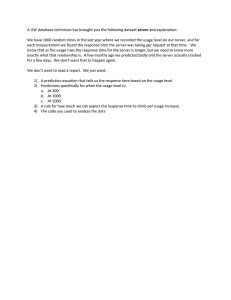

The turbo fan aircraft minimum cost climb technique P. Mirosavljević, S. Gvozdenović and O. Čokorilo The Faculty of Transport and Traffic Engineering, University of Belgrade, Belgrade, Serbia Abstract Purpose – The purpose of this paper is to define minimum cost technique of turbo fan transport aircraft in the presence of dynamic change of aircraft performance. Results can be practical applicable in airlines for achieving minimal operation costs. Design/methodology/approach – Logarithmic differential is applied for defining conditions in order to achieve optimal Mach number for minimal climb cost. This condition is solved numerically by using Newton-Ramphson method, to obtain optimal Mach number distribution with altitude. Conclusion about optimal top of climb (TOC) is defined after analyses for different aircraft mass and cost indexes. Findings – Proposed method of minimum cost climb resulting in potential savings up to 5 per cent compared to Aircraft Flight Manual climb law. Proposed method also made correction of climb law and optimal TOC under existence of aircraft performance degradation. Practical implications – Use of defined climb law and optimal TOC will minimize cost of en route flight profile. Originality/value – At present, there is no definition of climb technique for minimum cost of en route flight profile, under dynamic degradation of aircraft performance. Final results are standardized to become applicable and easy to use with modern and old type of flight management system. Keywords Air transport, Aeroplanes, Operating costs, Aerodynamics Paper type Research paper subject in many papers and research studies as a phase which represent connection between initial climb and cruise with relatively small investigation of costs generate during that phase. In the operative flight preparation, planners can use climb law which is published in Aircraft Flight Manual (AFM) or climb law defined by flight management system (FMS) according to set cost index (CI). FMS performance data base is not aware of dynamic change of aircraft performance and should be updated if is that possible. Dynamic changing in airline environment for many air companies are often overlooked and become source of hidden costs. Optimal vertical short-haul flight profile was the topic for many authors. In order to achieve optimal flight path, other authors used calculus of variation which is apply on total energy aircraft model. Such an example is work of Schultz and Zagalsky (1972) who implemented calculus of variation to develop optimal flight path. Barman and Erzebrger (1976) developed optimal short-haul flight which includes minimum costs trajectory. Optimal flight profile was developed according to aircraft model based on approximation of energetic condition of the aircraft. The calculus of variation was again used to achieve optimal result. Simons and Jenkinson (1985) developed sub-optimal, short-haul minimum fuel flight profile, for propeller aircrafts by using multivariable optimizations to develop flight profile with minimum usage of fuel. Many authors analyzed flight only to find result for optimizing climbing, descending or cruising resulting minimum usage of time (Ojha, 1993) and fuel (Calise, 1977). In the paper (Ojha, 1993), authors achieved minimum time climb with included presumptions. Authors like Maido (2006) stress out the need of more detailed variation of data and multiple approach in order to achieve quality results, which would be lost if we would include presumptions. One can notice that conditions for minimum costs climb are not enough researched and defined. Nomenclature AF ¼ Acceleration factor CASopt ¼ optimal CAS CF ¼ Fuel price (USD/kg) CT ¼ flight hour price (USD/Fhr) CTOC ¼ total en route flight cost (USD) ¼ aerodynamic drag coefficient Cx Cz ¼ aerodynamic lift coefficient F ¼ Fuel flow(kg/s) K ¼ 1 þ AF mcl1 ¼ aircraft mass at the beginning of climb RCC ¼ Rate of climb cost (USD/m) ROC ¼ Rate of climb (m/s) Rx ¼ aerodynamic drag force (N) Tn ¼ turbo fan engine net thrust (N) TOCopt ¼ Optimal top of climb TOD ¼ Top of descent VT ¼ True air speed [m/s] X ¼ range [m] r ¼ air density in ISA conditions (kg/m3) Introduction Recently, there is rising competition between air carriers which require costs determination and reduction. The process of cost reduction demand determination of all sources of costs and possibilities for their reduction. The climb phase was The current issue and full text archive of this journal is available at www.emeraldinsight.com/1748-8842.htm Aircraft Engineering and Aerospace Technology: An International Journal 81/4 (2009) 334– 342 q Emerald Group Publishing Limited [ISSN 1748-8842] [DOI 10.1108/00022660910967327] 334 The turbo fan aircraft minimum cost climb technique Aircraft Engineering and Aerospace Technology: An International Journal P. Mirosavljević, S.Gvozdenović and O.Čokorilo Volume 81 · Number 4 · 2009 · 334 –342 The present models of minimum time climb and minimum fuel climb flight path model are optimized on the basis of flight efficiency without concerning operative efficiency of such flight. The paper which represent need for connection between operational and flight efficiency is McLean (2006), also highlighted need for accomplishment of both goals. It was noticed that solution for minimum cost climb technique which cover both operational and flight efficiency, under of presence of dynamic disturbance, is not identified. In this paper, is shown method for solution of that optimization problem. The optimization problem solution must be standardized in form of climb law and top of climb (TOC), for application in aircraft operations. The aim of this paper is defining optimal climb strategy on short haul flights with satisfied criterion of minimal operations cost under presence of dynamic disturbance, with results standardization for operative application. During transport aircraft exploitation is evident degradation of aircraft performances, as a result of non-adequate aircraft maintenance. The degradation range is from 1 per cent on the first 3,000 Fhr to 10 per cent (IATA, 2004). Cook et al. (2007) had defined importance of dynamic disturbance, which arise before flight and can influence on total operation costs. The problem which was analyzed is practical and is present in everyday aircraft operations. It should take optimal result get as close as possible to operative use, which means air traffic control restrictions must be obeyed. The transport aircraft in flight operations use climb law in form of IAS/M (McLean, 2006). In the paper, we also show technique which gives us sub-optimal law of climbing based on optimization results. Sub-optimal law of climbing has minimum exception margin from the optimal speed distribution in climbing. Sub-optimal climb law consists of calibrated air speed (CAS) speed and M number, which makes it useful in operative exploitation obeying system limitations. In cases from works Schultz and Zagalsky (1972) and Barman and Erzebrger (1976) in which authors researched optimization of all flight phases, were not analyzed acceleration phase on TOC, from speed in the end of climbing to speed in the beginning of cruising. In this paper, the influence of acceleration phase, on total operating cost, is also calculate. The aircraft climb optimization is possible on the base of aircraft documents and/or FMS. The basic aircraft flight planning documents are AFM, Flight Planning and Performance Manual (FPPM) (The Boeing Company, 2003a, b) and Performance Engineers Manual (PEM) (The Boeing Company, 1985). In the content of AFM is usually only one climb law available without options of optimization. The FMS memory where is entered performance data base (PDB), is not enough to contain all different aircraft performance model. PDB depends on aircraft engine combination. It is possible that FMS’s PDB not match to aircraft on which is installed, exactly. In that case, air carrier must conduct corrections of PDB to achieve total match between aircraft model. During aircraft exploitation, PDB is tune, when aircraft drag and engine characteristic begin to deviate, form book level. Recently, there exists methods for prediction of aircraft performance deviation, on which base is determined PERF FACTOR (Airbus Industry, 2002). Some aircraft like ERJ145, Fokker100, and B737300 do not have option of update PDB by PERF FACTOR. For such cases, flight preparation must conduct on actual aircraft performance data in pre flight preparation. For aircraft equipped with older types of FMS without option of update PDB flight must be prepare on the basis of add-on software which is offered by aircraft manufacturer (Airbus IFP) or as service offered from other companies (Lido OC). The trend of update of PERF FACTOR and also possibilities of PDB update is possible on the basis of data obtain by aircraft performance monitoring (APM), such as flight operational quality assurance (FOQA). Form FOQA is possible to gather data on the daily basis for every aircraft in fleet. This opens possibility of daily aircraft performance optimization based on real data, before each flight for each aircraft in air carrier’s fleet. Generally, this paper is organized in three parts. In the first part of the paper proposes methodology for determination of new minimum cost-climb technique, under aircraft drag and engine performance degradation. The second part analyzes influence of aircraft mass and CI on optimal TOC choice, which minimize en route flight profile under consideration of dynamic aircraft performance change. The third part of the paper proposes method which prepare obtained solutions in the first part of paper, for application in passenger aircraft FMS. In the case when aircraft is equipped with older type of FMS without option of PDB update (IATA, 2004) by proposed method final results are applicable during pre-flight FMS preparation. In the case when is aircraft without FMS by proposed method, final results are applicable for flight on the base of air speed indicator, Mach meter and altimeter. The purposed method is alternative to flight preparation based on AFM and FPPM data. Assumptions In the paper, B737-300 type of aircraft is accepted as reference aircraft, equipped with older generation of FMS without PDB update option. In order to research climb impact, we analyzed simplified flight profile which includes only en route part of flight. In order to use comparison, in the paper, we use tabular calculation method (Jenkinson et al., 1999) for fuel, time and distance calculation. This model is based on “step by step” calculation of each phase of chosen intervals heights in climbing and descending, and for chosen parts of range in cruising. Assumptions that are accepted are as follows: small angle of climb (Houghton and Brock, 1970), e.g. g , 138 and cos g < 1, sin g < g, CAS ¼ IAS, aircraft’s weight is equal to lift force and drag force is equal to cruising pressure power. Besides these assumptions, we also used assumptions about ISA flight conditions. The range that aircraft performs during cruise is calculated as difference between total range R (km) and range which aircraft makes during descending, climbing and speeding: Rcr ¼ R 2 Rdes 2 Rcl 2 Racc ð1Þ Speed limits in all flight phases are in form of maximum speed CASMO and maximum MMO. In order to research climb impact, we analyzed simplified flight profile which includes only en route part of flight. En route phase starts with climbing 335 The turbo fan aircraft minimum cost climb technique Aircraft Engineering and Aerospace Technology: An International Journal P. Mirosavljević, S.Gvozdenović and O.Čokorilo Volume 81 · Number 4 · 2009 · 334 –342 to 1,500 ft QNH to TOC based on optimal climb law, acceleration phase on cruising height to cruising speed, cruising with constant height from TOD, with constant descent law 074/250 kt to 1,500 ft QNH. This cruise and descent regime was taken from FPPM (The Boeing Company, 2003b). Such cruising and descending phase model was chosen in order to display the usefulness of minimum costs climb technique. For climbing, there is used maximum climb thrust setting, whereas in cruising, program of continual thrust setting decrease is used as cruise progresses, because the cruise is done under const h and const Mcr. In descending, regime of minimum power is used (low idle thrust). In order to define optimal Mach number distribution for minimum climb cost, it is necessary to present aerodynamic data and aircraft engine data in functional form, with influence of dynamic degradation. Entry data for flight’s parameters definition are taken from PEM. The aircraft high-speed drag polar is presented through coefficient of aerodynamic drag Cx which is function of two constants Cz and M. The program APM is used for determination of DC drag correction, as a percent of real data change compared to PEM data. Since function which describes coefficient of aerodynamic drag, equation (2) also includes coefficient Prandtl, we achieve the average square of coefficient of correlation from 0.95, compared to data of aircraft’s manufacturer (The Boeing Company, 1989): k5 M DC ð2Þ Cx ¼ k3 þ k4 M þ pffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffi 1 þ 100 1 2 M2 on SL. Fuel flow for climb and cruise phases is presented by equation (10): 2 ! pffiffiffiffi Tn Tn F ¼ dt ut ffst þ D · þE· d d ð10Þ 0:453 FC 1þ 3600 100 ð3Þ k4 ¼ k40 þ k41 C z þ k42 C 2z ð4Þ k5 ¼ k50 þ k51 C z þ k52 C 2z ð5Þ ð12Þ ffst ¼ ffst0 þ ffst1M þ ffst2M 2 ð13Þ where F (kg/s) fuel flow, FC (per cent) fuel flow correction. This correction is consequence of engine characteristic degradation. Approximation of realistic parameters of fuel flow of aircraft engine (The Boeing Company, 1985), by use of interdependence presented by equations (11)-(13) can be calculated by square of coefficient of correlation from 0.96. Aircraft climb model In order to set climb parameters, we applied basic climb equals, in which height altitude of 1,500 ft QNH to TOC climb altitude was divided to i (i ¼ 1, . . . , j) segments. The aircraft mass in first climb segment is mcl1. For each climb segment ith, we define spent time tcli, fuel gcli and range Xcli. Equations which describe climb flight are (Jenkinson et al., 1999): pffiffiffi pffiffiffi dh ¼ M · asl · u sin g < M · asl · ug dt pffiffiffi pffiffiffi dX ¼ M · asl · u cos g < M · asl · u dt dmcl ¼ 2F cl dt Rz ¼ g mcl pffiffiffi dðM · asl · uÞ · mcl ¼ Tncl 2 RX 2 g · mcl g dt By analyzing interdependence of characteristics of turbo-fan engines (Kahayas, 2007; Raymer, 2006; Mair and Birdsall, 1992) and realistic characteristics of engine (The Boeing Company, 1985), we notice that equation (6) of approximation of realistic parameters of engine’s parameters with square of coefficient of correlation from 0.998: ð14Þ ð15Þ ð16Þ ð17Þ ð18Þ Limitations on which basis we calculate climb flight are: . available thrust is equal to the maximum climb thrust: T max cl ¼ Tncl . . Tn ¼ T o þ A · M þ B · M2 d N1 N1 2 A ¼ a1 þ pffiffiffiffi a2 pffiffiffiffi ut ut N1 N1 2 B ¼ b1 pffiffiffiffi þ b2 pffiffiffiffi ut ut N1 N1 2 T o ¼ t1 pffiffiffiffi þ t2 pffiffiffiffi ut ut ð11Þ 2 E ¼ e0 þ e1M þ e2M where DC (per cent) is aircraft drag correction as a consequence of aerodynamic degradation. Where coefficients are k3, k4 and k5: k3 ¼ k30 þ k31 C z þ k32 C 2z D ¼ do þ d1M þ d2M 2 ð6Þ . ð7Þ . ;hi ; i ¼ 1; . . . ; j ð19Þ fuel flow is function of flight altitude, Mach number and thrust during climbing; climb can be considered up to height which represents operative top of the flight, and which is defined by ROCmax ¼ 2.54 m/s (500 ft/min); flight is straight, without turns or change of flight direction; and the change of climb angle is small g_ ¼ 0. ð9Þ Parameters needed to define climb parameters for flight in ith segment height intervals, with constant M number in troposphere are: ROCi, for used fuel, ðROCi =F i Þ and for flight range in climb it is necessary to first define climb angle gi: pffiffiffiffi Group of functions (7)-(9) present influence N1= ut on parameters of corrected thrust Tn/d (N), where d is relationship between pressures of ambient air and pressure ð20Þ mcl i ¼ mcl i21 2 g cl i21 ; ði ¼ 2; . . . ; jÞ pffiffiffiffi ðM i ·asl · ui ðTncl i 2RXi ÞÞ=ðg ·mcl i Þ ; ði ¼ 1; ...;jÞ ð21Þ ROCi ¼ 120:133M 2i ð8Þ 336 The turbo fan aircraft minimum cost climb technique Aircraft Engineering and Aerospace Technology: An International Journal P. Mirosavljević, S.Gvozdenović and O.Čokorilo Volume 81 · Number 4 · 2009 · 334 –342 ROCi Fi pffiffiffiffi ð22Þ ðM i ·asl · ui ðTncl i 2RXi =g ·mcl i ÞÞ=ð120:133M i Þ ; ¼ Fi ði ¼ 1; ...; jÞ ðTncli 2 RXi Þ=ðg · mcl i Þ ; ði ¼ 1; . . . ; jÞ ð23Þ gi ¼ ArcSin 1 2 0:133M 2i Unit climb costs can be formulated by linking unit climb time costs that are function of climb time and unit climb fuel costs, which are function of fuel spent while climbing. Based on equation (33) it is possible to calculate speed of costs change with height. By multiplication of unit time costs with integral function of climb time, we get change of unit time costs with altitude in form: CT 1 1 USD 1 USD ! ð34Þ 3; 600 ROCi 3600 Fhr ðm=sÞ m For basic ith segment of climb, it is possible to define time needed in order to climb from height hi2 1 to height hi: Z hi dh ; ði ¼ 1; . . . ; jÞ ð24Þ t cl i ¼ ROC i hi Z hi Fi g cl i ¼ dh; ði ¼ 1; . . . ; jÞ ð25Þ hi ROCi pffiffiffi ð26Þ X cl i ¼ t cl i ðcos gi ÞM i asl ui ; ði ¼ 1; . . . ; jÞ and by multiplication of unit fuel costs with sub integral function of climb fuel we get change of unit fuel costs with altitude in the form of: Fi USD ðkg=sÞ USD ! ð35Þ CF kg ðm=sÞ m ROCi After we arrange this redefined condition of minimum climb costs on ith climb segment, we can calculate the definition of costs change with altitude RCCi (USD/m) (rate of climb cost): Climbing parameters from i ¼ 1, which fits to segment of height at the beginning of climbing to i ¼ j, which fits to segment of height TOC are total climb time, fuel and range: t cl ¼ j X t cl i ð27Þ g cl i ð28Þ i¼1 X cl i 1; 000 ð29Þ RCCi ¼ j X i¼1 Pj Rcl ¼ Optimization of Mach’s climb number under minimum costs criterion For each segment of climbing, it is possible to define it by method of logarithmic differential, optimal Mi number for minimum climb costs. Total operation climb costs on ith climb segment Ccl i ðUSDÞ, consist of climb fuel cost and climb time cost. We can develop function of climb costs as follows: C cl i ¼ ðCT · t cl i Þ 3; 600 þ CF · g cl i þ ln Gcli þ ln K i 100 CI þ ln CF F i þ1 3; 600 F i ð30Þ ð38Þ The condition for minimizing RCC i is achieved by logarithmic differential lnRCCi by lnMi. The result of differential is, then, equalized with 0 and solved by Mi. Condition for minimum climbs costs, in case if we optimize by Mi, for the representative engine performance, can be presented as: › ln RCCi d ln M i ¼ 0 ð39Þ d ln RCCi ¼ › ln M i Minimizing climb cost Ccl i is possible if we minimize sum of costs of fuel spent and time spent on ith climb segment. In operative conditions of exploitation, it is necessary to express costs Ccl i as function CI (McLean, 2006; Root, 2001), so to define which criteria stresses more importance: CT ¼ CI CF · 100 ð36Þ Aim of optimizing is minimizing of RCCi. The aim of optimizing can be achieved if we define optimal distribution of M number with climb altitude. Technique used to find condition of optimal Mi for each ith climb segment is logarithmic differential. Lets logarithm RCCi on ith climb segment: 1 CT ln RCCi ¼ ln þ CF Fi ROCi 3; 600 Ki pffiffiffiffi ¼ ln ð37Þ M i asl ui ððTncli 2 Rxi Þ=ðGcli ÞÞ CT þ CF F i þ ln 3; 600 pffiffiffiffi ln RCCi ¼ 2ln M i 2 ln asl ui 2 lnðTncli 2 Rxi Þ i¼1 g cl ¼ CT 1 Fi þ CF 3; 600 ROCi ROCi ð31Þ As a solution of this dilemma, it is possible to set up function of costs Ccl i as a sum of time and fuel costs on ith segment: › ln K i › lnðTncli 2 Rxi Þ › ln F i 2 þ › ln M i › ln M i › ln M i › lnðð100=3600ÞðCI=F i Þ þ 1Þ þ › ln M i 0 ¼ 21 þ ðCT · t cl i Þ ð32Þ 3; 600 þ CF · g cl i Z hiþ1 Z hiþ1 CT 0:3048 Fi dh þ CF 0:3048 dh ð33Þ C cl i ¼ 3;600 hi ROCi ROCi hi C cl i ¼ ð40Þ Condition for calculation of Mi on ith climb segment for minimum climb costs Ccli: 337 The turbo fan aircraft minimum cost climb technique Aircraft Engineering and Aerospace Technology: An International Journal P. Mirosavljević, S.Gvozdenović and O.Čokorilo Volume 81 · Number 4 · 2009 · 334 –342 CI 100 M ›K i › lnðTncli 2 Rxi Þ 212 0¼ þ1 · › ln M i F i 3600 K i ›M ð41Þ › ln F i þ › ln M i Figure 1 The change of DCTOC with TOC, for minimum cost climb technique, mcl1 ¼ 41,000 kg 100 0 It can be develop tree cases, CI ¼ min, CI ¼ (any value between min and max) and CI ¼ max (Figure 5). After aircraft reaches TOC, we calculate fuel, time and distance needed to speed up to Mcr. After set up of optimal Mach number distribution in minimum cost climb, it can be defined second phase of optimization, which is determination optimal TOC. This optimization task has goal minimization of en route flight profile total operational costs. In the end, we can calculate sum of results: total fuel spent in all flight phases gt (kg), time tt (Fhr) and costs CTOC (USD) in all flight phases: g t ¼ g des þ g cr þ g acc þ g cl ð42Þ t t ¼ t des þ t cr þ t acc þ t cl ð43Þ DCTOC (USD) –100 TOC Min cost climb CI5 deg Min cost climb CI20 deg Min cost climb CI30 deg Min cost climb CI50 deg Min cost climb CI90 deg Min cost climb CI5 Min cost climb CI20 Min cost climb CI30 Min cost climb CI50 Min cost climb CI90 –500 –600 –700 20,000 22,000 ð44Þ 24,000 26,000 28,000 30,000 TOC (ft) where CT(USD/Fhr) denotes to the cost of time and CF(USD/kg) denotes to the cost of fuel. As we said, the second optimization task is to find TOC to minimize total operating costs CTOC: CTOC ! min –300 –400 Total expenses during en route flight are CTOC represented by equation (44): tt CT þ g t CF C TOC ¼ 3; 600 –200 Figure 2 The change of DCTOC with TOC, for minimum cost climb technique, mcl1 ¼ 51,000 kg 50 ð45Þ 0 Optimization of TOC under minimum costs criterion –50 –100 DCTOC (USD) There have been several experiments on presented model en route flight profile, in order to notice advantages and disadvantages of climbing on different TOC. In order to research influence of climb technique, we took into consideration following three factors that influence time, fuel and costs of total flight: CI (from 5 to 90)., aircraft mass at the beginning of climb mcl1 (41,000, 51,000 and 61,000 kg) and altitude TOC (from 20,000 to30,000 ft). All analysis are done for short-haul range R ¼ 840 km. Aircraft flight model and presented model of aerodynamic and engine characteristics is used for making software OPTCLIMB on platform Mathematicaw5.1. Results which are acquired by software, can help in process of defining optimal TOC (Figures 1-3) for given CI. It can be determined measure of en route cost deviation DC TOC from minimal en route cost. That deviation must be minimized, which is criterion for defining optimal TOC for is given aircraft mass, range and CI: –150 –200 Min cost climb CI5 deg Min cost climb CI20 deg Min cost climb CI30 deg Min cost climb CI50 deg Min cost climb CI90 deg Min cost climb CI5 Min cost climb CI20 Min cost climb CI30 Min cost climb CI50 Min cost climb CI90 –250 –300 –350 –400 –450 20,000 22,000 24,000 26,000 TOC (ft) 28,000 30,000 total operating cost can be achieve by application of minimum climb cost technique to TOCopt, with or without presence of dynamic disturbance caused by aircraft performance degradation. In this, particular case is assumed aerodynamic degradation DC ¼ þ 3 per cent and fuel-flow degradation FC ¼ þ 3 per cent. In case of climb with mcl1 ¼ 41,000 kg, Figure 1, we found TOCopt ¼ 30,000 ft for range of CI from 5 to 50. For CI value from 50 to 90, it can be determined decrease of TOCopt from 30,000 to 26,000 ft. In case of climb with mcl1 ¼ 51,000 kg, DC TOC ¼ minðC TOC ; TOC ¼ 20; 000 ft; . . . ; 30; 000 ftÞ 2 C TOC ð46Þ DC TOC ! 0 From analysis conducted at fixed range R ¼ 840 km, it was determined DC TOC change (Figures 1-3) with TOC. The criterion DC TOC ¼ 0 define optimal TOC or TOCopt. The mark deg on Figures 1-3 denote to case when is present aircraft performance degradation. Minimization of en route 338 The turbo fan aircraft minimum cost climb technique Aircraft Engineering and Aerospace Technology: An International Journal P. Mirosavljević, S.Gvozdenović and O.Čokorilo Volume 81 · Number 4 · 2009 · 334 –342 Figure 3 The change of DCTOC with TOC, for minimum cost climb technique, mcl1 ¼ 61,000 kg For lower altitudes, climbing is performed with constant CAS, and for higher altitudes with const M, because of shape of optimum M number curve change, as it is shown on Figure 4. Finding optimal distribution of change of M number with altitude, for minimum costs climb technique, can be calculated based on iterative procedure Jenkinson et al. (1999). In the procedure, first, we numerically define by Newton-Ramphson method (Bressound, 2006), values of optimal M numbers, for different altitudes h, then, acquired result is analytically described with function M from h. By iterative procedure for array of j segments of altitudes h, we acquire optimal M numbers for minimum costs climb technique for defined CI. Those are solutions results of equation (30). Afterwards, we proceed to approximation of numeric data for altitude h and optimal M number, by method of smallest square. Let us name this approximate function fopt. For defined function fopt, we define surface below fopt in function of altitude h. In order to define speed CASopt we should define minimum differences between functions fopt and M opt0 which is function CASopt and h. Functional connection M opt0 ¼ f ðCASopt ; hÞ is defined by equation (47): 50 0 –50 DCTOC (USD) –100 –150 Min cost climb CI5 deg Min cost climb CI20 deg Min cost climb CI30 deg Min cost climb CI50 deg Min cost climb CI90 deg Min cost climb CI5 Min cost climb CI20 Min cost climb CI30 Min cost climb CI50 Min cost climb CI90 –200 –250 –300 –350 –400 20,000 22,000 24,000 26,000 TOC (ft) 28,000 vffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffi u2 0 0 11=ð7=2Þ 3 1 u 2 !7=2 u6 1 CAS 7 opt M opt0 ¼ u 1þ0:2 21A þ1A 215 t45@ @d asl kt 30,000 Figure 2, we found TOCopt form 28,000 to 30,000 ft for range of CI from 5 to 50. For CI value from 50 to 90, it can be determined decrease of TOCopt from 28,000 to 22,000 ft. In case of climb with mcl1 ¼ 61,000 kg, Figure 3, we found TOCopt form 27,000 to 24,000 ft for range of CI from 5 to 30. For CI value from 30 to 90, it can be determined decrease of TOCopt from 24,000 to 20,000. ð47Þ where d presents relative ambient pressure in troposphere. We can notice a very important fact, that Mach’s number Mopt special case of CASopt on altitude hco. The function that links Mopt number and CASopt speed, on altitude hco for troposphere can be calculated by equation (48): vffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffi u2 0 0 11=ð7=2Þ 3 1 u 2 !7=2 u6 1 CAS 7 opt M opt ¼ u 1þ0:2 21A þ1A 215 t45@ @d asl kt co The sub-optimal climb law Once distribution of optimal M number values, with altitude h is defined, for minimum costs climb technique, it is necessary to enable operative use of achieved result, so that it can be applicable in FMS or flight management and guidance system (FMGS). That presents new optimization problem that is: adjustment of theoretic results, to practical use, in the way that optimization results are approximated in form of constant speed CAS and constant M number, (climb law), so to be entered before take-off in FMS or FMGS. Post-optimal results adjustment to operative use requires solving of new optimization task. The aim of post-optimal adjustment is: . to define constant speed CAS and up on what altitude hco (cross-over altitude) it takes to apply const CAS, with least differences from optimal change of M number with h, (defined for minimum costs); . to define hco, up to which constant CAS is applied and from what we begin to apply climb with const M number; . to find M number that is constant during climb, and that is applied from altitude hco and which has least deviation from optimum change of M number with altitude h (defined for minimum costs).That is achieved by satisfying the condition described in equation (41); and . constant CAS and constant M represent optimum combination (climb law), connected to altitude hco, on which it comes to cross-over from CAS to M. ð48Þ Figure 4 The approximation of optimal Mach number function with altitude h, form minimal operating cost 35,000 Const M which is the best approximation of optimal M change with altitude h 30,000 h (ft) 25,000 Const CAS which is the best approximation of optimal M change with h altitude M number change with h for min climb cost 20,000 15,000 Altitude hco at which climb law change from const CAS to const M 10,000 5,000 0 0.4 339 0.5 0.6 M 0.7 0.8 The turbo fan aircraft minimum cost climb technique Aircraft Engineering and Aerospace Technology: An International Journal P. Mirosavljević, S.Gvozdenović and O.Čokorilo Volume 81 · Number 4 · 2009 · 334 –342 where dco is relative ambient pressure in troposphere on altitude hco, asl kt (kt) speed of sound on SL, CAS(kt). General condition can be defined, as a minimization of sum of absolute difference surfaces, shown in equation (49). This general condition is satisfied under condition given in equation (50). Solution of optimization task is in finding two variables CASopt and hco. By using numerical Newton method of minimization we get solution of these two variables in range of given conditions (50). In equation (49) in square brackets, the sum of absolute differences of surfaces is shown: . First one below function of fopt (from starting altitude at beginning of climb h0 to altitude hco) and another surface below curve defined by equation (47) (from altitude of beginning of climb altitude h0 to altitude hco). . Another surface, second in square bracket in equation (49) is below function fopt (from altitude of cross-over hco to altitude at the end of climb hj) and surface below curve defined in equation (48) (from altitude of cross-over hco to altitude at the end of climb hj): Company, 2003b) proposed climb law 280/0.74, cruise at Mcr ¼ 0.74, descent law 074/250. Analyzes show reduction of total operating cost from 4.8 to 3.2 per cent, as shown on Figure 6, for mcl0 ¼ 51,000 kg and R ¼ 840 km: Z hco Minimize CASopt ;hco Z hj M opt2f opt dh jM opt0 2f opt jdhþ h0 St ref ¼ ð49Þ subject to ð50Þ M opt # M MO and M opt0 # M MO ; and h0 # h # hj ; and h0 # hco # hj The minimization of equation (49) under condition (50) obtain two variables hco and CASopt on which base can be develop third variable Mopt. In this way can be obtained solution with minimal differences between function fopt and climb law consist of CASopt and Mopt and pressure altitude hco. On Figure 5 is represented operative adoption of function fopt to climb law, which provide minimum cost climb. Figure 6 The percent of total en route operating costs savings The application of proposed climb method 5.00 TOC = 30,000ft Proposed method can be also applicable if we do not have FMS on board in aircraft and have a goal to minimize operating costs with climb technique. We can compare cost from proposed method CTOC and cost Cref , generated with FPPM (The Boeing 4.80 CI M 0.6 CAS TOC = 22,000ft TOC = 25,000ft 4.40 Stref [%] 0.7 x =ma TOC = 20,000ft 4.60 Figure 5 The comparison of optimal climb law 310/0.652 with optimal function M ¼ f (h) for minimum time climb(CI ¼ max), minimum cost climb (CI ¼ 40) and minimum fuel climb(CI ¼ min) 0.65 ð51Þ The second way of application of proposed climb technique is for aircraft equipped with FMS, but without PDB update option, for aircraft where is detected performance degradation as a dynamic disturbance. In the paper, presented method accounts disturbance of aircraft performance, expressed in form of variables DC and FC, for correction of climb law and TOCopt in order to achieve minimum en route total operating costs. If we have case mcl1 ¼ 51,000 ft, R ¼ 840 km, CI ¼ 40 with no aircraft performance degradation, presented method of minimum climb technique obtain as result climb law 311/0.664 and pressure altitude hco ¼ 19,183 ft, TOCopt ¼ 27,000 ft selected from Figure 2, with total operating costs CTOC ¼ 6,977 USD. In case of aircraft performance degradation in presented by variables DC ¼ 3 per cent and FC ¼ 3 per cent, for same other condition, presented method correct optimal climb law 309/0.662 and pressure altitude hco ¼ 19,346 ft. If we take TOCopt ¼ 27,000 ft from previous case we achieve total operating cost CTOC ¼ 7,107 USD. It is evident cost jump for 1.829 per cent (130 USD) as a consequence of aircraft performance degradation. The major goal of method is minimization of total operating cost in new conditions it can be shown if is introduce new TOCopt ¼ 28,000 ft we can obtain new result CTOC ¼ 7,105 USD and new climb law 309/0.666 and hco ¼ 19,727 ft. By conducted correction we achieve minimization of total operating costs of en route flight profile under dynamic disturbance. hco M opt ¼ f ðCASopt ; hco Þ; and M opt0 ¼ f ðCASopt ; hÞ; and CASMIN # CASopt # CASMO ; and C ref 2 C TOC £ 100 C ref 0 M=0.652 =31 0 CI=4 TOC = 27,000ft 4.20 4.00 3.80 3.60 0.55 min 3.40 CI= 0.5 0.45 3.20 0.4 3.00 0 5,000 10,000 15,000 20,000 25,000 0 h (ft) 20 40 60 CI 340 80 100 The turbo fan aircraft minimum cost climb technique Aircraft Engineering and Aerospace Technology: An International Journal P. Mirosavljević, S.Gvozdenović and O.Čokorilo Volume 81 · Number 4 · 2009 · 334 –342 Conclusion Calise, A. (1977), “Extended energy management method for flight performance optimisation”, AIAA Journal, Vol. 15 No. 3, pp. 314-21. Cook, A., Tanner, G., Williams, V. and Meise, G. (2007), “Dynamic cost indexing”, paper presented at 6th EUROCONTROL Innovative Research Workshops & Exhibition, EUROCONTROL Experimental Centre, Brétigny sur Orge, 4-6 December. Houghton, E.L. and Brock, A.E. (1970), Aerodynamics for Engineering Students, 2nd ed., Edward Arnold, New York, NY. IATA (2004), Guidance Material and Best Practices for Fuel and Environmental Management, IATA, Montreal, Ref. No: 9093-01, ISBN 92-9195-444-6, available at: www.iata.org/ NR/rdonlyres/66A62927-D1CB-474C-821E16F68FB6F7C7/0/Fuel_Action_Plan.pdf/ (accessed 8 December 2008) Jenkinson, L.R., Simpkin, P. and Rhodes, D. (1999), Civil Jet Aircraft Design, Arnold Publishing, London. Kahayas, N. (2007), “Aeronautical technology for future subsonic civil transport aircraft”, Aircraft Engineering & Aerospace Technology, Vol. 79/6, pp. 600-10. McLean, D. (2006), “The operational efficiency of passenger aircraft”, Aircraft Engineering & Aerospace Technology, Vol. 78, pp. 32-8. Maido, S. (2006), Aircraft Performance, Wiley, New York, NY. Mair, W.A. and Birdsall, D.L. (1992), Aircraft Performance, Cambridge University Press, Cambridge. Ojha, K.O. (1993), “Fastest climb of a turbojet aircraft”, Journal of Aircraft, Vol. 30 No. 1, pp. 127-9. Raymer, D. (2006), Airplane Design: A Conceptual Approach, 4th ed., AIAA, Reston, VA. Root, R. (2001), Cost Index, Performance Engineer Operations, Flight Operations Engineering, Seattle, WA, November. Schultz, R. and Zagalsky, N. (1972), “Aircraft performance optimisation”, Journal of Aircraft, Vol. 108, p. 114. Simons, D. and Jenkinson, L.R. (1985), “The determination of optimum flight profiles for short-haul Routes”, Journal of Aircraft, Vol. 12 No. 8, pp. 669-74. In the paper, it has been solved tree optimization problem in presence of dynamic disturbance, expressed in form of aircraft performance degradation: . it was defined climb technique for minimum climb cost; . it was defined TOCopt which in combination with climb technique for minimum climb cost minimize total operating cost of en route flight profile; and . achieved results is standardized for application in FMS or it can be apply in any aircraft which is equipped with altimeter, air speed indicator and Mach meter. In the paper, it was defined new approach for defining conditions for minimum cost climb technique and defined also new parameter for achieving optimization goal, minimization of RCC. In the process of defining optimal TOC it was shown influence of choice of TOCopt on en route total operating costs. Recalling assumptions of constant cruise Mach number and constant descent which isolated climb influence on total operating costs it is obvious existence of further development of cost optimization in cruise and descent phase. In the paper, it was also shown condition for TOCopt determination, for given CI, as a extension of minimum cost-climb technique. Presented technique is especially applicable on short-haul flights, where climb range can have length of about 40 per cent of total range. The practical benefit from proposed method, climb for minimum cost, for air operator can be synthesized in reduction of total cost from 3 to 5 per cent compared to AFM proposed flight profile. The second benefit is correction of climb law and TOCopt for achieving minimum en route operating costs in presence of aircraft performance degradation. Indirect benefit can be obtaining form information how much aircraft degradation costs. References Airbus Industry (2002), Getting to Grips with Aircraft Performance Monitoring, Airbus, Customer Service, Flight Operations Support and Line Assistance, Toulouse, December, pp. 98-134, available at: www.smartcockpit. com/pdf/flightops/aerodynamics/22/ (accessed 8 December 2008) Barman, J. and Erzebrger, H. (1976), “Fixed-range optimal trajectories for short-haul aircraft”, Journal of Aircraft, Vol. 13 No. 10, pp. 748-54. (The) Boeing Company (1985), Performance Engineers Manual B737300 CFM56-3-B1, Flight Operations Engineering, 3-L57A, The Boeing Company, Chicago, IL, April 1. (The) Boeing Company (1989), Jet Transport Performance Method, Flight Operations Engineering, D6-1420, 7th ed., The Boeing Company, Chicago, IL, May. (The) Boeing Company (2003a), Climb and Descent, Section 7, 737-300/-400/-500, The Boeing Company, Chicago, IL, Performance Engineers Course, Flight Operations Engineering, April. (The) Boeing Company (2003b), Enroute Performance, Section 6, 737-300/-400/-500, The Boeing Company, Chicago, IL, Performance Engineers Course, Flight Operations Engineering, April. Bressound, M.D. (2006), A Radical Approach to Real Analysis, 2nd ed., available at: www.macalester.edu/aratra/edition2/ chapter3/chapt3a.pdf/ (accessed 8 December 2008) Further reading Asselin, M. (1997), Introduction to Aircraft Performance, AIAA, Reston, VA. About the authors P. Mirosavljević received his BS in Air Transport Engineering from The Faculty of Transport and Traffic Engineering, University of Belgrade, in 1996, and receive his MSc in from the same faculty in 2001. He was accepted as PhD student in 2003. He has been working since 1997 at The Faculty of Transport and Traffic Engineering, as Teaching and Research Assistant at lectures in courses: Flight Mechanic (1997-present), The Transport Aircraft (1997-2003) and The Transport Aircraft Performance (2008-present). His research interests are in the areas of aircraft performance optimization, aircraft cost management, flight mechanics and airplane appraisal process. P. Mirosavljević is the corresponding author and can be contacted at: perami@sf.bg.ac.rs S. Gvozdenović, PhD, received his BS in Air Transport Engineering from The Faculty of Transport and Traffic 341 The turbo fan aircraft minimum cost climb technique Aircraft Engineering and Aerospace Technology: An International Journal P. Mirosavljević, S.Gvozdenović and O.Čokorilo Volume 81 · Number 4 · 2009 · 334 –342 Engineering, University of Belgrade, in 1975. He was working from 1975 to 1978 as Chief Engineer in aircraft factory UTVA, on general aviation maintenance. He received his MSc from The Faculty of Transport and Traffic Engineering in 1990. He was accepted as PhD student in 1990 and graduated in 1993. He has been working since 1978 at The Faculty of Transport and Traffic Engineering, the first as Teaching and Research Assistant at lectures in courses: Flight Mechanic (1978-1994), The Transport Aircraft (1978-1994) and than as Professor at lectures in courses: Flight Mechanic (1994-till now), The Transport Aircraft (1994-till now) and The Transport Aircraft Performance (1994-till now). He is the Dean of The Faculty of Transport and Traffic Engineering. His research interests are in areas of aircraft performance optimization, aircraft cost management, flight mechanics and airplane appraisal process. O. Čokorilo received her BS in Air Transport Engineering from The Faculty of Transport and Traffic Engineering, University of Belgrade, in 2002, and receive her MSc from the same faculty in 2007. She was accepted as PhD student in 2008. She is working from the 2002 at The Faculty of Transport and Traffic Engineering, as Teaching and Research Assistant at lectures in courses: The Transport Aircraft (2003-till now). Her research interests are in areas of safety management system, risk management and aircraft cost management. To purchase reprints of this article please e-mail: reprints@emeraldinsight.com Or visit our web site for further details: www.emeraldinsight.com/reprints 342