way to reset the display to a single viewport is to move the pointer back down toward the middle part of the screen, where the viewports intersect. Then hold down the mouse button and move the crosshairs back to the upper left corner. Drag them all the way off the screen and release. Then you can reset the display to a Southeast Isometric view. So why don't you experiment with these commands? Try the zoom options, change the views (top, front, southwest isometric), change the display size of the node numbers, and set up multiple viewports. Get familiar with these display options and it will be helpful as you work with CAESAR II in your career. 29 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC CAESAR II® Fundamentals - Example One Video 5 1. We're back in our model and now we're ready to begin the analysis of this line. One thing to mention is the piping code that we're running, which is the ASME B31.3 Code. CAESAR II has a number of codes built into it. If you click the down arrow where the code is displayed, you can see the list of available codes to work with. 2. The analysis uses this toolbar. Click the Start Run button. CAESAR II will check our geometry and our settings. If it notices something that it we need to verify or correct, it will display some messages or warnings above the center of gravity report. The messages will appear in Green or Red. Green messages are things you will need to verify. CAESAR II will be able to run the analysis, but it's suggesting you check these. Red messages are errors that need to be fixed before proceeding. CAESAR II will not be able to continue the analysis until the items mentioned in the red messages are corrected. 3. So this example checked out OK. Click the Running Man button (the Batch Run button). The system will start the analysis. 4. This is the screen that shows the results of the analysis that CAESAR II has done. On the left are some load cases that CAESAR II has created and recommended and used for its analysis. You can see that this problem has five load cases. The first two are called operating load cases. Included in those are the weight and the temperature and pressure. 5. The first load case analyzes the system in one of its operating conditions. The load case includes the piping system's weight, the higher temperature and the pressure. 30 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example One Video Five 6. The second operating load case looks at the weight and the lower temperature (ambient) and the pressure. The way this works, if you click one of these load cases and select it, you could then come over to the right area where the reports are listed and click one of them. Then you can see the results that CAESAR II obtained for the load case you selected when it went through and calculated all the results. We'll do this soon. 7. The third load case listed is called the Sustained load case. It involves the weight and the pressure. This represents the piping system in its installed state, but not operating and heated up yet. 8. CAESAR II has also created two Expansion load cases. The first one is called L4. Load Case L4 analyzes what happens to the system as it heats up from ambient temperature (Sustained Load Case L3) to its high temperature (Operating Load Case L1). Using this Expansion load case you can view and check the stresses caused as the system expands from ambient to hot. 9. The last load case, L5, is looking at the expansion between the second temperature and the installed (ambient) temperature. CAESAR II is going to assume ambient at 70 degrees Fahrenheit, but this can be changed in the configuration settings for all jobs or on individual jobs. 10. Later, we'll create another load case down to illustrate how this is done, and it will analyze the expansion between the highest temperature and the lowest temperature. 11. Before we take a look at some of these results, there is a thing or two to mention. If we take a look at the B31.3 piping codes in appendix S, we'll find a lot of detail in here on how these calculations were set up and done. If you'd like to get a more in-depth look at this, you could review the copy we included in your notes with ASME's permission. When we run our results and we compare the answers to the examples, we're going to be running with default CAESAR II settings. 31 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example One Video Five 12. For our first report, Click on Operating Load Case 1. Click on the report called Local Element Forces. This will return for us is a report that shows the different forces and bending moments for the different nodes in the model. 13. Click the View Reports button, which will display the results on the screen. The system has other report display options. Next to the View Reports button are other buttons that will send the report out to Microsoft Excel® or Microsoft Word®. 14. The system will generate the report for us. The report shows the different nodes, and then the different forces, in X, Y, and Z, and also the different bending moments around X, Y, and Z. 15. If we look at node 10, we can see the Fx. The force in the x direction is 5956, and the moment around Y is 15872 (15871.9). So let's just remember these values which we'll compare to the Code results - 5956 and 15872. 16. Looking at the Code and scrolling down, we'll see their results. They had 5960, and their bending moment result was 15870. So we're within a 1% range of their calculated results. 32 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example One Video Five While we're viewing the results shown by the Code, let's take a look at some of the other numbers listed. The report also includes horizontal and vertical deflections. Let's look at these three nodes, nodes 15, 20, and what they call 30 near. In CAESAR II, that node is number 28 (we'll discuss this numbering difference in a later video). These three nodes have horizontal deflection values of 0.72, 1.44, 1.73. 17. Now we'll see what CAESAR II came up with for these same values. We'll toggle back to CAESAR II, and close this report. Then we'll stay in the same load case, and click on the Displacements report. 18. Click on the View Reports button, and the results will display on the screen. Looking at the results for nodes 15, 20, and 28, we can see we're getting the same values: 0.72, 1.44, and 1.73. So our model and analysis is producing the same numbers that we saw in the B31.3 Code example. 19. So you go ahead and experiment with this for a while. Run some of these other reports. You can see how they look and you can get a sense of some of the things that CAESAR II can report out. 20. In the next video, we'll create a custom report. We'll set a report up that looks just like the one shown in the Code. We'll include the axial forces, bending moments, and horizontal and vertical deflections, and we'll be able to see how our results compare to the example problem in the Code. 33 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC CAESAR II® Fundamentals - Example One Video 6 1. In this video, we're going to build a custom report. This will be a good exercise to go through since this will be useful to you in the future. We'll format our output results so that they can easily be compared to those listed in the B31.3 Code example. The way we build a custom report is through using this tool bar up along the top of the screen. 2. When we build a custom report it will appear in the list in the lower part of the screen. The first button is to create a new report, so Click on the Add New Custom Report button. When it first appears, the report is untitled. Highlight the report title (Untitled) Type: Example One - OPE - Report One As we look at this report set up, in the left area of the screen we have some template settings. We have a header section and the report body section, and we have options on changing the type of the fonts and the sizes. We also have a preview area to the right that lets us see the report as we develop it. 3. The report we're going to build is going to be similar to the one we saw earlier in the B31.3 examples. Let's take a quick look at that for a moment. If we look at the report, we can see that it has four columns. It has an axial force column, bending moments, and then horizontal and vertical deflections. So these are going to be the fields that we pull into our custom report. 34 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example One Video Six 4. I'll toggle back over to the report builder, and we'll take a look at adding these fields to our report. Down toward the bottom is where we'll be able to access that information we need. So the first thing we can do is Click on the area called global forces. Click the small arrow next to it. Click the arrow next to Axial Forces. This is the value that will be in column one in the new report. 5. In the field called Column Order, Change the 0 to a 1. In the field called Precision, Change the 2 to a 0. This means the report will display whole numbers with no decimals. You'll notice the report flashes as you hit enter each time. This is indicating it's updating. 6. The second column will be Bending Moments. The one we need to include is the moments around z. Click the arrow next to MZ. Set the column number to 2. Set the precision to 0. 7. The next two columns will be Displacements. Click the arrow next to Displacements. Click the arrow next to DX. Set the column number to 3. Leave the precision set to 2. Click the arrow next to DY. Set the column number to 4. Leave the precision set to 2. OK. So now we'll save this. What we'll do is Click the X in the corner to close it, and the system will prompt us to save the report as we exit. Click Yes to save it. 35 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example One Video Six 8. The custom report appears in the list. Click on the new report to highlight it. Click the View Report button to view the report on the screen. The system will display the results. In viewing the report, we can see the title shown as expected. Also we can see the different columns are filled out. So it's very easy to build a custom report in CAESAR II. 9. What I'll do next is copy some of these and paste them into a page showing how they compare to the results in the B31.3 piping code. In the meantime, why don't you pause the video and build the report as shown. 10. I've copied and pasted the results that we obtained in our report next to the calculated the results that the B31.3 Appendix S example calculated. I've left a few of these fields off the list for simplicity, and also so that we could show these side-by-side a little easier. 36 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example One Video Six If we compare our results to the Code results, we can look at node 15 and see how closely we match. The Code had an axial force of negative 5,960 and a bending moment of 7,900. Our computed results had a negative 5,956 and 7,897. So we're within a fraction of 1% of what they calculated. We had similar results when we compare the displacements. The Code showed 0.72 and 0.05 for the vertical. We had the same numbers: 0.72, 0.05. As we look down the list at the other results we can see that CAESAR II had results that are virtually identical to the Code results. The note down here in the B31.3 Code is saying that these are average from commercial programs with a variance within units conversion tolerance. So our calculator results are coming out as expected. So great. What we're going to do in the next video is we'll look at the sustain load case and some of the calculated results that we get from that. After that we'll write a new expansion load case that will let us check the expansion across the full range of temperatures from highest to lowest. 37 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC CAESAR II® Fundamentals - Example One Video 7 1. In this video we're going to take a look at the sustained load case, and we'll compare our calculated results with what appears in the Code. Shown is a table from the B31.3 piping Code, and we can see that there are several different columns. Included is an axial force value, there is a column for the bending moment, and there is a column for the sustained stress. CAESAR II will refer to sustained stress as a code stress. 2. Notice how the tables lists the nodes. It includes a node 30 far and node 40 far. 3. When we first designed our system, we specified a distance from node 20 to node 30 in the x direction, and then we went from 30 to 40 in the y, and so forth. 4. When we got to node 30, we treated it like it was in the corner-or the vertex-- as the line went from node 20, to node 30, and on to node 40. This is how CAESAR II models a line in the input piping screen. 5. However, when the analysis is run, CAESAR II will shift these nodes, and add additional nodes around the bends. Node 30 will actually shift up around the bend, when you examine the results in the report. The same will happen for node 40. CAESAR II will shift further around the bend during its analysis. 38 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example One Video Seven 6. As these nodes get shifted, CAESAR II will add a couple of additional intermediate points. So at the beginning of the bend, we'll see there's now a new node called node 28. At the midpoint of the bend is a new node 29, and at the end of the bend we'll find node 30. 7. So when the report in the Code shows a node called 30 far, it's referring to the point on the far end of the elbow. The same is true for node 40 far. 8. The output reports in CAESAR II list all of the bends in the line. In the table in the piping Code, only some are shown. 9. The B31.3, Appendix S result for the Axial Force on node 10 is 735. On node 30 it becomes 4,470, and at node 50, the value is back to 735. So let's see what we get when we run our analysis in CAESAR II. I'll toggle over to that, and when we left CAESAR II earlier we were viewing results in the operating load case. 10. We'll select the sustained load case, and we'll click on the report called global element forces extended. Click the button to produce the report and display it on the screen. 39 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example One Video Seven When we review the calculated results for node 10, CAESAR II returned a value of 735, which matched the value listed in the Code's results. The same agreement occurs at node 30, where we see CAESAR II calculated 4,470 for that, which matched the number shown in the Code. You remember they call that node 30 far, which corresponds now to our node 30. Likewise, If we check the values at node 50, we can see that we matched that as well. 11. Let's take a look now at the computed values that we got for bending moments. On node 50, we had a bending moment of 27,936. We can also see that we had a high bending moment on node 20, and it was 41,400. Then when we look at the value for node 10, we have 12,730. So let's see what the Code came up with for those. 12. Under bending moment for the Code results, they showed 27,930, 41,400, and 12,730. So our results came out virtually the same. 40 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example One Video Seven 13. Let's see how we compare when we take a look at the sustained stresses. In the B31.3 examples, they go from 8,560 up to 14,370, and back down to 11,650. Let's see how we did in CAESAR II with these. 14. I'll toggle back over to CAESAR, and we'll close out this report. This was our extended forces report. What we do now is we'll Click on the stresses extended report. Click on the button to view the report on the screen. The report displays a series of header values across the top of the screen, and the results are listed below. 15. Scrolling down, we can see the computed results for the different nodes. 41 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example One Video Seven For the values listed as sustained stress, CAESAR II will refer to this as a code stress. So the values we got are Node 10: 8,572 Node 20: 14,388 and Node 50: 11,656. 16. Checking the values in the report, they went from 8,560 14,370 and 11,650. So the results computed by CAESAR II came out as expected, and matched those given in the example. This is a good point to pause the video. Go ahead and get your model and analysis to here. Run these reports, compare results, and then we'll continue on after this. 42 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC CAESAR II® Fundamentals - Example One Video 8 1. Now we're going to take a look at these two expansion load cases. The first expansion load case is load case four, and it's checking the expansion between load case one and three. So it's the expansion between the highest temperature and the ambient temperature. 2. The last load case recommended by CAESAR II was the expansion load case which checks the expansion between the coldest temperature and ambient temperature. What we'll do in this video is write a new load case that will show the full range of expansion, from the lowest temperature, up to the highest temperature. This will show us how much our system is going to expand across this full range of temperatures. 3. The way you build a new load case is using the load case editor. Close out the window which shows the load cases and the reports, and we'll return back into our main screen. This button is the one that we'll click to open the load case editor. When we click on that, it shows us our various load cases. These are the ones that CAESAR II has generated for us and recommended. At any time, you can click on this Recommend button, and it will update the list, showing the load cases it recommends. 4. Now we'll create a new load case. Click in this L5 space to make it active. Click the small button that has a plus, which will an add a new entry in the list. Click inside the L6 area, and we can begin to add some new information. 43 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example One Video Eight 5. This load case will calculate the expansion across the full range of temperatures. In this case, that will be the difference between L1 and L2 (L1 is at the high temperature and L2 is at the lowest temperature). If we take that difference, the system will calculate the line across the full range of expansion. 6. Click down in the square next to L6, and it becomes active. Type: L1 - L2. In the field for the Stress Type column, Click, and click the down arrow, then click on Expansion. The new load case is now defined. Now we'll test it. 7. Click the Running Man button to start the analysis, and CAESAR II will calculate its results, and include this load case as well. 8. We see now that our new load cases appeared in the list of load cases analyzed. Later, if we click it to highlight it, we will be able to select some of the various reports, and view the calculated results that occurred from using this load case. At this time, we're going to set up a custom report that matches the one shown in the B31.3 example. 44 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example One Video Eight 9. I'll scroll back over and take a look at the example shown in the code. They have a report in here that has the forces in x and y, it has the moments around z, and it has the expansion stress (CAESAR II will refer to this expansion stress as the code stress). 10. Now we'll set up a custom report with these four columns. Go back to CAESAR II, and Click on Create a New Custom Report. A new report template will open up for us, which we can begin to edit it. 11. Click in the Name field. Type: Example One - EXP - Report Two 12. Click the small symbol next to Global Forces, which will expand it, and scroll down to FX. Click the small symbol next to FX, which expands it. Set it to column number one. Set its precision to zero. Press <Enter> or click in a different filed to finish this step. The report will flash as it updates. 45 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example One Video Eight 13. The next entry is going to be for FY. Expand that, and set it for column number two Set Precision to zero and press <Enter>. The next column is for the moment around Z (MZ). Expand MZ. Set this to be Column number three. Set the Precision to zero for this field also. 14. For the last column, we'll come down under Stresses, and expand that. Scroll down, and find "CODE STRESS." Expand that. Set it to column number four, with a precision of zero. 15. So the report is done. Close the report, and the system will prompt us to save it as we exit. Click Yes to save it. The new report will appear on our Custom Report list. 16. Now, we'll click on the Expansion Load Case, we'll click on the Example One Expansion Report Two, and we'll go ahead and run that. We'll tell the system to display that on the screen, and we'll see what kind of results we come up with. 46 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example One Video Eight 17. Let's take at look at the results in the report. On node 10, we had for FX: 5,635. For FY: 255. The MZ is 3,390. The Code Stress is 579. The code had results of 5,640 (we had 5,635). They show 260 (we were at 255). We both came out with 3,390 for MZ. For the Code Stress we both had 579. 18. So we're well within a 1% range here, a fraction of 1% difference, and they're saying that these come from a variance of unit conversion tolerances. 47 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example One Video Eight This was an interesting lesson, and you can see that as you get familiar with this, it gets easier to navigate. In this example, we created a new load case for ourselves, we created a new custom report for it, and we compared our values to those shown here in the code. Another thing to notice is they include values for nodes 30 mid and 40 mid. In our CAESAR II report these would correspond to nodes 29 and 39. So you can compare some of the results that we see in this report against the corresponding nodes in the CAESAR II output report. So great! We covered a lot of ground in this, and in the next video we'll continue on to something new. 48 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC CAESAR II® Fundamentals - Example One Video 9 1. Now let's take a look at some of the ways CAESAR II can display its results graphically. Click on the 3D Plot button. You'll see toolbars similar to what we saw when we were inputting in the data for the model, plus some new ones. For instance, we can view the graphic output based on the load case. Click on the down arrow by the Load Cases. Select the Operating Load Case. 2. Click on the Deflected Shape button. The system will display how the model will deflect as it expands or reacts to the installed forces and moments. Roll the wheel forward to zoom in. 3. Click the Grow button next to it. The system will show how the line will grow over time as the temperature changes. So we can view how the model changes based on different load conditions. 4. Next to that is a toolbar that can show us the displacement, the maximum in X, Y, and Z. 49 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example One Video Nine Click the Maximum DX button. The system will display where the maximum displacement in X occurs. In order to see it better, Click the Translucent Objects button. We can see the writing come through. That's going to be where the Maximum Displacement in X occurs. The Maximum Displacement in Y occurs at node 40. 5. The toolbar to the right of that is going to display the maximum forces. Click on the Maximum FX button. Pan down and we can see that's going to occur at node 10. Click on the Maximum FY. We can see that's occurring at node 20. Forces in Z won't come into play in this example. 6. Click on the Max MZ button. We can see that occurs at node 50. So we see this gives us is a way to display graphically some of these forces, moments and displacements. 50 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example One Video Nine 7. This next toolbar can be used to display stresses in a line. And it can display these graphically using colors and text. When we talk about stresses in a line, we should be taking a look at it in terms of the expansion load case or the sustained load case. 8. Click on Expansion Load Case 6. Click on the Overstress button. The system says there are no overstressed points in this line. Click it again to turn that off. 9. Click on the Max Stress button. The system shows that occurring at node 39. Click it again to turn this off. 10. Click on the Stress Colors by Value button. Click the Translucent Objects button to turn that display mode off. The system now shows these stresses distributed in the line. And we can see that the higher the stresses get, the redder the color is going to get. So along nodes 30, and around to 40 are going to be where these maximum stresses occur. Click the button again to turn these off. 51 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example One Video Nine 11. Click the Stress Colors by Percent button. The system shows the higher stress levels are occurring around the elbows. This is displaying the calculated stress (the Code Stress) by percent of the allowable. In this line we're somewhere over 40% but less than 60% of the allowable stress. So this is a great way to see how the stresses are distributed and how close they are getting to the maximum allowed stress. Click the button again to close it. 12. Now we'll take a look at the selection options toolbar. Click on the Zoom to selection button (the magnifying glass). Click an object, click one of the components (click the vertical line in this model). The system will zoom in to that area and it will show a split screen. We'll see what's called an Element Viewer screen down toward the bottom. 52 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example One Video Nine 13. We can select from the different load cases listed on the left. The system displays the different results that have been calculated based on these load cases. So if we look at element 30 to 38 we can see some information on it. CAESAR II would have a node 40 on the corner when it was originally modeled, but when we put a bend there and analyze it, the system shifts node 40 over to this point on the far end of the elbow when it shows its results. The midpoint of the elbow becomes node 39 and the beginning point of the elbow is now node 38. So that's why this element we selected is shown as going from node 30 to 38. 14. Click another object along the way. The system will display results on that. What's nice about using this viewer is that you can get the graphics combined with the output results and it just gives you a really nice way to get an overall view of the model. 53 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example One Video Nine You can click on different parts of the model, use different load cases, view the different reports within those load cases, and see exactly how this is all working out. 15. Close the Element Viewer. 16. Click Options Click View Animation. The system will open another screen. On this screen, we also have the different load cases to select from. Select Operating Load Case 1. 17. Click the Motion button. The system will switch into a single line display mode. It will show the animation of the line expanding as it changes, based on this load case. You can see how ends of the line are fixed, since those are anchored. 54 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example One Video Nine Click the Volume Motion button next to it. This is a little bit easier to see on the screen. We have some other options we can do. We can display node numbers, and we can print this out. Click File. Click Print Motion. The system will actually assign it to your printer, and it will also show how the line looks as it expands through its full range of motion. So this is the animation. This is the Reset Plot button. It will reset the plot back to the way it displayed it initially. This screen also has options for viewing the plot different directions and rotating it. To exit this animation screen, you'll just click the x up in the corner, and it'll take you back to the screen where all the reports are. Now you go through this video and your notes, and do each one of these steps and practice this and get familiar with it. And then, as we go on in the later examples, this will be easy for you to use as needed. 55 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC CAESAR II® Fundamentals - Example One Video 10 1. When you first come into CAESAR II, this is the screen that you see. 2. Click the Home tab. If we wanted to, we could click Open and open up some jobs that we've done in the past, or we can start something new. We also have links or buttons going across that can take us to other screens. 3. If we click on the piping input, it could take us to the input spreadsheet, where we could begin to model the geometry of our job or modify it. We could model underground piping. If we had checked off the box about structural steel, we could model structural steel shapes in here. There's a catalogue of them that we can use. 4. When we're ready to run the analysis, we could click on one of these two buttons. For this course, it's going to be the static analysis that we'll do for several examples. Later, we could view reports. We could look at the printed reports based on load cases. There's just a wide variety of them here. We can also generate a stress isometric through this area. 5. We could also set the configuration here as well as add new materials. 56 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example One Video Ten 6. Click Configure. The system will open up the configuration screens for us. One of the things that you'll typically do when you go into this configuration screen is you'll take a look at the databases first. 7. Click Database Definitions. 8. Click Units File Name. I'm set for English, so I'll be using Imperial Units. But if you had to do a job in millimeters, you can click the down arrow and list the various choices available. You can see there are units files that are specific to different countries: a Japanese units file, French, and German. CAESAR II ships with a collection of these. For the work we do in this course, we'll be set to English. 57 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example One Video Ten 9. Another thing to look at is the default spring hanger table. We can see that it's currently set to use the Anvil catalog. If I click the down arrow, we can see there are over 30 of these in here that we could choose from. So if you're working a job where you want to use Lisega for your hangers, you could select that manufacturer from the list and then when you put in a spring hanger, CAESAR II would use their catalog to select from. Expansion Joints can be set in a similar fashion. There are several of those in here that you could choose from as your default choice. 10. For the Valve/Flange listing we have files that we can pull data from. There's a CADWorx file shown that has a collection of valves, and their weights, lengths, and information. So when we place valves into the model, they'll pull data from this file. If we look a little further, we have a screen here where we could set up some information about fiberglass reinforced pipe. 11. Click Geometry Directives. Here we set the automatic node numbering increment. Later, when we build our model, our nodes will move in increments of 10. It's good to have a good increment size here so that later, if you decide to modify the model, you can add new geometry between two existing nodes. 58 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example One Video Ten 12. Click Graphics settings. This lets us change the display settings. We'll look at this again later, but this will affect a particular job. If we save this configuration, it's going to be in this fundamentals course files folder. So, all the files that we create in this folder will have these settings. When you start CAESAR II for the very first time, you get a screen that comes up about configuration. Whatever settings you change in that gets saved in the system folder as the default configuration. But when we change it later, like I'm doing now, that would go into a particular folder. So, each folder, each job, can have its own configuration file that would be for that group of files. 13. Click Miscellaneous options. Here you can set the automatic save time interval. 14. Click SIFs and Stresses. CAESAR II uses a multiplier of 1 for whatever's in the code. The code we're going to mainly working with his B31.3. That's what these examples will use. So, whatever the code says for the SIF, that's what CAESAR II will use when it does the calculations. Close the screen without saving. This is how you would change the configuration on a particular job if needed. 59 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example One Video Ten 15. Click on the Analysis tab. When we have our geometry built, we could begin to run the static or dynamic analysis of the model. We have other things that we can do down in here. We can check the stresses on nozzles connected to equipment. This group of buttons is called Outboard Processors, and they are programs that give extensive options for various types of analysis. We can use these to analyze flanges. We can analyze expansion joints and structural steel. These are ways to take a look at the analysis of steam turbines, nozzles on pumps, compressors, different kinds of exchangers and heaters. A lot of things can be interfaced through this screen, and there's more than one way to get to all of this. 16. Click on the Output tab. Here we can look at our reports. Depending upon your model there are static and dynamic reports. We can animate our displacements in our static reports, as well as dynamic. This tab also takes us to running and configuring Stress Isometrics. 60 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example One Video Ten 17. Click Interfaces. Here we can interface to some other programs. There are options for AFT Impulse, PIPENET, and others. We also have interfaces to CAD systems including Smart Plant 3D and a really nice interface to CADWorx Plant Professional. Later, in one of our examples, we're going to export a model from CADWorx, open and analyze it in CAESAR, and then if we like, we could send back any changes to CADWorx. It's bidirectional. 18. Click Utilities. Here we have another option to work with materials and modify the configuration. We can change the units in a model. If you get a model in one set of units, you want to convert it over, you can use this click right here to do so. We have a link to the System folder. If we click on that, that's where the default configuration file is located. If we scroll drown, we'll find it, and here it will be under CAESAR.cfg. So, that's going to be the settings that we did initially when you first loaded in CAESAR II. 61 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example One Video Ten If you modified it for a particular job, and you wanted that to become your default configuration, you could copy your configuration file from your job folder down to this system folder, and then it would be your default configuration. The right in area of this panel is for licensing the hardware lock, and there are some diagnostics that the technical support people can use to help you verify things, if you need assistance for your installation. So, great! We covered quite a few options here. Explore this area in CAESAR II and then we'll continue on to something new. 62 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC CAESAR II® Fundamentals - Example Two Video 1 1. In this lesson, we're going to model this line, and this is the second example in the B31.3 Appendix S Piping Code. If we look at the geometry of this line, we can see that there is an anchor and a restraint (in the Y direction) on each end of the line. The line is symmetrical, and there is a +Y restraint in the center of the line at node 50. As this line begins to heat up, we could anticipate that it's going to lift off (to some extent) from the +Y restraint in the center segment. We'll put this into CAESAR II, analyze it, and we see what kind of results the system generates. 2. A nice thing about this problem is that we can use it to begin to show some other features in CAESAR II as well. For instance, we'll take the central +Y restraint out, and we'll analyze it and see if it fails. Then we can use that as an opportunity to design a hanger for that location. 63 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Two Video One 3. So let's get started. I'll go ahead and toggle over to CAESAR II, and we'll start a new file. Click New. Type: EXAMPLE_2 for the name. The file will be saved in the CAESAR II Fundamentals Course Files folder. The system is set for Piping Input. Click OK. CAESAR II will display our units. Again, we're going to be in Imperial Units for this. Click OK. Now we can start putting in our piping input. 4. When we read about this problem in Appendix S, it says that it has similar design parameters to Example One, and it's going to use the same materials as the first example. So let's go ahead and start putting that in. 5. In the Diameter field, Type: 16 <Enter>. Notice the message in the lower area of the screen when you press Enter. CAESAR II is telling you that it's making some conversions, or entering a more precise value. You may hear a beep to alert you as it makes these modifications. 6. For Weight/Schedule (Wt/Sch), Type: 30 <Enter>. CAESAR II will convert this Schedule 30 to the Wall Thickness. 64 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Two Video One 7. For Corrosion, Type: 0.063 <Enter>. 8. For Material, Type: 106 <Enter>. CAESAR II will use its default material for 106, which is A106 Grade B. It will automatically fill out the Pipe Density field and other material properties for that selection. 9. For Fluid Density, Type: 1SG <Enter>. Note: You have to type in SG, or you'll get incorrect results. 10. In the Temp 1 field, Type: 550 <Enter>. In the Temp 2 field, Type: 30 <Enter>. In the Pressure 1 field, Type: 550 <Enter>. 65 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Two Video One 11. In the Insul Thk field, Type: 5 <Enter>. In the Insulation Density field, Type: 11/1728 <Enter>. The information given was 11 pounds per cubic foot. This is entered as 11/1728 since CAESAR II requires this to be in pounds per cubic inch (1 cubic foot is equivalent to 1728 cubic inches). 12. We're getting ready to start modeling the geometry of the line. Let's take a quick look at it. We can see that our line is going to go in the horizontal direction from nodes 10 over to 30, then it will travel up in the plus Y direction, turn back to horizontal, turn down, and end with a horizontal run. Included in the code is a table that lists the actual distances between the nodes in this model. We'll use that table as we build our CAESAR II model. 66 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Two Video One 13. If you'd like to try this on your own, go right ahead and do that, and then you can follow along with the video after that. Or if you'd like to just watch the video first or follow along with it, that's fine, too. 14. Now we'll get this started. The first segment is going to be from node 10 to 15. Click in the To node field. Change the 20 to a 15. Click in the DX field. Type: 20- <Enter>, to enter a value of 20 feet. Click Continue. 15. The next segment will be from 15 to 20. Click in the To node field. Change the 25 to 20. Click in the DX field. Type: 20- <Enter>. Double click Restraints. Select a Y Restraint for this node. Click Continue. 16. The next segment is going to be from nodes 20 to 30. In the DX field, Type: 10- <Enter>. Double Click Bend. The system will place a Long Radius Bend at node 30. Click Continue. 67 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Two Video One 17. The next segment is node 30 to 40. In the DY field, Type: 20- <Enter>. Double click Bend. The system will place a Long Radius Bend at node 40. Click Continue. 18. The next segment will be from node 40 to 50. In the DX field, Type: 30- <Enter>. Double click for Restraints. Select a +Y restraint for node 50. This will support the line from underneath; it's like the line is resting on a beam or other type of support. Click Continue. 19. The next segment now will be from node 50 to 145. Click in the To node field and change it to 145. In the DX field, Type: 30- <Enter>. Double click Bend. The system will place a Long Radius Bend at node 145. Click Continue. 20. Next the line will drop down to node 130. Click in the To node field and change it to 130. In the DY field, Type: -20- <Enter>. Double click Bend. The system will place a Long Radius Bend at node 130. Click Continue. 68 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Two Video One 21. The next segment will be from 130 to 120. Change the To node to 120. In the DX field, Type: 10- <Enter>. Double Click Restraints. Select a Y Restraint for node 120. Click Continue. 22. The next segment will go 120 to 115. Change the To node to 115. In the DX field, Type: 20- <Enter>. 23. The last segment will be from 115 to 110. In the DX field, Type: 20- <Enter>. Double Click Restraints. Select an Anchor for node 110. 24. At the beginning of the line is another anchor. Click the First Element button. Double click Restraints. Select an Anchor, which will be on node 10. So great. I think our model is done now. We're in good shape. Let's change display to show the restraints and anchors larger. So make sure you have your model to this point, and then on the next video, we'll start to run the analysis. 69 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Two Video One 70 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC CAESAR II® Fundamentals - Example Two Video 2 1. We'll analyze this soon, but first let's take a look at some of the other options that we have here in this piping input screen. 2. If you recall earlier, when we were setting up our screen, we docked the spreadsheet. We held down on the top area of the spreadsheet, and moved the mouse over to the left. When the mouse pointer touched the edge of the toolbars, the spreadsheet snapped into place. So you do that now. Hold down the mouse button in the top bar area of the spreadsheet, drag over and touch the left toolbars, then release. Once it's docked, you can minimize it by clicking the small pin in the upper right area of the spreadsheet. This changes it into a tab, which you can click to restore. 3. Now we have a little more room to view the results. The first toolbar we'll take a look at is called the Legends toolbar. These buttons are used to show the different materials, wall thicknesses, pressures and temperatures in the model. 4. Click on the Materials button. The system displays the materials in the model. In this example the model shows it is all A106 grade B material. If the material in the model varied, the display would show that. 71 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Two Video Two 5. The other buttons display other properties of the line. They will show the Piping Codes, Insulation, Diameters, Wall Thicknesses, Forces, Uniform Loads, Wind and Wave Loads, Temperatures, Pressures, Corrosion, Pipe Density, Fluid Density, and Insulation Density. So this toolbar lets us quickly see the various settings and parameters that make up our piping model. It's a good way to visually check your work. 6. This button displays Line Numbers. If we had a model that had several different line numbers in it, we could see those by different colors. 7. These buttons are used to Move Geometry in a model, and reposition the different parts of the model from one location to another. 8. If needed, turn off any button you have active to close the window next to the plot. I'll toggle the fluid density button to reset my screen, and we'll look at some additional display options. 9. This toolbar and button on the left has to do with the plot. Click on the Reset Plot button. This button resets the display to the default plot, showing the first segment as the current element. It also displays the line in the southeast isometric orientation. 10. This button (Reset View) sets the system to regenerate as you add elements to the model. As long as this button is lit, the system will automatically update the plot with each new addition to the model and Zoom Extents. For a large model, this can be something you might want to disable. It will still update as new elements are added, but it will not do a Zoom Extents. 72 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Two Video Two 11. The Lock Graphics button will actually lock the display so it won't try to update itself as new things get added. That might be useful if you have a large model, which you may not want to update each time you a component. You could lock the display, add a number of components, and then later update it yourself with the Reset View button. 12. Next we have an Archive Button. If I click on that, it lets us put in a password. Then we can lock our input file so that we're the only ones that can access it. 13. This is the Insert button. It will let us add a new element, either before or after our current element. We will use this command extensively in some videos which follow. 14. This is the Delete Element button. It prompts to verify we want to really delete the current element. I'm going to say no on that. 15. Next is a Break button. Using this, we can insert a new node or multiple nodes when given a number. For example, we can insert nodes from node 10, each a certain distance apart. This could get very useful if you need to modify a model. 73 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Two Video Two 16. This is the Global Coordinates button. Using this we can set node 10 to have a certain XYZ coordinate in the model. If we export this model back out to CADWorx or to SmartPlant 3D, it would come in at the proper coordinates in the CAD model. CADWorx has a bidirectional link to and from CAESAR II, so that we can send a file from CADWorx into CAESAR II for analysis. If the line gets adjusted in CAESAR II, the changes can be sent back cleanly into the CADWorx model and update it. 17. The next button is the Close Loop button. If you click Continue, then enter in two node numbers and click on this button, the system will insert a new element between them. 18. This is the Increment Nodes button. Currently by default CAESAR II has a node increment of 10, which is set in the configuration dialog box. You can set the increment to other values if you like (for instance, 5). However, you definitely want to have a large enough number in here that will allow you to insert additional nodes in a segment if you need to modify a model at a later time. 19. This is the Distance calculation button. You can enter in two nodes, and the system will calculate the distance between them. For example, let's check the distance between 10 and 120. When we put those nodes in the dialog box the system calculated a distance of 120 feet. It will show the diagonal distance, and the distances along the X, Y, and Z axes. 74 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Two Video Two 20. This button will access the Valve and Flange Database. CAESAR II has a database of valves and flanges, and can provide the proper weight for them to use in its calculations. 21. Here is the Expansion Joint Modeler button. CAESAR II includes a modeling system for Senior Flexonics Pathway Div EJ. When this button is clicked, the system will open a series of dialog boxes for input. Then it will place an expansion joint based on your input. 22. Next is the Title button. This allows you to edit or add a title and some notes for your job. 75 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Two Video Two 23. This button opens the Hanger Design Criteria dialog box. CAESAR II includes a large number of hanger vendors, with a wide variety of hangers available for modeling. The box displays the current settings for the hangers, and you have the option to change these. For instance, hangers will have a load variation of 25%, and the manufacturer is set to Anvil by default. 24. The next buttons open up SIF Scratchpad dialog boxes. Looking at one, we can enter a node to see the SIF for that element (a bend, tee, etc.) Using this dialog box, the SIF can be modified and recalculated as needed, based on specific additional information when available. 25. This button is the Special Execution Options button. If you need to change some things for your analysis, you can do that in this dialogue box. For instance, the Ambient Temperature can be set as needed here for this particular job (the default setting is found in the Configuration settings). Go ahead and work through some of these viewing options, and get familiar with them. Take a few minutes and experiment with these. It will make it easier for you as you go along with the course, and also when you use CAESAR II professionally. 76 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC CAESAR II® Fundamentals - Example Two Video 3 1. The next thing we want to look at is this list button. Click on the List Input button. The system will display a spreadsheet or a table that has the different elements with their distances and other information about the model. 2. Click on row 2 (nodes 15 to 20) and notice how that element highlights in the model. We can see it's currently set for 20 feet. 3. This interface gives us new ways to work with the model. Click in the field where it says 20 feet. Change that to value 100 feet and press <Enter>. Notice what happens to the model. You'll see it updates the length of that segment. 4. Set that 100 feet back to 20 feet. We don't really want to change it. I just wanted to show you the power of this interface. 5. On this line we're working on, there's a restraint on node 20. Since this is our current element, the restraint button on the toolbar on the right is highlighted. Click on the next row (node 30 to 40), the bend button will light up. If I have two lines that form a corner and I don't have a bend there, I can use this interface to add a bend. 6. The same idea can work with other elements. For instance, if I have a sequence of elements and maybe I want to put an anchor or a restraint in them, I can click on the Restraints button to add it to the model. Using the list and the selection tool button, and the toolbar on the right will let you insert other kinds of elements similar to the way it was done when we worked with the input spreadsheet. So this is really nice way to work in CAESAR II. 77 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Two Video Three 7. Now along the bottom of the list display are tabs which will show other aspects of the model. For instance, you can see the materials. Click on the Materials tab. And this first row-- this A106 grade B is what propagated on down. Click the Bends tab. The system will display information about the location of the bends in the model. Click on the Restraints tab. Now the system will display information about the Anchors and the Y restraints. So you can see, using this list box and its tabs gives us another good way to get an organized, easy to use view of the model. 8. Click on the arrow next to the List button. Click on Close All Lists. 78 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Two Video Three 9. Now when we clicked on the List Input button, it opened up all the lists. Some users like to just have one or two lists open and then work that with the rest of the screens to get their model built. We'll take a look at that now. 10. Click the arrow next to the List input button. Click the Elements list. These lists are kind of nice because what you can do with these is if you push them over to the side like we did the input spreadsheet earlier, they'll dock. 79 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Two Video Three Then you can turn them on and off, and they will become tabs that you can activate when you need them. Another example might be to add the Restraints list. 11. Click on the Restraints list. Dock it as you did earlier with the Elements list. 12. So now you can open up the input spreadsheet, or the elements list, or the restraints list as needed. It's a quick and efficient way to work with the system. Click the arrow next to the Input List button, and Click Close All Lists. 80 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Two Video Three 13. The Edit Tools toolbar along the bottom of the screen has a group of buttons that will open up dialogue boxes with model information. Click the Node Number Edit Window button. This window displays the nodes in the current element. Notice there's a Name check box. The system allows you to assign a name to a node (like Pump Nozzle). The dialog box will update as you select other elements. Close this dialog box. 14. Click the Mini-Delta Box button (this shows distances between nodes). Close this dialog box. 15. Click the Mini-Pipe Size Box button. This will show information on the size of the pipe as well as various properties. Close this dialog box. Other buttons along the toolbar will display information on temperatures, materials, elastic properties, and densities. 81 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Two Video Three 16. Click on the Mini Aux Screen Box button. We saw this information displayed on the side of the input piping spreadsheet. The dialog box has tabs along the left side which will display additional information. Close this dialog box. 17. The Block Operations toolbar (normally along the lower right area of the screen) can be used to modify the geometry in the model. Select the two end elements in the line. Hold down the Shift key as you select them. Click on the Rotate button. Click the About Y-axis button. Set Degrees to 90 (Note: There's also an option to add bends) Click OK. 82 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Two Video Three The elements rotate. Undo this rotation (use Control_Z). Other buttons on this toolbar let you…. Duplicate, Delete, Renumber, Invert, and Change the Sequence of elements within your model. We'll use these extensively in a later video as we modify the geometry in a model. We covered a lot of information in this video. So take some time and go over these things we discussed. Experiment with them since you'll be using them later in the course and in your work. 83 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC CAESAR II® Fundamentals - Example Two Video 4 1. We're back in our model now and ready to run the analysis. To test things, let's create an error or something that will cause a warning when the error checker checks the model. 2. If you recall, when we entered the value for Fluid Density, we typed in a 1SG. The system converted that to 0.03611. The SG represents Specific Gravity, which is how CAESAR II expects the units in that field. Let's make an error, and see how CAESAR II reacts to this. 3. In the Fluid Density field, Type: 1 <Enter>. This will cause the line to be evaluated with a much heavier fluid than before. 4. Click on the Error Checker button. 5. The system returns some messages. If we scroll up, we can see the system is notifying us that the fluid density is more than twice the typical value. 6. So this is good. It's giving us an indication that something is questionable that we should check. The message is in green, so CAESAR II can still run the analysis. If the message is in red, then the setting or error would have to be corrected before the system can proceed. 84 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Two Video Four These other warnings are just letting us know that if we were modeling this line with bent pipe (if we were doing bends, five radius, three radius bends around these corners where these elbows are now), we would need to check the wall thickness. The system has calculated that modeling with bends instead of elbows would require a heavier wall thickness. Since we're using fittings this message is not applicable. Close the message dialog box. 7. Click in the Fluid Density field, and Change the 1.00000 to 1SG. Press <Enter> and the system will change it to 0.03611. 8. Click on the Error Checker button. We'll see the messages about the bends, but the message about a large fluid density is now gone. 9. One other thing to say about these warnings, if you double click on the warning itself, the system will take you right to that point in the input spreadsheet. This makes it easier to take a close look at your input. 10. Click the Batch Run button (the running man button). CAESAR II will start the analysis of this line. 11. The system displays the analysis results screen. 85 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Two Video Four 12. Click on Operating Load Case 1. Click on Restraints. Click on the View Reports button. 13. The system displays the FY on node 10 is 3161. The code showed a value of 3150 for that node. So our results are well within 1% of the predicted value. 14. Lower down in the list at node 20 our results were 13239. The code showed 13250 - virtually the same. At node 10, under the value for Mz, we calculated 19904. The code showed 19900. Again, the results are virtually the same. 86 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Two Video Four 15. Now let's take a look at the plot of the line, particularly at the +Y restraint at node 50. Click on the 3D Plot button. Click on the Front View button. Zoom in to the node 50 area, at the midpoint of the top element. Click on the Grow button. The system will display how the line expands as it heats up. We can see that the nodes around the elbows are displaced. Also we can see that the line lifts off the +Y restraint at node 50. 87 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Two Video Four 16. Click Options. Click View Animation. The system will open a new window to display the line as it moves. Click the Front View button. 17. Zoom into the area around node 50 (in the center area of the top segment). Click the Motion button. The system switches to a single line display and shows the movement of the line as it expands. 88 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Two Video Four We can see there's some travel up and down on this line as it expands. This line is actually lifting up a little bit off the +Y restraint at node 50. 18. Close the animation screen window. Click the Piping Input button. We're going to take this as a nice opportunity to size a spring hanger for this line at node 50, which we'll do in the next video. 89 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC CAESAR II® Fundamentals - Example Two Video 5 1. What we're going to do in this video is we're going to see how CAESAR II can help us design a hanger for our line. For this example, we'll start by removing the support under node 50. Click on the segment (node 40 to 50) to make it current. Double click the Restraint check box, and the system will delete the +Y restraint at that node. 2. Click the Batch Run button to re-run the analysis. 3. We can see that the Sustained Load Case has failed the code's allowed values, since it is displayed in red in the list. 4. Click on the Sustained Load case to highlight it. Click on Stresses in the Standard Reports section. Click on the View Reports button to show the results on the screen. 90 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Two Video Five 5. In the report, we see that it failed in that load case. 6. Looking at node 20, we see that we have a code stress, a calculated stress of 18,851 and our allowable was 18,450. So our line has a value of 102% of the allowable stress. Since the line is symmetrical, a similar situation will occur at node 120. 7. Based on these results, we can see that our design requires additional support. This will be an excellent example for us to use CAESAR II's hanger module to select and install a hanger for us at node 50. 8. Click on the button to return to the piping input spreadsheet. 9. Select the element 40-50. Double click Hangers. 91 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Two Video Five 10. The system displays an ANVIL catalog, which is the default (this is set in the configuration file). CAESAR II has a variety of hangers available for selection, but for this example we'll use an ANVIL hanger. We'll also accept the default settings, such as allowing a load variation of up to 25%, and using a short-range spring if available. 11. Click the Error Checker. CAESAR II has come back with some other suggested load cases here. Load case 1 that is listed here is going to be used to calculate the deadweight load carried by that spring. Load case 2 is used to calculate the thermal deflection, the change in position between the cold and the hot at that spring point. With these two numbers, the deadweight and the travel, the program can go to the Anvil catalog and select a spring that will meet this demand. And then any other additional load cases that the user might want will be analyzed after that. 12. Click the Batch Run button to start the analysis. 92 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Two Video Five Since we have a different set of load requirements, we changed the system and added a hanger. The program is asking if we want to return to the load case definitions. 13. Click OK. CAESAR II returns us back to the previous set of load cases that we used earlier. The system always tries to go back to the previous set, but these are insufficient for this. 14. Click the Recommend button. The system will now recommend a new set of load cases for us. We have two new load cases listed. 93 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Two Video Five The first load case calculates the dead load. To do this, the system puts a rigid restraint at node 50, and it calculates the dead load on it. The second load case is used to calculate the amount of travel for the hanger. What it does is it removes the rigid restraint at node 50, but it mimics the actual hanger capability by specifying a force in the upward vertical direction (+Y) at that hanger point. That force is equal to the load that we got from the first load case. Load case 2 calculates the thermal deflection, the change in position between the cold and the hot position of the node at that spring point. So using these two numbers, the dead load and the travel, the system can take these over to the hanger catalogue, where the catalog selection is then included in the model (both the spring rate and preload) for the remaining load cases 15. You'll notice there's another load component here called H. This represents the hanger preload. So the system is putting the spring right in the model and preloading it with a theoretical cold load, which will then be included in every operating case and every sustained case. This theoretical cold load is the operating load (from Load Case1) plus the selected spring rate times the node's travel between the installed and operating positions (estimated in Load Case 2). 16. Click Use Recommended Load Cases, Yes. 17. Now we'll add one more load case that will give us the full expansion. 18. Click in the space next to L7, and click the Add button. 94 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Two Video Five This new load case will be L8. Type in: L3 - L4, and select EXP for the stress type. This will give us the expansion across the full range of temperatures. Now we'll re-run the analysis. 19. Click on the Batch Run button (Running Man) again. We can see the sustained load case up here now doesn't appear in red. So adding this hanger has relieved the excessive stresses in the system, and we're within the code recommended values now. 20. Let's take a look at the hanger that has been selected. Select the Hanger Table with Text and Display on the Screen. 95 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Two Video Five The system selected an Anvil hanger, a triple spring hanger. It's a 16-inch size and we can see the vertical movement was quite a bit, 2.839 inches. This is figured on the T1, on the hot load case, and it's carrying almost 7,000 pounds. The range is between 5,250 pounds and 9,000 pounds, so we're well within the range that's recommended for this. The spring rate was 500 pounds per inch, and we had a load variation of 21%. The allowable is 25%. This is a large hanger, it's 49 inches long (a little over four feet). This length is the hanger itself not including the hardware. Close this dialog box. Now let's take a look at these load cases. 21. Click Operating Load Case 3, and Hold down the Shift key and Click the next two load cases. So we'll review the results from load case 3, 4, & 5. Select the Restraint Summary, and display it on the screen. In this report, we see we have load case 3, 4, and 5, and these values are appearing right down in here for 3, 4, and 5. Scrolling down and looking at node 50, and we can see these are the values for that. So you can see how easy it is to have CAESAR II design and select a spring hanger for you. You can simply insert a hanger at the appropriate node, and CAESAR II will chose one that fits your design criteria. 96 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Two Video Five 22. All right, let's go ahead and close out this report. Click the input piping screen button, and we're going to take a look at one more thing. 23. First let's save our file. You'll save it in your folder - the CAESAR II Fundamentals Course folder. Click File. Click Save As. Type: EXAMPLE TWO WITH HANGER <Enter>. 24. Click on the element between nodes 45 and 50. Click on the Hanger option on the Input Spreadsheet (one click). This dialog box also has an option to place a Spring Support under a line, instead of an overhead hanger. You can click this space for that option. This will give you a negative space, and you'll have some choices for a spring support. Great! I wanted you to see this. We've covered a lot of ground here. Get your model up to this point, and then we'll go on from here. 97 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC CAESAR II® Fundamentals - Example Two Video 6 1. All right, so we've taken a look at some of our results. Let's go ahead and close this screen out, and we'll get back to the main screen that we have when we start up a new file. What we'll do in this video is we're going to generate a stress isometric. 2. Click the Generate Stress Isometrics button. 3. The system will bring up a screen that shows our model, and I'm going to maximize this. If we want, we can just create an isometric right here. Click Create Isometric Drawing. Click Use Default Style. Click OK. So let's see what the system will produce if we don't do any additional steps here; this is the default version. 4. Now to view the isometric, you need to have AutoCAD or an AutoCAD viewer. I happen to have AutoCAD installed on my machine, so it'll just open up the isometric in plain AutoCAD. Click View. We can see what the system produces. There is an anchor on the end, and it dimensions the measurements down the lines. It labels the pipe size and locates the Y restraint. We also see a symbol for a hangar. This is the basic stress isometric form that it will produce. 98 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Two Video Six 5. Close this stress isometric drawing (you don't need to save it). Minimize the viewer. Cancel and exit out of the dialog boxes to return to the plot. What we'll do now is add some additional annotation. 6. Click the Edit Stress Annotations button. This dialog box has a series of tabs along the side of the dialog box. 99 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Two Video Six Click on the Input tab. Click the down arrow for Feature. This gives some annotation options. 7. Click on Node Numbers. Select some of the node numbers: 10, 20, 30, all the way to the end of the line. Click on the Output tab. 8. Here we have some load cases that we could show some results from those load cases. So let's put some information on the restraints (we're set for CASE 1, OPERATING CASE CONDITION) Click on node 20. Click the check box for Hangar Data. Check the box for node 50. 100 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Two Video Six 9. All right, so I think we have enough here to take a look at it. Let's go ahead and generate this one. Click Create Isometric Drawing. Click OK (Use Default Style). Click View it (and Open if needed). 10. So now we have a little bit more going on here. We have our same dimensions and labeling, but now we have some forces displayed here for this Y restraint. Also the isometric contains hanger information. We have information about the loading, the size of it, the movement, the spring rate. So you can see that you have a lot of options here in CAESAR II on how you can display information on your stress isometrics. When you run a stress isometric using the Default option, CAESAR II saves the drawing in the folder where the model is located. Also it will use the same units in the isometric as the model. If you need to produce stress isometrics quickly, you can use the Default settings, then have your drafter modify the title block as needed. 101 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Two Video Six 11. Exit out of the two dialog boxes. Let's say now that you wanted to use a certain size border, or you wanted to have your company logo in the title block. Also, perhaps you want to use the same input settings for your annotation on the stress iso, and you would like to save them as a standard template. 12. To save your input annotation settings, Click the StressIso pull-down menu, Click Save Template. Note: You can save the input annotation in a template, but the system does not allow you to save any output (results) annotation in a template. Later, when you want to use your saved settings in a new model you just click "Apply Template." Let's say not that you wanted to run your stress isos and save them in a particular folder. Also you want to use a particular border, with your title block instead of the default border. 13. The first step is to Create a folder on your C: drive to store the stress isos. For this example, name the folder CAESAR_II_Stress_Isos . 14. Click Create Isometric Drawing. Click Create New Style Click OK. A dialog box appears. Click Browse to select your folder and then Click Create. 102 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Two Video Six The system adds the necessary files to the folder we created. 15. For units, Select Imperial/Inch Bores. For Drawing Size, Leave it set to A2. (Note: The system works best with this setting.) Click Create Drawing. Click View to view the drawing. The system has now created the drawing and stored it in our folder. The drawings get stored in a "Drawings" sub-folder. In the Isometric Style folder is the drawing that the system uses for the border. If you have your drafter/designer modify this in AutoCAD (or Microstation if you use that), you can change it to suit your company's needs (include your logo, modify the title block, etc.) If you want additional information on modifying the appearance and settings in the stress isometrics you can review the material in I-Config. This has extensive documentation on how the stress isometrics get created. 103 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC CAESAR II® Fundamentals - Example Two Video 7 1. We're back in our model and this is the file that we saved earlier. This is EXAMPLE_2_WITH_HANGER. Make sure you're set to nodes 10 to 20. In this example we're going to take a look at this area of the input spreadsheet that we can use in CAESAR II to specify Occasional Loads. So far, we've analyze the sustained stresses on the piping system to verify it's not overstressed or in danger of collapse. We've also analyzed the expansion stresses and found them to be within the allowable values. 2. However, piping systems can be subject to other types of occasional force-based loads, and in this area of the spreadsheet, we can specify some of these. For instance, the first box shown here can be used to specify a Point Force. This might be the force caused by a Relief Valve discharging. We can check to see if that overloads the weldolet connection between the relief valve and the header pipe. 3. The next box allows us to specify Uniform Load. We could specify a G load on the piping system that can represent the inertial e effects on the piping system as the ground beneath it shakes. We would be able to see if our system can withstand this type of load without yielding. 4. The third one is for Wind and Wave Loads. Double click the Wind and Wave Loads check box. This is what we're going to use in this example. A dialogue box to the right will open up, and we can see that we can specify either a wind load or a wave load. The system is set for one or the other, because both of these types of loads will not occur simultaneously on the same group of elements. 5. We'll specify a Wind Load for this example. 104 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Two Video Seven 6. Click in the space for the wind shape factor. Press the F1 key (to open up the Help system). It says a wind shape factor is a coefficient that is used to model wind as it goes around chimneys and tanks and other similar structures. A value of 0.5 to 0.65 is typically used for cylindrical sections. If we use a value of 1 here, that would tell the system that the wind does not flow around the shape, that it's just blocking the wind. However, since piping is cylindrical, the wind will hit the shape and then flow around the edges of it. So we're going to be between 0.5 and 0.65 for this factor. Type: 0.6 <Enter>. 7. Next the system asks for the global coordinates for node 10. We'll leave that set to 0,0,0. Click OK. We'll get enough elevation for this line to see how wind loading can affect it. This is all that needs to be set in this section. What we've entered is a carry-forward item. We checked the box for wind and wave on the first element. If we go to the next element, that check box disappears, but the information is still in there. It's carrying forward, and we don't have to keep coming back and checking that box again. We don't need to check it again unless we want to change the value. If we did that, the new value would start carrying forward from where it was input. 8. Click on Start Run button to start the Error Checker. We're getting the same warnings that we got before relating to the bends. In our case, these are fine. 9. Now let's take a look at the Load Case Editor. 105 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Two Video Seven 10. Click on the Edit Static Load Cases button, which will open up the Load Case Editor. We're getting a message that the loads for this job have changed. Remember, we've added a wind load here, so click OK and we'll see what the system shows. We can see we have some new load cases that have been set up. However, we don't see them in our load case listings in the editor. If we click on the Recommend button, hoping that it would give us these new load cases, CAESAR II is not going to do that. It will not recommend load cases for occasional loads. 11. Now, one thing to ask here is if we're dealing with a linear or nonlinear system. For this example, we're going to say it's linear. We have anchors on each end and our restraints act in both directions. We have a hanger in the middle of the line. So for this example, we'll be working with a linear system. This allows us to evaluate wind independent of any other loads. 12. Looking over on the left side of the dialogue box, we can see that we have four wind load cases that we can define. In a few minutes, we'll add one of these into our list of load cases. What we're going to do first, we're going to look at this Wind Load Case tab. 13. Click on the Wind Load Case tab. This is where we can actually define the wind vectors, the magnitude and direction of the different winds. The system has 4 of them. This would be for 1, and then we can go right on up to 2, and 3 and 4 and so forth. 14. For this example, when we look at our model, we could say that our maximum wind effect is going to occur when the wind blows across the model in the Z direction. So we're going to use one wind load case here, and we're going to set it up to be coming in the +Z direction. We could go either way, but we'll get the same effects as long as it's blowing across the model. 106 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Two Video Seven 15. Click in the space to specify the direction cosine. It will be in the Z direction. Type: 1 <Enter>. 16. Now we'll set up the rest of the required parameters. If you have your own wind pressure profile or wind velocity profile you can use that. We'll use CAESAR II to help us create that. CAESAR II ships with a collection of different building codes, international building codes, and this is where we'll start. 17. Select the ASCE 7 building code, which is the US building code. Depending on the order that you click these, the system may or may not blank out the wind direction cosine field. In my case it did, so I'm going to type a 1 and press Enter in that field again. Now we start filling out some of these other parameters. 107 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Two Video Seven 18. For the Basic Wind Speed, the system is looking for that input in feet per second. Click in that field, and Type: 120 <Enter>. That will approximate a wind speed of about 80 miles an hour. 19. Click in the Wind Exposure field, and press the F1 key. The code says that Exposure 4 would be for a flat, coastal area. For this example we'll assume that the structure of this piping system is being constructed in Houston, Texas, which is a fairly flat coastal area. So we're going to use a 4 for that. Close the Help screen. In the Wind Exposure field, Type: 4 <Enter>. 20. This next field, Structural Damping Coefficient. We'll just leave that set like it is. Currently, it's set for 3%, which is the default. 21. Click in the Structural Classification field and press the F1 Key. We're probably going to use this number 2 here for that. This is for everything but these special cases. Category 3 would be for buildings more than 300 people. Category 4 would be for essential structures, facilities like hospitals and police stations. So we'll just use category 2 for this example. The system has a value of 2 preset, so we can leave that. 22. Click in the Importance Factor field. In this example, we're not going to change that. Leave it set to 1. 108 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Two Video Seven The building code lists various kinds of structures and buildings. This value would be changed for buildings of higher importance such as a hospital or a police station. If we were dealing with those types of important structures, we would enter 1.5 in this field, and the wind loads would be multiplied times 150%. This would give more assurance they could withstand a severe wind event. 23. For the natural frequency, structural frequency, leave that set at 0. We don't have any data on that. If you had it, then you could put it in. That can come into play with certain wind gusts that the system might encounter. 24. The fields down in the lower area of the dialog box are based on topography. In this example we don't have any hills nearby, or any crest of hills close to us, so we'll leave these set to 0. So great! I think we're at a perfect place to stop the video. Go ahead and get your model to this point, and then we'll continue on after that! 109 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC CAESAR II® Fundamentals - Example Two Video 8 1. OK. Now that we have our wind loads defined, let's go back to the Load Case Editor. We'll incorporate these into a new load case or two, and we'll use that in analysis. 2. Click the Load Case Editor tab. Click on Load Case number 8. Let's just say we wanted to try a test using this load case. It would be nice if we could just drag one of these wind load cases over to our list and run it. So I'm going to click the plus sign to add a new load case to the list. Then I'll take this Wind Load Case number 1 and just drag and drop it down into the new load case, and hopefully this would work. It's actually going to give us an error, but I wanted to show you this. I'll select an Occasional load for this load case. All right, so everything looks good, let's see if it works. 3. I'll click the Batch Run button to run the analysis. The system comes back with an error. It's saying that the end of the load case strings must have an algebraic load case listed. The wind load case is a fundamental load cases so it's not allowed at the end. So I'll click the OK button and we'll delete this last load case we just tested. 110 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Two Video Eight 4. What we need to do is add this wind load case higher up in the list. Click on L5 (Load Case 5). Click on the + sign. The system inserts a new row in the list of load cases. We get a message asking renumbering these lower three rows in the load case list. These rows are combination load cases. One of them is L3 minus L5. It'll be down in the list, below L5 in the list. Since the lower set of load cases don't contain any terms greater than L5, adding new rows in the list won't interfere with how they're numbered. If we were inserting a row above L5, and our original L5 became L6, then that would affect the terms in these combination load cases, but it doesn't come into play here. Click No (about renumbering). The system will insert a row into the list, and we can see these combination terms now will not be affected because whatever I'm doing is down below L5. Click in the space, and drag and drop Wind Load Case number 1 into the space. Click Occasional for the stress type. 111 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Two Video Eight This Stress Type is what the system uses to establish the equations for calculating the stresses with these different load cases. It will also establish the allowable stress for these particular load cases. For occasional loads, these stresses are not calculated by themselves. They offer additional opportunities for the system to collapse when they're combined with a sustain load case. So we do a combination of these two, the sustained and the occasional, and check the stresses there to see if they've exceeded the allowed values. 5. Now we'll add a new combination load case. Click in the L9 space. Click the + (Plus) sign. Type: L5 + L6 Select OCC for the stress type. This will represent the sustained load case plus the occasional wind load, and this stress will be an occasional stress. What the system will allow for this stress will be 1.33 times the hot allowable stress. Whereas back when it's does the sustain load case analysis, it just uses the hot allowable stress for that value. Here it will take that and allow us to use 1.33 times that value. 112 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Two Video Eight 6. OK, so we think we're almost done, and we can try to run this, but we're not quite there yet. Let's try to run it and see what happens. Click on the Analysis (Running Man) button. The system gives a warning here. It says: In an occasional load case combination of a sustained and occasional load case, the combination method is neither scalar nor absolute while the code requires that. The B31.3 Piping Code doesn't actually say it this way, but this is how CAESAR II notifies us. So we have a couple of choices. We can just say OK, just ignore it, or we can return to the Load Case Options to set this. 7. Click OK. The system takes you to the Load Case Options. 113 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Two Video Eight Now, the program has even highlighted the cell that we need to focus on, and it's for our sustained plus our wind load. Looking under the combination method, we can see that it has an algebraic value entered there, but our message said that we need to have a scalar or absolute method there. The combination method is not used for basic load cases in the upper area of the load case list. There's nothing to combine there. The system will just simply calculate them and move forward. When it gets down on these expansion load cases, it will combine them in an algebraic fashion. 8. What it's doing is algebraically combining the bending moments for these different load cases. Once it gets that value, it uses that to calculate the stress. So it uses an algebraic combination for these. However, when you get down to this occasional one, what we want to put down there is a scalar combination method. 9. Now, there's a subtle difference between putting scalar here and putting absolute here. What's happening is when the system calculates the stresses for occasional load cases, it's going to just combine them with their scalar value. It's not going to worry about the signs when it does the combination. 10. But when the system calculates the displacements and the forces, it will use an algebraic method for that. 11. That's the way it's going to happen if we have scalar here. If we switch this over to absolute, then the system will use an absolute value for all three of these (stresses, displacements, and forces), but we want scalar only for stresses. So that's a subtle distinction in working with occasional loads, but it's worth noting. In our case, we want to use scalar for this. 12. When we look at this list of options for our load cases, we see we have a check box under Snubbers Active. The system can accommodate us to have a snubber in the model and use it only on this particular load case. Let me just show you very briefly how that works (you don't have to do this unless you like). 114 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Two Video Eight 13. I'm going to save this set-up for a moment, and then I'll go back to the Input Processor. I'll click Save and close this. 14. I'll click on the element going to node 40. This would be a good place for a snubber. 15. I'll double click Restraints. I'll Select a Z Snubber. A snubber will provide damping here. It's going to act in fast movement, but not act in slow movement. That would be a way we could get this in there. Let me go ahead and take it out. We don't really want it in the model. 115 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Two Video Eight 16. Now I'll start the Error Checker. Next I'll open the Load Case Editor. If we check the options tab, we can see that having a Snubber in the model is like having a selectable restraint, and it's just another nice feature that's in CAESAR II. It's only active for the wind load case. 17. We're ready to run the analysis now. Click the Running Man button. Select the Occasional Load Case. Select the Displacement report. Display it on the screen. 116 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Two Video Eight 18. At the midpoint along the top center was node 50. We can see that this is deflecting in the Z direction over 8 inches. This is quite a large deflection, and it just shows that pipe is very flexible. Now, one thing to mention here is we do have a hangar at node 50, so we'll see some coupling between the hangar and the line, and we won't see this full amount of displacement. This displacement is caused by a force in the Z direction. When CAESAR II analyzes a hangar, it looks at it strictly in the Y direction. Close the Displacements report. 19. Now let's take a look at the stresses. Select the Occasional Load Case. Select the Stresses report. We'll see what we get on that. Does the wind plus the sustained is going to put this in jeopardy and possibly collapsing? 117 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Two Video Eight Well, we're not seeing red, but this is pretty amazing. Our ratio is 94% here of the allowable. So that's pretty intense. 20. Scrolling down in the report, that happened on node 10. So the initial anchor on the end of the line has some large stresses that have been calculated (94% of the allowable). 21. Let's do one more thing. Close the stresses report. Click on the Sustained Load case (Load case 5). Hold down the Control key. Click on the Occasional Load case 6 and Click on the Occasional Load case 10. Click on the Code Compliance report. Click Display on the Screen. 118 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Two Video Eight 22. You remember when we set these up that we said use scalar values, combine 5 and 6 for this load case 10 here. Let's just see how that happened. Scroll down in the report and we can see how this is working. We see that we have a value in 5 and 6, and they combine together to give us the value in load case 10. So we can see these are just a simple summation here, and the system is doing scalar like we expect. 23. Close this report. Click the button to return to the Piping Input screen. Click File. Click Save As. Save this as EXAMPLE_2_WITH_WIND. Get your model to this point. Go through all of these steps, and run the reports, and make sure you're really clear on this. I think we had a great lesson here. We covered a lot of ground on this and we got to see a number of features in CAESAR II. So great. Get everything done up at this point, and then we'll explore something new in CAESAR II after this! 119 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC CAESAR II® Fundamentals - Example Three Video 1 1. This line is Example 3 in Appendix S in the B31.3 piping codes, and it's an interesting problem. 2. The line has two 24-inch diameter headers on each side, and two runs along the upper and lower sides of 20-inch diameter pipe. As the line operates, only one of the runs will be active at a time. 3. When the top horizontal run is active, it will be at 250 degrees Fahrenheit in temperature and 250 psi in pressure. The lower run will be turned off at that time, and will be a 0 psi and at ambient temperature, which in this example is 40 degrees Fahrenheit. 4. So what happens is this top part will expand and push these tees out. Then one week later, the system will alternate and the top branch will be turned off and the bottom branch will be turned on. This will cause the lower line to expand and the tees in the center of the headers will experience a moment reversal over time. 120 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Three Video One 5. The code states this line is set to alternate once a week for the expected life of the system, which is 20 years. This cycling will not have enough of an impact to affect and will not require any analysis for fatigue. 6. We’ll be modeling two operational scenarios. Scenario one will be when the upper line is active, and scenario two is when the lower line is active. Later, when you use CAESAR II in your work, and you have a model that includes a manifold with multiple lines connected to it. You’ll be able to use this as an example. 7. Let's take a look at the model as it is given. We are given some Y restraints at nodes 10, 210, 140, and 240. On the left we have an anchor. On the right end the line is free to move in X. That end (node 310) will have Z, Y, and Rotational Restraints. 121 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Three Video One 8. As each run is active it is set at 250 psi, and 250 degrees F. As that occurs the other run is set at 0 psi and 40 degrees F. Then, a week later these settings are switched. 9. Click File. Click New. Type: Example_3 for the name. Click OK. Click OK to accept the Units settings. 122 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Three Video One 10. Dock the piping input spreadsheet as needed. Click in the Pipe Diameter field. Type: 24 <Enter>. Click in the Wall Thickness field. Type: 0.375 <Enter>. The code specifies this as a gas fluid, so we don’t need to be concerned about the Fluid Density (it can be left blank). Leave the Corrosion field blank. 11. Click the Down Arrow next to the Material field. Select A53B. Click in another space to accept that. The system will fill out other fields based on that material. 12. The first leg of the model will be the input line. It will always be pressurized and hot. Click in the T1 field. Type: 250 <Enter>. Click in the T2 field. Type: 250 <Enter>. Click in the P1 field. Type: 250 <Enter>. Click in the P2 field. Type: 250 <Enter>. 13. Now we’ll start modeling the line. Click in the DX field. Type: 5- <Enter>. Double click Restraints. Click Anchor, to place an anchor on node 10. 123 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Three Video One Double click SIFs and Tees. Click Welding Tee, which will put a Welding Tee on node 20. Click another field to finish that. This section of the model is always at pressure and temperature. From here, in the header section, the pressure and temperature will alternate from high to low. 14. Next we'll model the upper branch. Click Continue. Change the To Node to 40. Click in the DZ field. Type: -5- <Enter>. Change the Temperature and Pressure settings as needed. T1: 250 T2: 40 P1: 250 P2: 0 Click in the DZ field. Type: 5- <Enter>. Double click the Chevron next to temperature. A small windows opens up displaying the operating conditions for the current element. We can see that the first case is going to be 250 degrees and 250 psi, and the second case is going to be 40 degrees ambient and 0 pressure. Click on the first element in the model. You can see that it’s always pressurized and at temperature. 124 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Three Video One 15. Our current settings will propagate to new elements. Click the last element we just added to make it current. Close the small Edit Operating Conditions dialog box. Click Continue. Change the To Node to 45. Click in the DZ field. Type: -2.5- <Enter>. Double Click SIFs & Tees. Select Welding (for node 40). Next we’ll model the element from 40 to 110. 125 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Three Video One 16. Click Continue. Change the From Node to 40. Change the To Node to 110. In the DX field, Type: 5- <Enter>. One thing to notice is this section of the model will be 20” diameter pipe. Click in the Diameter field. Type: 20 <Enter>. Changing settings after an element is modeled and still current is the easiest way to have new settings propagate from your current element forward. Double Click Restraints. Click Y (for node 110). Click another space to finish that. 17. Click Continue. We'll enter the length for the element between 110 and 120. In the DX field, Type: 5- <Enter>. 18. Click Continue. We'll enter the length for the element between 120 and 130. In the DX field, Type: 5- <Enter>. This will be a Rigid Element. Double Click Rigid (this can represent a valve or flow meter). In the space for weight, Type: 2000 <Enter>. 126 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Three Video One 19. Click Continue. We'll enter the length for the element between 130 and 140. In the DX field, Type: 5- <Enter>. Double Click Restraints. Click Y (for a Y restraint at node 140). 20. Click Continue. We'll enter the length for the element between 140 and 340. In the DX field, Type: 5- <Enter>. Double click SIFs and Tees. Click Welding (to place a welded tee at node 340). So we covered a lot in here. Why don't we pause at this point? I think we're making really good progress in this model, so get your model to here and we'll carry on after this. 127 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC CAESAR II® Fundamentals - Example Three Video 2 1. All right, we're back at our model now and we're going to model the rest of the line. The lower section we'll model will have different temperature and pressure values than the section we just completed (they'll be reversed). 2. We don't want to change these at this point because, if we do, it can affect the last element we modeled in the previous video. We’ll continue the header and the switch the temperature and pressure settings after the element gets modeled. Let's take a look at our sketch for a moment. We're going to be modeling the element that goes from node 20 down to node 30 and then from 30 to 35. These will be 24-inch pipe with the opposite settings for the pressure and temperature than what we used in the upper portion of the header. 3. Click Continue. Set the From node to 20. Set the To node to 30. In the DZ field, Type: 5- <Enter>. 128 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Three Video Two 4. The system initially models the element as a 20-inch diameter pipe. In the Diameter field, Type: 24 <Enter>. The system updates the model. 5. Now we'll change the temperature and pressure values for this section of the model. In the Temp 1 field, Type: 40 <Enter>. In the Temp 2 field, Type: 250 <Enter>. In the Pressure 1 field, Type: 0 <Enter>. In the Pressure 2 field, Type: 250 <Enter>. 6. Double-click the chevron next to the Temp 1 field. We can see that we have our temperatures inverted and our pressure inverted for this segment. So you just have to change the settings at the proper time so that it doesn't affect some previous element in your model. Close this dialog box. 129 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Three Video Two 7. Click Continue. Set the From node to 30. Set the To node to 35. In the DZ field, Type: 2.5- <Enter>. Double click SIFs and Tees. On node 30, Select a Welding tee. 8. Click Continue. 130 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Three Video Two 9. Change the From node to node 30. Change the To node to node 210. In the DX field, Type: 5- <Enter>. In the Diameter field, Type: 20 <Enter>. Double Click Restraints Click Y. Click in another space to <Enter> that selection. 10. Click Continue. This element will be from 210 to 220. In the DX field, Type: 5- <Enter>. 11. Click Continue. This element will be from 220 to 230. In the DX field, Type: 5- <Enter>. Double click Rigid. For the Weight, Type: 2000 <Enter>. 131 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Three Video Two 12. Click Continue. This element will be from 230 to 240. In the DX field, Type: 5- <Enter>. Double click Restraints. Select a Y restraint. 13. Click Continue. Set the To node to 330. In the DX field, Type: 5- <Enter>. Click Save. 14. Next we'll model this header across the right end of the model. In CAESAR II, when you have tees in the a model like this, the system will treat them as if they had caps on the ends of the tees. CAESAR II will analyze this as a pressurized system. 15. Click Continue. Set the From node to 335. Set the To node to 330. In the DZ field, Type: -2.5- <Enter>. In the Diameter field, Type: 24 <Enter>. 132 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Three Video Two 16. Click Continue. Set the To field to 320. In the DZ field, Type: -5- <Enter>. 17. Click Continue. Set the To node field to 340. In the DZ field, Type: -5- <Enter>. This element will have the values for T1 and T2 reversed. In the Temp 1 field, Type: 250 <Enter>. In the Temp 2 field, Type: 40 <Enter>. In the Pressure 1 field, Type: 250 <Enter>. In the Pressure 2 field, Type: 0 <Enter>. These settings will now propagate through the elements which follow. 133 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Three Video Two 18. Click Continue. Set the To node to 345. In the DZ field, Type: -2.5- <Enter>. The next step is to model the end of the line, going from node 320 to node 310. 19. Click Continue. Set the From node field to 320. Set the To node field to 310. In the DX field, Type: 5- <Enter>. In the Temp 2 field, Type: 250 <Enter>. In the Pressure 2 field, Type: 250 <Enter>. Our pipe segments are now modeled correctly. Let's take a look at the line and display the different temperatures and pressures. 20. Click on the Show Temps button. Click on Temp 1. The system will display the higher temperature in the upper run and the lower temperature in the lower run. 134 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Three Video Two 21. Click on Temp 2. You can see how the system updates the display. 22. The same works with pressure. Click on Show Pressures. Click on Pressure 1. Click on Pressure 2. You can see how the system displays the high and low pressure in the line. Click on Show Pressures to turn that off. We'll continue working on the model in the next video. 135 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC CAESAR II® Fundamentals - Example Three Video 3 Now we'll continue working on the model. 1. We need to put some restraints on the end of the line. Double click Restraints. On node 310, Select a Y restraint. On node 310 Select a Z restraint. On node 310, Select a Rotational Y restraint. On node 310, Select a Rotational Z restraint. 2. We have one last thing to do to finish the model. As this model was being built, Tees were left out of two locations. Click the Show Tees button. 136 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com 3. CAESAR II Example Three Video Three Click Wire Frame, to display the model as a wire frame. We can see that tees need to be added at nodes 330 and 320. 4. Select the element from node 240 to node 330. 5. Double click SIFs & Tees. At node 330, select a Welding Tee. 6. Select the element from node 320 to node 310. 7. Double click SIFs & Tees. At node 320, select a Welding Tee. 137 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Three Video Three 8. Dock the input spreadsheet and minimize it. 9. Click the 3D Rendering button to go back to shaded mode. 10. Click the Show Tees button to turn off the Tees. 11. Now let's run the analysis of this line. 12. Click the Error Checker button. We can see we have a nice Center of Gravity Report. We're not getting any warnings or errors. 138 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Three Video Three 13. Click the Batch Run button. 14. Select the Expansion Load Case 5. This will be the operating load case minus the sustained load case. Select the Global Element Forces. Display it on the screen. 15. We see here on Node 10, we're 108,987. On Node 30, we're 33,709. I'm going to toggle over to the Appendix S and just see what they had. We had similar numbers, 108,755, 33,850. So our numbers are coming out within a fraction of 1%. Now you get your model completed, and then run the analysis of this yourself and compare your results with what appears in the B31.3 Appendix S Piping Codes. Then if you're doing the quizzes, we'll have a quiz that follows so we can just verify results, and after that, we'll go on to something new! 139 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC CAESAR II® Fundamentals - Example Four Video 1 1. What we're going to do in this lesson is work with a line that was created in a 3D CAD modeling system and exported out to CAESAR II for analysis. So the CAD modeling system will produce a file that CAESAR II can open up and analyze. I thought this was interesting and I wanted to show you how this happens. This is a screen in CADWorx Plant Professional software, one of the 3D CAD systems owned by Intergraph™ Corporation. We have a line here, a 3D model, and we can see that this line is a discharge line coming out of a couple of pumps. The line comes up in vertical and goes over into the rack and travels down the pipe rack and connects to a vertical vessel. 2. In CADWorx Plant Professional software and also SmartPlant 3D, we have the ability to take a 3D line like this and export it out to CAESAR II, and the system will automatically build a C2 file. It's a file that we can open right up into CAESAR II and modify and analyze. So it's a great time saver. As stress analysts we won't need to recreate the geometry again, we can just work with something that's sent directly from the designers right to us. 140 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Four Video One 3. Later, if we need to, we can also modify the geometry in CAESAR II and send it back to the CAD system. When we do that, the CAD system will import in the modified geometry. Now, depending on the version you're running and the particular CAD system whether it's CADWorx or SmartPlant or something else, you have different tools in each of these systems that you can use to model restraints. In the CADWorx system itself, in the CADWorx Plant II ribbon tab, we have some different restraints that we can put in. 4. We have a limited number here; we don't have all the them. We have a translational restraint, an anchor, a spring hanger, a guide, snubber, and a rotational restraint. When these get exported out, the results may vary based on the versions of the software in the CAD system and also CAESAR II. Now, I'm going to go up to the View tab for a second, and I'll show you something. If I go back to Visual Styles and I go to 2D Wireframe, and I'll zoom in, you can see where I manually placed some restraints in this CAD modeler. If I double click this one, this is a translational restraint. The main thing I want to get accomplished with this is get this located in the model in the proper location, and later I can tell CAESAR II if it's a +Y or it's a rotational restraint about x, or whatever type of restraint it is. Placing it in the model will produce some nodes and a restraint located properly in the model. So wherever we have these restraints, elbows, and components, we'll end up with nodes in our CAESAR II file, and the geometry will be correct. 141 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Four Video One 5. The way this gets exported is just clicking a button on the CADWorx ribbon. When I click this Export (System Out) button, I get prompted for a file location and to Select Components. I'll window all of the components and press Enter. The system asks if you do want to assign start locations, and if you press No, it just starts running and it builds the CAESAR II input file for you. 6. So I'll go ahead and do that in the background, and then what we'll do in a moment is we'll open this file up in the CAESAR II. 142 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC CAESAR II® Fundamentals - Example Four Video 2 1. All right. So we're back in Caesar II. Let's go ahead now and open up that file that was exported out of the 3D modeling system. Click Open. Click Export_Initial_A (it’s in the CAESAR II Fundamental Course Files folder). Click the Piping Input button to see how the data comes in to CAESAR II. 2. It looks like we have some pretty nice geometry here. Zoom in for a minute and take a look at the model. You can see that the node numbering came out very nice in the CAESAR II model. It started out at node 10 and went right around the geometry nicely. 3. In looking at the restraints, they came in as rotational restraints. This can vary depending upon the version and type of CAD system you export from. Later, we’ll change these to +Y restraints. So depending upon the system and what the designer has available to input his restraints, you will have to take a look at those and perhaps modify them. 143 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Four Video Two 4. In looking at the file, we see that we're missing a restraint in this area of the line. That's a really long span, and that's the normal span between these two. So we'll have to add a restraint in here. What can cause that is if the piping designer did not snap the restraint correctly to the line in the CAD modeling system. This is an error that you’ll see from time-to-time as you export in lines from a CAD model. 5. Now we’ll change the restraints. Click on an element where the restraint is connected to make it current. Double click the Restraint check box. Change it to a +Y restraint. 6. Now we need to add a node and a restraint that is missing in this model. So now, what we need to do is add a new node in here in this area right in here. Click the element between node 140 and node 150. Click the Break current element button. The system displays a dialog box. 144 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Four Video Two 7. For the New Node Number field, Type: 145 . For the Distance field, Type: 240. This distance will be from Node 140. This is for the distance (20 feet x 12 = 240). Click the field to Get Support From Node, Type: 140. Click OK. The system inserts the new node with its restraint. 8. Change the other restraints as needed. Make them all +Y Restraints. 9. Click the “First Element” button. Set the Temperature 1 to be 300 degrees F. Set the Pressure 1 to be 250 PSI. 10. Notice the material didn't come through in this example. In the Material field, Type: 106 <Enter>. The system will fill out the values based on 106 Grade B material. 145 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Four Video Two 11. In the Fluid Density field, Type: 0.72sg <Enter>. When you press Enter it converts to a decimal value. 12. In the next video we’ll set up some nozzle displacement values, to model how the pump nozzles will expand as they heat up. For now we’re in great shape. Why don’t you get your model to here and we’ll go on after that? . 146 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC CAESAR II® Fundamentals - Example Four Video 3 1. In this video, we're going to enter in some values for the displacements of the nozzles for the pump discharge and the nozzle coming out of the vertical vessel. CAESAR II has a field in the input spread sheet for displacements. The pump nozzles in this model are located 18 inches straight up above the pump center line. So as they heat up and expand, they'll have a displacement in the +Y direction. 2. CAESAR II has some information we can use to calculate how much they will displace. Double-click the small double chevron symbol near the temperature field. The system will show you the value to use to calculate the expansion for this material. We can just take this number and multiply it times 18 inches, which is our distance from the pump center line up to the face of the nozzle, and it'll give us the value for the y distance for our displacement. 3. I've calculated that result, and now we’ll enter it into our model. Double Click the Displacement field. In the DY field, Type: 0.027324 <Enter>. In the other fields, Type: 0 <Enter>. You must put 0 in these other fields, otherwise the system will let the nozzle move in these directions. These fields represent the other degrees of freedom the nozzle can move in. 4. One thing to note here is that we are doing this at node 10. That's the node for the first pump nozzle. Now we’ll do the same for the other pump’s discharge nozzle. 147 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Four Video Three Have the Select tool turned on. Click on the Rigid Element on the right pump. This element will be from node 80 to 90. Double-click Displacements. In the DY field, Type: 0.027324 <Enter>. In the other fields, Type: 0 <Enter>. Next we'll take a look at the vertical vessel. 5. Here are the measurements for the nozzle location on the vertical vessel. We can see the Skirt Height is 5’0”. Skirt to Nozzle Centerline is 19"-3". Vessel Centerline to Face of Nozzle is 3’-6”. When we do the calculations, the skirt temperature will be set to 100 degrees, and the vessel from the skirt up will be set to 300 degrees. We can calculate this in a traditional way using a calculator. For this example though we’ll build a quick model of this in CAESAR II and let the system calculate it for us. First we’ll save our current model. 6. Click File. Click Save As. Type: EXPORT_REV <Enter>. 148 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Four Video Three 7. Click File. Click New. For the name, Type: NOZZLE CALCULATIONS Click OK. On the configuration screen, Click OK. 8. In the Material Field, Type: 106 <Enter>. 9. In the Diameter Field, Type: 60 <Enter>. 10. For the Wall Thickness, Type: 0.75 <Enter>. 11. In the Temperature Field, Type: 100 <Enter> This will be the temperature for the skirt of the vessel. 12. We’re ready to model the element between node 10 and node 20. In the DY field, Type: 5- <Enter>. Double click Restraints. Select Anchor (this will be on node 10). Click in another field to enter that value. 149 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Four Video Three 13. Click Continue. In the DY field, Type: 19.25- <Enter>. In the Temperature Field, Type: 300 <Enter>. 14. Click Continue. This will be for node 30 to node 40. In the DZ Field, Type: -42 <Enter>. In the Diameter Field, Type: 8 <Enter>. 15. In the Schedule Field, Type: 30 <Enter>. 16. Click the Error Checker (Start Run) button. We’ll get a message about the element from nodes 30 to 40. Since we had a change of direction here with no type of Tee connection specified the system is warning us about it. However, we can still run it and get good results. 17. Click the Running Man button. 150 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Four Video Three 18. Click on the Operating Load Case. Click on Displacements, and Display the results on the screen. 19. On node 40, we have the displacement values shown in the DX, DY, and DZ fields. So these are the values we’ll use when we enter in the displacements in the nozzle dialog box later. This is one way you can determine the displacements. Of course, it’s perfectly fine to do it the traditional way using a calculator and sketches. This is simple, easy to do, and you can save and modify it if your design changes. 151 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Four Video Three 20. Return back to the Piping Input screen. Save this model. 21. Open the EXPORT_REV model. 22. We’ll go to node 240. Click the Find Node button. Type: 240 <Enter>. You should be at node 240 now in your model. 23. Double click Displacements. In the DX field, Type: 0 <Enter>. In the DY field, Type: 0.36 <Enter>. In the DZ field, Type: - 0.0639 <Enter>. In the RX field, Type: -0.0008 <Enter>. In the RY and RZ fields, Type: 0 <Enter>. \\\\\ We've got our model pretty far along here now. Get yours to this same point, and then save it. In the next video, we'll analyze the line and take a look at the forces, moments, and the stresses in this line, and we'll see if it's in compliance with the code. Then we'll do something interesting after that. We'll take a look at the nozzle limit checks that are built into CAESAR II. It's not unusual when you have pump nozzles and you have lines leaving them at temperature that these nozzles can get overloaded. Sometimes you have to modify the geometry of the piping in order to get those back within compliance. We'll see if we run into that in this example. It's just another aspect of CAESAR II. It's very powerful, and it'll be worthwhile for us to look at that. 152 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC CAESAR II® Fundamentals - Example Four Video 4 1. We're in the EXPORT_REV file model and we've got a little bit of clean up to do before we continue. 2. Select the element between node 10 to 20. We can see there's a restraint here and we really shouldn't have one. What we're going to have instead on these nodes are going to be some displacements. We don't need to have additional restraints on these. 3. If I do a single click on restraints, I can see that we have a node 350 and a node 360. There's also an anchor. So these were probably left over from part of the line that I took out. There was a weldolet, pipe nipple, gate valve and pressure gauge out here on each side of these discharge lines. Earlier I cleaned those out. 4. Apparently all of these leftover nodes were not deleted, so we have a couple left. Let's run the error checker and we'll see what it tells us. I'll tell it to run and the system will come back and say that it has some information it can't find here. It says there's an element that doesn't appear anywhere else in the model. 153 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Four Video Four 5. So these errors are from the leftover nodes remaining in the model. We'll get rid of them. Click Find Node. Type 350 and Click OK. The system will report the node is not found. So let's clean this up. We'll cancel out of this. 6. Double click Restraints. Click OK to delete the restraint. 7. Select the element from node 80 to 90. Click Restraints once. Note it's an anchor. We'll delete that. Double click Restraints. Delete that restraint as well. 8. Our displacements values that we put in earlier are going to take care of these two nodes (node 10 and node 90). What the system will do when a displacement has been set is it will actually-- based on the thermal growth of this pump-- move these nodes to the correct position. Then the system will act as though it anchors them at that point. So we'll start getting some forces and moments on these nozzles in this new displaced position. 9. All right, so if we run our analysis now, we'll get nice results, at least for the piping. What we'll find though later, when we do some nozzle limit checks, is that there are excessive forces and moments on these pump nozzles. 154 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Four Video Four 10. So let's go ahead and set up these nozzle limit checks now and then we'll run the analysis of the line. Select the first element (node 10 to 20). Double click the Nozzle Limit Check box. The system will open up a dialogue box for additional information. 11. For the Comparison Method, Select Absolute. Next the system requires the Reference Vector. On a pump, the reference vector is down the center line of the pump, pointing from the back of the pump (the motor side) to the suction nozzle. 12. For our pump, this direction is in the +Z direction. In the dialog box, Type: 1 in the Z field. 13. Next we need to enter information for the Load Limits. Click the button Read from File. Select API 610. Click Open. Select the Top Discharge direction. 14. When CAESAR II works with nozzles and interfaces with other programs it uses a local coordinate system for the nozzles. For these nozzles, the pipe direction in the local coordinate system is a. So the a direction, when we look at results later, will be up in the +Y direction. Direction b matches the reference direction, which we specified as +Z, since it was the direction from the pump motor to the suction nozzle. 155 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Four Video Four The direction for the c-axis is going to be the cross product of those two, and it will end up being in the +X direction. So the first nozzle is set up correctly. 15. Click on the element from 80 to 90, and we'll set up the nozzle limit checks for that. Double Click Nozzle Limit Check. Again, do the same procedure. Set the Comparison Method for Absolute. The Reference Vector will be the same (type a 1 in the Z field). For the Load Limits, Select Read From File. Select the API 610 information and a TOP discharge. 16. The discharge line goes straight up off the center line so everything is set for these two nozzles. 17. Pan and Zoom over to the end of the line where it connects to the vertical tower. Select the Flange on the end of the line. We'll do a nozzle limit check on this end as well. I don't think we have to be too rigorous on this because it will come in fine. There's not a whole lot of stress on this end. 18. Double Click the Nozzle Limit Check box. Set the Comparison Method for Absolute. The Reference Vector will be straight up (type a 1 in the Y field). 156 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Four Video Four The information for this nozzle will be read in from a file. Select Australian 1210. Click Open. Select 300 pound nozzle. This will give us some information on the loads on that nozzle. It analyzes the nozzle where the nozzle and the vessel shell actually intersect. If we don't see anything way out of line, then we should be fine in what we're doing for this example (this is just a classroom exercise). Later, if we wanted to do so, we could start adding some checks on the flange itself. For this exercise we'll use these settings and see how this goes. 19. Let's do one more thing now before we run the analysis. Click File. Click Save As. Type: EXPORT_REV_2. All right - get your file to here, and then after that, we'll run the analysis. 157 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC CAESAR II® Fundamentals - Example Four Video 5 1. OK. So now we're ready to run the analysis. 2. Click the Running Man button. Let's take a look at some of the results. Click the Operating Load Case and Hold down Shift and click on the Sustained Load Case. Select the Restraint Summary report and Display it on the screen. 3. The system will show us some of the forces and moments in our piping system. We can see we have forces and moments about X, Y, Z. Displayed are the results for the Operating Load Case and the Sustained Load Case. Around Node 10 and Node 90, we can see we have some large reactions in the X direction. 158 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Four Video Five 4. What's happening here is caused from thermal expansion, because we can see, in the Sustained Load Case, that these reactions are quite small. But when the system heats up and the lines begin to expand, it puts some real thermal strain on these nodes. This results in a large bending moment around the Z-axis on these nodes. So we're getting some large forces and moments around these two pump nozzles. 5. If we scroll down through the rest of the report, we can see that we don't have excessive loading going on in the rest of the system. At the end of this line, where the line connects into the vertical vessel we have more reasonable values. So our maximum forces and moments are going to be occurring around these two pump nozzles. 6. Let's take a look at the Sustained and Expansion Load Cases. Let's check for stresses on this, and we'll see if our piping itself is not overstressed. 159 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Four Video Five In the Sustained Load Case report we can see that our ratio is at about 13% of allowable stress, so the piping is fine as far as stress goes in the Sustained Load Case. If we check the Expansion Load Case, we can see that our ratio is about 36% of the maximum allowed stress. So our piping system itself is going to be well within the allowable limits for stress. Where we'll run into trouble is going to be on the nozzle loading. Let's take a look at that now. 160 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Four Video Five 7. Click on the Operating Load Case. Click on the Nozzle Check report. Click on the Display on Screen button. The report displays forces and moments around the a, b, and c axes. This is the local coordinate system used in the nozzle limit check analysis. In our system, a is in the +Y direction (the direction of the pipe), b is in the +Z direction (the direction down the pump centerline from back to front), and c is in the +Y direction (the cross product of the first two vectors). So the report is showing a very large force in the -X direction on that pump nozzle, and we're actually 17 times over the allowable. That force in the minus X direction is causing a large moment around the Z axis as well. 161 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Four Video Five The moment around the b-axis (which is actually in a global coordinate system is the Z-axis), is about 26 times greater than what is allowed. We have a lot of work to do here in getting this nozzle to come into compliance. Let's see what's causing this. Let's take a look at the plot, and we'll try to get an idea of what's going on here with our geometry. 8. Exit the reports and Click the 3D Plot button. Zoom in to the area around the two pump nozzles. 9. Click the Grow Plot button. Click the down arrow next to it. Click Adjust Defection Scale. Type: 15 <Enter>. So now if we look at our model, we can see that it's heating up, and it's expanding up in the positive Y direction. It's also pushing out in both X directions (plus and minus direction). One leg is pushing out down the negative X direction, and as it expands, it puts a large force in the minus X direction against the first nozzle. This produces a large bending moment around the Z-axis as the line expands. The opposite happens on the other pump. The line connecting the two discharge lines expands in the plus X direction, and it puts a negative bending moment around Z as grows. 162 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Four Video Five 10. Let's go ahead now and take a look at some of these forces and moments in more detail. Click the Show Element Viewer Grid button. The system will display an element viewer. Put the mouse over the top area of the viewer grid and drag to the left and release. The viewer grid will dock along the left margin of the plot screen. 11. Select the Operating Load Case. Click the + next to it and Select Restraints. So the Element Viewer Grid lets you see results for different load cases as you view the plot. If we look at Node 10, we can see here we have a large force in the minus X direction, and then we have a corresponding moment in the plus c around that node. We can also see how the opposite happens on the other pump nozzle, where on Node 90, we get a positive force in the X and a negative bending moment. 163 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Four Video Five So using this kind of viewer in your model as you pan around and look at things can help you get a clearer picture of what's going on physically in your model. This is one of the best ways to go about reviewing your results - start out with a plot and take a look at it and see what's actually happening physically in your model as the different loading conditions apply. That way, later on, when you go back and look at the printed reports, you'll have a better understanding of how your model is reacting. So now you do this. Go ahead and pan around, look at it, take a look at this viewing grid, and get clear on what's happening in this model and then we'll talk about how do we fix this. What we need to do is get more flexibility in this system. When a line has a short run like this between the two discharge lines, along with a short set of vertical lines there's not a lot of flexibility in the line as it expands. One way we might increase flexibility in a system like this is to increase the length of these legs coming up out of the discharge nozzles. So we'll take a look at what would happen if we bring these legs up higher and bend them back toward the rack, and then connect them. What kind of forces and moments will we get on these nozzles when we try that? We'll explore these ideas in the next video. 164 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC CAESAR II® Fundamentals - Example Four Video 6 1. Open the file called EXPORT_REV_3. It's in your CAESAR II Fundamentals Course Files folder. In this lesson, we're going to take a look at this file. I thought it might be interesting to explore some different geometries and ideas on how to go about lowering some of these forces and moments when we do our nozzle limit checks. In our first model, we had a connecting line between the two pump discharge lines only a few feet up above the pump nozzles. As it expanded, it pushed out in the X direction causing excessive bending moments around the Z-axis. What would happen if we took that line and moved it further away from the nozzles? Then it would still expand, but the discharge lines would be longer and this connecting line would be quite a distance away from these nozzles. 165 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Four Video Six 2. Well, the first thought would be that this could give us some better flexibility when it came to expanding in the X direction and producing these moments around Z. We'll see if that's true soon when we run the analysis. But in doing this kind of work, there are always trade-offs. If we move our connecting line further away from the nozzles, we now have long legs in the Z direction, then drop down in the vertical direction. We'll get a lot of flexibility as far as the expansion in X, but this vertical drop here is probably going to add some large forces in the Y direction. When you take the weight of this pipe, and then you take the weight of these rigid elements, these valves, that's a lot of weight. The nozzle limit check had a maximum allowed force in the Y direction of approximately 1,100 pounds, so we could be close to that here now. Then if we get some thermal strain added to that we could have solved one issue but created another one. So let's run this and see what happens. 3. Click the Error Checker button. We have a nice Center of Gravity Report with no warnings or errors. 4. Click the Running Man button to start the analysis. Click on the Sustained Load Case. Select the Restraint Summary report. Display the report on the screen. 166 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Four Video Six Looking at Node 10 here in the Sustain Load Case, our force coming down in Y is over 1,000 pounds. So when we start looking at the nozzle limit checks, we'll probably have too much weight here since we're already approaching the limits on that. 5. So this design is going to cause issues in vertical, but let's see what it does if we do run the nozzle limit check. 6. Select the Operating Load Case. Select the Nozzle Limit Check. Display the results on the screen. Note: The report of the results are shown on the next page. If we look at our results, we're better than we were before. Our forces are still excessive, but now it's the forces in the vertical direction. We had 1,100 pounds allowed and we're at 1,902, so we're almost double. Look at the bending moments, we're 2.7 times excessive here, and this is coming down on the moments around the X-axis. 167 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Four Video Six The moments around the Z-axis are within the allowable limits, which we fixed by lengthening the line in this model compared to the first model we checked. But our moments around the Xaxis now are excessive. So we got a trade-off. We were able to solve one part of it, but we ended up creating trouble on another part of the model. 7. Close the report. Click on the Input Piping screen button. We're going to continue to explore this. I have another file for you to open up, and it has some length back in the -Z direction, but it is shorter in the vertical direction. 8. The line will look like this. Instead of coming straight up and over like we did earlier, we're going to elbow out and down and then up and over. By having these extra elbows in the line, the model will have increased flexibility. What we'll find when we run this geometry, which is coming up in the next video, is that this geometry almost passes the nozzle limit check - it's really almost there. However, there'll be some excessive bending moments in one particular direction, and we'll have to model a dummy leg for this. 168 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Four Video Six So this is a great opportunity for us to see how to go about doing that. Then in the videos that follow the dummy leg, we're going to take this starting geometry that we used in this video, and we're going to edit it and change it into this new geometry. This will just give us a chance to see how to work with different editing tools in CAESAR II, and change geometry, rearrange elements, and renumber nodes as a model evolves. So these geometries that we come up with in these next few videos are for illustrative purposes only, and will serve us very well as we explore some of the different features and ways that we can work with CAESAR II. So great! Let's go ahead and get these started! 169 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC CAESAR II® Fundamentals - Example Four Video 7 1. Open the CAESAR II file called: EXPORT_DUMMY_LEG_EXAMPLE. In this lesson, we're going to take a look at this line. This is a modified version of the export line that we've been working with. It will serve as a good example for us to see about modeling a dummy leg. What happens when we analyze this line is that it's going to come in really close to passing the nozzle limit checks. But the way the geometry works in this line is that it pushes back in the -Z direction as it heats up and expands. That results in a moment around the X axis that is greater than what's allowed in the nozzle limit checks. But this gives us an excellent opportunity to model a dummy leg in this line to reduce that moment. In the process we'll learn some new features and techniques in CAESAR II. 170 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Four Video Seven 2. First let's run the analysis. Click the Error Checker button. We can see the system produces a center of gravity report for us, and there are no warnings in the report. Click the Running Man button to start the analysis. 3. Click on the Operating Load case. Click on the Nozzle Check report. Display it on the screen. We can see that this is close to being within the recommended limits. It's just over 1 here - the bending moment around X is shown at 1.086 around node 10, which is at the first nozzle. The other forces and moments are within range, so we won't need to be concerned about them. We just need to take care of this one issue, which is about 100 foot pounds or so excessive. Close out this report. Return to the Input Piping screen. 171 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Four Video Seven 4. Click on the second element. This is the two foot six inch element. It has a bend on the end of it. The next element as we move along the line is going to be a two foot element. It also has a bend on the end of it. These two elements are modeled one after the next, and to insert a dummy leg starting between them we need to have a separate node where they touch. 5. We'll break the second element. Select the second element. Click the Break button. In the dialog box, set the break for two elements. The system should split it for us. 6. Click in another field in the dialog box. The system breaks the element at the midpoint and assigned node numbers for us. The two elements each have a length of one foot. Click OK. We now have two elements. From node 18 to 20 is a one foot element, and if we click Next Element we'll see from 20 to 22 we have another one foot element. 172 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Four Video Seven 7. Select the Previous Element. This is where we'll start the dummy leg. First let's take a look at these bends in this area. Look at the element from node 14 to 18. It has a bend. If we look at the bend information we can see the node numbers around the bend. We also see that the first one is called a zero degree node. That's at the start of the bend, and it's node 16. Following node 16 comes node 17. This node occurs at the midpoint of the bend. Then, at the end of the bend is node 18. So that's the way CAESAR II defines its bends. 8. Click Next Element. Looking further we can see that from node 18 to 20 we have a one foot element. There's no bend on this element. From node 20 to 22 there is another bend. We might expect to see a zero degree node here on node 20, and then a midpoint at 21 and the end of the bend at 22. The zero degree node is not on here. When we break an element with the geometry we started with in this example, the system does not insert the zero degree node, which is good in this situation. 173 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Four Video Seven In the future, if you have an element that you're trying to connect a dummy leg to and there's a zero degree node on that same node you're connecting to, you'll need to go ahead erase it. Then you can connect a dummy leg there. 9. Click Previous, and return to the element from node 18 to 20. This is where we're going to connect our dummy leg. 10. Click Insert. We'll put a new element after the current one. This will be from node 20 to node 1,000. In the -X direction, Type: -2-6 <Enter>. The system added the pipe at the same diameter, and when modeling a dummy leg it's common to make it a smaller diameter, typically smaller by one or two sizes. 174 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Four Video Seven For this example, we'll just go down one size. In the Diameter field, Type: 6 <Enter>. Now the dummy leg is a six inch diameter pipe. 11. When we changed the size to 6", the system set all the following pipes to that same diameter. 12. Click on the element following the dummy leg. In the Diameter field, Type: 8 <Enter>. Click on some of the following elements and verify everything is 8" except the dummy leg, which is 6". All right, I think this is a really good stopping point. Why don't you get your model to here, and then we'll continue after this. 175 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC CAESAR II® Fundamentals - Example Four Video 8 1. Let's check something now in the model. If we click on this first element, we can see that it's an 8-inch pipe and it has a standard wall thickness of .3220. Then if we click on the dummy leg, we can see that it's a 6-inch pipe, but it has the same wall thickness as the larger pipe. So we need to update this. 176 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Four Video Eight 2. Click in the Wt/Sch field, Type: S <Enter> (for Standard Schedule). The system will convert the wall thickness to the correct value. However, this value (.2800) is like the size, and it will propagate on down through the rest of the line as well. If we click on the next element, I can see that it's got the same wall thickness, so let me change that. 3. Select the element following the dummy leg. In the Wt/Sch field, Type: S <Enter>. You can see it's set for .3220, and if we click somewhere further down the line these following elements will have the same value. 4. Select the dummy light leg. When the system starts to calculate the flexibility of this dummy leg, it's going to base it on the length of the leg as it comes from Node 20 all the way down to the end. Set the display to Single Line. We can see that it's going to treat it like it's this full length, like it's 2 feet, 6 inches long when it does the calculations. In reality, the dummy is not really that long. It's shorter because it merges with the elbow a few inches down toward the corner from node 20. Set the display mode back to Shaded. What we can use here to model this more realistically is we can use an offset command to get it more or less the proper length. The dummy leg connects to the elbow around 8" down from the end, in the -X direction. 177 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Four Video Eight 5. Double click Offsets. In the X field, Type: -8 <Enter>. This tells CAESAR II to use the shorter length for its calculations for the flexibility of the dummy leg. It doesn't update the plot, it simply uses this new length (2'6" 8") for its calculations. 6. Double click Restraints (the dummy leg is the current element). Select a +Z restraint at node 1000. 7. Now we can start the analysis. Click the Error Checker. We get some warnings saying we have three elements connecting at node 20 with no defined intersection type. In this case we don't need anything further, so we'll continue with the analysis. 178 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Four Video Eight 8. Click the Running Man button. Select the Operating Load Case. Select the Nozzle Check report. Display it on the screen. First of all we're not seeing red numbers in the report, which is good. We have the same kind of forces that we had before, but our moments are less. If we scroll over and look where we had issues before, the moments are lower and are now within the recommended range. 9. Now, let's take this one step even further. We're going to look at some other things we can do to perhaps get an even better picture of this. 10. Close the report. Return back to the Input Piping screen. When you have a dummy leg like this connected to an elbow, it cuts down the flexibility of the elbow. It's stiffer, and it just can't bend as much. One way some people approximate that, is by changing the elbow type to a single flange. 179 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Four Video Eight 11. Click on the element from node 18 to node 22. 12. Click Bend once to activate the dialog box. Change the Type to Single Flange. This makes the elbow stiffer, and it begins to approximate what happens when a dummy leg is connected to an elbow. In Appendix D of the B31.3 piping code it says that a flanged elbow is stiffer, or more rugged, than a non-flanged elbow. 13. Let's look at this a little closer. Click on the Bend SIF Scratchpad button. For the node number, Type: 22 and click OK. For our example we currently have a single flange elbow. The flange will act somewhat as a stiffening ring and help prevent the elbow from ovalizing, and therefore making it less flexible, and stronger. 180 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Four Video Eight 14. The scratchpad shows that CAESAR II is going to use a stress intensification factor of 1.5. It will also have an out of plane flexibility factor of 5 and 1/2. 15. If we take this flange off, we should see this flexibility factor increase, and the stress intensification factor go up as well. Let's do that. Set the Bend Type back to a blank space. Click Recalculate. Now we see the stresses are going to be multiplied by 1.9, and it's going to be more flexible. So this bend will have less strength, and more flexibility. 181 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Four Video Eight The flexibility factor is calculated as follows. If you have a straight run piece of pipe that is equal to the center line arc length of this elbow, the elbow would be seven times more flexible than the straight piece of pipe. So you get a lot of flexibility in a small package with an elbow here. 16. When you change a bend type like this, CAESAR II doesn't add any weight to the elbow or modify its length. It simply changes the factors that uses as it does the calculations. 17. Click Cancel to exit the scratchpad. Click No, we want to keep the single flange bend. Click the Error Checker button. Click the Running Man button. 18. Select the Operating Load Case. Select the Nozzle Check report. Display the results on the screen. 19. When we look at the moments, there is not a large difference compared to what we had earlier, but it does give us a more realistic picture of what's happening with that dummy leg. 182 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Four Video Eight So great, I thought this was interesting and I wanted you see how to do this. Go ahead and go through these steps, and make sure you understand what we're doing, and then we'll go on after that! 183 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC CAESAR II® Fundamentals - Example Four Video 9 1. Open the file named EXPORT_REV_3. The file is located in the CAESAR II Fundamentals Course Files folder. In this video, we're going to modify the geometry of this line. This will be interesting, because we're going to do this within CAESAR II. We'll leave some of these elements in place, and we'll delete out some others then model in new geometry. 2. We'll establish the coordinates for one node that we want to maintain, and then we'll learn some new CAESAR II tools to edit the model. When we checked this model earlier in a previous video, it was really pretty close to being in compliance with the code's requirements. The pipe stresses were fine when we checked it using the various load cases. Where it failed, however, was when we ran the nozzle limit check. There are excessive forces and moments on the pump discharge nozzles, so we need to decrease those by adding flexibility. 184 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Four Video Nine 3. One thing we'll do is we'll lower the height of the two lines leaving the discharge nozzles on the pumps. When we take these discharge lines up high and turn them toward the pipe rack, it does help reduce some of the forces in the X direction. Having the line which connects the two discharge lines located further away from the pump nozzles lowers these forces. So we can increase flexibility in one direction, but we end up increasing forces in the vertical direction of the nozzles. 4. We're going to modify the geometry to look like this. The new discharge lines will come part way in vertical, then elbow out and down toward the pipe rack. Adding two elbows will give us quite a bit of flexibility around the nozzles. By laying the valves (the rigid elements) down in horizontal, and putting a support near them, we should also see a decrease in the vertical loads on the nozzles. Then by extending the line across the rack we should see increased flexibility in this line, and hopefully the excessive forces and moments that we had around these pump nozzles will be significantly reduced. 185 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Four Video Nine Note: This exercise is for illustrative purposes only in using CAESAR II software and no recommendation for any specific application is intended or implied. So let's get going on this. 5. What we'll be doing soon is we're going to break our model right in here at node 60. Once we break it that will allow us to easily modify the section near the pumps. After it has been changed, we'll get everything connected back up again. 6. When you start breaking a model in CAESAR II, the broken segment of that model will default to repositioning itself back at 0, 0, 0. The system will prompt you if that's what you want to do. That's one option and once you've done it a time or two it's easy. However, for this example, we'll leave ours at its current location. Either way will work. Let's first check the coordinates of the end of the line. That way we can use this to verify the model hasn't shifted when the modifications are completed. 7. Click on the end of the line, on the flange connecting to the vertical vessel. This is the element going from node 250 to 260, where node 260 is the end of the model. Click the Distance button. The system will return back the distance from the origin to the current node. Click OK. The system displays the coordinates of node 260. Later on when we check this, we can verify that our nozzle is still in the same place after we've broken the line and rebuilt it. If it isn't, at least we'll know how far off we are, and how much we have to adjust it. 186 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Four Video Nine 8. Pan back to the area of the model where the discharge lines are joined. The +Y restraints in this area represent the pipe rack. In our new version of this model, the two discharge lines will extend down past that and be laying on top of the rack, then connect after that. How the new version will be modeled. 9. We'll break the line at node 120. Then we'll reposition node 120 back a little bit in the -Z direction. The element from node 120 to node 130 has plenty of length, and we have room to shorten it as needed. When we check it, it's over 4 feet 1 inches long. So we'll end up moving node 120 back in the -Z direction for a distance of 1 foot 6. This will give us room for the two discharge lines to extend over the pipe rack and be supported. Then they will be connected and continue down the rack after that. 10. Click on the element between node 60 to node 120. 11. Click the Distance button. The coordinates are 56 feet, 15 feet 4, 32 feet. The x and the y values will not change. The location in z will change, but currently it's at 32 feet back from the origin. We'll move the node back toward the rack a distance of 1 foot 6. So the new z coordinate will be at 33.5 feet. 187 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Four Video Nine 12. Click the Delete button. Click Yes. The system prompts for the new location of node 120. Type: 56.00034, 15.3594, -33.5 Click OK. 13. We have something else to adjust here. The segment from node 120 to node 130 has been shifted but remains the same length. The starting node, (120) has been repositioned. The system keeps elements connected, so all of the remaining elements following node 120 have also been shifted back. This would cause a problem if we don't fix it, since the end of the line no longer connects to the vertical vessel. So now we'll shorten the element between node 120 and node 130 by a distance of 1'6". This will bring all of the remaining geometry back where it was before we moved things. When we're done, node 120 will remain where it currently is, and the rest of the line will come back 1'6" and end up where it was originally in the model. 14. The distance from node 120 to node 130 is 4 feet 1.011 inches. That's 49.011 inches. 15. In the DZ field, Type: -31.011 <Enter>. Zoom in to the end of the line (node 260). Select the Flange on the end of the line. Click on the Distance button. We can see we have the same distance as before. So this is how you want to check things. You should go ahead and record some coordinates for some of the endpoints of your model, or points that you want to have remain in the same position. Then after you've made your adjustments, you can verify the model is correct. 188 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Four Video Nine Pan back down to the area of the line near the pumps. 16. To rebuild this geometry there are several options. We could simply click the first element, and start adjusting things as we go. What we're going to do here though is keep the first element, and then we'll delete the others around the line to end (where it ends on the second pump discharge). Then we'll rebuild the first side of the line, and explore some of the features in CAESAR II to copy and mirror elements in a model. This will be a great example for that. 17. Click on the end of this part of the line where it ends on the second pump. Click the Delete Element button. Click Yes. Node 10 will remain in place, and the element we selected will be deleted. 18. Click the Select Group button. Click one point and drag the mouse to window the elements to be deleted and release the button (all of the elements from node 10 on in this section of the line). 189 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Four Video Nine Hold down the Control key and make more than one window if needed to select all the elements to be deleted. Click Delete Element. Click Yes. 19. Click File. Click Save As. Type: EXPORT_REV_4 <Enter>. I think we made really good progress. We're in a great place now to pause the video. So you get your model to here, and then we'll carry on after this! 190 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC CAESAR II® Fundamentals - Example Four Video 10 1. We're back at our model now, and we're in the EXPORT_REV_4 file. What we'll be doing in this lesson is modeling the discharge line as it comes out of the pump nozzle. We'll actually do half of it. We'll take it from the nozzle up and lay it back down up and over to a point where it will connect at the upper centerline. Then, in the later videos, we'll model the other side of it, and we'll use some different CAESAR II techniques as we do that part of the line. 2. Click on the first element of the line. This will be a Flange. 191 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Four Video Ten I have a sketch of where we're headed with this. Let me toggle over. We see the first element's going to be a flange and then there'll be a straight, vertical piece of pipe with an elbow. In CAESAR II when you dimension elements that have bends on them, you actually dimension up to where the corner of that elbow would be, as if it was a square-cornered elbow. Then if there are two elbows adjacent to each other end-to-end, the dimensions are entered as corner to corner distances. So that's how we'll have to input the measurements as we key this in. You can see further up the line that we have an element that is a straight piece with an elbow on each end, so the measurement we'll enter for that is going to be the corner to corner measurement. 3. We're on node 10 to 20. In the DY field, Type: 4.5 <Enter>. When we model flanges and valves in CAESAR II we can input their information manually, like this one, or we can use a built-in valve and flange database. In a moment we'll use the database features. 192 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Four Video Ten Click the Reset View button (turn it off). This will keep the system from zooming extents each time an element gets added to the model. Click Rigid (to open the information for it). We can see this has a weight of 1187. When it was modeled initially, it represented a couple of valves and a flange on one end of them. In this weight field, Type: 68 <Enter>. This will represent a single flange with a gasket. The system uses 67 for the flange plus 1 for the gasket. That's how CAESAR II would enter this in if it did it out of a database. 4. As we model this line we'll change the node increment to four. Set the nodes to be 10 to 14, and that way we'll have plenty of nodes as we build all these elements in this model. Click on another field to update the entry. Now we'll continue modeling the line. Since this is part of the model near the beginning, and there are a number of elements that are part of this file as well, we won't use the Continue button to add new elements. Click the Insert button. Click OK, to insert the element after the current element. Set the nodes to be 14 to 18. In the DY field, Type: 2-6 <Enter>. Note: Some of the following illustrations were done after the model was completed. 193 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Four Video Ten Double Click Bend. This will be a Long Radius bend. 5. Click the Insert button. Click OK to insert after the current element. Set the nodes to be 18 to 22. In the DX field, Type: -2- <Enter>. Double Click Bend This will be a Long Radius bend. 6. Click the Insert button. Click OK to insert after the current element. Set the nodes to be 22 to 26. In the DZ field, Type: -2-6 <Enter>. 194 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Four Video Ten 7. Click the Insert button. Click OK to insert after the current element. Set the nodes to be 26 to 30. At this point, we're going to have a flange and then we'll have a check valve and a gate valve and another flange. So for this, we'll just click in any field that we like. What we'll do here is use the valve flange database. 8. Click on the Valve Flange Database button. For Rigid Type, Click Flange, For End Type, Click FLG. For Class, Click 300. Click OK. The system automatically places a flange for us. Click Rigid once to see the parameters. We can see it has a length of 4 and 1/2 inches. It's put it at 68 pounds (Flange plus Gasket weight). 195 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Four Video Ten The valve flange database is from the CADWorx Plant Professional 3D modeling system. The database contains a variety of valves and flanges, and different end conditions and classes. Using this can save a lot of time since we don't have to look up all of these. The system will automatically do that and input their weights and lengths as it goes. Exit the dialog box showing the properties for the rigid element. We just placed a Flange. Next we'll place a Check Valve, Gate Valve, and another Flange. For this group of elements we'll use a smaller node increment. Click Insert. Click OK for after the current element. Set the node number to be 30 to 32. Click the Valve Flange Database. Select a Check Valve. Select NOFLG (No Flange) for this. Select 300 for the class. Click OK. We can see it's given it a rigid weight of 620, so it's working like it should. 196 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Four Video Ten 9. Click Insert. Click OK for after the current element. The nodes will be 32 to 34. Click the Valve Flange database. Select GATE. Select NOFLG. Select 300. Click OK. We see this gate valve has a weight of 500. 10. Click Insert. Click OK for after the current element. The nodes will be 34 to 36. Select FLANGE. Select FLG. Select 300. Click OK. 197 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Four Video Ten From here, we're going to have a one foot length segment and then we'll put a plus y under that. So this is where we'll put a support to hold some of this weight. 11. Click Insert. Click OK for after the current element. The node increment will be 36 to 40 (we'll go back to a node increment of 4). In the DZ field, Type: -1- <Enter>. Double-click Restraints. Select +Y for the restraint. Click in another field to update it. 12. Click Insert. Click OK for after the current element. The nodes will be from 40 to 44. From here the line will travel back toward the pipe rack and then turn up. In the DZ field, Type: -1- <Enter>. Double Click Bend. The system will insert a long radius bend at the end of the line. 198 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Four Video Ten When we place the next element, this elbow will appear, turned up. 13. From here, we want to turn the line up so that we can get to the proper level and eventually connect out to node 120. Let's measure the distance up that we'll need. Click Distance. In the dialog box set it for node 44 to node 120. Click OK. The system returns a distance in Y of 7'11.813 inches. This is what we'll use as we turn out line up to the proper level. 14. Click Insert. Click OK for after the current element. The nodes will be 44 to 48. In the DY field, Type: 7-11.813 <Enter>. Double Click Bend. 199 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Four Video Ten From here the line will travel back to the pipe rack. 15. Click Insert. Click OK for after the current element. The nodes will be 48 to 52. I measured the distance earlier and it will be the distance back to the pipe rack. In the DZ field, Type: -3-10.875 <Enter>. Double click Restraints. Select a +Y Restraint for this node (this will represent the pipe rack). From here the line will travel back to where it lines up with node 120. 16. Click Distance. Set the nodes for 52 to 120. Click OK. The distance in Z is -2'4 5/8" Click OK to exit the dialog box. 200 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Four Video Ten 17. Click Insert. Click OK for after the current element. The nodes are 52 back to 56. In the DZ field, Type: -2-4.625 <Enter>. Double Click Bend. The system will place a long radius bend. 18. Click Distance. Set the nodes for 56 to 120. Click OK. The distance in X is 5' 7.004". 19. Click Insert. Click OK for after the current element. In the DX field, Type: 5-7.004 <Enter>. 201 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Four Video Ten Let's just verify this. Let's see if we're connected exactly or within a thousandth of an inch or so between node 60 and node 120. 20. Click Distance. Set the nodes to 60 and 120. Click OK. The system shows all zeros here in x, y and z fields. We can see there is a small value for the diagonal. Later we'll set node 120 to be node 60 and it will be exactly right. For now it's fine. So this would be a good point to save our file. 21. Click File. Click Save As. Type: EXPORT_REV_5 for the name and save it. Now you go ahead and recreate these steps and get your file built to here, and then we'll carry on after this. 202 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC CAESAR II® Fundamentals - Example Four Video 11 1. We're back in our model now, and what we want to do is finish it up. We could go about this several different ways. One way would be to just build the rest of these components again on the other side and get some more modeling practice. What we're going to do though for this example, is to select all these components we just modeled and use some editing tools in CAESAR II to Copy/Mirror them. 2. Click on the Select Group button. Click one point to for the corner of a window and hold down the mouse button and drag the mouse to capture these components. You'll see they all highlight. 203 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Four Video Eleven Click the Duplicate Elements button. Under options we'll click on the Mirror Y-Z button. Click the At End of Input button. Set the node increment to 300. Click OK. The system prompts for where we want to locate this new set of elements. It's defaulting to 0,0,0 for the position. Click OK for this. The system places the new set of elements at 0,0,0 in our model. Let's take a look at something. 3. Click on the List Input. Click Elements. The system displays an element list for us. 204 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Four Video Eleven We can see all the elements listed, along with their information. The nodes that we duplicated went from node 10 down to node 60. Then when we ran the command to duplicate that group and it produced the elements listed from 310 to 360. 205 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Four Video Eleven The system placed these nodes at the end of our model. We'll look at something later on how to go about renumbering these nodes. Close the Element List. To get our model connected like we would like, we'll change a node number in one of the new elements. 4. Click the element in the new group we just created that is from node 350 to 360. It is the last element in the group. 5. In the To Field, where it has 360, Type: 60 <Enter>. This will reposition the group we created over to connect to node 60, and we'll have a nice connection now. When you do this a time or two, it gets pretty easy to see how CAESAR II can be told to connect various parts of a model together. Next we'll renumber the nodes. 6. If we select the first element (starting with the flange on the first discharge line) and click Continue, we can see how the elements follow one after the other. The line continues as we modeled it, but it doesn't continue right around to the other discharge nozzle. It will continue from the first discharge nozzle down to node 60 then it will start traveling back and down the pipe rack. We want it eventually to go from the first discharge nozzle around and over to the second discharge nozzle. From there it will go to back to node 60 and travel down the pipe rack. To get the sequence direction right we first have to invert the node numbers on the copied leg we created with the mirror/copy command. 206 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Four Video Eleven 7. Click on the Select Group tool button. Window the group of elements we created with the mirror/copy command. If you hold down the Control Key you can select multiple windows as needed. Click the Invert button. This will reverse the order of the elements. Click on one of the elements we just reversed. Click the Next Element button and you will see how they sequence from one element to the next toward the end of the line on the second pump's discharge nozzle. 8. The next thing to do now is to have this group of elements we just reversed follow our first group (on the first pump's discharge nozzle). We want to progress through the model from the first discharge line up and around and over to the second pump's discharge nozzle. 9. Select the same group of elements we just reversed. Use the Control Key for more than one window if needed. Then what we want to do is tell this group to follow the element from node 56 to node 60. Click on the Change Sequence button. Select Follow. Click on the element from node 56 to node 60. The system will take a second or two, and the elements will be set to follow each other in the sequence we want. 207 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Four Video Eleven So let's just see if this worked. Zoom in to the first discharge line, and select an element. Click the Next Element button and sequence down the line. You should see the elements progress down the first discharge nozzle and around over to the second pump’s discharge nozzle. So great!. We got this working just like we want. Now all we need to do is get these nodes renumbered, so that they make sense and the model is better organized. Right now, as we progress through the elements, we go from node 10 to node 60, then from node 300 to node 360, then back to node 120. 10. Click the Up Arrow here by the List button. Click Elements. We'll get an element list. Select all the elements Click in the space by the 1 in the first element, then scroll down and hold down the Shift key, and click in the space near the number at the bottom of the list by the last element. The system will highlight the entire list. Right Click on the mouse. A pop up dialog box appears. Click Block Operation. Click Node A dialog box appears. 208 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Four Video Eleven Click the Renumber check box. Set the start node to 10. Set the Increment to 10. Click OK. Close the Element List. 11. Turn on the Node Numbers. We can see how they came out like we want. This procedure is very useful to clean up your model after you've modified it. 209 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Four Video Eleven 12. Click on the element where the discharge lines and the line going down to the pipe rack connect. This used to be nodes 56 to 60 before we renumbered them. In my model it is now the element from node 140 to 150. If we click on the element that branches off from it and starts traveling down the pipe rack we can see that's 300 to 310. 13. In the 300 field, Type: 150 <Enter>. This connects these exactly and there are no gaps in the model since every node is properly connected. 14. Zoom in around this connection we just worked on. Click on the element from node 140 to node 150. We have three lines intersecting here. Double Click SIFs and Tees. Select a Welding Tee for this node. Click on the Display Tees button to verify it's like we want. Click the Display Tees button again to turn that off. We covered a lot of ground in this lesson, and made use of some great CAESAR II editing commands. Get your model to here, then we'll run the analysis of this line and check our results! 210 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC CAESAR II® Fundamentals - Example Four Video 12 1. We're almost ready to run the analysis of this line. Out of curiosity, I decided to put another point in along one of the spans, in order to take a look at the deflection. Sometimes if you're running a steam line or some processes where you don't want to have some condensate gathering, you will want to add some additional data points just to get more information about it. 2. To do that, Select the element to break. Click the Break button. Insert a single node 345 after node 340. The distance is 120. The system requires the distance in inches in this dialog box, so for 10 feet, it's 120 inches. The system placed a new node at the midpoint of this span. This is optional. You don't have to do this. I just wanted to do it to check some things. 3. The other thing that happened in this model is when I first ran my error check I had some errors get listed. One error said that node 260 had been re-defined and did not to be done twice. The way I cleared them was to click on the element and delete the bend. Then I went to the next element and also deleted that bend. Then I ran the error check again. I knew the system would give me a message about a change of direction there, which it did. So all I had to do was come back and put the bends back into the elements as before, and everything worked fine. So I'm not quite sure what happened there on my system. You may or may not even get that same errors, but if you do, that's how I was able to fix it. 211 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Four Video 12 4. The Center of Gravity report is now fine. Click on the Running Man button. Click on the Operating Load Case. Click on the Nozzle Check. We can see now that it's within the allowed limits. 212 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Four Video 12 Now when you do these in real life, of course, you know if you're somewhere under 200%, it's possible to get the design approved if you do some more extensive analysis and coordinate things with the client and pump vendor. That analysis would happen back on the first input screens, where we have the API610 outboard processor that can be used to analyze a number of things. Also a number of engineering firms have standard pump installation details that show recommended line geometries for piping designers. These recommendations have evolved over the years and will generally produce good results when nozzle checks get run. But we benefited a lot from this exercise and were able to use a number of CAESAR II commands and features. So now, why don't you go ahead and run the analysis on your line, and then take a look at some of the other things here. Take a look at some of the loads on the restraints. Perhaps check out the stresses in this line. Just take a good look at it, because there are a lot of things yet that can be explored. All right, so now, at this point, we've completed our course materials. We've been able to get into CAESAR II and build 3D models using the input processor, assign restraints, set up bends and Ts, add valves and flanges, and we were able to analyze our results. 213 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Four Video 12 We checked our model for consistency and ran the analysis, and we've been able to view reports, and understand how to make custom reports. We've explored the different display options for both the input screen and the plotted results. We designed a hanger and included a wind load in one of the models. 214 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Four Video 12 We worked with a model that had different temperatures and pressures in its branches. We saw how to take an imported 3D CAD model and analyze it and modify it as needed. We explored how changing the geometry of a line can increase its flexibility, and how modifying a line always involves trade-offs. 215 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC PipingDesignOnline.com CAESAR II Example Four Video 12 We also modeled a dummy leg for a line, learned some great CAESAR II editing tools, and worked with the nozzle limit check features in the software. So we covered a lot of territory in this course. The goal was just to get you to a point where you could navigate the software, and get a fundamental understanding of how to use the software. So thank you so much for taking the course. I hope you enjoyed it half as much as I did putting it together. Congratulations for seeing this through. and I look forward to seeing you in the future as we add additional training materials for CAESAR II! Anthony W. Horn PipingDesignOnline.com admin@pipingdesignonline.com 216 Copyright© 2014 All Rights Reserved CAD Training Technologies, LLC ASME B31.3-2008 APPENDIX S PIPING SYSTEM STRESS ANALYSIS EXAMPLES INTRODUCTION Fig. S301.1 Simple Code Compliant Model The example in this Appendix is intended to illustrate the application of the rules and definitions in Chapter II, Part 5, Flexibility and Support; and the stress limits of para. 302.3.5. The loadings and conditions necessary to comply with the intent of the Code are presented. 10 20 50 12.2 m 3.05 m 9.15 m (40 ft) (10 ft) (30 ft) 40 45 Y S300.1 Definitions and Nomenclature Z global axes: These are Cartesian X, Y, and Z axes. In this Appendix, vertically upward is taken to be the +Y direction with gravity acting in the −Y direction. X 15 6.10 m (20 ft) S300 30 Asf : cross-sectional area of the conveyed fluid, considering nominal pipe thickness less allowances Asp : cross-sectional area of the pipe, considering nominal pipe thickness less allowances Fsa : sustained axial force including the effects of weight, other sustained loads, and internal pressure is,i : in-plane sustained stress index ≥ 1.00 (The stress index equals 0.75i i for all components included in Appendix D in the absence of more applicable data and in accordance with para. 319.3.6.) is,o : out-plane sustained stress index ≥ 1.00 (The stress index equals 0.75i o for all components included in Appendix D in the absence of more applicable data and in accordance with para. 319.3.6.) Ms,i : in-plane bending moment for the sustained condition being evaluated Ms,o : out-plane bending moment for the sustained condition being evaluated Mst : torsional moment for the sustained condition being evaluated Pj : piping internal pressure; see para. 301.2; when more than one condition exists for the piping system, each is subscripted (e.g., P1, P2, …) Ssa : stress due to the sustained axial force summation, Fsa /Asp S sb : stress due to the indexed sustained bending moments’ vector summation Sst : stress due to sustained torsional moment Tj : pipe maximum or minimum metal temperature; see paras. 301.3 and 319.3.1(a); when more than one condition exists for the piping system, each is subscripted (e.g., T1, T2, …) Y+: a “single acting support” that provides support in only the vertically upward direction and is considered to be “active” when the pipe exerts a downward force on the support. The pipe is free to move upward, i.e., the pipe “lifts off” the support; the support in the “liftoff” situation is considered to be “removed” from providing support, i.e., inactive, during the load condition considered. S301 EXAMPLE 1: CODE COMPLIANT PIPING SYSTEM S301.1 Example Description This example is intended to illustrate the design of an adequately supported and sufficiently flexible piping system. The piping system in Fig. S301.1 is fabricated from ASTM A 106 Grade B seamless pipe (i.e., E p 1.00); the pipe is DN 400 (NPS 16) with a nominal wall thickness of 9.53 mm (0.375 in.), 127 mm (5 in.) thickness of calcium silicate insulation, and 1.59 mm (0.063 in.) corrosion allowance; the fluid has a specific gravity of 1.0. The equivalent number of cycles expected for the piping system is fewer than 7 000 [i.e., f p 1.00 in accordance with para. 302.3.5(d)]. The piping system is in normal fluid service. The installation temperature is 21°C (70°F). The reference modulus of elasticity used for the piping analysis is 203.4 GPa (29.5 Msi) from Appendix C, Table C-6 in accordance with paras. 319.3.2 and 319.4.4, and Poisson’s ratio is 0.3 in accordance with para. 319.3.3. The piping internal pressure, maximum and minimum metal temperatures expected during normal operation, and the design conditions are listed in 217 ASME B31.3-2008 Table S301.1 Temperature/Pressure Combinations Conditions Table S301.3.1 Generic Pipe Stress Model Input Term Pressure Temperature Design conditions 3 795 kPa (550 psi) 288°C (550°F) Operating (P1,T1) maximum metal temperature 3 450 kPa (500 psi) 260°C (500°F) Operating (P2,T2) minimum metal temperature 0 kPa (0 psi) −1°C (30°F) Installation temperature 0 kPa (0 psi) 21°C (70°F) Table S301.1. The design conditions are set sufficiently in excess of the operating conditions so as to provide additional margin on the allowable stress for pressure design as required by the owner. Operating conditions: internal pressure, P1 maximum metal temp., T1 minimum metal temp., T2 installation temperature Value 3 450 kPa (500 psi) 260°C (500°F) −1°C (30°F) 21°C (70°F) Line size Pipe DN 400 (NPS 16) Schedule 30/STD, 9.53 mm (0.375 in.) Mechanical allowance, c Mill tolerance Elbows Fluid specific gravity 1.59 mm (0.063 in.) 12.5% Long radius 1.0 Insulation thickness Insulation density 127 mm (5 in.) 176 kg/m3 (11.0 lbm/ft3) Pipe material Pipe density Total weight Unit weight ASTM A 106 Grade B 7 833.4 kg/m3 (0.283 lbm/in.3) 7 439 kg (16,400 lbm) 248.3 kg/m (166.9 lbm/ft) S301.2 Design Conditions The design conditions establish the pressure rating, flange ratings, component ratings, and minimum required pipe wall thickness in accordance with para. 301.2.1. For example, ASME B16.5 requires a minimum of Class 300 for ASTM A 105 flanges. Also, the minimum required pipe wall thickness, tm , is determined from the design conditions by inserting eq. (3a) into eq. (2); terms are defined in para. 304.1.1 and Appendix J: E p 1.0 P p design pressure p 3 795 kPa (550 psi) S p allowable stress from Appendix A, Table A-1 p 125 MPa (18.1 ksi) at design temperature 288°C (550°F) Y p 0.4 from Table 304.1.1 Insert eq. (3a) into eq. (2): tm p t + c p p T, from nominal pipe wall thickness, T, considering a mill tolerance of 12.5%. Select DN 400 (NPS 16) Schedule 30/STD nominal wall thickness from ASME B36.10M: T p 9.53 mm (0.375 in.) T p (9.53 mm)(1.00 − 0.125) p 8.34 mm (0.328 in.) Since T ≥ tm (i.e., 8.34 mm > 7.69 mm), the selection of the nominal pipe wall thickness, T, for Schedule 30/STD pipe is acceptable. The long radius elbows specified for this piping system are in accordance with ASME B16.9 and are specified to be for use with Schedule 30/STD wall thickness pipe. S301.3 Computer Model Input PD +c 2(SE + PY) (3795 kPa)(406.4 mm) + 1.59 mm 2[(125 MPa)(1.00) + (3795 kPa)(0.4)] p 6.10 mm + 1.59 mm p 7.69 mm (0.303 in.) In accordance with para. 304.1.2(a), t must be less than D/6 for eq. (3a) to be appropriate without considering additional factors to compute the pressure design thickness, t (i.e., t < D/6, or 7.69 mm < 406.4 mm/6). Since 7.69 mm (0.303 in.) < 67.7 mm (2.67 in.), eq. (3a) is applicable without special consideration of factors listed in para. 304.1.2(b). Now select a pipe schedule of adequate thickness. Determine the specified minimum pipe wall thickness, 218 Tables S301.3.1 and S301.3.2 list the “node numbers,” lengths, etc., for each piping element displayed in Fig. S301.1. A bend radius of 1.5 times the nominal pipe diameter [i.e., 609.6 mm (24 in.)] and nominal wall thickness of 9.53 mm (0.375 in.) are used for the elbows in the computer model. Generic computer program option “flags” are as follows: (a) include pressure stiffening on elbows (b) exclude pressure thrust and Bourdon effects (c) use nominal section properties for both the stiffness matrix and the displacement stress analysis (d) use “nominal less allowances” section properties for sustained stress, SL (e) include axial load and internal pressure force in the sustained stress, SL ASME B31.3-2008 Table S301.3.2 Element Connectivity, Type, and Lengths From To DX, m (ft) DY, m (ft) 10 15 6.10 (20) ... 10 anchor 15 bisection node 15 20 6.10 (20) ... 20 Y support 20 30 3.05 (10) ... Three-node elbow [Note (1)] 30 40 ... 6.10 (20) Three-node elbow [Note (1)] 40 45 3.05 (10) ... Informational node 45 50 6.10 (20) ... 50 anchor Element Type GENERAL NOTE: This piping system is planar, i.e., DZ p 0 m (ft) for each piping element. NOTE: (1) The specified element lengths are measured to and/or from each elbow’s tangent intersection point. (f) intensify the elbows’ in-plane bending moments1 by 0.75ii (≥ 1.0) in the calculation of the elbows’ effective sustained longitudinal stress, SL S301.4 Pressure Effects For the operating, sustained, and displacement stress range load cases, the effect of pressure stiffening on the elbows is included to determine the end reactions in accordance with Appendix D, Note (7). The effects of pressure-induced elongation and Bourdon effects are not included, as both are deemed negligible for this particular example. S301.5 The Operating Load Case The operating load case is used to determine the operating position of the piping and reaction loads for any attached equipment, anchors, supports, guides, or stops. The operating load case is based on the temperature range from the installation temperature of 21°C (70°F) to the maximum operating metal temperature of 260°C (500°F), in accordance with para. 319.3.1(b). The operating load case in this example also includes the effects of internal pressure, pipe weight, insulation weight, and fluid weight on the piping system. Both pipe stiffness and stress are based on the nominal thickness of the pipe. Pipe deflections and internal reaction loads for the operating load case are listed in Table S301.5.1. Piping loads acting on the anchors and support structure are listed in Table S301.5.2. S301.6 The Sustained Load Case Sustained stresses due to the axial force, internal pressure, and intensified bending moment in this example 1 ASME B31.3 does not address the issue of using a stress intensification factor as the stress index to be applied to piping components for sustained loads; stress intensification factors are based on fatigue test results. Establishing the proper index is the responsibility of the designer. This example uses 0.75 times the stress intensification factor for the sustained case. are combined to determine the sustained longitudinal stress, S L . The sustained load case excludes thermal effects and includes the effects of internal pressure [P1 p 3450 kPa (500 psi)], pipe weight, insulation weight, and fluid weight on the piping system. Nominal section properties are used to generate the stiffness matrix and sustained loads for the computer model in accordance with para. 319.3.5. The nominal thickness, less allowances, is used to calculate the section properties for the sustained stress, SL, in accordance with para. 302.3.5(c). A summary of the sustained load case internal reaction forces, moments, and sustained stresses, SL, is provided in Table S301.6. Since this example model lies in only one plane, only the sustained bending stress due to the in-plane bending moment is not zero. The inplane bending moment is intensified1 at each elbow by the appropriate index 0.75ii (≥ 1.0), where ii is the inplane stress intensification factor from Appendix D for an unflanged elbow. Note that sustained stresses for the nodes listed in Table S301.6 do not exceed the 130 MPa (18,900 psi) sustained allowable stress, Sh , for A 106 Grade B piping at the maximum metal temperature, T1 p 260°C (500°F), from Appendix A, Table A-1. By limiting SL to the sustained allowable, Sh, the piping system is deemed adequately protected against collapse. S301.7 The Displacement Stress Range Load Case The displacement stress range, SE, in this example is based on the temperature range from the installation [21°C (70°F)] to minimum metal temperature [T2 p −1°C (30°F)] and from the installation [21°C (70°F)] to maximum metal temperature for the thermal cycles under analysis [T1 p 260°C (500°F)], in accordance with para. 319.3.1(a). The displacement stress range, SE, for each element is calculated in accordance with eq. (17) and is listed in Table S301.7, along with the internal reaction loads. Nominal section properties are used to generate 219 ASME B31.3-2008 Table S301.5.1 Operating Load Case Results: Internal Loads and Deflections Node Number Axial Force, N (lb) (Signed) [Note (1)] Bending Moment, N-m (ft-lb) (Unsigned) [Note (1)] Horizontal Deflection, mm (in.) [Note (1)] Vertical Deflection, mm (in.) [Note (1)] 10 15 20 30 near 30 mid 30 far +26 500 (+5,960) −26 500 (−5,960) −26 500 (−5,960) −26 500 (−5,960) −46 300 (−10,410) −37 800 (−8,500) 21 520 (15,870) 10 710 (7,900) 47 560 (35,080) 57 530 (42,440) 69 860 (51,530) 65 320 (48,180) 0.00 18.3 (0.72) 36.7 (1.44) 44.0 (1.73) 44.7 (1.76) 41.4 (1.63) 0.00 −1.3 (−0.05) 0.00 −3.7 (−0.14) −2.3 (−0.09) 0.4 (0.02) 40 near 40 mid 40 far 45 50 −25 920 (−5,830) −36 250 (−8,150) −26 500 (−5,960) −26 500 (−5,960) −26 500 (−5,960) 63 930 (47,160) 70 860 (52,270) 65 190 (48,080) 14 900 (10,990) 47 480 (35,030) −23.0 (−0.91) −26.4 (−1.04) −25.7 (−1.01) −18.3 (−0.72) 0.00 15.1 (0.59) 17.8 (0.70) 19.2 (0.75) 13.5 (0.53) 0.00 NOTE: (1) Loads and deflections are averaged from commercial programs with a variance within units’ conversion tolerance. Table S301.5.2 Operating Load Case Results: Reaction Loads on Supports and Anchors Global Axis Forces and Moments Node FX, N (lb) (Signed) [Note (1)] FY, N (lb) (Signed) [Note (1)] MZ, N-m (ft-lb) (Unsigned) [Note (1)] 10 anchor 20 support 50 anchor −26 500 (−5,960) ... +26 500 (+5,960) −12 710 (−2,860) −63 050 (−14,180) +2 810 (+630) 21 520 (15,870) ... 47 480 (35,030) NOTE: (1) Loads and deflections are averaged from commercial programs with a variance within units’ conversion tolerance. Table S301.6 Sustained Forces and Stresses [Allowable, Sh p 130 MPa (18,900 psi)] Node Axial Force, N (lb) (Signed) [Note (1)] Bending Moment, N-m (ft-lb) (Unsigned) [Note (1)] Sustained Stress, SL, kPa (psi) [Note (2)] 10 anchor 20 support 30 far 40 far 50 anchor +3 270 (+735) −3 270 (−735) −19 880 (−4,470) +3 270 (+735) +3 270 (+735) 17 260 (12,730) 56 130 (41,400) 16 320 (12,040) 2 340 (1,730) 37 860 (27,930) 59 100 (8,560) 99 200 (14,370) 72 700 (10,540) 46 050 (6,680) 80 350 (11,650) NOTES: (1) Loads, deflections, and stresses are averaged from commercial programs with a variance within units’ conversion tolerance. (2) Axial forces have their sign retained and do not include the signed axial pressure force, which is also included in the sustained stress, SL. 220 ASME B31.3-2008 Table S301.7 Displacement Stress Range [SA p 205 MPa (29,725 psi)] Global Axis Forces and Moments Node FX, N (lb) (Unsigned) [Note (1)] FY, N (lb) (Unsigned) [Note (1)] MZ, N-m (ft-lb) (Unsigned) [Note (1)] SE From Eq. (17), kPa (psi) [Note (1)] 10 anchor 20 support 30 mid 40 mid 50 anchor 25 070 (5,640) 25 070 (5,640) 25 070 (5,640) 25 070 (5,640) 25 070 (5,640) 1 130 (260) 1 130 (260) 19 330 (4,350) 19 330 (4,350) 19 330 (4,350) 4 600 (3,390) 9 250 (6,820) 60 250 (44,440) 76 740 (56,600) 92 110 (67,940) 4 000 (580) 8 040 (1,170) 137 000 (19,870) 174 500 (25,300) 79 900 (11,600) NOTE: (1) Loads, deflections, and stresses are averaged from commercial programs with a variance within units’ conversion tolerance. the stiffness matrix and displacement stress in the piping in accordance with para. 319.3.5. Since this example model lies in only one plane, only the in-plane bending moment is not zero. The in-plane moment is intensified at each elbow by the appropriate Appendix D stress intensification factor, ii, for an unflanged elbow. For simplicity, the allowable displacement stress range, S A , is calculated in accordance with eq. (1a). Though eq. (1a) is used in this example, it is also acceptable to calculate SA in accordance with eq. (1b), which permits SA to exceed the eq. (1a) value for each piping element, based on the magnitude of each element’s sustained stress, SL. The following terms are as defined in para. 302.3.5(d) and Appendix J: f p 1.00 for ≤ 7 000 equivalent cycles, from Fig. 302.3.5 or eq. (1c) SA p f (1.25Sc + 0.25Sh) p (1.00)[(1.25)(138 MPa) + (0.25)(130 MPa)] p 205 MPa (29,725 psi) Sc p allowable stress from Appendix A, Table A-1 p 138 MPa (20.0 ksi) at T2 Sh p allowable stress from Appendix A, Table A-1 p 130 MPa (18.9 ksi) at T1 T1 p maximum metal temperature p 260°C (500°F) T2 p minimum metal temperature p −1°C (30°F) Note that each piping element’s displacement stress range, based on minimum to maximum metal temperature for the thermal cycles under analysis, SE, does not exceed the eq. (1a) allowable, SA. By limiting SE to SA, the piping system is deemed adequate to accommodate up to 7 000 full excursion equivalent cycles. Considering both the sustained and displacement stress range load cases, the piping system is compliant with the requirements of the Code; redesign of the piping system is not required unless the sustained or operating reaction loads at either anchor data point 10 or 50 exceed Fig. S302.1 Lift-Off Model 12.2 m (40 ft) 3.05 9.15 m m (30 ft) (10 ft) 9.15 m (30 ft) 3.05 m (10 ft) 12.2 m (40 ft) 50 Y X 145 40 6.1 m (20 ft) 10 15 20 30 130 120 115 110 the allowable loads for the attached equipment nozzle or the support structure at node 20 is overloaded. The nozzle load and support structure analyses are beyond the scope of this Appendix and are not addressed. S302 EXAMPLE 2: ANTICIPATED SUSTAINED CONDITIONS CONSIDERING PIPE LIFT-OFF S302.1 Example Description This example is intended to illustrate the analysis of a piping system in which a portion of the piping lifts off at least one Y+ support in at least one operating condition. The emphasis of this example is to describe the effect this removal of support has on the determination of anticipated sustained conditions. The same principles utilized for this example would also apply for guides and stops (that are single directional or gap-type) that are not engaged during any anticipated operating condition. The examples in this Appendix are intended for illustration purposes only and are not intended to portray the same as either adequate or even acceptable piping geometries and/or support scenarios. The piping system in Fig. S302.1 is the same in material and dimensional properties as in Example 1; see para. S301.1. Note 221 (08) ASME B31.3-2008 Table S302.1 Temperature/Pressure Combinations Conditions Design conditions Operating (P1, T1) maximum metal temperature (Operating Case 1) Operating (P2, T2) minimum metal temperature (Operating Case 2) Installation temperature S302.4 Pressure Effects The pressure effect considerations are the same as those for Example 1; see para. 301.4. Pressure Temperature 3 968 kPa (575 psi) 3 795 kPa (550 psi) 302°C (575°F) S302.5 The Operating Load Case 288°C (550°F) 0 kPa (0 psi) −1°C (30°F) ... 21°C (70°F) The operating condition evaluated and discussed in this example, Operating Case 1, includes the effects of pipe weight, insulation weight, fluid weight, internal pressure [P1 p 3 795 kPa (550 psi)], and temperature [T1 p 288°C (550°F)]. An operating load case is evaluated to determine the operating position of the piping and determine the reaction loads for any attached equipment, anchors, supports, guides, or stops. In particular, each operating load case’s support scenario is evaluated or assessed by the designer in order to determine whether any anticipated sustained conditions need to be evaluated with one or more Y+ supports removed. Further operating load case discussion can be found in para. S301.5. Piping loads acting on the anchors and support structure for Operating Case 1 are listed in Table S302.5.1. Note that only nodes 10 through 50 are listed in the following tables; this is both for convenience, since the model is symmetric, and for comparison to Example 1, e.g., the loads, deflections, and stresses for nodes 10 through 40 are the same as for nodes 110 through 140 except that some signs may be reversed. that both the design and operating conditions are well below the creep regime; therefore, the piping system will not develop any permanent creep-related displacements, relaxation, or sag. S302.2 Design Conditions The design conditions are similar to those in the Example 1 model; see para. S301.2 and Table S302.1. Note that the minimum thickness remains unchanged from Example 1 even though the design conditions have increased slightly. The hydrotest pressure does increase from 6 039 kPa (875 psi) to 6 729 kPa (975 psi). S302.3 Computer Model Input Table S302.3 lists the node numbers, lengths, etc., for each piping component that is displayed in Fig. S302.1. The computer-based options are the same as those for the Example 1 model; see para. S301.3. S302.6 Sustained Conditions S302.6.1 The Sustained Stress, SL, Calculations. The designer has elected to calculate the stresses based on the following sustained loads in order to determine Table S302.3 Generic Pipe Stress Model Input: Component Connectivity, Type, and Lengths From To DX , m (ft) DY , m (ft) Component Type 10 15 6.10 (20) ... 15 20 20 30 6.10 (20) 3.05 (10) ... ... 10 anchor 15 informational node 20 Y support Three node elbow [Note (1)] 30 40 45 40 45 50 ... 3.05 (10) 6.10 (20) 6.10 (20) ... ... Three node elbow [Note (1)] Informational node 50 Y+ support 110 115 −6.10 (−20) ... 115 120 120 130 −6.10 (−20) −3.05 (−10) ... ... 110 anchor 115 informational node 120 Y support Three node elbow [Note (1)] 130 140 145 140 145 50 ... −3.05 (−10) −6.10 (−20) 6.10 (20) ... ... Three node elbow [Note (1)] Informational node ... NOTE: (1) The specified component lengths are measured to and/or from each elbow’s tangent intersection point. 222 (08) ASME B31.3-2008 Table S302.5.1 Results for Operating Case 1: Reaction Loads on Support and Anchors Node Fx , N (lb) (Signed) [Note (1)] Fy , N (lb) (Signed) [Note (1)] Mz , N-m (ft-lb) (Unsigned) [Note (1)] 10 anchor 20 support 50 Y+ −26 600 (−5,975) ... ... −14 050 (−3,150) −58 900 (−13,250) 0 [Note (2)] 27 000 (19,900) ... ... NOTES: (1) Loads and deflections are averaged from commercial programs with a variance within units’ convergence tolerances. Magnitudes of loads for nodes 10 and 20 are the same for 110 and 120, but may differ in sign. (2) No support is provided at the node 50 Y+ restraint for Operating Case 1. the sustained stress, SL, for each sustained condition that is evaluated; see para. S302.6.2: (a) the absolute value of the sustained axial mechanical and pressure force summation (b) the vector summation of indexed sustained bending moments (c) the sustained torsional moment The sustained stress, SL, is computed in the manner described in Example 1 and illustrated in eqs. (S1), (S2), and (S3). Terms not defined below are described in para. 319.4.4, Appendix J, and para. S300.1. SL p 冪(|Ssa | + Ssb)2 + 4Sst2 (S1) where Ssa p stress due to sustained axial force for the sustained condition being evaluated p Fsa/Asp Asp p cross-sectional area of the pipe, considering nominal pipe thickness less allowances Fsa p sustained axial force, which includes both the sustained axial mechanical force and the longitudinal pressure force for the sustained condition being evaluated The longitudinal pressure force is Pj ⴛ Asf for piping systems that contain no expansion joints, where Asf p cross-sectional area of the conveyed fluid considering nominal pipe thickness less allowances p d2/4 d p pipe inside diameter considering pipe wall thickness less allowances NOTE: For piping systems with expansion joints, it is the responsibility of the designer to determine the axial force due to the longitudinal pressure in the piping system. Ssb p where 冪(is,i Ms,i)2 + (is,o Ms,o)2 Z (S2) is,i p sustained in-plane stress index ≥ 1.00 is,o p sustained out-plane stress index ≥ 1.00 Ms,i p sustained in-plane bending moment for the sustained condition being evaluated Ms,o p sustained out-plane bending moment for the sustained condition being evaluated NOTE: The stress index equals 0.75ix (where x p o or i) for all components included in Appendix D in the absence of more applicable data and in accordance with para. 319.3.6. Sst p Mst/2Z (S3) where Mst p torsional moment for the sustained condition being evaluated S302.6.2 Anticipated Sustained Conditions. All anticipated sustained conditions utilizing all possible support scenarios should be considered. The designer has identified four anticipated sustained conditions for this piping system; each is listed in Table S302.6.2.1, along with the support status of the node 50 Y+ support, as either assessed by analysis or determined by the designer. The designer has deemed the Sustained Condition 3 as both controlling the sustained design and requiring evaluation. (08) S302.6.3 Results for the Evaluated Sustained Condition. The Sustained Condition 3 reflects the support scenario of the Operating Case 1, excludes thermal effects, and includes the effects of internal pressure [P1 p 3 795 kPa (550 psi)], pipe weight, insulation weight, and fluid weight on the piping system. A summary of the Sustained Condition 3 internal reaction forces, moments, and sustained stresses, SL, appears in Table S302.6.3.1. See para. S301.6 for additional information concerning the sustained stress determination. S302.7 Displacement Stress Range Load Cases The displacement stress range load cases are not listed, since they are not the subject of this example. 223 (08) ASME B31.3-2008 Table S302.6.2.1 Sustained Load Condition Listing 1: 2: 3: 4: Sustained Condition Node 50’s Support Status (Active/Removed) As installed [Note (1)] P1 [Note (2)] P1 [Note (2)] P2 [Note (2)] Active Active Inactive Active NOTES: (1) The original (as-installed) condition considers only pipe weight and insulation weight without fluid contents or internal pressure. (2) The Sustained Conditions reflect the support scenario of the related Operating Conditions, exclude thermal effects, and include the effects of the related internal pressure, pipe weight, insulation weight, and fluid weight on the piping system. Table S302.6.3.1 Sustained Forces and Stresses for Sustained Condition 3 With Node 50 Support Removed [Allowable Sh p 124.5 MPa (18,100 psi) ): Fails] Global Axis Forces and Moments [Note (1)] Node Fx , N (lb) (Signed) [Note (2)] Fy , N (lb) (Signed) [Note (2)] Mz , N-m (ft-lb) (Unsigned) Sustained SL , kPa (psi) [Notes (2), (3)] 10 anchor 20 support 30 far 40 mid 50 Y+ 12 575 (2,825) 12 575 (2,825) 12 575 (2,825) 12 575 (2,825) 12 575 (2,825) 8 385 (1,885) 64 565 (14,515) 34 985 (7,865) 21 950 (4,935) 0 [Note (4)] 3 995 (2,945) 82 845 (61,095) 29 985 (22,115) 32 770 (24,165) 62 885 (46,375) 48 645 (7,055) 129 975 (18,850) 101 920 (14,780) 108 525 (15,740) 109 385 (15,865) NOTES: (1) Loads and deflections are averaged from commercial programs with a variance within units’ convergence tolerance. The magnitude of loads and stresses for nodes 10 through 40 are the same for 110 and 140, though the loads may differ in sign. (2) Forces have their sign retained, but do not include the signed axial pressure force necessary to compute the axial stress, which is included in the sustained stress, SL. (3) Stress may differ by slightly more than units’ conversion tolerance. (4) No support is provided at the node 50 Y+ restraint for Sustained Condition 3. (08) S302.8 Code Compliance: Satisfying the Intent of the Code The Sustained Condition 3 results indicate that the piping system is not protected against collapse for the cycles under analysis when considering the Operating Case 1. Therefore, redesign of the piping system is required. If the piping system is redesigned such that it is compliant with the intent of the Code, then the piping system would require no further attention unless the sustained, hydrotest, or operating reaction loads at either anchor data point 10 or 110 exceed the allowable loads for the attached equipment nozzle, or the support structure at either node 20 or 120 is overloaded. The nozzle loads and support structure analyses are beyond the scope 224 of this Appendix and are not addressed. Although the occasional load cases are important to the design and analysis of a piping system, they are not discussed in this example. S303 EXAMPLE 3: MOMENT REVERSAL S303.1 Example Description This example is intended to illustrate the flexibility analysis required for a piping system that is designed for more than one operating condition and also experiences a “reversal of moments” between any two of the anticipated operating conditions. The examples in this Appendix are intended for illustration purposes only and are not intended to portray the same as either ASME B31.3-2008 Fig. S303.1 Moment Reversal Model 1.52 m (5 ft) 1.52 m (5 ft) 1.52 m (5 ft) 1.52 m (5 ft) 1.52 m (5 ft) 45 40 345 110 10 8 890 N 120 (2,000 lb) 130 (typical) 140 20 Pipe anchor 30 0.76 m (2.5 ft) 340 310 1.52 m (5 ft) Pipe anchor but free in X 1.52 m (5 ft) North 320 210 220 230 240 Pipe 35 support (typical) adequate or even acceptable piping geometries and/ or support scenarios. Both the design and operating conditions are well below the creep regime. The piping system in Fig. S303.1 consists of two headers and two branches, which are referred to as gas “meter runs.” Only one of the branches is in service (operating) at a given time; the out-of-service branch is purged and at ambient condition. The design specification calls for each of the meter run branches to alternate in and out of service once per week for the piping system’s planned 20-year service life, i.e., f p 1.20 in accordance with para. 302.3.5(d). The piping system is fabricated from ASTM A 53 Grade B pipe (E p 1.00), both piping headers are DN 600 (NPS 24) and the branches are DN 500 (NPS 20), and both branch and header are 9.53 mm (0.375 in.) thick. For simplicity, each piping segment or component is 1.524 m (5 ft) in length. The piping system is in normal fluid service. The fluid is gaseous; is considered to add no weight; and to be neither a corrosive nor an erosive hazard, i.e., there is no corrosion allowance. The line is not insulated. The installation temperature is 4.5°C (40°F). The reference modulus of elasticity used is 203.4 GPa (29.5 Msi) and Poisson’s ratio is 0.3. Consideration is given to the close proximity of the three tees in each header in accordance with the guidance in para. 319.3.6, and the stress intensification factors from Appendix D are considered to adequately represent the header tees for this piping system. The piping internal pressure, and minimum and maximum metal temperatures, expected during normal operation for each meter run and the design conditions, are listed in Table S303.1. The design conditions are set sufficiently in excess of the operating conditions so as to provide additional margin on the allowable as required by the owner. S303.2 Design Conditions The design conditions establish the pressure rating, flange ratings, components ratings, and minimum 330 X 335 Z 0.76 m (2.5 ft) required pipe wall thickness. ASME B16.5 requires a minimum of Class 300 for ASTM A 105 flanges. The minimum required wall thickness for both the branch and header is 4.4 mm (0.171 in.), considering a 12.5% mill tolerance; therefore, selection of the standard wall thickness of 9.5 mm (0.375 in.) is acceptable. S303.3 Computer Model Input Table S303.3 lists the node numbers, lengths, etc., for each piping component that is displayed in Fig. S303.1. Note that flanges and valve components are not explicitly included in the model listing in Table S303.3. For simplicity, an entire branch (from tee centerline to tee centerline) is considered to be at the operating conditions listed in Table S303.1, e.g., the East meter run branch from nodes 40 through 340 operates at 1 724 kPa (250 psi) and 121°C (250°F) for Operating Case 2. The computer-based options are the same as those for the Example 1 model, except that pressure stiffening is not included in the analyses for this example; see para. S301.3. S303.4 Pressure Effects Neither pressure stiffening nor Bourdon effects are included in the analyses. S303.5 Operating Load Case(s) The operating load case is used to determine the operating position of the piping and reaction loads for any attached equipment, anchors, supports, guides, or stops. The owner has mandated in the design specification that the meter runs and piping be more than adequately supported. Therefore, the operating load case, while necessary to set the limits of the strain ranges, does not contribute to the emphasis of this example, and its output is not included. 225 ASME B31.3-2008 Table S303.1 Pressure/Temperature Combinations Header(s) Condition Design Operating Case 1 [Note (1)] Operating Case 2 [Note (2)] Installation temperature West Branch East Branch Pressure Temperature Pressure Temperature Pressure Temperature 2 069 kPa (300 psi) 1 724 kPa (250 psi) 149°C (300°F) 121°C (250°F) 2 069 kPa (300 psi) 1 724 kPa (250 psi) 149°C (300°F) 121°C (250°F) 2 069 kPa (300 psi) 0 kPa (0 psi) 149°C (300°F) 4.5°C (40°F) 1 724 kPa (250 psi) ... 121°C (250°F) 4.5°C (40°F) 0 kPa (0 psi) ... 4.5°C (40°F) 4.5°C (40°F) 1 724 kPa (250 psi) ... 121°C (250°F) 4.5°C (40°F) GENERAL NOTE: For computer based temperature and pressure data input, consider the West Branch temperature and pressure to be in effect from nodes 30 through 330 as listed in Table S303.3. Likewise, consider the East Branch temperature and pressure to be in effect from nodes 40 through 340 as listed in Table S303.3; see para. S303.3. NOTES: (1) East Branch is at ambient conditions. (2) West Branch is at ambient conditions. Table S303.3 Generic Pipe Stress Model Input: Component Connectivity, Type, and Lengths From To DX , m (ft) DZ , m (ft) Component Type 10 20 1.52 (5) ... 30 35 40 45 ... ... ... ... 1.52 (5) 0.76 (2.5) −1.52 (−5) −0.76 (−2.5) 10 anchor (DN 600 Header) 20 welding tee 30 welding tee 35 simulated end cap 40 welding tee 45 end cap 20 30 20 40 40 110 1.52 (5) ... 110 120 130 140 120 130 140 340 1.52 1.52 1.52 1.52 (5) (5) (5) (5) ... ... ... ... 30 210 1.52 (5) ... 210 220 230 240 220 230 240 330 1.52 1.52 1.52 1.52 (5) (5) (5) (5) ... ... ... ... 310 320 −1.52 (−5) ... 320 330 320 340 330 335 340 345 ... ... ... ... 1.52 (5) 0.76 (2.5) −1.52 (−5) −0.76 (−2.5) GENERAL NOTE: (East DN 500 Branch) 110 Y support 120 pipe segment 8 890 N (2,000 lb) meter 140 pipe segment 340 welding tee (West DN 500 Branch) 210 Y support 220 pipe segment 8 890 N (2,000 lb) meter 240 pipe segment 330 welding tee (DN 600 Header) 310 anchor [free in the X (axial) direction] 320 welding tee 330 welding tee 335 end cap 340 welding tee 345 end cap This piping system is planar, i.e., DY p 0 m (0 ft) for each piping component. 226 ASME B31.3-2008 Table S303.7.1 Case 1: Displacement Stress Range [Eq. (1a) Allowable SA p 248.2 MPa (36 ksi): Passes] Global Axis Forces and Moments Node Fx , N (lb) (Signed) [Note (1)] My , N-m (ft-lb) (Signed) [Note (1)] Eq. (17) SE , kPa (psi) [Note (2)] 10 anchor 20 tee 30 tee 40 tee 0 0 −78 485 (−17,645) 78 485 (17,645) 147 470 (108,755) −147 470 (−108,755) 45 900 (33,850) 45 900 (33,850) 55 610 (8,065) 189 945 (27,550) 84 360 (12,235) 84 360 (12,235) 110 Y 120 130 meter 140 Y 78 485 78 485 78 485 78 485 (17,645) (17,645) (17,645) (17,645) 45 900 45 900 45 900 45 900 (33,850) (33,850) (33,850) (33,850) 25 155 25 155 25 155 25 155 340 tee 210 Y 220 230 meter 78 485 (17,645) −78 485 (−17,645) −78 485 (−17,645) −78 485 (−17,645) 45 900 45 900 45 900 45 900 (33,850) (33,850) (33,850) (33,850) 84 360 (12,235) 25 155 (3,650) 25 155 (3,650) 25 155 (3,650) 240 Y 330 tee 310 anchor 320 tee −78 485 (−17,645) −78 485 (−17,645) 0 0 45 900 (33,850) 45 900 (33,850) −147 470 (−108,755) 147 470 (108,755) 25 155 (3,650) 84 360 (12,235) 55 610 (8,065) 189 945 (27,550) (3,650) (3,650) (3,650) (3,650) NOTES: (1) Loads are averaged from commercial programs and are directly affected by the stiffness chosen for valves, flanges, and other relatively stiff components. (2) Stress may differ by slightly more than units’ conversion tolerance. S303.6 Sustained Load Case Sustained stresses due to the axial force, internal pressure, and intensified bending moment in this example are combined to determine the sustained stress, SL. For reasons similar to those expressed for the operating load case, the sustained load case output is not included. largest overall stress differential for the piping system in accordance with paras. 319.2.1(d), 319.2.3(b), and 319.3.1(b), i.e., SE, the “stress range corresponding to the total displacement strains.” The resulting load combination and SE for each piping component are listed in Table S303.7.3. S303.7 Displacement Stress Range Load Cases S303.8 Code Compliance: Satisfying the Intent of the Code The displacement stress range, SE, is computed in accordance with para. 319.2.3(b), in which the strains evaluated for the original (as-installed) condition (for this particular example) are algebraically subtracted from the strains evaluated for the Operating Case 1 as listed in Table S303.1. Similarly, the displacement stress range, SE, is computed from the algebraic strain difference evaluated from the as-installed condition to the Operating Case 2 as listed in Table S303.1. The individual displacement stress range, SE, along with the internal reaction loads, is evaluated for each piping component in accordance with eq. (17) and is listed in Tables S303.7.1 and S303.7.2 for Operating Cases 1 and 2, respectively. The algebraic strain difference between the two resultant case evaluations discussed above produces the The piping system is compliant with the sustained load requirements of the Code. The displacement stress range from the original (as-installed) condition to each of the operating cases indicates the piping system is in compliance with the intent of the Code even when limited to the eq. (1a) allowable, SA. But, the “stress range corresponding to the total displacement strains,” which considers the algebraic strain difference between the two operating cases, indicates that the piping system is not protected against fatigue for the cycles under analysis even when considering the eq. (1b) allowable, SA. Therefore, redesign of the piping system is required. The redesign should consider the additional impact of average axial displacement stresses in accordance 227 (08) ASME B31.3-2008 Table S303.7.2 Case 2: Displacement Stress Range [Eq. (1a) Allowable SA p 248.2 MPa (36 ksi): Passes] Global Axis Forces and Moments Node Fx , N (lb) (Signed) [Note (1)] My , N-m (ft-lb) (Signed) [Note (1)] Eq. (17) SE , kPa (psi) [Note (2)] 0 0 55 610 (8,065) 189 945 (27,550) 84 360 (12,235) 84 360 (12,235) 10 anchor 20 tee 30 tee 40 tee 78 485 (17,645) −78 485 (−17,645) −147 470 (−108,755) 147 470 (108,755) −45 900 (−33,850) −45 900 (−33,850) 110 Y 120 130 meter 140 Y −78 485 (−17,645) −78 485 (−17,645) −78 485 (−17,645) −78 485 (−17,645) −45 900 −45 900 −45 900 −45 900 (−33,850) (−33,850) (−33,850) (−33,850) 25 155 25 155 25 155 25 155 340 tee 210 Y 220 230 meter −78 485 (−17,645) 78 485 (17,645) 78 485 (17,645) 78 485 (17,645) −45 900 −45 900 −45 900 −45 900 (−33,850) (−33,850) (−33,850) (−33,850) 84 360 (12,235) 25 155 (3,650) 25 155 (3,650) 25 155 (3,650) 240 Y 330 tee 310 anchor 320 tee 78 485 (17,645) 78 485 (17,645) 0 0 −45 900 (−33,850) −45 900 (−33,850) 147 470 (108,755) −147 470 (−108,755) 25 155 (3,650) 84 360 (12,235) 55 610 (8,065) 189 945 (27,550) (3,650) (3,650) (3,650) (3,650) NOTES: (1) Loads are averaged from commercial programs and are directly affected by the stiffness chosen for valves, flanges, and other relatively stiff components. (2) Stress may differ by slightly more than units’ conversion tolerance. 228 ASME B31.3-2008 Table S303.7.3 Load Combination Considering Cases 1 and 2, Total Strain Based: Displacement Stress Range [Eq. (1b) Allowable SA p 379.8 MPa (55.1 ksi): Fails] Global Axis Forces and Moments [Note (1)] Node Fx , N (lb) (Signed) My , N-m (ft-lb) (Signed) Eq. (17) SE , kPa (psi) [Notes (2), (3)] 10 anchor 20 tee 30 tee 40 tee 0 0 −156 970 (−35,290) 156 970 (35,290) 294 940 (217,510) −294 940 (−217,510) 91 800 (67,700) 91 800 (67,700) 111 220 (16,130) 379 890 (55,100) 168 720 (24,470) 168 720 (24,470) 110 Y 120 130 meter 140 Y 156 970 156 970 156 970 156 970 (35,290) (35,290) (35,290) (35,290) 91 800 91 800 91 800 91 800 (67,700) (67,700) (67,700) (67,700) 50 310 50 310 50 310 50 310 340 tee 210 Y 220 230 meter 156 970 (35,290) −156 970 (−35,290) −156 970 (−35,290) −156 970 (−35,290) 91 800 91 800 91 800 91 800 (67,700) (67,700) (67,700) (67,700) 168 720 (24,470) 50 310 (7,300) 50 310 (7,300) 50 310 (7,300) 240 Y 330 tee 310 anchor 320 tee −156 970 (−35,290) −156 970 (−35,290) 0 0 91 800 (67,700) 91 800 (67,700) −294 940 (−217,510) 294 940 (217,510) 50 310 (7,300) 168 720 (24,470) 111 220 (16,130) 379 890 (55,100) (7,300) (7,300) (7,300) (7,300) GENERAL NOTE: The sustained stress used in determining the eq. (1b) allowable for nodes 20 and 320 is SL p 28 380 kPa (4,115 psi). NOTES: (1) Loads are averaged from commercial programs and are directly affected by the stiffness chosen for valves, flanges, and other relatively stiff components. (2) Stress may differ by slightly more than units’ conversion tolerance. (3) The additional impact of average axial displacement stresses in accordance with the recommendations in para. 319.2.3(c) has not been included in determining the displacement stress range. with the recommendations in para. 319.2.3(c). If the piping system is redesigned such that it is compliant with the intent of the code, then the piping system would require no further attention unless the sustained, hydrotest, or operating reaction loads at either anchor data point 10 or 310, or meter runs 130 or 230, exceeded the allowable loads for the attached equipment, nozzles, or support structure. The meter loads, nozzle loads, and support structure analyses are beyond the scope of this example. Although the occasional load cases are important to the design and analysis of a piping system, they are not discussed in this example. 229