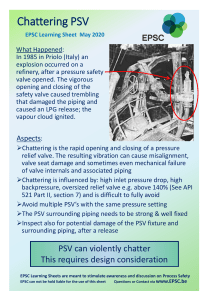

Client code TECNOMARE S.p.A. Tecnomare code PAP-002 originating division originating office: document codes Process Activity Procedure 002 Two-Phase Relief PSV Sizing distribution: PROS Dept. supplementary notes: questo documento è da intendersi come COPIA NON CONTROLLATA. 9 8 7 6 5 4 3 2 1 0 rev. 21/11/2014 date Issue for Internal Use description 18 ESA/IGU pages prepared checked approved authorised The contents of this document are property of TECNOMARE S.p.A. The entire document or parts of it cannot be used or reproduced in any form for different purposes than the one it was produced for. Tecnomare S.p.A shall protect its rights according to the law. Client code Tecnomare code PAP-002 date: page: 2 Revision Sheet Revision Changes 0 First Issue authors: ESA/IGU Client code Tecnomare code PAP-002 date: page: 3 TABLE OF CONTENTS 1. 2. 3. INTRODUCTION ................................................................................................................................4 1.1 SCOPE ................................................................................................................................................ 4 1.2 ACRONYMS ........................................................................................................................................ 4 SPREADSHEET ...................................................................................................................................5 2.1 GENERAL INPUT DATA ............................................................................................................................. 5 2.2 OMEGA METHOD CALCULATION PARAMETERS (1ST SHEET) ............................................................................. 6 2.3 HEM CALCULATION PARAMETERS (2ND SHEET)............................................................................................. 7 2.4 OUTPUT RESULTS ................................................................................................................................... 7 HOW TO USE ....................................................................................................................................8 3.1 SHEET 1 – OMEGA METHOD .............................................................................................................. 8 3.2 SHEET 2 – HEM METHOD ................................................................................................................... 9 APPENDIX A ‐ PROCEDURES.................................................................................................................... 13 A.1 GENERAL ............................................................................................................................................ 13 A.2 LEUNG OMEGA METHOD ....................................................................................................................... 14 A.2.1 Two‐phase Flashing or Non‐flashing Flow ............................................................................... 14 A.2.2 Subcooled Liquid ...................................................................................................................... 15 A.3 HOMOGENEOUS EQUILIBRIUM MODEL ..................................................................................................... 16 authors: ESA/IGU Client code Tecnomare code PAP-002 date: page: 4 1. INTRODUCTION 1.1 SCOPE Scope of this document is to provide guidelines and procedure aimed to preliminarly size a pressure safety valve for multiphase relief in case of overpressure, implementing the procedure explained by the Std. API 520 8th Ed. - Annex C. PSV Size spreadsheet is named “PSV 2-Phase_Calculation Sheet Rev0.xls” and it is contained in the folder “PROS/Programmi Processo/PSVs” of internal library. Task of process engineer shall be to define relief flow rate, physical properties of fluid at the relieving conditions and line size of piping upstream and downstream PSV. Futhermore, Pressure Safety Valve Datasheet is to be prepared by process engineer and provided to STAU unit to finalize valve sizing choosing the suitable orifice type to be installed. The following table explain how to fill the format items of the “PSV 2-Phase_Calculation Sheet Rev0.xls” spreadsheet. 1.2 ACRONYMS In this specification the following definition and abbreviations are applied. API American Petroleum Institute HEM Homogeneous Equilibrium Method MAWP Maximum Allowable Working Pressure PED Pressure Equipment Directive PSV Pressure Safety Valve Std. Standard authors: ESA/IGU Client code Tecnomare code PAP-002 date: page: 5 2. SPREADSHEET “PSV 2-Phase_Calculation Sheet Rev0.xls” is made by two separate sheets, respectively for resolution using the Omega Resolution Method and Integral Resolution Method. Spreadsheet cells highlighted with green colour represent the input of calculation. The remain cells will be calculated though formulas specified inside and write-protected in order to prevent any accidental change. The selection of the right method will be explained in the following section. For further details refer in Appendix A where the topic is more extensively discussed. 2.1 GENERAL INPUT DATA Row Name Description 1 Item / Tag The PSV tag number which the below column is referring to has to be reported here 2 MAWP Use design pressure when MAWP is not available 3 Contingency Valve arrangement and relief design case shall be specified here according to the corresponding note 4 Set Pressure Ps (barg) PSV initial opening pressure 5 Overpressure Criteria Corresponds to the standard used to calculate the overpressure (API or PED) 6 Maximum Accumulated Pressure (%) Percentage of Ps corresponding to full lift open pressure 7 Allowable Overpressure (%) Percentage of set pressure aimed to calculate the full-lift open pressure of PSV. It depends on the contingency choosen for the relief case 8 Relieving Pressure P0 (barg) Full-lift open pressure 9 Relieving Temperature T0 (°C) Temperature estimated at the relieving start, depending on the type of event leading to overpressure 10 Bubble Point Pressure Pv (bara) Vap-Liq equilibrium pressure at the relieving temperature to be specified when the fluid is liquid at the relieving conditions. 11 Total Backpressure (barg) Build-up + Superimposed Backpressure. % total of backpressure as a function of Ps will be calculated 12 Suggested Valve Type Valve type (Balance bellow or Pilot-operated) is automatically determined depending on total backpressure specified authors: ESA/IGU Client code Tecnomare code PAP-002 date: page: 6 Row Name Description 13 Relieving Liquid Flowrate (kg/h) Estimated liquid flowrate to be relief shall be specified into this cell 14 Relieving Gas Flowrate (kg/h) Estimated liquid flowrate (or supercritical fluid) to be relief shall be specified into this cell 15 Liquid Density (kg/m ) As specified in the note, when liquid phase is present at the inlet of PSV, liquid density evaluated at Pv shall be specified. Otherwise, liquid density at P0, 16 Gas Density (kg/m3) Gas density evaluated at P0 shall be specified 17 Liquid Viscosity (cP) Liquid viscosity at relieving conditions (T0, P0) shall be specified 18 Overall Fluid Density (kg/m3) Overall fluid density evaluated at P0 is automatically calculated here 3 2.2 OMEGA METHOD CALCULATION PARAMETERS (1ST SHEET) 19 P90% (bara) 90% of set pressure is calculated and shall be set in Hysys simulation in order to estimate physical properties for two-point Omega parameter 20 Overall Fluid Density @ P90% (bara) Overall fluid density evaluated at P90% shall be estimated by isentropic expansion 21 Omega Parameter ω 22 Transition saturation pressure ratio (ηst) Depends on ω (2nd method only) 23 Saturation pressure ratio (ηs) Depends on set pressure (2nd method only) 24 Flashing System Show if the fluid to be relief flashes through the PSV or not (2nd method only) 25 Subcooling Region Show the region (low or high) in which the system falls into (2nd method only) 26 Critical Pressure Ratio ηc Depends on ηs and could be estimated by equation or chart 27 Backpressure ratio ηa Depends on the backpressure imposed on the discharge of the PSV 28 Fluidodynamic Critical Pressure (bara) 29 Fluidodynamic Flow Region 30 Maximum theoretical Mass Flux (kg/m*s2) authors: ESA/IGU Depends on the specific automatically calculated volume or density, Limit pressure above which a critical flux occurs Show if the flux is critical or not Mass flux can be relief by the PSV Client code Tecnomare code PAP-002 date: page: 7 2.3 HEM CALCULATION PARAMETERS (2ND SHEET) 19-27 28 29 30 Representative Point Table Maximum theoretical Mass Flux (kg/m*s2) Pressure at the throat of the nozzle (bar a) Overall Density at the throat of the nozzle (kg/m3) Some recapitulatory point from the table XX is listed here with its pressure and density Mass flux can be relief by the PSV Pressure at which maximum max flux occurs Density at which maximum max flux occurs 2.4 OUTPUT RESULTS Relates the effective flow rate at the end of the PSV nozzle with the theoretical one Takes into accoun the possible presence of a rupture disk upstream PSV Related to the backpressure imposed downstream the relief valve It is the minimum orifice area required for the relief at operating conditions 31 Discharge coefficient Kd 32 Combination correction factor Kc 33 Backpressure correction factor kb 34 Required PSV discharge Area (mm2) 35 PSV orifice type 36 Selected PSV discharge Area Effective PSV orifice area installed on the equipment 37 Selected PSV Rated Flowrate Effective flow rate through PSV at relief conditions 38 Liquid Reynolds Number Reynolds Number of liquid phase during the relief 39 Viscosity correction factor Kv Related to the presence of liquid at the inlet of PSV 40 Effective required PSV discharge Area 41 CHECK on Selected Area 42 Notes Preliminary choice of orifice type by API 526 PSV discharge area recalculated using Kv Check between line 36 and 40 In addiction to the above, it has to be noted that a control valve may be subjected to different operating scenarios (e.g. operation with different fluids along the plant life). In such a case, a different column shall be prepared and the analysed scenario specified in the notes. authors: ESA/IGU Client code Tecnomare code PAP-002 date: page: 8 3. HOW TO USE 3.1 SHEET 1 – OMEGA METHOD A preliminary check about the suitability of Leung Omega Method shall be done by checking if the fluid falls into the thermodinamic supercritical region. Check is done automatically by the spreadsheet, giving a warning as shown in Tab. 1. In this case, the use of HEM method is recommended. Check on Omega Method Validity: Thermodynamic bar a Critical Pressure: Thermodynamic °C Critical Temperature: Omega Method Validity: WARNING! 9 93 NO For fluid conditions near the thermodynamic critical point, Omega Method could underestimate PSV orifice area. It is suggested to use API 520 Integral Method in that case. Table 1. Check Leung Method Validity Relevant input data to be provided to the spreadsheet for PSV sizing are: Design Parameters MAWP, design case and number of PSV installed shall be specified. According to contingency, relieving pressure will be calculated (line 8). Physical Properties Thermodinamic and physical properties at the relieving conditions and at the 90% of relieving pressure shall be specified. Depending on the total backpressure imposed downstream PSV (hypotized or estimated by Aspen Flare System Analyzer), pressure safety valve type is suggested (line 12). Material Balances According to design scenario, gas and liquid flowrates to be relief shall be specified (lines 13-14); Correction Factors In order to estimate effective required discharge area, correction factors (lines 31-32-33-39) shall be estimated. Finally, preliminary choice of PSV orifice type and valve inlet/outlet diameter shall be done as specified in Std. API 526. authors: ESA/IGU Client code Tecnomare code PAP-002 date: page: 9 3.2 SHEET 2 – HEM METHOD Homogeneous Equilibrium Model is suitable for PSV sizing for all the scenarios listed in Section A.1, given that it depends on liquid/vapor (or gas) phase equilibrium during the relief through the PSV orifice. However, equilibrium physical properties to be put into “PSV 2-Phase_Calculation Sheet Rev0.xls Sheet 2 Tab 3” shall be achieved by isentropic expansion from relieving pressure up to maximum mass flux will be calculated using Process Simulation (in this PAP, Hysys v8.3). In the following description, procedure to be follow is reported: Design Parameters MAWP, design case and number of PSV installed shall be specified. According to contingency, relieving pressure will be calculated (line 8). Physical Properties Thermodinamic and physical properties at the relieving conditions shall be specified. Depending on the total backpressure imposed downstream PSV (hypotized or estimated by FlareNet Simulator), pressure safety valve type is suggested (line 12). Material Balances According to design scenario, gas and liquid flowrates to be relief shall be specified (lines 13-14); HYSYS Simulation In order to obtain couple of Pressure vs Overall Density points (in the “PSV 2-Phase_Calculation Sheet Rev0.xls - Sheet 2 Tab 3” can be specified maximum 50 points), a case sudy is to be set to perform isentropic expansion of the flow stream, starting from its relieving pressure. In the following screenshots, Aspen HYSYS v8.3 has been taken into account, but the same versions of HYSYS. Once composition, pressure and temperature have been specified in the flow stream to be relieved, molar entropy shall be specified as input (Fig 1) to be kept fixed during the expansion Figure 1. Setting for Isentropic Expansion Then, create new Case Studies: pushing the button “Add” in the interface “Set up” (Fig. 2), we can select the variables “Pressure” (indepentent variable) and “Mass Density” (dependent variable) authors: ESA/IGU Client code Tecnomare code PAP-002 date: page: 10 Figure 2. Set Up Interface Settings Figure 3. Add New Variables In the lower part of Fig. 2, we could select State Input Type = Nested, specifying low and high bound, then specifying the step size equal to: 50 Ticking “Step Downward” and clicking on “Run”, from the interface “Results” (Fig. 4) the 50 pairs of points are available to be copied and pasted in “PSV 2-Phase_Calculation Sheet Rev0.xls - Sheet 2 Tab 3” (Tab. 2). The calculation sheet will automatically select the row corresponding to the maximum mass flux. authors: ESA/IGU Client code Tecnomare code PAP-002 date: page: 11 Figure 4. Results Interface Pressure Overall Density Pressure Integrand Summation Mass Flux bara kg/m3 Pa m2/s2 m2/s2 kg/s*m2 1 50.0 65.42 5000000 0 0 0 2 49.0 63.76 4900000 -1548 -1548 3548 …. 33.0 39.15 3300000 -2508 -33436 10125 n 32.0 37.73 3200000 -2601 -36037 10130 …. 2.0 2.00 200000 -39960 -300966 1549 50 1.0 0.99 100000 -66890 -367856 852 # Table 2. Fluid Isentropic Path N.B. copy and paste the results checking that decimal separator is set as dot, otherwise change your Regional Options. authors: ESA/IGU Client code Tecnomare code PAP-002 date: page: 12 Correction Factors In order to estimate effective required discharge area, correction factors (lines 31-32-33-39) shall be estimated. Main design properties (maximum mass flux, related pressure and density) from “Tab. 3 – Fluid Isentropic Path” will be automatically specified respectively into lines 28-29-30. Finally, preliminary choice of PSV orifice type and valve inlet/outlet diameter shall be done as specified in Std. API 526. authors: ESA/IGU Client code Tecnomare code PAP-002 date: page: 13 APPENDIX A - PROCEDURES A.1 GENERAL PAP-002 refers to the sizing methodology described in Std. API 520 8th Ed. (Annex C), in which Leung Omega Method (section A.2) and Homogeneous Equilibrium Method (section A.3) are examined: in the first one, fluid physical properties are calculated through the Omega two-point parameter, related to the fluid specific volume at the relieving conditions; the second method is based on the thermal and mechanical equilibrium of the two phase fluid, assuming it as a “pseudosingle phase fluid”. Leung Omega Method has been modified also to fit experimental data for subcooled liquid at the PSV inlet (section A.2.2). The procedure applies to all the scenarios (Tab.3) in which a relief of two-phase fluid occurs but, according to the several scenarios could be verified, the following criteria shall be taken into account for the choice of the right correlation to be used. Two-phase Liquid/Vapour Relief Scenario 1 - Two-phase system (liquid vapor mixtures, including saturated liquid) enters PSV and flashes. No non-condensable gas present. Example Saturated Liquid/vapour propane system enters PSV and liquid propane flashes 2 - Two-phase system (highly subcooled liquid and either non-condensable gas, condensable vapour or both) enters PSV and does not flashes. Highly subcooled propane and nitrogen enters PSV and the propane does not flash Procedure A.2.1 or A.3 3 - Two-phase system (the vapor at the inlet contains some non-condensable gas and the liquid is either saturated or subcooled) enters PSV and flashes. Non-condensable gas enters PSV. Saturated Liquid/vapour propane system and nitrogen enter PSV and the liquid propane flashes Procedure A.2.1 or A.3 4 - Subcooled liquid (including saturated liquid) enters PSV and flashes. No condensable vapour or non-condensable gas enters PSV. Subcooled propane enters PSV and flashes Procedure A.2.2 or A.3 Table 3. Two-Phase Relief Scenarios authors: ESA/IGU Correlation Procedure A.2.1 or A.3 Client code Tecnomare code PAP-002 date: page: 14 A.2 LEUNG OMEGA METHOD A.2.1 Two-phase Flashing or Non-flashing Flow The first methodology is focused on estimating the two-point Omega parameter ω as follows: 9 1 .1 Where is the specific volume evaluated at 90% of the PSV inlet pressure, m3/kg; is the specific volume evaluated at the PSV inlet pressure, m3/kg. According to the type of flux at the outlet of the PSV, maximum mass flux results on: .2 2∗ ∗ ln 1 1 ∗ 1 1 . .3 1 Where G is the mass flux, kg/s*m2 ; P0 is the pressure at PSV inlet, Pa; is the specific volume evaluated at the PSV inlet pressure, m3/kg; ηa is the backpressure ratio, ηa= Once the value of the maximum mass flux has been determined, the required orifice area can be calculated using Equation (A.4): 277.8 ∗ .4 Where A is the required effective discharge area, mm2; W is the mass flow rate to be relief, kg/h; Kd is the discharge coefficient, preliminarly set as 0.85 in case of two-phase mixture or saturated liquid entering the PSV inlet, 0.65 for a single phase (sub-cooled liquid); Kb is the backpressure correction factor; Kc is the combination factor, set to 1.0 if a rupture disk is not installed upstream PSV, 0.9 otherwise; Kv is the viscosity correction factor. authors: ESA/IGU Client code Tecnomare code PAP-002 date: page: 15 A.2.2 Subcooled Liquid The second method is applied to system in which presence of a subcooler or saturated liquid occurs, whitout any presence of gas phase (condensable vapor or non-condensable gas) at the inlet of PSV. The subcooled liquid either flashes upstream or downstream of the PSV throat depending on which subcooling region the flow falls into, respectively low and high subcooling region. 9 1 .5 Where l is the mass density evaluated at 90% of the PSV inlet pressure, kg/m3; is the mass density evaluated at the PSV inlet pressure, kg/m3; According to the type of flux at the outlet of the PSV, maximum mass flux results on: 2 1 2 ln ∗ 1.414 . 1 1 ∗ 1 .6 . .7 Where G is the mass flux, kg/s*m2; P shall be set to PS for critical flow, Pa for sub-critical flow, Pa; η is the backpressure ratio, set to ηc for critical flow, ηa for sub-critical flow; Once the value of the maximum mass flux has been determined, the required orifice area can be calculated using Equation (A.8): 16,67 ∗ .8 Where A is the required effective discharge area, mm2; Q is the volumetric flow rate to be relief, l/h; l0 is the mass density evaluated at the PSV inlet pressure, kg/m3; Kd is the discharge coefficient, preliminarly set as 0.85 in case of two-phase mixture or saturated liquid entering the PSV inlet, 0.65 for a single phase (sub-cooled liquid); Kb is the backpressure correction factor; Kv is the viscosity correction factor. authors: ESA/IGU Client code Tecnomare code PAP-002 date: page: 16 A.3 HOMOGENEOUS EQUILIBRIUM MODEL HEM is the only procedure applicable for all the two-phase relief PSV sizing. As a hypothesis, PSV inlet nozzle is assumed to be the limiting flow element of a fully opened relief valve, through which an isentropic expansion occurs (so, adiabatic and reversible). The general energy balance for isentropic nozzle flow is 2∗ ∗ ∗ 2 .9 Where: G is the mass flux, kg/s*m2 ; v is the specific volume of the fluid, m3/kg; is the mass density of the fluid, kg/m3; P is the stagnation pressure of the fluid, Pa; P0 is the fluid condition at the inlet to the nozzle; t is the fluid condition at the throat of the nozzle where the cross-sectional area is minimized. The integral (A.9) shall be evaluated numerically by direct summation over small pressure intervals and using the hypothesis of isentropic expansion introduced above. The resolution of (A.1) shall be made by means of “PSV 2-Phase_Calculation Sheet Rev0.xls - Sheet 2 Tab 3”, explained in Appendix B. Finally, the required orifice area can be calculated using Equation (A.4). authors: ESA/IGU