Mechanics of Material Project Report: Beam Load Cell Weight Machine

advertisement

UNIVERSITY OF ENGINEERING & TECHNOLOGY

PROJECT REPORT OF

MECHANICS OF MATERIAL

COURSE TITLE:

MtE-222L: MECHANICS OF MATERIAL

SEMESTER:

TH

BS-4

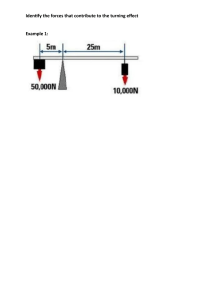

SUBMITTED BY:

MUNEEB FAYYAZ

21PWMCT0793

HUZAIFA HAIDER

21PWMCT0776

AQSA INAM

21PWMCT0787

SUBMITTED TO:

PROF. DR FARID KHAN

DEPARTMENT OF MECHATRONICS ENGINEERING

Table of Contents

ABSTRACT: ......................................................................................................................................... 3

A

INTRODUCTION: ....................................................................................................................... 3

OBJECTIVES: ...................................................................................................................................... 3

B

LITERATURE REVIEW: ........................................................................................................... 3

WEIGHT MACHINE: ............................................................................................................................ 3

TYPES OF WEIGHT MACHINE: ..................................................................................................... 4

C

MAIN COMPONENTS:............................................................................................................... 6

BLOCK DIAGRAM: ............................................................................................................................ 9

D

APPROACH AND METHODOLOGY: ................................................................................... 10

a.

HARDWARE: ............................................................................................................................. 10

i.

DESIGN OF THE LOAD CELL:.............................................................................................. 10

ii.

SOLIDWORKS SIMULATION: .............................................................................................. 10

iii.

FABRICATION OF THE BEAM: ........................................................................................ 12

b.

CIRCUIT DESIGNING: ............................................................................................................ 14

c.

PROGRAMMING: ..................................................................................................................... 17

PROJECT IMAGE:............................................................................................................................ 19

RISKS AND DIFFICULTIES: .......................................................................................................... 19

BUDGET: ............................................................................................................................................ 19

REFERENCES: .................................................................................................................................. 20

PROJECT TITLE

WEIGHT MACHINE OF BEAM LOAD CELL

ABSTRACT:

Beam load cell weight machines are widely used in various industries for accurate and

precise weight measurement applications. These machines employ the principle of strain

gauges mounted on a beam to convert the applied force into an electrical signal, which is then

used to determine the weight of an object or load. This abstract provides an overview of beam

load cell weight machines, highlighting their working principle, key components, advantages,

and applications.

A INTRODUCTION:

The beam load cell weight machine consists of one or more load cells strategically positioned

beneath a weighing platform or structure. As a load is applied to the platform, the load cell

deforms proportionally, generating a measurable electrical output. This output is then

converted into weight readings that can be displayed on a digital screen or integrated into a

computer system for data analysis and processing.

Beam load cell weight machines play a crucial role in weight measurement applications

across various industries. These machines utilize the principle of strain gauges mounted on a

beam to convert applied force into an electrical signal, enabling accurate and precise weight

readings.

OBJECTIVES:

•

•

•

•

To demonstrate the working of a load cell.

To design a weight machine that should provide accurate and precise measurements of the

measured weight.

The weight machine should be robust and able to withstand regular use without losing its

accuracy or performance.

The weight machine should have a user-friendly interface that is easy to understand and operate.

B LITERATURE REVIEW:

WEIGHT MACHINE:

Beam load cell weight machines are widely used in various industries for accurate and

precise weight measurement applications. These machines employ the principle of strain

gauges mounted on a beam to convert the applied force into an electrical signal, which is then

used to determine the weight of an object or load.

PURPOSE:

The purpose of a beam load cell weight machine is to accurately and precisely measure the

weight or applied force of an object or load. These machines are designed to provide reliable

weight measurements in various industries and applications. The primary purpose of a beam

load cell weight machine can be summarized as follow:

ACCURATE WEIGHT MEASUREMENT:

The main purpose of a beam load cell weight machine is to provide accurate and precise

weight measurements. By utilizing strain gauges mounted on a beam, these machines can

convert the applied force into an electrical signal, which is then processed to determine the

weight of the load with high accuracy.

QUALITY CONTROL:

Beam load cell weight machines play a crucial role in quality control processes across

industries. They are used to ensure that products meet specified weight requirements,

enabling manufacturers to maintain consistency, reliability, and compliance with regulations.

These machines help identify any variations in weight that may indicate defects or

inconsistencies in production.

INVENTORY MANAGEMENT:

In logistics and warehousing operations, beam load cell weight machines are employed for

efficient inventory management. By accurately measuring the weight of goods and materials,

these machines enable precise tracking and recording of stock levels, ensuring accurate

inventory control and efficient supply chain management.

MATERIAL HANDLING:

Beam load cell weight machines are utilized in material handling equipment, such as

conveyor belts and forklifts, to determine the weight of goods being transported. This

information helps optimize load capacities, prevent overloading, and ensure safe and efficient

material handling processes.

RESEARCH AND DEVELOPMENT:

Beam load cell weight machines are also used in research and development settings,

particularly in scientific laboratories and engineering facilities. They enable precise weight

measurements for experiments, testing, and prototyping purposes, supporting the

development and validation of new products and technologies.

TYPES OF WEIGHT MACHINE:

There are several types of weight machines available to cater to different weight

measurement needs. From beam load cell weight machines for industrial applications to

digital weighing scales for household use, each type of weight machine utilizes specific

technologies and mechanisms to ensure accurate and precise weight readings. The selection

of the appropriate weight machine depends on factors such as the application, weight

capacity, accuracy requirements, and environmental conditions. Some of the most commonly

used weight machines are discussed below:

BEAM LOAD CELL WEIGHT MACHINE:

Beam load cell weight machines are widely used in industrial and commercial settings. They

employ the principle of strain gauges mounted on a beam or cantilever to measure the

bending or deflection caused by the applied load. The strain gauges convert this mechanical

stress into an electrical signal, which is then processed to determine the weight. Beam load

cell weight machines are known for their accuracy, durability, and suitability for heavy-load

applications.

PLATFORM SCALES:

Platform scales, also known as floor scales, consist of a large weighing platform on which the

load is placed. These scales typically use load cells or hydraulic sensors beneath the platform

to measure the weight. Platform scales come in various sizes and weight capacities, making

them suitable for weighing large and heavy objects. They find applications in industries such

as logistics, manufacturing, and agriculture.

COMPRESSION LOAD CELL WEIGHT MACHINES:

Compression load cell weight machines are designed to measure the weight or force applied

in a compression or downward direction. These machines utilize load cells that are

specifically designed to measure compressive forces. Compression load cell weight machines

are commonly used in applications such as material testing, force monitoring, and industrial

weighing where the load is applied in a vertical direction.

TENSION LOAD CELL WEIGHT MACHINE:

Tension load cell weight machines are used to measure the weight or force applied in a

tension or upward direction. These machines employ load cells that are engineered to

measure tensile forces. Tension load cell weight machines are frequently used in applications

such as crane scales, hanging scales, and force testing where the load is suspended or pulled

upward.

DIGITAL WEIGHT SCALES:

Digital weighing scales have become ubiquitous in household and commercial settings. These

scales utilize strain gauge load cells or piezoelectric sensors to measure the weight. Digital

weighing scales offer precise and instant weight readings and often come with additional

features such as weight conversion, tare function, and memory storage. They are commonly

used in kitchens, bathrooms, fitness centers, and retail stores.

C MAIN COMPONENTS:

1. LOAD CELL

A load cell is a transducer that converts force into measurable electrical output. Although

there are many varieties of force sensors, strain gauge load cells are the most commonly

used type.

Fig 1: Load cell

2. STRAIN GAUGES

A strain gauge is a device that measures the change in electrical resistance when a force is

applied. It converts force, pressure, tension, weight, etc., into a change in electrical

resistance which can then be measured. When external forces are applied to a stationary

object, stress and strain are the results.

Fig 2: Strain gauge

3. HX711 AMPLIFIER:

The HX711 amplifier is a widely used integrated circuit (IC) designed specifically for

amplifying and converting small electrical signals from load cells or strain gauges into

measurable digital data. It serves as a critical component in precision weighing

applications, where accurate and reliable measurements are required.

The HX711 amplifier is typically interfaced with microcontrollers, such as Arduino or

Raspberry Pi, through a simple two-wire communication protocol (usually SPI or I2C).

This allows for seamless integration into various electronic systems, enabling users to

easily access and process the converted data.

Fig 3: HX711 Load cell amplifier

4. LCD DISPLAY:

The term LCD stands for liquid crystal display. The 16x2 LCD display is a widely used

alphanumeric display module that consists of 16 columns and 2 rows, hence the name

"16x2." It utilizes liquid crystal technology to display characters, numbers, symbols, and

basic graphical elements, providing a simple and effective means of visual feedback in

electronic projects.

One of the distinguishing features of the 16x2 LCD display is its simplicity in terms of

interfacing with microcontrollers and other electronic devices. It typically connects using a

parallel interface, where each character or command is sent to the display module using a set

of data lines and control signals. This makes it compatible with a wide range of

microcontrollers and allows for easy integration into various projects.

In addition to character display, the 16x2 LCD module also supports basic graphical

functions. It can display simple bar graphs, custom characters, and even limited pixel

manipulation. While it may not match the graphical capabilities of more advanced displays,

the 16x2 LCD still offers a versatile and cost-effective solution for many applications.

5. I2 C MODULE:

I2C stands for Inter-Integrated Circuit. It is a bus interface connection protocol incorporated into

devices for serial communication.

Fig 4: 16x 2 LCD display with I2 C module

6. BATTERY:

A 12V battery would be used to power the circuit of the weight machine.

Fig 5: 12v battery

7. ARDUINO NANO:

The Arduino Nano is a microcontroller-based device with 16 digital pins that can be used for

various purposes. It can be used for almost every task, from minor to massive industrial-scale

projects. It can also be used for prototyping and developing new applications. Arduino Nano

is simply a smaller version of Arduino UNO, thus both have almost the same functionalities

Fig 6: Arduino nano

BLOCK DIAGRAM:

Fig 7: Block diagram

D APPROACH AND METHODOLOGY:

a. HARDWARE:

i.

DESIGN OF THE LOAD CELL:

For this project, a cantilever beam is selected, having a length of 5cm(50mm), width of

1cm(10mm), and height of 1cm(10mm). The Solidworks design of the beam is given below.

Fig 8: Cantilever beam load cell

ii.

SOLIDWORKS SIMULATION:

The solidworks simulation of the beam was done. Keeping one of the sides of the beam fixed a load

of 50N was applied on the free end of the beam to observe the stress, strain and displacement in the

beam.

Fig 9: Stress due to 50N load

Fig 10: Displacement due to 50N load

Fig 11: Strain due to 50N load

iii.

FABRICATION OF THE BEAM:

1. MATERIAL SELECTION:

A bar of mild steel was selected for making the load cell. Considering the factors such as

material strength, and weight-bearing capacity.

2. MEASUREMENT AND MARKING:

Measure the desired length of the beam on the square bar using a measuring tape or ruler.

Make sure to mark the starting and ending points accurately. Keeping the length of the beam

as 5cm, width as 1cm, and height as 1 cm.

3. CUTTING:

Use a saw or cutting tool appropriate for the material of the square bar to cut along the

marked lines. Ensure a clean and straight cut to maintain the integrity of the beam.

Fig 12: Cutting of the bar

4. DRILLING:

After cutting the square bar to the desired length, drill the required number of holes for

creating the cavity of the beam to weaken its strength, so it can give us deflection whenever

loaded by a weight. Also drill four holes on both the ends of the beam so that it can be fixed

on a platform.

Fig 13: Drilling holes

5. FINISHING:

Smooth out any rough edges or imperfections using a grinder or file. This step helps improve

the appearance and functionality of the beam.

Fig 14: Finishing

b. CIRCUIT DESIGNING:

STRAIN GAUGES:

1. SELECTION OF STRAIN GAUGE:

Choose the appropriate type of strain gauge based on the application requirements, such as

foil strain gauges or semiconductor strain gauges.

Fig 15: Strain gauges

2. SOLDERING:

Use a proper soldering iron to attach conducting wires in order to make it work. Make sure

that the wires are properly soldered.

Fig 16: Soldered strain gauges

3. CONTINUITY CHECKING:

Check the continuity of the wires after soldering through the digital or analog multimeter.

4. MOUNT THE STRAIN GAUGES:

Attach the active strain gauges to the appropriate positions on the beam load cell. Ensure that

they are securely mounted and aligned properly. The strain gauges should be placed in a

manner that allows them to measure the bending or deflection of the load cell accurately.

Fig 17: Mounting the strain gauges

5. CONNECTION OF STRAIN GAUGES:

Connect the strain gauges to the Wheatstone bridge circuit. Each strain gauge has two leads

that need to be connected. Follow the manufacturer's instructions for proper wiring and

connections.

Fig 18: Wheat stone bridge circuit

Fig 19: Wheat stone bridge

6. APPLYING EXCITATION VOLTAGE:

Apply a stable and constant excitation voltage across the two opposite corners of the

Wheatstone bridge. This voltage serves as the power supply for the bridge circuit and is

typically in the millivolt range.

7. MEASURE OUTPUT:

Connect a voltage measuring device or a signal conditioning circuit to the remaining two

corners of the Wheatstone bridge. This is where the output voltage is measured. The output

voltage is proportional to the change in resistance of the active strain gauge, which is

influenced by the applied load on the beam load cell.

Calibrate the Wheatstone bridge by applying known loads to the beam load cell and recording

the corresponding output voltages. Use this calibration data to establish a linear relationship

between the output voltage and the applied load.

8. CONNENTING LOAD CELL TO AMPLIFIER:

Connect the output wires of the load cell to the input terminals of the amplifier circuit. And

do proper wiring and connections.

9. CONNECTING AMPLIFIER TO ARDUINO:

Wire the amplifier circuit to the appropriate pins of the Arduino. Ensure the connections are

correct, and refer to the microcontroller's documentation for the pin configuration.

10. CONNECT LCD:

Connect the LCD display to Arduino according to the specified pin connections. Utilize the

appropriate library to display weight readings and other relevant information on the LCD.

c. PROGRAMMING:

Use the programming language compatible with Arduino that is C/C++ to read the amplified

load cell signal. The Arduino code for the weight machine is given below:

Arduino code:

#include "HX711.h"

#include <Wire.h>

#include <LiquidCrystal_I2C.h>

LiquidCrystal_I2C lcd(0x27, 16, 2);

int dout = 4;

int sck = 5;

HX711 scale;

float units, ounces = 0;

float calibration_factor = 10.32;

int button = A0;

void setup() {

Serial.begin(115200);

pinMode(button, INPUT);

lcd.init();

// initialize the lcd

// Print a message to the LCD.

lcd.backlight();

lcd.print("Digital Balance");

scale.begin(dout, sck);

scale.set_scale();

scale.tare();

long zero_factor = scale.read_average();

Serial.print("Zero factor : ");

Serial.print(zero_factor);

}

void loop() {

if (digitalRead(button) == 0) {

scale.tare();

}

//delay(50);

scale.set_scale(calibration_factor);

Serial.print("Reading: ");

units = scale.get_units(), 10;

if (units < 500)

{

units = 0.00;

}

ounces = units * 0.035274;

Serial.print(units);

Serial.print(" grams");

Serial.print(" calibration_factor: ");

Serial.print(calibration_factor);

Serial.println();

if (Serial.available())

{

char temp = Serial.read();

if (temp == '+' || temp == 'a')

calibration_factor += 0.01;

else if (temp == '-' || temp == 'z')

calibration_factor -= 0.01;

}

delay(500);

float kg = units / 1000;

Serial.print("Grams: ");

Serial.print(units);

Serial.print(" !! KG: ");

Serial.println(kg);

lcd.setCursor(0, 1);

lcd.print("Weight:");

lcd.print(kg);

lcd.print(" KG

");

}

CALIBRATION:

Place known weights on the load cell and compare the displayed values with the actual

weights. Adjust the calibration parameters in the code if necessary to improve accuracy.

PROJECT IMAGE:

Fig 20: Project image

RISKS AND DIFFICULTIES:

•

•

•

As we have selected a mild steel bar for making the load cell, cutting and drilling holes

was difficult due to its hardness.

Soldering the strain gauges was difficult due their sensitivity and small size.

Calibration of the weight machine to accurately measure the load.

BUDGET:

Table 1: Components list

Components

Cost

Arduino nano

1200/-

HX711 Amplifier

200/-

I2C module

700/-

16x2 LCD display

500/-

Mild steel Bar

500/-

Strain gauges

Per 80/-

Wooden Base

1000/-

Total cost

5500/-

REFERENCES:

https://www.researchgate.net/publication/327471393_Development_of_an_Electronic_Weighing_Ind

icator_for_Digital_Measurement

https://circuitdigest.com/microcontroller-projects/arduino-weight-measurement-using-load-cell

https://www.techtarget.com/whatis/definition/LCD-liquid-crystal-display

https://www.theengineeringprojects.com/2018/06/introduction-to-arduino-nano.html

https://www.electronicshub.org/wheatstone-bridge/