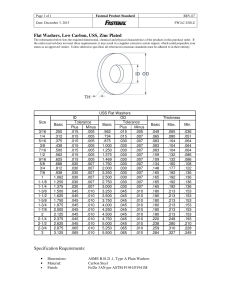

EXPERIMENT - 9 Devansh Sharma (22IM10015) Inala Jahnavi Mehar Sai (22IM10016) Jatin Gupta (22IM10018) Jishnu Mukherjee (22IM10019) Objectives of the Study: (i) To explore state-of-the-art machine learning (ML) tools for object detection (ii) Identify object characteristics using image processing (iii) CUSUM Chart Measuring Instruments/Apparatus/Software Required: Hardware: 1. Conveyor belt 2. Hikvision camera 3. ESP 32 motor control unit 4. Wifi Router 5. Workstation 6. Washer AI/ML Tools: 1. Yolo V8 2. Roboflow 3. Byte track Coding platform: 1. Python (Google colab and desktop) Connectivity Tools: 1. Rest API Measurement Tools: 1. Vernier caliper Methodology Measurement: Using the program measure the length of the diagonal of each of the bounding boxes, around the washers. Collect observed value of for several washers. Determine the outer diameter of the same washers using vernier calipers. Establish the relation . Tasks 1. Recall the model created for Experiment No. 5. Use the model to detect objects from the video file “output_roi.avi”. 2. Upload a video file on the MS Teams channel demonstrating detection of washers using YOLO V8, in the video, show green bounding boxes for washers with outer diameters within specification limits, and red bounding boxes for non-conforming washers. 3. Create a tabular CUSUM chart with the collected data and identify the instance from which the process started producing non-conforming units. Assume average of first 10 values, σ=standard dev of first 10 values. 4. Write a python program for generation of CUSUM chart, indicating control limits, and origin of shift in the process. INFERENCE: Effectiveness of Object Detection: The YOLO V8 model proved very effective in detecting washers, accurately placing bounding boxes around them in real-time. This high detection accuracy shows that the model is well-suited for real-time inspection tasks in an industrial environment, where reliable detection is critical. Accuracy in Measurement: The measurements of the bounding box diagonals gave a useful initial estimate of washer dimensions, which we then cross-checked with measurements taken using a vernier caliper. The close match between these measurements shows that the model is robust in detecting size variations, making it a dependable tool for identifying dimensional inconsistencies. CUSUM Chart Analysis: The CUSUM chart was successful in tracking the stability of the process. It helped us identify the point at which washers started to deviate from specified limits, indicating a possible production issue. This shift detection highlights the value of the CUSUM chart as an early warning tool, which could allow for quick adjustments and help maintain quality. Impact of Model and Measurement: Using machine learning together with traditional measurement tools provided a well-rounded quality control system. This approach not only ensures accurate detection but also improves the precision of our dimensional assessments, enabling us to efficiently spot non-conforming washers. Overall Implications: Combining AI with CUSUM control charts in quality control shows strong potential for maintaining consistent product quality. This approach can easily be scaled and applied to other types of production lines, offering a pathway to more effective quality control processes across various manufacturing setups.