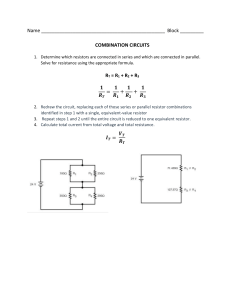

Electrical and Electronic Technology for CSEC® Online support 3 Great Clarendon Street, Oxford, OX2 6DP, United Kingdom Oxford University Press is a department of the University of Oxford. It furthers the University’s objective of excellence in research, scholarship, and education by publishing worldwide. Oxford is a registered trade mark of Oxford University Press in the UK and in certain other countries. © Oxford University Press 2018 The moral rights of the authors have been asserted. First published in 2018 CVQ is the Registered Trademark of the Caribbean Association of National Training Authorities (CANTA). ® All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form or by any means, without the prior permission in writing of Oxford University Press, or as expressly permitted by law, by licence or under terms agreed with the appropriate reprographics rights organization. Enquiries concerning reproduction outside the scope of the above should be sent to the Rights Department, Oxford University Press, at the address above. You must not circulate this work in any other form and you must impose this same condition on any acquirer. British Library Cataloguing in Publication Data Data available 978-0-19-839547-8 1 3 5 7 9 10 8 6 4 2 Paper used in the production of this book is a natural, recyclable product made from wood grown in sustainable forests. The manufacturing process conforms to the environmental regulations of the country of origin. Printed in Great Britain by CPI Group (UK) Ltd., Croydon CR0 4YY Acknowledgements The publishers would like to thank the following for permissions to use their photographs: Cover image by Caribbean Examinations Council (CXC). p9: Kino / age fotostock/SuperStock; p24: Shutterstock; p58: photonic 7/Alamy Stock Photo; p72: Shutterstock; p78t: Shutterstock; p78b: Shutterstock; p79: Shutterstock; p109t: Shutterstock; p109b: Shutterstock. Artwork by MPS Ltd., OUP and Cenveo. Although we have made every effort to trace and contact all copyright holders before publication this has not been possible in all cases. If notified, the publisher will rectify any errors or omissions at the earliest opportunity. Links to third party websites are provided by Oxford in good faith and for information only. Oxford disclaims any responsibility for the materials contained in any third party website referenced in this work. John Blaus Vernon Daniel Wilbert Nunes Bachan Ramdhan Online support Contents Introduction ������������������������������������������ 1 4. Electrical installations .................... 62 1. Electrical principles and measurements���������������������������������� 2 4�1 Introduction �������������������������� 62 1�1 What is electricity? ����������������� 2 4�2 Circuits �������������������������������� 64 1�2 Separating charges ����������������� 5 4�3 Wiring methods and terminations ������������������������� 70 1�3 Electric current ����������������������� 6 4�4 Lighting circuits �������������������� 74 1�4 Basic laws of electromagnetism ������������������� 9 4�5 Lamps ��������������������������������� 78 1�5 Ohm’s law ���������������������������� 14 4�6 Conduits ������������������������������ 82 1�6 Resistivity ���������������������������� 21 4�7 Testing and commissioning ��������������������� 90 1�7 Circuit protective devices������� 24 4�8 Fault diagnosis ��������������������� 94 1�8 Principles of a�c� and d�c� current flow �������������������� 29 4�9 Fuses and circuit breakers ���������������������������� 102 1�9 Resistance, inductance, and capacitance ������������������� 35 5. Electronics ................................... 104 1�10 Cells and batteries ������������� 44 2. Electrical and electronic drafting .......................................... 45 2�1 Drawings and circuit diagrams ������������������������������ 45 2�2 Electrical symbols ����������������� 47 2�3 Scale drawings ��������������������� 51 3. Electrical power, power and machines ....................................... 52 3�1 How is electricity produced? �� 52 5�1 Resistors ��������������������������� 104 5�2 Capacitors ������������������������� 108 5�3 Semi-conductor devices������� 111 5�4 Rectification ����������������������� 114 5�5 Transistors ������������������������� 116 5�6 Integrated circuits ��������������� 119 5�7 Thyristors ��������������������������� 119 Glossary ������������������������������������������� 124 Index ����������������������������������������������� 125 3�2 Transformers ������������������������ 56 Access your support website for additional content and activities here: www.oxfordsecondary.com/9780198395478 ii Introduction Electrical and Electronic Technology for CSEC® A CXC Study Guide has been developed by experienced teachers and examiners, working closely with the Caribbean Examinations Council (CXC®) and focuses on the development of competencies. It concentrates on the areas of the syllabus that are most challenging to learn and are considered essential to the development of skills required by the programme and entry into the world of work. The content has been constructed around workshop investigations to support the process of relating theory to practice and practice to theory. These are designed to align with the school-based assessment and allow students to review progress effectively. This gives the student a positive role in managing their own learning. Additionally, there are opportunities for students to use reflective techniques to identify what went well, what might have been done more effectively and how similar activities might be approached in the future (skill transfer). The study guide and associated activities support a range of pedagogy to make learning engaging, interactive and efficient, leading to a deeper understanding. The range of pedagogy includes: 1. Assessment of and for learning 2. Cooperative learning 3. Differentiation 4. Embedding language, literacy and numeracy 5. Experiential learning 6. Learning conversations 7. Relating theory and practice 8. Using e-learning and technology. Remember, where applicable, candidates who successfully complete the CSEC examinations in the Technical Syllabuses will receive two awards: the CSEC Technical Proficiency Certificate and a CVQ* (Caribbean Vocational Qualification) Statement of Competence. We are confident that this book will provide students with the skills to succeed in their course of study and beyond. * CVQ is the Registered Trademark of the Caribbean Association of National Training Authorities (CANTA). 1 1. Electrical principles and measurements 1.1 What is electricity? Can you imagine life without lighting, heating, computers, televisions, fridges, and air conditioning? The development of electricity as a useful supply of energy in the home is relatively recent. It is credited principally to Thomas Edison, the inventor of the first efficient light bulb in the 1870s. Energy can be converted from one form to another, but cannot be created or destroyed. Electrical energy (electricity) coming through a cable to a television makes it work – the energy is converted into light, sound (and heat). Electricity is produced by converting the energy in one of three ways: ● From chemical energy, e.g. batteries ● From magnetic and kinetic energy, e.g. wind turbines, power stations which use various forms of fuel (wood, coal, gas, oil, nuclear, tidal) ● From the Sun (solar), e.g. converting energy from the Sun to charge a battery, or to feed into the main power grid. Gas Every known substance is composed of particles – atoms or molecules, which are held together by chemical bonds. Atoms and molecules Solid are always in a state of rapid motion. In a solid they are densely packed together and movement is restricted. In a liquid the particles are less tightly Liquid bound, and there is more free movement. In a gas, the particle movement is almost unrestricted, the Figure 1.1 The three states of matter substance can expand and contract in any direction. Atoms consist of even smaller particles, called sub-atomic particles. At the centre of each atom is the nucleus, which is made up of protons and neutrons. Protons possess a positive charge, and neutrons have no electrical charge. Electrons circle the nucleus and possess a negative charge. All atoms possess equal numbers of protons and electrons, so the atom is electrically neutral. – – Orbiting electrons – – + + + + + + + + + + – – Neutrons – Protons – Nucleus – – Figure 1.2 Sub-atomic particles (this shows an atom of neon) 2 The simplest atom is that of hydrogen which has one proton and one electron, whereas aluminium has 13 protons and 13 electrons. Electrons orbit the nucleus in shells at varying distances. Those nearest the nucleus are held in place more strongly than those furthest away. These distant electrons are easily moved from their orbits and so are free to join those of another atom, whose own distant electrons may in turn leave to join another atom, and so on. Movement of these ‘free’ electrons is electricity. Atoms or molecules that have gained or lost electrons are called ions. Proton Electron A material that allows the movement of free electrons is a conductor, and one that doesn’t is an insulator. Metals are made up from a lattice of positive ions surrounded by a sea of free electrons which can move about. This means that it is easy for charges to move freely through metals, so they are good conductors of electricity, e.g. copper, aluminium, tungsten. Al Most other solid materials do not have free electrons or other charge carriers and so it is difficult for a current to flow. These materials are called insulators, e.g. rubber, plastic, wood. Figure 1.3 A hydrogen atom (top) and an aluminium atom Some materials lie between the two extremes of conductivity and can conduct current under certain conditions. These are known as semi-conductors. Silicon is a widely used semi-conductor which will only conduct current when another substance such as germanium is added to the silicon. Iron Copper Conductors Germanium Silicon Semi-conductors Glass Diamond Fused silica Insulators Conductivity Figure 1.4 Conductivity Conductivity is the ability of a material to carry electrical charge. Put simply, if a material can carry electrical charge easily, then this material is considered to have good conductivity, for example, copper and aluminium. However, materials with a poor conductivity do not carry electrical charge easily, for example, wood, glass and plastic products. 3 Why don’t you? Test a range of materials to see whether they are conductors or insulators. You can use a simple lamp or an ammeter. Place the material in the circuit to find out if it can conduct electricity Figure 1.5 A simple conduction test Electricity – movement of free electrons. Atom – the smallest part of an element that can take part in a chemical change. Molecule – a group of atoms bonded together. Key terms Nucleus – the positively charged central core of an atom made up of protons and neutrons. Proton – a stable sub-atomic particle occurring in all atoms with a positive charge. Neutron – a stable sub-atomic particle with no charge. Electron – a stable sub-atomic particle with a negative charge. Ions – atoms or molecules that have gained or lost electrons. Conductor – a material that conducts electricity. Insulator – a material that doesn’t readily conduct electricity. Semi-conductor – a material that can conduct electricity under certain conditions. Questions For each of the following questions choose the correct answer. 1 2 3 4 At the centre of each atom is the nucleus. This is made up from: a) Electrons b) Protons c) Molecules d) Free electrons Which of the following is not a good conductor? a) Tungsten b) Aluminium c) Brass d) Magnesium oxide Which of the following is not a good insulator? a) Mercury b) Impregnated paper c) Mica d) Rigid plastics 1.2 Separating charges ro d Electrons gained by cloth Pe rsp ex Po ly th en er od Most materials are Atoms become uncharged because they are positive as Atoms a result of composed of neutral atoms. become losing electrons positive as When some materials Electrons gained a result of by rod are rubbed together, the losing electrons –– – frictional forces can cause –– + + + + 1+ – ++ electrons to be transferred + – – ++ + + – from one material to another. + + – – Because the protons are – Dry cloth tightly bound in the nucleus, Dry cloth they cannot move from place to place. This transfer of Figure 1.6 Charging a plastic rod electrons results in both of the materials becoming electrically charged. ● When extra electrons enter an object, the object becomes negatively charged. ● When electrons leave an object, the object becomes positively charged. Rubbing a polythene rod with a dry cloth will cause electrons to move from the cloth to the polythene rod. The rod will become negatively charged because it has extra electrons, and the cloth will now become positively charged as it has fewer electrons than protons. Did you know? If a Perspex rod is rubbed, electrons will move from the rod to the cloth, leaving the rod positively charged and the cloth negatively charged. Charged particles produce a force on each other in a similar way to magnets: ● Opposite charges attract each other. ● Similar charges repel each other. Static electricity Key term Why don’t you? Have you ever experienced a small electric shock when touching the handrail of a moving escalator? Have you ever rubbed a balloon against you and then stuck it on a wall? Have you noticed how particles of dust are attracted to computer monitors and TV screens? Static electricity causes this. It is a type of induced charge. Investigate the effect of induced charge by cutting a sheet of paper into small pieces and placing on the desk. Charge up a plastic rod using a cloth and place the cloth near the pieces. ● What happens to the pieces of paper? ● Explain why the charged rod affects the uncharged pieces of paper. Static electricity – a build-up of charge on the surface of an object. The charge remains until it is discharged, for example, by touching the object. This can cause a mild electric shock. 5 1.3 Electric current Table 1.1 Terminologies relating to electrical measurement and quantities Measured in units Unit symbol I This is the flow of electrons, or the flow of charge. The rate of this flow of charge is measured in amperes ampere A Charge The quantity of electricity. One coulomb of charge is conveyed in one second by a current of one amp Q coulomb C Potential difference One volt is the energy transferred by one coulomb as it passes between two points in a circuit V volt V Electromotive force (e.m.f.) The voltage produced by an electrical power source, e.g. an e.m.f. of 9 V for a battery or an e.m.f. of 115 V for a mains supply E volt V Power The rate at which energy is transferred by electrically powered items, e.g. a light bulb may be 60 W, a fridge may be 200 W P watt W Energy This is the ability to perform work or to move or change things W or E joule J Resistance The level of opposition to the flow R of current in a circuit ohm Ω Capacitance The ability to store electric charge C microfarad μF nanofarad nF picofarad pF Name Description Current Symbol Inductance The opposition created by a changing current in a magnetic field which induces a reverse voltage L henry H Frequency The rate at which alternating current (a.c.) completes a cycle f hertz Hz 6 Electric current The flow of electric charge is a current. This flow of charge is caused by a potential difference between two points of a circuit. The current is driven through the circuit by the electromotive force (e.m.f.). The size of a current is the rate of flow of charge, and this is measured in a unit called the ampere (A). The relationship is normally written as: Charge transferred = current × time Did you know? Worked example Q=I×t What is the current in a wire if a charge of 300 C is transferred in 30 seconds? Q=I×t Q I= t 300 I= 30 I = 10 A The symbol for current is I, which related to the intensity of electron flow and is measured in amperes (A). Current in circuits Electrical charges move round circuits made up of metal wires and components. Copper or aluminium are usually used for these as they are both good electrical conductors. This current is not lost or used up as it travels around the circuit, but is transformed to power electrical devices. (However, a small amount of energy is lost as heat.) Some examples of electrical transformations include: Electrical motors transform electrical energy into kinetic energy, allowing objects to move. Electricity can be converted into light using filament light bulbs, LEDs or fluorescent tubes. Conventional current is described in terms of a flow of positive charge. In circuits the energy is actually carried by a flow of negative charge. This means that the particles carrying charge are moving in the opposite direction to the conventional current. The current in a metal wire is caused by a flow of electrons from a negative terminal to a positive terminal. Conventional current is a flow of positive charge from a positive terminal to a negative terminal. Direction of conventional current Battery + Did you know? Television sets convert electrical energy to sound and images. Direction of electron flow Figure 1.7 Flow of charge 7 The causes and effects of electric current To use electrical power we need a current to be pushed by the electromotive force around a conductive circuit. Table 1.2 The main sources of an electromotive force Chemical An example of this is a battery. A battery is made up from two different metal plates and an electrolyte. Electrons from one metal plate will flow through the electrolyte to the other plate. This causes an imbalance in the two plates: one will be positive, one will be negative. This reaction causes the electrons to flow and produce a current. Batteries can be used to run small hand-held devices, e.g. a torch. Thermal (heating or lighting) This occurs when electrons flow between two different metals at different temperatures. This arrangement is known as a thermocouple and is used in appliances which heat up to extreme temperatures, e.g. in an oven or a furnace. Magnetic A magnetic field can be used to generate a flow of electrons. We call this situation electromagnetic induction. If a conductor is moved through a magnetic field, then an e.m.f. will be induced in it. Provided that a closed circuit exists, this e.m.f. will then cause an electric current to flow. An example of this would be an alternator or generator. Potential difference is the cause of the movement of charge. A charged particle will move to a position where it will have less potential energy and so will move to a lower point in an electric field. The reference point that potential is measured against is the Earth which is taken as zero potential or 0 V. A voltage of 115 V means a potential of 115 V above 0 or Earth. Table 1.3 The effects of electricity Chemical effect Did you know? Cells Batteries Electroplating 8 Thermal (heating/ lighting) effect Light bulb Fan heater Cooker Iron Kettle Magnetic effect Motors Transformers Circuit breakers Bell Electromotive force (e.m.f.) is the total force measured in volts causing a potential difference between two points, thus causing a flow of electrons. A current cannot exist without a potential difference. The bigger the difference, the bigger the flow. So a 115 V mains supply has a greater flow than a 9 V cell battery. 1.4 Basic laws of electromagnetism Magnetism is hard to define – you may know about the attraction or repulsion of one material by another material, but why does this happen? Why do you only see it in some materials, particularly iron? Materials that are attracted by a magnet such as iron, steel, nickel and cobalt have the ability to become magnetised. These are called magnetic materials. A magnetic field is a region of space in which a magnetic material will experience a force. The shape of a magnetic field is not as simple as that of an electric field, as there are always two poles involved. Lines of force N S Figure 1.8 The poles of a magnet Why don’t you? Place a bar magnet under a sheet of paper and sprinkle iron filings on the paper. These filings will align with the field lines and the shape of the field will be clearly seen. What happens if you place a second magnet under the paper? Figure 1.9 Field lines shown with iron filings There are two types of magnets – the permanent magnet and the electromagnet. A permanent magnet is a material that displays a magnetic field of its own. Examples of permanent magnets are the bar magnet and the horseshoe magnet. 9 Why don’t you? An electromagnet is a temporary magnet as the magnetic field will only be present whilst there is a current flowing through a coil of wire wound around it. If current is moving along a wire, a field of magnetic flux will be created. The direction of the field will depend upon the direction of the current. Examples of electromagnets include doorbells and relays. An example of a relay is used in cars, where a small current from the ignition circuit is used to turn on a larger current in the starter motor. Using your right hand, imagine curling your fingers around the wire while sticking your thumb out in the direction of the conventional current. The curved direction of your fingers shows you which way the magnetic field loops. Field nt Curre Did you know? Figure 1.10 The right-hand grip rule ● Opposite poles attract each other: north poles attract south poles. ● Like poles repel each other: north poles repel north poles, and south poles repel south poles. ● The closer the magnets are to each other, the stronger the force (flux) between the magnets. ● The lines of flux flow from the north pole of the magnet to its south pole. ● The lines of flux never cross each other. ● Magnetic materials placed near either pole of a magnet will be attracted towards it. Direction of screw travel Direction of turning The corkscrew rule The corkscrew rule helps us to understand the relationship between current flow and magnetic fields. If we think of a normal right-hand threaded screw, the rotation of the tip represents the direction of the current through a straight conductor. The direction of rotation of the screw represents the direction of rotation of the magnetic field. Current flow Magnetic flux Figure 1.11 The corkscrew If a wire is formed into a coil, and a current is passed rule through it, it becomes an electromagnet, otherwise known as a solenoid. Figure 1.12 is a section through a coil, with the arrows showing the direction of current flow for different magnetic fields. Because the turns of the coil would be wound close together, all the individual magnetic fields shown in Figure 1.12 would Figure 1.12 Direction of combine to form one overall large magnetic field. In order current for different fields to make the electromagnet stronger, an iron core may be 10 Why don’t you? fitted in the centre of the coil. This helps to concentrate the flux here. This is the principle used to produce magnetic fields in relays, contactors and motors, etc. Build your own electromagnet using a large iron nail, a low voltage power supply (a 9 V battery), and a length of insulated wire. Wrap the wire around the nail in a tight coil, and connect each end of the wire to the battery. Test the power of the electromagnet by seeing if the nail will attract other iron or steel objects. N S Figure 1.13 Using an iron core First finger pointing in the direction of the field (N to S) Fleming’s left-hand rule Fleming’s left-hand rule (also known as the motor rule) enables us to determine the direction of the force acting on the wire when we know the direction of the current and the magnetic field. To understand this rule, using your left hand: ● Separate your thumb, first and second fingers so that they all point at right angles to each other. Thumb points in the direction in which the conductor tends to move Second finger pointing in the direction of the current in the conductor Figure 1.14 Fleming’s left-hand rule ● Point your First finger in the direction of the magnetic Field (i.e. north pole to south pole). ● Point your seCond finger in the direction of the Current (from the positive terminal to the negative terminal). You may have to twist your hand to do this but make sure you keep your fingers at right angles to each other. ● Your thuMb will show the direction of the force acting on the wire (Movement). Why don’t you? Have a go at making an electric motor using the following items: ● an AA cell battery ● a strong cylinder magnet ● a small nail ● a short piece of wire with insulation removed at each end. You should be able to create a motor which will spin rapidly. Explain how this happens. 11 Electromagnetic induction When a conductor is moved through a magnetic field so that it cuts through the flux, the electrons in the conductor experience a force which attempts to make them move. This is the electromotive force (e.m.f.). If the conductor is connected to a circuit, then the e.m.f. will produce an induced current in the circuit. To understand this induced current flow, you need to imagine the magnetic field lines around the magnet being cut by the conductor as it moves through them. It is the cutting of these lines of magnetic flux which places a force on the electrons. Electromagnetic induction occurs when there is a relative movement between a magnet and a conductor, so that the magnetic flux lines are being cut. You can see the effect of induction by moving a wire rapidly through a magnetic field. The current induced in the circuit will be very small, but can be measured using a sensitive ammeter. Note the current only exists when the wire is moving through the magnetic field. There is no current when the wire is stationary. Movement of wire Ammeter Magnets Figure 1.15 Demonstrating electromagnetic induction Did you know? These factors affect induced current: ● The stronger the magnetic flux, the larger the induced current. ● The longer the conductor, or the more loops of wire, the greater the induced current. ● The faster the wire is moved in relation to the magnet, the greater the current. ● Reversing the direction of the magnetic field (i.e. changing north and south poles) will also reverse the direction of current. Questions 1 In your own words, describe a magnetic field and state the first law of magnetism. 2 List four factors which affect the resistance of a conductor. 3 Describe what is meant by the resistivity of a material. 12 Measuring instruments There are two types of meters measuring voltage, current and resistance, presenting the results in either analogue or digital form. Analogue Analogue meters use a pointer moving over a scale and within limits. They are capable of a continuous indication of Moving-coil voltage or current. The most important on aluminium analogue instrument is the moving-coil former meter. Soft-iron core N S Pole piece The meter consists of a coil of fine + – copper wire, mounted on an aluminium forma and pivoted at either end so it is Figure 1.16 The moving-coil meter free to rotate in a strong magnetic field. The magnetic field is provided by a small but powerful, permanent magnet with shaped pole pieces. The coil itself is provided with a soft iron core to produce an intense radial magnetic field. When a direct current is passed through the coil, it takes up a position dependent on the size of the current. Digital Digital meters are devices which show the readings as a numerical display using a liquid crystal display (LCD) or light-emitting diode (LED) technology, rather than pointing to a measure on a scale. Why don’t you? Why don’t you? Key terms Ammeter – an instrument used for measuring current. Voltmeter – an instrument used for measuring voltage. It measures the potential difference between two points. Multimeter – combines the features and characteristics of both an ammeter and a voltmeter, and measures current, voltage and resistance. Digital multimeters are the most commonly used measuring devices. Using a voltmeter, measure the voltage at socket outlets in your workshop, classroom and other college/school socket outlets. Record these voltages in a table and compare your readings with those from other students. If there is a variation in readings at socket outlets, discuss reasons why this may be the case. Describe using diagrams how you would take a current reading from a power circuit when a load has been switched on. 13 1.5 Ohm’s law So far we have established that current is the amount of electrons flowing in a conductor and that a force known as the e.m.f. (or voltage) is pushing them. We also know that the conductor will try to oppose the current by offering a resistance to the flow of electrons. Ohm’s law is the result of research by a 19th century German physicist G S Ohm into the relationship between current, voltage and resistance in an electrical circuit. His findings are summarised as Ohm’s law: The current flowing in a circuit is directly proportional to the voltage applied to the circuit and inversely proportional to the resistance of the circuit, provided that the temperature affecting the circuit remains constant. Put simply, Ohm’s law means that the amount of electrons passing by every second will depend on how hard we push them, and what obstacles are put in their way. Did you know? Ohm’s law: V voltage (V ) Current (I ) = resistance (R) or V I= R I V R V =I×R I V R I = V R I R R = V I Figure 1.17 The equation triangle (the vertical line is multiply, the horizontal is divide) Worked example 1 Using Ohm’s law If a voltage of 100 V is applied to a 5 Ω resistor, calculate the current flow. Using Ohm’s law, V = I × R or Then 100 = I × 5 100 I= = 20 A 5 Worked example 2 If the resistance in this circuit is increased to 10 Ω, it can be seen that the current flow reduces: 100 Then I = = 10 A 10 If you double the resistance, the current is halved. If the voltage is increased to 200 V and produces a current of 20 A, what is the resistance? V Using the formula R = I 200 Then R= = 10 20 For a constant current, voltage is proportional to resistance. 14 Question 1 Using Ohm’s law copy and complete the following table. V I 1 110 5 2 240 3 4 5 115 R 4 10 12 15 6 3 We now understand the relationship between resistance, voltage and current, but electrical circuits may contain many resistors and they may be connected in different ways. For example, series circuits, parallel circuits or a combination of both series and parallel circuits. R1 = 16 Ω Series circuits A series circuit is when a number of resistors (or other components) are connected end to end, and then connected to a power supply or battery. The total resistance is calculated by adding up the resistance of each individual resistor, i.e. Rt = R1 + R2 + R3 Did you know? Rt = (16 + 24 + 48) Ω = 88 Ω + – Battery R2 = 24 Ω R3 = 48 Ω Figure 1.18 A series circuit ● The total circuit current (I) is the voltage (V ) divided by the total resistance (Rt). ● The current will be the same value at every point in the series circuit. ● Resistors in the same circuit may have different values. The amount of electrons flowing through each resistor will vary. We use voltage to push these electrons through a resistor. ● The potential difference across each resistor is proportional to its resistance. ● The bigger the resistor the more voltage is used. So applying Ohm’s law to the series circuit, you would then have three different voltage readings (known as voltage drop). The supply voltage (V ) will be equal to the sum of all the potential differences across each resistor. In other words if we add up the p.d. across each resistor (the amount of volts dropped across each resistor), it should come to the value of the supply voltage. We can show this as: Vt = V1 + V2 + V3 Power The total power in the series circuit is equal to the sum of the individual powers used by each resistor. To calculate the power in (watts) in a direct current (DC) circuit we can use the formula: P=V×I 15 Calculations with a series circuit 6.2 Ω Two resistors of 6.2 Ω and 3.8 Ω are connected in series with a 12 V battery. 3.8 Ω Calculate: a) the total resistance b) the total current flowing c) the potential difference across each resistor 12 V Figure 1.19 Worked example 3 d) the total power used by each resistor. a) To find the total resistance, we add up the value of the individual resistors. Therefore: Rt = R1 + R2 b) I = V R I= 12 10 Rt = (6.2 + 3.8) Ω Rt = 10 Ω I = 1.2 A c) Across R1: V = I × R, therefore V1 = I × R1 = 1.2 × 6.2 = 7.44 V Across R2: V = I × R, therefore V2 = I × R2 = 1.2 × 3.8 = 4.56 V d) P = V × I, therefore the total power will be P = 12 × 1.2 = 14.4 W Power used by R1: P1 = V1 × I, therefore P1 = 7.44 × 1.2 = 8.93 W Power used by R2: P2 = V2 × I, therefore P2 = 4.56 × 1.2 = 5.47 W Parallel circuits If a number of resistors are connected together as shown they are said to be connected in parallel. In this type of connection, the total current divides among the different branches of the circuit. However, it should be noted that the ‘pressure’ pushing the electrons along (the voltage), will be the same through each of the branches. Therefore any branch of a parallel circuit can be disconnected without affecting the other remaining branches. 16 R1 R2 Figure 1.20 A parallel circuit The following rules apply to a parallel circuit: Did you know? The total circuit current (I), is found by adding together the current through each of the branches: It = I1 + I2 The same potential difference will occur across each branch of the circuit: Vt = V1 = V2 Where resistors are connected in parallel and, for the purpose of calculation, it is easier if the group of resistors is replaced by one large resistor (Rt): 1 1 1 = + Rt R1 R2 Calculations with a parallel circuit 16 Ω Three resistors of 16 Ω, 24 Ω and 48 Ω are connected as shown across a 230 V supply. Calculate the total circuit current. 24 Ω 48 Ω There are two ways of doing this: Method 1 Worked example 4 Find the equivalent resistance (Rt) of all the V branches and then use I = R 1 1 1 1 1 1 1 Remember: = + + = + + Rt R1 R2 R3 16 24 48 From I = V R 230 V supply Figure 1.21 1 3+2+1 = Rt 48 R 48 6 = and Rt = 8 Ω then t = 1 6 48 I= 230 and therefore I = 28.75 A 8 Method 2 Find the current through each resistor and then add them together. V 230 I1 = gives I1 = and therefore I1 = 14.38 A R1 16 V 230 I2 = gives I2 = and therefore I2 = 9.58 A R2 24 V 230 I3 = gives I3 = and therefore I3 = 4.79 A R3 48 As It = I1 + I2 + I3 then It = 14.38 + 9.58 + 4.79 = 28.75 A 17 Calculations with series and parallel circuits This type of circuit combines both series and parallel circuits as shown. To calculate the total resistance in a combined circuit, we must first calculate the resistance of the parallel group. Then, having found the equivalent value for the parallel group, we simply treat the circuit as being made up of series connected resistors. R1 = 10 Ω R2 = 20 Ω R3 = 30 Ω 110 V supply Figure 1.22 A series and parallel circuit Calculate the total resistance of this circuit and the current flowing through the circuit, when the applied voltage is 110 V. Worked example 5 Step 1 Find the equivalent resistance of the parallel group (Rp): 1 1 1 1 = + + Rp R1 R2 R3 1 1 1 + + 10 20 30 1 6+3+2 = Rp 60 = = 11 60 Rp 1 = 60 11 therefore Rp = 5.45 Step 2 Add the equivalent resistor to the series resistor R4: Rt = Rp + R4 = 5.45 + 10 = 15.45 Ω Step 3 Now, using Ohm’s law, we can calculate the current in the circuit: I= 18 110 15.45 I = 7.12 A R4 = 10 Ω Questions 1 Two resistors of equal value are connected to three other resistors of value 33 Ω, 47 Ω, and 52 Ω to form a series group of resistors with a combined resistance of 160 Ω. What is the resistance of the unknown resistors? Choose from: a) 7 Ω b) 14 Ω c) 28 Ω d) 44 Ω 2 The four field coils of a motor are connected in series. Each has a resistance of 33.4 Ω. a) Calculate the total resistance. b) Determine the value of an additional series resistance which will give a total resistance of 164 Ω. 3 Four resistors of values 23 Ω, 27 Ω, 33 Ω, and 44 Ω are connected in series. It is required to modify their combined resistance to 140 Ω, by replacing one of the existing resistors by a new resistor of value 40 Ω. Which of the resistors should be replaced? 4 A circuit has three resistors all connected in series. The resistance values are 10 Ω, 20 Ω, and 25 Ω. The resistors are connected to a 110 V supply. Calculate the following: a) the total circuit resistance b) the total circuit current flow c) the p.d. (potential difference) across each resistor d) the power that each resistor uses and the total power. 5 The following groups of resistors are connected in parallel. In each case calculate the equivalent resistance. Where necessary, make the answers correct to two significant figures (all values are in ohms). a) 2, 3, 6 b) 3, 10, 5 c) 9, 7 d) 4, 6, 9 e) 7, 5, 10 f) 14, 70 g) 12, 12 h) 15, 15, 15 i) 40, 40, 40, 40 6 A cable carries a current of 65 A with a voltage drop of 13 V. What must be the resistance of a cable which, when connected in parallel with the first cable, will reduce the voltage drop to 5 V? 7 Resistors of 24 Ω and 30 Ω are connected in parallel. What would be the value of a third resistor to reduce the combined resistance to 6 Ω? 19 8 Three PVC-insulated cables are connected in parallel, and their resistances are 0.012 Ω, 0.015 Ω, and 0.008 Ω. With a total current of 500 A flowing on a 110 V supply, calculate: a) the current in each cable b) the combined voltage drop over the three cables in parallel c) the individual voltage drop over each cable in a parallel circuit. 9 An electric fire of resistance 24.8 Ω, an immersion heater of resistance 34.8 Ω, a microwave oven of resistance 45.9 Ω, and a toaster of resistance 120 Ω are connected to a 230 V power circuit. Calculate the current taken by each appliance and the total current drawn from the supply. 10 A 230 V electric kettle has a resistance of 88 Ω and is connected to a socket outlet by a twin cable, each conductor of which has a resistance of 0.1 Ω. The total resistance of the cable from fuse board to the socket is 0.8 Ω. Calculate the total resistance of the whole circuit. 11 Calculate the resistance and the current drawn from the supply by the following equipment: a) a 4 kW 230 V immersion heater b) a 600 W 230 V microwave oven c) a 1 kW 230 V electric fire d) a 750 W 230 V stereo system. 12 For the circuit shown below, calculate: a) the resistance of the parallel group b) the total resistance. R1 = 9 R3 = 2.3 R2 = 4 50 V 13 For the circuit shown below calculate: a) the total resistance b) the supply voltage. R1 = 0.3 R3 = 6 R2 = 2 6A 20 1.6 Resistivity So far when we have looked at Ohm’s law, we have always had circuits where we introduced a known resistance (R) into them. However, even if we removed this resistor from the circuit, we would still have some resistance within the circuit, caused by the actual conductor or cable. The factors that influence cable resistance are: ● The material used Each material has its own resistance to the electron flow, shown by the resistivity symbol (r), the Greek symbol ‘rho’. It is measured in ohm-metres or microohm-millimetres (μΩ mm). ● The length A longer cable has a greater resistance. ● The cross-sectional area A cable with a greater cross-sectional area has a lower resistance. This is the formula for resistance and resistivity: resistivity × length cross-sectional area ρ×I R= A Resistance = Did you know? Worked example 1 Did you know? The resistivity for each material is found by measuring the resistance of a 1 m cube of the material, then, as cable dimensions are measured in millimetres (i.e. 1.5 mm2, 2.5 mm²), this figure is divided down to give the value of a 1 mm cube. Resistivity values: Copper is 17.8 µΩ mm. Aluminium is 28.5 µΩ mm. Find the resistance of the field coil of a motor where the conductor’s crosssectional area is 2.0 mm², the length of wire is 4000 m and the material resistivity is 18 µΩ mm. ρ×I R= A 4 000 000 72000 000 18 = = 36 R= × 1000 000 2 2000 000 The value of r is given in millionths of an ohm millimetre. If we have 18 µΩ mm, then we have 18 millionths of an ohm: 18 1000 000 In calculations, all units should be the same. Here the length is in metres, but everything else is in millimetres. So you write 4 000 000 mm. 21 Worked example 2 A copper conductor has a resistivity of 17.8 µΩ mm and a cross-sectional area of 2.5 mm². What is the resistance of a 30 m length of this conductor? ρ×I A 17.8 × 30 × 10 3 R= 2.5 × 106 R = 0.2136 R= then A copper conductor has a resistivity of 17.8 μΩ mm and is 1.785 mm in diameter. What is the resistance of a 75 m length of this conductor? Worked example 3 Step1 You need to use the following formula to convert the diameter into a crosssectional area (use p = 3.142): A= π d 2 3.142 × 1.785 × 1.785 10.01 = = = 2.5mm2 4 4 4 Step 2 Put in the correct values in the resistance equation: ρ × I 17.8 × 10 −6 × 75 × 10 3 17.8 × 10 −3 × 75 = = 2.5 A 2.5 17.8 × 75 1335 = = = 0.534 2.5 × 10 3 2500 R= Questions 1 Calculate the resistivity of aluminium, if a 100 m length of cross-sectional area 4 mm2 has a measured resistance of 0.7 Ω. 2 Calculate the resistance per 100 m of the following sizes of copper cable: a) 1.5 mm2 b) 6 mm2 c) 10 mm2 3 Calculate the diameter of an aluminium busbar, which is 25 m long and has a resistance of 0.001 39 Ω. 4 Calculate the resistance of 35 m of 1 mm² copper cable. 5 Calculate the resistance of 35 m of copper busbar whose dimensions are 50 mm by 5 mm. The effect of temperature on resistance of a conductor When a current is passed through a cable or conductor the temperature rises. An example is the element of an electric kettle. The effect of this heat on the resistance of the conductor depends on the material the conductor is made from. 22 Did you know? ● ● ● The resistance of pure metals such as copper or aluminium increases as temperature increases, i.e. they have a positive temperature coefficient. The resistance of certain alloys (e.g. constantin or manganin) does not change much with increases in temperature, i.e. they have a zero temperature coefficient. The resistance of carbon and electrolytes (liquids used in batteries) decreases when the temperature increases, i.e. they have a negative temperature coefficient. Calculating resistance increase There are two formulae for calculating the increase in resistance of a conductor due to temperature change, depending on whether the temperature increases from a baseline temperature or whether the temperature increases between two different temperatures. Formula A Formula B Temperature increases from a baseline Temperature increases between two value (e.g. 0 °C) intermediate temperatures Rf = R0 (1 + a t) where R0 = resistance at 0 °C R2 1 + αt2 = R1 1 + αt1 Rf = final resistance where R1 = first temperature a = temperature coefficient R2 = second temperature t = rise in temperature a = temperature coefficient t1 = first temperature The resistance of a coil of copper wire at 0 °C is 100 Ω. Calculate the resistance of the coil at 30 °C. The temperature coefficient of the copper is 0.004/°C. Rf = R0 (1 + at) = 100 × (1 + 0.004 × 30) = 100 × 1.12 = 112 Ω Worked example 5 Worked example 4 t2 = second temperature The coils in a motor have a resistance of 200 Ω at 20 °C. Find the resistance of the coils when the motor temperature increases to 40 °C. The temperature coefficient of the conductor is 0.004/°C. R2 1 + αt 2 = R1 1 + αt 1 R2 1 + 0.004 × 40 = 200 1 + 0.004 × 20 R2 1 + 0.16 = 200 1 + 0.08 R2 1.16 = 200 1.08 200 × 1.16 R2 = 1.08 R2 = 214.81 23 1.7 Circuit protective devices A circuit protective device is a safety device, designed to disconnect the electrical circuit when the conditions are faulty or dangerous to protect both equipment and people. These devices are normally fuses or circuit breakers. Figure 1.23 Cartridge fuses Cartridge fuses The cartridge fuse consists of a porcelain tube with metal end-caps to which the element is attached. It is filled with granulated silica. This type of fuse is generally found in plug tops used with standard socket outlets. There are two main fuse ratings available, the 3 A, which are used with appliances up to 720 W (e.g. radios, table lamps), and the 13 A fuse used for appliances rated over 720 W (e.g. irons, kettles, fan heaters, electric fires, lawnmowers, toasters, refrigerators, washing machines, and vacuum cleaners). High breaking capacity (HBC) fuses The HBC fuse is a sophisticated variation of the cartridge fuse, and is normally found protecting motor circuits and industrial installations. It consists of a porcelain body filled with silica with silver element, and lug-type end caps. Another feature is the indicating bead, which shows when the element has blown. It is a very fast acting fuse and can discriminate between a starting surge and an overload. This type of fuse is normally found in distribution boards and at the mains intake positions. These types of fuse would be used when an abnormally high prospective short circuit current exists. Porcelain body End caps Indicating bead Figure 1.24 A sectional view of a typical HBC fuse 24 Miniature circuit breakers (MCBs) The circuit breaker is an automatic switch, which opens when there is excess current. The switch can be closed again when the current returns to normal, because the device does not damage itself during normal operation. The contacts of a circuit breaker are closed against spring pressure, and held closed by a latch arrangement. A small movement of the latch will release the contacts, which will open quickly under spring pressure to break the circuit. Compression spring Main contacts Trip leaver Pivot Re-set facility Figure 1.25 A miniature circuit breaker Normal currents will not affect the latch, whereas excessive currents will move it to operate the breaker. There are two basic methods by which over current can operate or ‘trip’ the latch: thermal and magnetic tripping. Thermal tripping The load current is passed through a small heater, the temperature of which increases as the current it carries increases. This heater is arranged to warm a bimetallic strip either directly, i.e. the current passes through the bimetallic strip, which in effect is part of the electrical circuit, or indirectly, i.e. the current passes through a coil wound around the bimetallic strip. The bimetallic strip is made of two different metals, normally brass and steel, brass expanding more than steel. These two dissimilar metals are securely riveted or welded together along their length. The rate of expansion of the two metals is different so that as the strip is warmed, it will bend and will trip the latch. The bimetallic strips are arranged so that normal currents will not heat the strip to tripping point. If the current flow increases beyond the rated value, the bimetallic strip is raised in temperature, bends and trips the latch. Current in Trip lever Contacts closed Directly heated bimetallic strip Current out Contacts open Figure 1.26 Thermal tripping 25 Magnetic tripping Contacts The principle used here is the force of attraction, which can be set up by the magnetic field of a coil carrying the load current. At normal currents the magnetic field is not strong enough to attract the latch, but overload currents operate the latch and trip the main contacts. Coil carrying current A simple attraction type – The magnetic field is set up by a current in the flexible strip attracting the strip to the iron, and releasing the latch. This is often used in miniature circuit breakers combined with a thermal trip. Magnetic plunger Oil-filled dashpot Oil-escape hole The oil dashpot solenoid type – This is used Figure 1.27 Magnetic tripping on larger circuit breakers. The time lag is adjustable by varying the size of oil-escape hole in dashpot position. Current rating is adjustable by vertical movement of the plunger. Motor starters A motor starter can provide several functions, such as: switching of supply to the motor ● protecting the motor from overload ● preventing automatic re-starting after a power failure ● provide means of stopping a motor safely in an emergency ● reversing of motor direction ● auto connecting in either star or delta to reduce high starting currents ● direct on line starter (DOL). ● Did you know? This type of starter basically switches a three-phase supply directly onto the stator windings. Start-up current is about 6 to 10 times full load current and start-up torque is about 150% of full load. This is usually limited to motors up to 5 kW. 26 Normally open contact in a control circuit means that the contact is normally open when the circuit is not energised. When the circuit is energised then the normally open contacts become closed and any normally closed become opened. Retaining contact is when the start button is released (take your finger off) then the supply is maintained to the coil and hence the three-phase supply remains connected to the motor. Direct on line starter (DOL) When a supply is connected to the coil of a contactor via a start button, this causes the coil to magnetise the former inside the contactor and subsequently attract the top former holding the three contacts causing them to close and supply three phases to the stator windings. Three-phase and neutral supply N L1 L2 L3 Start Stop Signal lamp ptc Thermistor Motor Ph Transformer Key terms Figure 1.28 Three-switch relay with ‘normally open’ start button Fuse – also known as ‘overcurrent protection’, disconnects a circuit when an overload or short circuit is present. Circuit breaker – a device which automatically disconnects the supply from a circuit in the event of excessive current flowing in the circuit. 27 The stop button is needed to de-energise the contactor coil and thus open the supply to the motor. Normally closed contacts are connected in series with the stop button, which will open the circuit should an overload condition occur and hence de-energise the coil and switch off the supply to the motor. All stop buttons (if there are more than one) are always connected in series with each other and also in series with other safety switches such as overloads and interlocks. They are also connected in series with any start buttons and contactor coils so that the control circuit supply can be interrupted. Start buttons (if there are more than one) are always connected in parallel with each other but in series with the coil and stop button. Three-phase and neutral supply connections N L1 L2 U V W Three-phase motor connection L3 230 V Coil Additional start buttons Start Stop O/L Additional stop buttons Figure 1.29 Remote stop/start control 28 1.8 Principles of a.c. and d.c. current flow Power factor Power factor is a number less than 1, which is used to represent the relationship between the apparent power of a circuit and the true power of that circuit. Power factor (p.f.) = power (watts) voltage (volts) × current (amps) In order to understand power factor, we need to look at alternating current (a.c.). What is alternating current? Alternating current (a.c.) is a flow of electrons which rises to a maximum value in one direction and then falls back to zero before repeating the process in the opposite direction. In other words, the electrons within the conductor do not drift (flow) in one direction, but actually move backwards and forwards. The journey taken, i.e. starting at zero, flowing in both directions and then returning to zero, is called a cycle. The number of cycles that occur every second is said to be the frequency and this is measured in hertz. Because an alternating current is continuously changing direction, the following are important: ● Instantaneous – the value at a specific instant in time ● Maximum/Peak – the highest value obtained in the cycle ● Average – the average value obtained across one half of the cycle ● r.m.s. (the root mean square) – produced to give a comparable value to those of a d.c. circuit and used for descriptive and calculation purposes. For calculation, we take the average value of a sinusoidal voltage or current to be 0.637 times the maximum value and we take the r.m.s. value to be 0.707 times the maximum value. Sinusoidal waveforms Steady rate of rotation Meter pointer swings from side to side Coil Commutator rings Brushes Alternating voltage Figure 1.30 A simple loop a.c. generator 29 When the loop in the generator is rotated within the magnetic field, an e.m.f. will be induced, at the rate of one cycle per rotation. The e.m.f. induced in the loop at any instant in time will depend upon the rate of ‘cutting’ through the lines of magnetic flux. + e.m.f. 1 cycle 0 Time – X Y X Y When the coil is vertical it X Y N S N S N S N S does not cut field lines and no Y X e.m.f. is induced. Maximum generation occurs when the coil Figure 1.31 The e.m.f. produced by an a.c. generator is horizontal and the maximum (a sine wave) amount of field lines are being cut. This induced e.m.f. will also cause an induced current (flow of electrons) within the circuit. Resistance (R) and phasor representation We can also represent a.c. by the use of phasors. A phasor is a straight line whose Lamp V length is a scaled representation of the size of the a.c. quantity and whose direction I represents the relationship between the 360° voltage and current, this relationship being known as the phase angle. Figure 1.32 shows the sine wave and Figure 1.33 is the phasor diagram for a filament lamp. Figure 1.32 The waveform for a Circuits like this are said to be resistive, and tungsten filament lamp (a.c.) in this type of circuit the values of e.m.f. (voltage) and current actually pass through the same instants in time together. In other words, as voltage reaches its maximum value, so does the current. I V This happens with all resistive components connected to Figure 1.33 A phasor an a.c. supply, and the voltage and current are said to be diagram for a tungsten ‘in phase’ with each other, or possess a zero phase angle. filament lamp (a.c.) Voltage and current are perfectly linked and are therefore said to possess unity power factor. This would be given the value of 1.0. A resistive component will consume power and the calculations are the same as for a d.c. circuit, i.e. P=V×I Resistive equipment (filament lamps, fires, water heaters, etc.) use this power to create heat, but such a feature in long cable runs, windings, etc. causes unsuitable power loss in the circuit. 30 Inductance (L) If a motor or transformer (something possessing windings) is used then the load is inductive. With an inductive load the voltage and current become ‘out of phase’ with each other. This is because the windings of the equipment set up their own induced e.m.f., which opposes the flow of the applied voltage and thus forces the flow of electrons (current) to fall behind the force pushing them (voltage). However, over one full cycle, we would see that no power is consumed. This is known as possessing a lagging phase angle or power factor. The voltage and current are no longer perfectly linked, so the circuit would be given a power factor of less than 1.0 (perfection), for example, 0.8. The sine wave and phasor diagram are shown in Figure 1.34, and the current is lagging the applied voltage by 90°. + I 90° 360° V V I – Figure 1.34 A sine wave and phasor diagram for an inductive circuit We assumed that the above circuit is purely inductive, however, in reality, this is not possible as every coil is made of wire and that wire will have a resistance. The opposition to current flow in a resistive circuit is resistance. The limiting effect to the current flow in an inductor is the inductive reactance which we are able to calculate with the following formula: XL = 2pfL where XL = inductive reactance (in ohms, Ω), f = supply frequency (in hertz, Hz), L = circuit inductance (in henrys, H). Power given as the result of the voltage and the current (P = V × I), is known as the apparent power, called the unity power factor given the value one (1.0). Depending upon the equipment, the true power (actual) in the circuit must take into account the phase angle (P = V × I × cos ∅) and will often be less than the apparent power but never greater. 31 If we have an inductive load, consuming 3 kW of power from a 230 V supply, with a power factor of 0.7 lagging, then the current (amount of electrons flowing) required to supply the load is: P = V × I × cos ∅ therefore by transposition: I= P V × cos ∅ and I= P V × p.f. therefore I= 3000 = 18.6 A 230 × 0.7 However, if the same size of load was resistive, then the power factor would be 1.0, and thus: P=V×I therefore by transposition I= P V therefore I= 3000 = 13 A 230 In other words, the lower the power factor of a circuit, then the higher the current will need to be to supply the load’s power requirement. It therefore follows that if the power factor is low, then it will be necessary to install larger cables, switchgear, etc. to be capable of handling the larger currents. There will also be the possibility of a higher voltage drop due to the increased current in the supply cables, with which a capacitor helps. Capacitance (C) A capacitor is a component which stores an electric charge. If a potential difference is applied across it, this energy can be returned back to the circuit. When a capacitor is connected to an a.c. supply, it is continuously storing the charge and then discharging as the supply moves through its positive and negative cycles. But, as with the inductor, no power is consumed. This means that in a capacitive circuit, we have a leading phase angle or power factor. The sine wave and phasors used to represent this are shown, where the current leads the voltage by 90°. + V I 360° 90° I V – Figure 1.35 A sine wave and phasor diagram for a capacitive circuit 32 As the capacitor provides a leading power factor, if connected in parallel across the load, it can help neutralise the effect of a lagging power factor. The opposition to the flow of a.c. to a capacitor is termed capacitive reactance, which, like inductive reactance, is measured in ohms and calculated using the following formula: XC = 1 2π fC where XC = capacitive reactance (ohms, Ω), f = supply frequency (hertz, Hz), and C = circuit capacitance (farads, F). Since in this type of circuit we have voltage and current but no power, the formula of P = V × I is no longer accurate. Instead, we say that the result of the voltage and current is reactive power, which is measured in reactive volt amperes (VAr). The current to the capacitor, which doesn’t contain resistance or consume power, is called reactive current. Phasors We can start from zero on the wave diagram with either the voltage or the current. In electrical science we often need to add together alternating values. If they were ‘in phase’ with each other, then we would simply add the values together. However, when they are not ‘in phase’ we need to use phasor diagrams. The chosen alternating quantity is drawn horizontally and is known as the reference. When choosing the reference phasor, it makes sense to use a quantity that has the same value at all parts of the circuit. For example, in a series circuit, the same current flows in each part of the circuit – therefore use current as the reference phasor. In a parallel circuit, the voltage is the same through each branch of the circuit and therefore we use voltage as the reference phasor. We can now measure all phase angles from this reference phasor, and the resultant is found by completing a parallelogram. In Figure 1.36, the result of adding A and B together will be phasor C. A C B Figure 1.36 The resultant of a phasor Impedance Components within an a.c. circuit are in opposition to the flow of current. To summarise: ● The opposition to current in a resistive circuit is called resistance (R), is measured in ohms and the voltage and current are in phase with each other. ● The opposition to current in an inductive circuit is called inductive reactance (XL), is measured in ohms and the current lags the voltage by 90°. ● The opposition to current in a capacitive circuit is called capacitive reactance (XC), is measured in ohms and the current leads the voltage by 90°. Circuits will contain a combination of these components. The total opposition to current is called the impedance (Z) of that circuit. 33 Questions 1 A coil of 0.25 H is connected in series with a 75 Ω resistor across a 100 V 50 Hz supply. Calculate the following: a) the inductive reactance of the coil b) the impedance of the circuit c) the circuit current. 2 A coil of 0.5 H is connected in series with a 50 Ω resistor across a 100 V 50 Hz supply. Calculate the following: a) the inductive reactance of the coil b) the impedance of the circuit c) the circuit current. 3 A coil of 0.75 H is connected in series with a 25 Ω resistor across a 100 V 50 Hz supply Calculate the following: a) the inductive reactance of the coil b) the impedance of the circuit c) the circuit current. 4 A coil of 0.145 H is connected in series with a 50 Ω resistor across a 230 V 50 Hz supply. Calculate the following: a) the inductive reactance of the coil b) the impedance of the circuit c) the circuit current d) the p.d. across each component e) the circuit phase angle. 5 A coil of 0.25 H is connected in series with a 70 Ω resistor across a 230 V 50 Hz supply. Calculate the following: a) the inductive reactance of the coil b) the impedance of the circuit c) the circuit current d) the p.d. across each component Key terms e) the circuit phase angle. 34 Frequency – the number of oscillations of alternating current in an electric system transmitted from a power station to the end-user per second. It is normally 50 Hz. Unity power factor – when the voltage and current in a circuit are ‘in phase’ with each other. Capacitor – a component which stores an electric charge if a voltage is applied across it. 1.9 Resistance, inductance, and capacitance Resistance (R) and inductance (L) in series I R L VR VL + I Ø Supply (Vs) V – Figure 1.37 A resistor connected in series with an inductor (a.c.) In a series circuit, the current (I) will be common to both the resistor and the inductor, causing voltage drop VR across the resistor and VL across the inductor. The sum of these voltages must equal the supply voltage. But, because this is an a.c. circuit, we have to use a phasor diagram to work this out. VL VS Ø Our reference phasor VR I In a series circuit, we know that VS VL current will be common to both the Ø resistor and the inductor, therefore current is our reference phasor. We VR also know that voltage and current Figure 1.38 Phasor diagrams for a resistor will be in phase for a resistor. connected in series with an inductor (a.c.) Therefore the voltage drop (p.d.) across the resistor (VR), must be in phase with the current. In an inductive circuit, the current lags the voltage by 90°, so voltage is leading current. This means that the voltage drop across the inductor (VL) will lead the current by 90°. We can then find the value of the supply voltage (Vs), by completing the parallelogram. When we draw phasors, we always assume that they rotate anti-clockwise and that the symbol ∅ represents the phase angle. Figure 1.38 shows two ways of drawing this. In example b) the phasors produce a right-angled triangle. We can therefore use Pythagoras’ theorem to give us the formula: Vs2 = VR2 + VL2 We can then use trigonometry to give us the different formulae, depending on the values that we have been given: cos ∅ = VR Vs sin ∅ = VL Vs tan ∅ = VL VR 35 Here are two examples: A coil of 0.15 H is connected in series with a 50 Ω resistor across a 100 V 50 Hz supply. Calculate the following: a) the inductive reactance of the coil b) the impedance of the circuit c) the circuit current. a) For inductive reactance, we use the formula XL = 2pfL (Ω) Worked example 1 XL = 2 × 3.142 × 50 × 0.15 = 47.1 Ω b) When we have resistance and inductance in series, we calculate the impedance using the following formula: Z 2 = R2 + XL2 which becomes Z = R2 + XL2 Z The first formula is the same as Pythagoras’ theorem for a right-angled triangle (A2 = B2 + C2). This is the impedance triangle and is drawn for this type of circuit as shown. Here, the angle (∅) between sides R and Z, is the same as the phase angle between current and voltage. If we therefore apply some trigonometry, the following applies: cos ∅ = R Z sin ∅ = XL Z tan ∅ = XL Ø R Figure 1.39 The impedance triangle XL R From Z = R2 + XL2 , Z = 502 + 47.12 = 68.69 c) As we are referring to the total opposition to current, we use the formula: I= 36 100 V = = 1.46 A Z 68.69 A coil of 0.159 H is connected in series with a 100 Ω resistor across a 230 V 50 Hz supply. Calculate the following: a) the inductive reactance of the coil b) the circuit impedance c) the circuit current d) the p.d. across each component Worked example 2 e) the circuit phase angle. a) XL = 2pfL, therefore XL = 2 × 3.142 × 50 × 0.159 = 50 Ω 2 b) Z = R + XL2 , therefore Z = 1002 + 502 = 111.8 V 230 = 2.06 A therefore I = Z 111.8 d) VR = I × R therefore V = 2.06 × 100 = 206 V c) I= VL = I × XL, therefore V = 2.06 × 50 = 103 V e) Using the right-angled triangle: tan ∅ = VL 103 = = 0.5 VR 206 On a calculator enter 0.5, then press the INV key then press TAN, you should see the number 26.6. In other words, current is lagging voltage by 26.6°. Resistance (R) and capacitance (C) in series + V C R VR VC I I Ø Supply (VS) – Figure 1.40 Resistance (R) and capacitance (C) in series In a series circuit the current (I) will be common to both the resistor and the capacitor, causing voltage drop (p.d.), Vr across the resistor and Vc across the capacitor. As with the resistance/inductance (RL) circuit previously, we can take current as the reference phasor. Similarly, the voltage across the resistor will be in phase with that current. Remember, in a capacitive circuit the current leads the voltage by 90º. Therefore, we can say that the voltage across the capacitor will be lagging the current. 37 As before we can now calculate the supply voltage (Vs) by completion of the parallelograms as follows: As with the inductor, we can apply Pythagoras’ theorem and trigonometry to give us the following formulae: Vs2 = VR2 + Vc2 cos ∅ = VR Vs sin ∅ = Vc Vs tan ∅ = Vc VR A capacitor of 15.9 µF and a 100 Ω resistor are connected in series across a 230 V and 50 Hz supply. Calculate the following: a) the impedance of the circuit b) the circuit current c) the p.d. across each component Worked example 3 d) the circuit phase angle. a) To be able to find the impedance, we must first find the capacitive reactance. 106 1 Xc = however, as the capacitor value is given in μF, we use X c = 2π fC 2π fC 106 106 = = 200 This gives us: X c = 2 × 3.142 × 50 × 15.9 4995.78 When we have resistance and capacitance in series, we use the following formula: Z 2 = R2 + X c2 which becomes Z = R2 + X c2 Therefore Z = 1002 + 2002 = 50 000 = 224 b) I= V 230 = = 1.03 A Z 224 c) VR = I × R = 1.03 × 100 = 103 V Vc = I × Xc = 1.03 × 200 = 206 V d) Using our right-angled triangle: tan ∅ = Vc 206 = =2 VR 103 If we then take our calculator and enter 2, then press the INV key, then press TAN, we should see the number 63.4. In other words, current is leading voltage by 63.4º. 38 Resistance, inductance, and capacitance in series (RLC) Consider Figure 1.41: Here we have a resistor connected in series with an inductor and a capacitor and then fed from an a.c. supply. Such an arrangement is often referred to as an RLC circuit or as a general series circuit. I R L C VR VL VC Supply (Vs) Figure 1.41 An RLC series circuit Again, as we have a series circuit, the current (I) will be common to all three components, causing voltage drop (p.d.) VR across the resistor, VL across the inductor, and VC across the capacitor. Here, VR will be in phase with the current, VL will lead the current by 90º (because the current lags the voltage), and VC will lag the current by 90º (because current leads the voltage in a capacitive circuit). Because VL and VC are in opposition to each other (one leads and one lags), the actual effect will be the difference between their values (see Figure 1.42). VL Our reference phasor VS VL – Vc VR I Vc Figure 1.42 An RLC circuit phasor diagram We calculate Vs by completing the parallelogram as follows: We apply Pythagoras’ theorem and trigonometry to give us the following formulae: VS2 = VR2 + (VL − VC )2 Z = R2 + ( XL − X C )2 And finally: cos ∅ = VR Vs sin ∅ = VL − VC Vs tan ∅ = VL − VC VR 39 A resistor of 5 Ω is connected in series with an inductor of 0.02 H and a capacitor of 150 μF across a 230 V and 50 Hz supply. Calculate the following: a) the impedance b) the supply current c) the power factor. a) In order to find the impedance, we must first find out the relevant values of reactance. Therefore: XL = 2pfL = 2 × 3.142 × 50 × 0.02 = 6.28 Ω Worked example 4 Xc = 106 1 = 21.2 allowing for microfarads = 2 × 3.142 × 50 × 150 2π fC The effect of inductance and capacitance together in series will be the difference between their values. Consequently, this means that the resulting reactance (X) will be found as follows: X = Xc - XL = 21.2 - 6.28 = 14.92 Ω We can now use the impedance formula as follows: 2 2 Z = R2 + ( X c − XL )2 , which gives us Z = 5 + 14.92 = 15.75 Note: XC is greater than XL. Therefore we subtract XL from XC. Also, as capacitive reactance is higher, the circuit current will lead the voltage. V 230 b) I = = = 14.6 A Z 15.75 R 5 = 0.32 and therefore p.f. = 0.32 leading c) cos ∅ = = Z 15.75 A resistor of 10 Ω is connected in series with an inductor of 0.5 H and a capacitor of 75 µF across a 230 V 50 Hz supply. Calculate the following: a) the impedance b) the supply current c) the power factor. a) We must first find out the relevant values of reactance. Worked example 5 XL = 2pfL = 2 × 3.142 × 50 × 0.5 = 157.1 Ω Xc = 106 1 = 42.43 allowing for microfarads = 2 × 3.142 × 50 × 75 2π fC The resulting reactance (X) will be found as follows: X = XL - Xc = 157.1 - 42.43 = 114.67 Ω We can now use the impedance formula as follows: Z = R2 + ( XL − X c )2 , which gives us Z = b) I = c) 40 52 + 114.672 = 114.78 V 230 = = 2.0 A Z 114.78 cos ∅ = R 5 = = 0.043 and therefore p.f. = 0.043 leading Z 114.78 Resistance, inductance and capacitance in parallel 60 µF There can obviously be any combination of 4.0 H the above components in parallel. However, to demonstrate the principles involved, we will look at all three connected across an a.c. supply. 50 Ω As we have a parallel circuit, the voltage (Vs) will be common to all branches of the circuit. Consequently, when we draw our parallelogram Supply (VS) we will use voltage as the reference phasor. 250 V 50 Hz In this type of circuit, the current through the Figure 1.43 An RLC parallel circuit resistor will be in phase with the voltage, the current through the inductor will lag the voltage by 90º and the current through the capacitor will lead the voltage by 90º. Normally when we carry out calculations for parallel circuits, it is easier to treat each branch as being a separate series circuit. We then draw to scale each of the respective currents and their relationship to our reference phasor, which is voltage. As with voltages VL and VC in the RLC series circuit, the current through the inductor (IL) and the current through the capacitor (IC) are in complete opposition to each other. Therefore, the actual effect will be the difference between their two values. We calculate this value by the completion of our parallelogram. The bigger value (IC or IL) will determine whether the current ends up leading or lagging. First find the current through each branch: V 230 IR = = = 4.6 A 50 R XL = 2p fL = 2 × 3.142 × 50 × 0.4 = 126 Ω therefore IL = V 230 = = 1.8 A XL 126 106 106 = 2π fC 2 × 3.142 × 50 × 60 V 230 = 53 = = 4.4 A therefore IC = Xc 53 XC = The actual effect will be IC - IL which gives us 4.4 - 1.8 = 2.6 A 5 4 Ic 3 2 (Ic – IL) IT = 5.2 A 1 28° 0 1 VS IR 2 3 4 5 6 1 IL 2 We now add this to IR by completing our scale drawing as shown. 3 This gives us a current of 5.2 A which is leading voltage by an angle of 28º. Figure 1.44 Scale drawing to find IR 41 Measuring current in an a.c. parallel circuit ● ● Why don’t you? ● VR Connect up the components of the circuit as shown. L Ensure the capacitor is not in circuit (i.e. switch ‘S’ is in the OPEN position). C Switch on the supply and record the current taken by the lamp in amps. Ac S A ● Close switch ‘S’ and record the current taken by the capacitor. ● Also record the new circuit current. ● Then, produce a phasor diagram (not to scale) showing all three currents recorded, using the supply voltage as your reference. ● Account for the difference in circuit current when the capacitor is removed. ● State the two functions performed by the choke (the inductor) and the function performed by the capacitor. ● How is the assumed current demand of a discharge lamp calculated, when only the lamp wattage and circuit voltage are known? Figure 1.45 Measuring current in a parallel circuit Measuring voltage in an a.c. series circuit Why don’t you? ● 42 Connect up the components of the circuit as shown. ● Switch on the supply. ● Using approved test probes and leads measure and record the following voltages: a) the voltage across the supply in volts b) the voltage across the choke VR L V V V Figure 1.46 Measuring voltage in a parallel circuit c) the voltage across the lamp. ● Switch off the supply and isolate the circuit. ● Produce a phasor diagram (not to scale) showing all three voltages recorded, using the circuit current as your reference. ● Account for the fact that the voltages across the series components do not add up to the supply voltage. ● Explain why special precautions are necessary when installing this type of luminaire in a workshop containing rotating machinery. ● What precautions should be taken with the disposal of this type of lamp? Questions 1 A small industrial unit is fed by a 400 V, three-phase, four-wire supply system. On the estate are three factories connected to the system as follows: a) Factory A taking 50 kW at unity power factor. b) Factory B taking 80 kVA at 0.6 lagging power factor. c) Factory C taking 40 kVA at 0.7 leading power factor. Calculate the overall kW, kVA, kVAR and power factor for the system. To clarify, you are trying to find the values of P (true power), S (apparent power) and Q (reactive power). First you need to work out the situations for each factory. 2 Three coils of resistance 40 ohms and inductive reactance 30 ohms are connected in delta to a 400 V, 50 Hz, three-phase supply. Calculate the following: a) the line current in each coil b) line current c) total power. 3 A balanced load of 10 ohms per phase is star connected and supplied with 400 V 50 Hz at unity power factor. Calculate the following: a) phase voltage b) line current c) total power consumed. 4 A resistor of 25 Ω is connected in series with an inductor of 0.2 H and a capacitor of 750 µF across a 230 V 50 Hz supply. Calculate the following: a) the impedance b) the supply current c) the power factor. 5 A capacitor of 15 µF and a 150 Ω resistor are connected in series across a 230 V 50 Hz supply. Calculate the following: a) the impedance of the circuit b) the circuit current c) the p.d. across each component d) the circuit phase angle. 43 1.10 Cells and batteries Primary cells are batteries that are not easily recharged and are therefore discarded after a single use, e.g. an AA battery used to power a clock or TV remote control. Primary cells are made from an absorbent material (but not a liquid), so are known as ‘dry cells’. Primary cells are cheap to produce and have low maintenance issues. Secondary cells are batteries which can be recharged and used many times, e.g. a car battery or back-up emergency lighting. They contain a liquid electrolyte (so are known as ‘wet cells’), are larger than primary cells, and require more maintenance. Table 1.4 Comparing primary and secondary cells Secondary cell Low initial cost to make / buy Higher initial manufacturing / purchase cost Disposable Regular maintenance required Replacement readily available Not as easily available Light and small, used in portable devices Less suitable for portable devices Good charge retention Poor charge retention Not good for heavy electrical loads Good for heavy electrical loads (starting vehicles) Key term Did you know? Why don’t you? Primary cell 44 Research and draw pictures of the different types of battery, including Leclanché, mercury and nickel–cadmium. Have you ever noticed signs of corrosion on a battery? This is known as ‘local action’, and is a result of a slow discharge of the battery when not connected to a circuit. The electrolyte attacks the impurities in the zinc case, forming small cells on the surface of the case, and eroding the case. The lifetime of a battery can be reduced due to an effect called polarisation. This is a chemical reaction inside the battery which reduces the effectiveness of the cell. Bubbles of hydrogen gas (an insulator) gather around the carbon electrode when the cell is in use and resist the flow of current. Polarisation – the shift of positive and negative electric charge in opposite directions within an insulator, or dielectric, induced by an external e.m.f. 2. Electrical and electronic drafting 2.1 Drawings and circuit diagrams People working in the electrical industry need to communicate complex technical information to others. A technical diagram is a means of conveying this information easily and clearly. In the electrical industry diagrams are used in different forms, for example: ● block diagrams ● layout diagrams ● circuit diagrams ● electrical symbols ● wiring diagrams ● scale drawings also known as site plans. ● schematic diagrams Block diagrams A block diagram can be used to relate information about a circuit without giving details of components or the manner in which they are connected. The components are represented by a square or rectangle. Gate circuit Reference Comparator Triac Motor Load Tachogenerator Figure 2.1 A block diagram Circuit diagrams A circuit diagram uses symbols to represent all circuit components and shows how these are connected, following a logical progression route from supply to output. The symbols used are internationally recognised circuit diagram symbols. N/C contact Reset ELV Supply Call point 1 3 Latching-on contact N/O contact 2 Relay coil 7 6 8 Alarm bell Figure 2.2 An alarm system 45 Wiring diagrams In a wiring diagram the physical layout is taken into consideration. The components and connections carry information of a specific nature regarding the wiring or connection of components. Relay Reset 4 3 5 6 2 1 8 7 Alarm bell Call point ELV supply Figure 2.3 Wiring diagram for an alarm system Schematic diagrams Schematic diagrams are similar to circuit diagrams, in that they do not show how to wire components but they do show a clear and logical progression route from supply to output. They tend to be used for larger, more complicated electrical diagrams such as control systems for motor starters and heating systems. (L3) (L1) `E´ `D´ ET Start 13 Δ14 a b 15 Δ 16 7 Stop Link b Δ a b M 14 13 8 O/L 15 16 L Y 11 12 M a 15 16 Figure 2.4 Schematic diagram for a full control circuit of an automatic star/delta starter Layout diagrams Layout diagrams are scale drawings prepared by an electrical consultant or engineer responsible for a particular installation and are based upon the architect’s drawings of the building. These drawings show the required position of all equipment, metering and control gear to be installed. They normally show the plan view of the installation, and internationally recognised location symbols are used. They are used to show the sequence of control of large installations. 4 Legend 4 65 W Scale 1:50 50 mm × 50 mm trunking run 4 Gang 1 way switch Lighting distribution board Main control Fluorescent luminaire Figure 2.5 Layout diagram for a warehouse (note the legend) 46 9 2.2 Electrical symbols Different countries have different voltages, electrical equipment ratings, and sockets. Over time the Caribbean will standardise these across the islands. Conductors Conductor: general symbol Flexible conductor Conductors in conduit Two conductors Alternative symbol: N = number of conductors " Connections Terminal or tag: general symbol (further detail may have to be given as shown below) Hinged or bolted contacts Link normally closed, with two bolted contacts Earth Earth connection Conductors & connection Crossing of conductors (no electrical connection) Junction of conductors Double junction of conductors Cells and batteries Symbol for primary or secondary cell (long line represents the positive pole) A number of cells in series Alternative symbol showing a battery of primary or secondary cells 47 Switches Single-pole, one-way switch Two-pole, one-way switch Cord-operated single-pole, one-way switch Two-way switch Intermediate switch Time switch Dimmer switch Normally closed Normally open Make contact (normally open) -1 way Two-pole switch mechanical link - neon switch Three-pole switch mechanical link - rotary Changeover contact -2 way 48 Lamps Lighting point or lamp: general symbol Wall lamp Emergency (safety) lightning point Spotlight Fluorescent lamps single Fluorescent lamps groups Miscellaneous Thermostat: block symbol t Restricted access push button for fire alarm Bell Indicator panel N = number of ways N Clock Fan Speaker Microphone 49 Rotating machines Alternating current generator G Direct current generator G Motor: general symbol M Socket outlets Socket outlet: General symbol Switched socket outlet Multiple socket outlet example: for 2 plugs 2 or Multiple switched socket outlet Example: for 2 plugs Figure 2.6 Common electrical symbols using international standards 50 2.3 Scale drawings Working drawings are the documents referred to when installing electrical circuits. For an installation to be completed accurately there needs to be plans or drawings of where everything should go. They are drawn to scale and contain internationally recognised symbols. When we draw to scale, to retain accuracy, everything needs to be made smaller by the same amount. The most common scales in electrical installation are 1:20, 1:50, 1:100, meaning everything is a 20th, a 50th or a 100th of its normal size, respectively. A materials list gives the electrical items that are needed in the installation. An architect or the customer will have specific requirements about the equipment to be installed, these are listed on specification sheets or ‘specs’ which give the technical details. 1:10 1:100 1:5 1:50 0 1 2 3 4 5 cm 0 10 20 30 40 50 cm 0 1 2 3 4 5m 0 100 mm 200 mm 0 1m 2m Why don’t you? Figure 2.8 Different scales (a) (b) (c) Figure 2.7 The location of several electrical components in a room; (a) the room, (b) the appropriate location of various components, (c) the position of the components on a plan of the room Draw the plans for a new car park lighting installation at Bay View Hotel. Guests have complained about security and poor visibility in the car park and the management want to install lighting. They want 12 lights equally spread around the car park, which measures 200 metres by 400 metres. The cable run from the distribution board to the first light is 16 metres and an allowance for termination of 1 metre for each of the 12 lights is needed. 1 Make a scale drawing of the car park and show the positions of all 12 lights. The first light is located in a corner position. Use the appropriate electrical symbols. 2 What is the total length of cable required and the total area of the car park? 3 Using information from local suppliers/internet, work out a materials list for the complete installation (lights, cables, lamps, cable clips, etc.) with prices to present to the management. 51 3. Electrical power, power and machines In this section we are going to look at how electricity is produced in large quantities to meet the needs of both households and industry. 3.1 How is electricity produced? Electricity is generated in power stations, by turning the shaft of a three-phase alternator. For example, water is heated until it becomes high-pressure steam and then this is forced onto the vanes of a steam turbine, which in turn rotates the alternator. In order to create the steam we use different primary sources of fuel. Traditionally, within the Caribbean islands, the majority of electricity is produced from oil-fuelled power stations; a smaller proportion comes from gas (especially in Trinidad and Tobago), and then coal. Burning these fossil fuels to produce electricity creates pollution and has a negative impact on the environment. The Caribbean islands are aiming to produce their electricity from other, renewable sources such as solar, wind and tidal power. Table 3.1 Sources of energy Primary source of energy Pros Fossil fuels – e.g. oil, gas, coal ● Produce vast quantities ● Established technology ● Relatively cheap to produce Mineral fuel (nuclear power) Did you know? Renewable – solar (photovoltaic), wind, tidal and geothermal 52 Cons ● Loss of electricity during production and distribution ● Not an infinite resource ● Negative impact on environment, e.g. greenhouse gases ● Risk of contamination ● Cheap to produce (although expensive start-up cost) ● Quiet ● Less wastage ● Smaller power output ● Using natural resources ● ● No greenhouse gases Not constant power generation Power plants create a lot of electricity, but a lot is wasted in the production and distribution of the electricity. Renewable sources are more effective as they are smaller, and can be sited closer to where the electricity is to be used. Step-up transformer switchyard Fossil fuel Hydro-plant Wind farm Low voltage transmission lines Residential customer High voltage transmission lines Business customer Residential transformer Transmission tower Industrial step-down transformer Figure 3.1 The power production process Electricity goes from the alternator to a transformer because the output of most alternators is about 25 000 V (25 kV) and we need to transform it to: ● 132 kV for the island grid system ● 66 kV and 33 kV for secondary transmission to towns ● 11 kV for high voltage distribution for industrial requirements ● 415/400 V for commercial properties ● 230/110 V for household supplies. Transmission at very high voltage results in a reduction in current and therefore a reduction in power line loss due to the heating effect. Without this, we would otherwise need to install very large cables and switchgear which would be very expensive. Why don’t you? At this point, the electricity is fed into the island’s distribution system – a network of overhead and underground power lines that link power stations together and are interconnected throughout the island. In Jamaica, the eight generation stations transmit at 138 kV to local distribution points, and 69 kV to 24 kV to feeders which also form part of the distribution network. Check out the interactive map showing Jamaica’s electrical distribution on: http://www.myjpsco.com/about-us/jamaicas-electricity-grid/ What new power plants are available? If a fault develops in any one of the contributing power stations or transmission lines, then electricity can be requested from another station on the system. Electricity is transmitted around the grid, mainly by the use of steel-cored aluminium conductors, which are suspended from steel pylons. We use overhead cables for three main reasons: ● The cost of installing cables underground is excessive. ● Air is a very cheap and readily available insulator. ● Air also acts as a coolant for the heat being generated in the cable. 53 Electricity is then ‘taken’ from the island’s grid via a series of appropriately located transformer sub-stations. These will eventually transform the grid supply back down to 11 kV and then distribute electricity at a local level. The 11 kV supply is transformed down to 400 V and distributed to the customer via a network of underground radial circuits or, in some rural areas, using overhead lines. Distribution to the customer Once the electricity has left the local sub-station, it will eventually arrive at the customer at the main intake position where these will be found: ● a sealed over-current device that protects the supply company’s cable ● an energy metering system to determine the customer’s electricity usage. It is after this point that the consumer’s installation is reached. This must be controlled by a main switch, which is located as close as possible to the supply company equipment and is capable of isolating all live conductors. In the average domestic installation, this device is merged with the means of distributing and protecting the final circuits in the consumer unit. Did you know? Electricity can be generated through different methods: ● Friction, e.g. production of static electricity when a balloon is rubbed against clothing ● Pressure, e.g. some cigarette lighters ● Heat, e.g. boiling water to generate steam to turn a turbine ● Light, e.g. photovoltaic (solar) light generates electricity ● Chemical action, e.g. in a primary or secondary cell (battery) ● Electromagnetic induction, e.g. an alternator in a power station. Renewable energy sources Key terms Renewable energy sources produce electricity without being used up. The sources are either quickly replaceable or have effectively unlimited lifespans. Several examples are shown in Table 3.2. 54 Fossil fuels – formed by a natural process over millions of years and include petroleum, coal, and natural gas. Transformer – an electrical machine with no moving parts which is used to change the value of an alternating voltage. Renewable energy – energy which is naturally replenished on a human timescale, such as sunlight, wind, rain, tides, waves, and geothermal heat. Table 3.2 A summary of some renewable energy sources in the Caribbean Energy source Example How it operates Key advantages Key disadvantages Solar power There are no large-scale solar power plants in the Caribbean but many new buildings have panels installed. Most homes in Barbados have solar water heaters on their roofs. The energy from sunlight is converted directly to electricity using semiconductor cells. No fuel required. Plenty of sunlight in the Caribbean. Electricity can be produced on the building in which it is to be used. Can’t produce electricity at night so battery storage required. Quite expensive to build. Hydroelectricity The Dominican Republic has 20 dams providing 10% of the electricity needs. Water is trapped behind a dam and used to drive turbines as it is allowed to escape. No fuel required. Can produce large amounts of electricity very quickly. Floods large amounts of land which is a precious resource on islands. Only small- and mediumscale systems can be used on Caribbean islands as there are few large valleys or rivers. Tidal power Tidal flows around the Caribbean could provide energy but are not used currently. Water is trapped in estuaries and drives turbines. No fuel required. Predictable energy output. There are very few suitable estuaries in the Caribbean islands. Alters habitats and wildlife. Wind turbines The Wigton wind farm on Jamaica produces 20 MW of electricity. The wind spins turbine blades mounted on towers. No fuel required. Plenty of wind around island systems. Largescale wind farms or small-scale local generation possible. Offshore turbines could affect tourism by spoiling views. Some noise pollution is produced, especially from large wind farms. Geothermal energy Beneath the volcanic islands of St Kitts and Nevis there are vast reserves of geothermal energy. Research projects are underway to develop a power station. Thermal energy released by radioactive decay within the Earth is used to heat water into steam and the steam drives turbines. No pollution is caused and sources are very reliable. Only a very few locations are suitable. Biofuels Sugar cane is grown on many islands and some could be used to produce oils or ethanol to replace crude oil. Biological material, such as wood, sugar cane, or ethanol, is burnt. New supplies can be grown fairly quickly. Does not add extra carbon dioxide to the atmosphere. The land used to grow fuel crops may be better used to grow food for increasing populations. (photovoltaic cells) 55 3.2 Transformers The transformer is used in electricity distribution, construction work and electronic equipment. It transforms voltage, which can enter the transformer at one level (input) and leave at another (output). When the output voltage is higher than the input voltage we say that we have a step-up transformer, and when the output voltage is lower than the input, we say that we have a step-down transformer. Transformers make use of an action known as mutual inductance. For example, two coils, A and B, are placed side by side, but not touching each other. Coil A has been connected to a d.c. supply via a switch, and coil B is connected to a meter. If the switch is in the open position, no current will flow in coil A; if the switch is closed, current will start to flow in coil A. Current flow through a coil will create a magnetic field, therefore, as the current in coil A increases up to its maximum value, it creates a changing magnetic flux. As long as there is a changing magnetic flux, there will be an e.m.f. ‘induced’ into coil B and this would be detected on the meter. The meter would briefly indicate a value of e.m.f. when the switch is closed, and then quickly return to zero. This is because it is the rising (changing) current that causes the change of magnetic flux. Once the current is at its maximum value, it has stopped rising (changing) and therefore there is no change of magnetic flux. If there were no changing magnetic flux there can be no e.m.f. induced in coil B. If the two coils were now wound on an iron core, we would find that the level of magnetic flux is increased, and the level of mutual inductance is also increased. If an a.c. supply instead of d.c. is used, the magnetic flux produced in coil A would be constantly changing with the frequency of the supply, and therefore constantly producing an e.m.f. in coil B. An a.c. supply is needed to allow transformers to operate correctly. There are two main types of transformer construction available: core and shell. A third type of transformer construction, toroidal, is also available. Core-type transformers The transformer in Figure 3.2 is double wound: ● the input is wound on one side of the iron core, the primary winding ● the output is wound on the other side, the secondary winding. Primary winding P Ip Vp Secondary winding Np Ns Is Vs Load N Figure 3.2 A single phase, double wound, core-type transformer The number of turns in each winding, the turns ratio, will affect the induced e.m.f. Np is the number of turns in the primary winding, and Ns is the number in the secondary. When voltage (Vp) is applied to the primary winding, it will cause a changing magnetic flux to circulate in the core. This changing flux will cause an e.m.f. (Vs) to be induced in the secondary winding. Assuming that we have no losses or leakage (i.e. the transformer is 100% efficient), then power input will equal power output and the ratio between the primary and secondary sides of the transformer can be expressed as follows: Vp Vs 56 = Np Ns I = s Ip A transformer has no moving parts, so if the following apply, it is a very efficient piece of equipment: ● Use laminated (layered) steel cores, not solid metal. In a solid metal core ‘eddy currents’ are induced which cause heating and power losses. Laminated cores, where each lamination is insulated, help to reduce this effect. ● Use soft iron with high magnetic properties for the core. ● Windings should be made from insulated, low resistance conductors. This will prevent short circuits occurring either within the windings, or to the core. Copper losses The resistance of the windings will cause the currents passing through them to cause a heating effect and subsequent power loss. This power loss (in watts) can be calculated using the formula: Pc = I2 × R Iron losses Losses take place in the magnetic core of the transformer, normally caused by eddy currents (small currents which circulate inside the laminated core of the transformer), and hysteresis (the force necessary to overcome magnetic flux density that remains in the iron core). Eddy currents are reduced by using a laminated core construction. Hysteresis is reduced by adding silicon to the iron from which the transformer core is made. Reducing leakage Some of the magnetic flux being produced by the primary winding will not react with the secondary winding and is often referred to as ‘leakage’. Splitting each winding across the sides of the core reduces this leakage, see Figure 3.3. Shell-type transformers In the shell-type transformer, both windings are wound onto the central leg of the transformer and the two outer legs are then used to provide parallel paths for the magnetic flux. Vp Vs Figure 3.3 Splitting the winding The autotransformer The autotransformer uses the principle of ‘tapped’ windings in its operation. Some devices are supplied P with the capability of providing more than one output, such as small transformers for calculators, Vp musical instruments or doorbell systems. Tapped VS connections are the normal means by which this is achieved. A tapped winding means that a connection N to the winding has been brought out to a terminal. By connecting between the different terminals, we Figure 3.4 An autotransformer can control the number of turns that will appear in that winding and we can provide a range of output voltages. An autotransformer has only one tapped winding, and the position of the tapping on that winding will dictate the output voltage. 57 One of the advantages of the autotransformer is that, because it only has one winding, it is more economical to manufacture. However, if the winding ever became broken between the two tapping points, then the transformer wouldn’t work and the input voltage would appear on the output terminals. Instrument transformers Instrument transformers are used in conjunction with measuring instruments, because it would be very difficult and expensive to design normal instruments to measure the high currents and voltages that we find in certain power systems. There are two types of instrument transformer, both being double wound: the current transformer, and the voltage transformer. The current transformer The current transformer (c.t.) has very few turns on its primary winding so that it doesn’t affect the circuit to be measured, with the actual meter connected across the secondary winding. Care must be taken when using a c.t. never to open the secondary winding while the primary is ‘carrying’ the main current. If this happened, a high voltage would be induced into the secondary winding. Apart from the obvious danger, this heat build up could cause the insulation on the c.t. to break down. A c.t. could be used inside a switchgear panel, where the busbar would pass through the centre of the c.t. and the meter would be connected across the two terminals at the top of the c.t. Figure 3.5 A current transformer The voltage transformer This is very similar to the standard power transformer, in that it is used to reduce the system voltage. The primary winding is connected across the voltage that we want to measure and the meter is connected across the secondary winding. Three-phase transformers A three-phase transformer can be best thought of as three single-phase transformers, which have then been connected together in a three-phase arrangement. Like their single-phase counterparts, three-phase transformers may be step-up or step-down. The arrangement of the windings (3 × primary and 3 × secondary) can then follow one of the following four patterns, where the windings are given as primary then secondary: ● Star – Star ● Delta – Delta ● Star – Delta ● Delta – Star R Supply Y B N N R Load Y B Figure 3.6 A three-phase transformer The electricity supply companies normally use Delta in high voltage transmission and then use a Delta–Star transformer in the local sub-stations. 58 A transformer having a turns ratio of 2 : 7 is connected to a 230 V supply. Calculate the output voltage. Transformer ratios are given in the order primary then secondary. Therefore in this example for every 2 windings on the primary winding, there are 7 on the secondary. Worked Example 1 We use the formula: Vp Vs = We transpose this to get: Vs = Np Ns Vp × Ns Np We insert the ratio into the formula: Vs = Vp × Ns Np = 230 × 7 = 805 V 2 Lets say that we know the number of turns in the windings to be 6 in the primary and 21 in the secondary. If we now apply this to the formula we get: Vs = Vp × Ns Np = 230 × 21 = 805 V 6 A single-phase transformer, with 2000 primary turns and 500 secondary turns, is fed from a 230 V a.c. supply. Find: a) the secondary voltage b) the volts per turn. Worked Example 2 a) Vp Vs = Np Ns Using transposition, re-arrange the formula to give Vs Vs = Vs = Vp × Ns Np 230 × 500 115 000 therefore Vs = 57.5 V = 2000 2000 b) In the primary In the secondary Vp Np = 230 = 0.115 volts per turn 2000 Vs 57.5 = = 0.115 volts per turn Ns 500 59 A single-phase transformer is being used to supply a trace heating system. The transformer is fed from a 230 V 50 Hz a.c. supply and needs to provide an output voltage of 25 V. If the secondary current is 150 A and the secondary winding has 50 turns, find: a) the output kV A of the transformer b) the number of primary turns Worked Example 3 c) the primary current d) the volts per turn. a) kV A = b) If c) If Vp Vs Vp Vs = volts × amperes Vs × Is 25 × 150 = = = 3.75kV A 1000 1000 1000 Np Ns then by transposition Np = Vs = 230 × 50 = 460 turns 25 I V ×I 25 × 150 = s then, by transposition Ip = s s = = 16.3 A Ip Vp 230 d) In the primary Vp Np In the secondary 60 Vp × Ns = 230 = 0.5 volts per turn 460 Vs 25 = = 0.5 volts per turn Ns 50 A step-down transformer, having a ratio of 2 : 1, has an 800 turn primary winding and is fed from a 400 V a.c. supply. The output from the secondary is 200 V and this feeds a load of 20 Ω resistance. Calculate the power in the secondary winding, and the power in the primary winding. Remember: The formula for power is P = V × I, and we can use Ohm’s law to find V current, I = . R Therefore, the current in the secondary winding: Worked Example 4 Is = Vs 200 = = 10 A Rs 20 The power generated in the secondary winding: P = V × I = 200 × 10 = 2000 W = 2 kW To find the current in the primary winding we transform: Vp Vs I = s Ip l × Vs Ip = s Vp = 10 × 200 2000 = = 5A Vp 400 Power generated in the primary winding: P = V × I = 400 × 5 = 2000 W = 2 kW (This proves that power input equals power output.) 61 4. Electrical installations 4.1 Introduction The Institute of Engineering and Technology (IET) Link The Institute of Engineering and Technology (IET) was previously known as the Institute of Electrical Engineers (IEE). This website gives the wiring regulations: http://electrical.theie.org/wiring-regulations/ Founded in 1871, the IEE is the largest professional engineering society in Europe and has a worldwide membership of just under 130 000. As well as setting standards of qualifications for professional electrical, electronics, software, systems and manufacturing engineers, the IET prepares regulations for the safety of electrical installations for buildings. The IET Wiring Regulations (BS 7671) have now become the standard for the UK and many other countries. It also recommends the requirements for ships and offshore installations internationally. The National Electrical Code (NEC) Link The National Electrical Code (NEC) is a regionally adoptable standard for the safe installation of electrical installations and equipment in the US. This website shows the National Electric Code: http://www.nfpa.org/codes-and-standards/all-codes-and-standards/list-ofcodes-and-standards?mode=code&code=70 It is part of the published National Fire Codes series. In some cases, the NEC is amended, altered and may even be rejected in lieu of regional regulations as voted on by local governing bodies. The NEC deals with the installation of these, in commercial, residential, and industrial premises: ● electrical conductors ● equipment ● signalling and communications conductors ● equipment ● fibre optical cables. 62 JS 21 Standards Link This code incorporates key technical content and requirements from the latest versions of ASHRAE and other standards, which are complex second or third generation standards. This website shows the JS 21 Standards: https://law.resource.org/pub/jm/ibr/js.217.1994.pdf The standards cover the following areas: ● energy ● comfort ● productivity. It encourages the design of new buildings and the retrofit of existing buildings so that they may be constructed, operated and maintained in a manner that reduces the use of energy without constraining the building function, or the comfort or productivity of the occupants, and with appropriate regard for cost considerations. Minimum standards and criteria are provided to conserve energy when designing new buildings and major retrofits. Recommended practices provide guidance for energy conserving design that demonstrates good professional judgment and exceeds minimum standards and criteria. Calculation methods and tools provide methods, compliance forms, and tools for determining compliance with these criteria and minimum standards. The tools include both manual and microcomputer-based calculation procedures. International codes Link The code provides minimum standards to safeguard life and property by regulating and controlling the design, construction and installation, quality of materials location operation and maintenance, and use of electrical installations and equipment. This website shows the international electric code: http://www.slideshare.net/gueste69b7bd/2003-international-electrical-code 63 4.2 Circuits Ring circuits In a ring circuit the phase, neutral and circuit protective conductors are connected to their respective terminals at the consumer unit and looped into each socket outlet in turn, and then returned to their respective terminals in the consumer unit. Each socket outlet has two connections back to the mains supply. For a standard domestic ring circuit: ● An unspecified number of socket outlets may be provided. Each socket outlet of twin or multiple sockets is regarded as one socket outlet. ● The floor area served by a single 30 A or 32 A ring final circuit must not exceed 100 m². Ring conductor rating not less than 0.67 times fuse rating Cable size not less than ring cable Non-fused spur P Cable size not less than ring cable E Spur box N Fused spur Fuse to suit cable size Stationary appliance Figure 4.1 A domestic ring circuit ● Consideration must be given to the loading of the circuit, especially kitchens which may require a separate circuit. ● When more than one ring circuit is installed in the same premises, the socket outlets installed should be reasonably shared amongst the ring circuits so that the assessed load is balanced. Permanently connected equipment Permanently connected equipment, e.g. cookers and water heaters, should be individually protected by a fuse and controlled by a switch or protected by a circuit breaker. 64 Fused and non-fused spurs Spurs may be installed on a ring circuit. These may Ring circuit be fused, but it is more common to install non-fused Single socket spurs connected to a circuit at the terminals of socket outlet outlets, at junction boxes, or at the origin of the circuit Ring circuit in the distribution board. A non-fused spur may supply only one single or one twin socket outlet, or one item Double socket of permanently connected equipment, e.g. a water outlet heater. The total number of non-fused spurs should not Figure 4.2 The connection exceed the total number of socket outlets and items of spurs of stationary equipment connected directly to the ring circuit. The size of conductor for a non-fused spur must be the same as the size of conductor used on the ring circuit. A fused spur is connected to a circuit through a fused connection unit. The fuse should be related to the current carrying capacity of the cable used for the spur. The total number of fused spurs is unlimited. Fuse connection unit (not exceeding 13 A) Appliance Ring circuit Figure 4.3 A fused connection unit Radial circuits In a radial circuit the conductors do not form a loop but finish at the last outlet. There is no maximum or specified number of sockets in a radial circuit, but this will be determined by the estimated load and safety requirements. Local wiring regulations must be adhered to. A2 radial circuit The current rating of the cables is determined by the rating of the overcurrent protection device, i.e. 30 or 32 A amp fuse or circuit breaker. This means that copper cables of not less than 4.0 mm² may be used and the floor area served may not exceed 75 m². See Figure 4.4. A3 radial circuit In domestic premises an A3 radial circuit is wired in 2.5 mm² copper cable and protected by a 20 A fuse or circuit breaker. Local regulations will specify the floor area within which any number of socket outlets may be installed. See Figure 4.5. A2 type circuit Floor area maximum 75 m2 A3 Type circuit Floor area maximum 75 m2 4 mm2 30 A Figure 4.4 A2 radial circuit 2.5 mm2 20 A Figure 4.5 A3 radial circuit 65 Emergency lighting Emergency lighting should be planned, installed and maintained to the highest standards of reliability, so that it will operate when called into action. Emergency lighting is not required in private homes where occupants are familiar with their surroundings, but in public buildings where people are in unfamiliar surroundings and need a well illuminated and easily identified exit route in an emergency. Emergency lighting is provided for two reasons: ● to illuminate escape routes, called ‘escape’ lighting ● to enable a process or activity to continue after a normal light failure, called ‘standby’ lighting. Escape lighting schemes should be planned to provide light for escape routes from a point within a building to a final exit. Obstructions should be visible in lower levels of illumination. The level of illumination required is 0.2 lux, which is similar to the brightness of the full Moon. Standby lighting is required in buildings where an operation or process once started must continue, even if the main lighting fails, e.g. hospital operating theatres and in industry. Maintained emergency lighting In this type of system the luminaire is supplied with a single light source which may be switched on and off as required. The emergency lamps are continuously lit using the normal supply when it is available, and change over to an alternative supply when the mains supply fails. The advantage of this system is that the lamps are continuously proven healthy and any fault is immediately obvious. Maintained emergency lighting is normally installed in places of entertainment where the normal lighting may be dimmed or turned off whilst the building is occupied, e.g. in theatres, cinemas, nightclubs. The emergency lamps are wired in parallel from a low voltage supply. Normally open relay Emergency supply Mains supply Transformer Rectifier Alarm bell Emergency lamps Figure 4.6 Maintained emergency lighting 66 Non-maintained emergency lighting In this type of circuit the emergency lamps are only illuminated if the normal mains supply fails. Failure of the main supply de-energises a solenoid and a relay connects the emergency lamps to a battery supply, which is maintained in a state of readiness by a trickle charger from the normal main supply. When the normal supply is restored, the relay solenoid is energised, breaking the relay contacts, which disconnects the emergency lamps, and the charger re-charges the battery. The disadvantage with this type of installation is that broken lamps are not detected until they are called into operation in an emergency, unless they are regularly maintained. A battery contained within the luminaire, together with a charger usually provides the emergency supply and relay making the unit self-contained. Normally open relay Mains supply Transformer Rectifier Emergency lamps Emergency supply Did you know? Figure 4.7 Non-maintained emergency lighting The lux (symbol: lx) is the SI unit of illuminance and luminous emittance, measuring luminous flux per unit area. It is equal to one lumen per square metre. 67 Fire alarm systems A correctly installed fire alarm system installation is of paramount importance. Life could be lost and property damaged if fire detection and alarm equipment have been incorrectly connected. Life protection Alarms are required in areas where a fire could lead to a high risk to life, e.g. sleeping areas, store rooms, kitchens, plant rooms, etc., and places where the occupants are especially vulnerable due to age, illness, or unfamiliarity with the premises. Property protection A satisfactory fire alarm system for the protection of property will automatically detect a fire at an early stage, indicate its location and raise an effective alarm in time to summon the fire fighting forces (both trained staff and professional fire brigade). Automatic detectors When choosing the type of detector to be used in a particular area it is important to remember that the detector has to discriminate between a fire and the normal environment existing within the building, i.e. smoking in hotel bedrooms, fumes from forklift trucks in warehouses, steam from kitchens and bathrooms. There are several automatic detectors available. See Table 4.1. Table 4.1 Automatic detectors Heat detectors (fixed temperature type) ● ● ● Heat detector (rate of rise type) ● ● Smoke detector ● ● Alarm sounders ● ● 68 A simple device designed to activate the alarm circuit once a predetermined temperature is reached Operates at either 60 °C or 90 °C Suitable for rooms where fluctuations in ambient temperature are commonplace, e.g. kitchen or boiler room Responds to rapid rises in temperature by sampling the temperature difference between two heat-sensitive thermocouples or thermistors mounted in a single housing Not suitable for boiler room or kitchen where fluctuations in ambient temperature occur regularly as this can result in nuisance alarms The optical smoke or photoelectric smoke detector operates by means of the light-scattering principle. A pulsed infrared light is targeted at a photo-receiver, but separated by an angled nonreflective baffle positioned across the inner chamber. When smoke and combustion particles enter the chamber, light is scattered and reflected onto the sensitive photo receiver and triggers the alarm. Detector heads for fire alarm systems should only be fitted after all work that could create dust is finished. Normally a bell or electronic sounder, which must be audible throughout the building in order to alert (and/or evacuate) the occupants of the building The alarm sounders should be loud enough to be heard above normal background noise, but not so high to cause permanent damage to hearing Key term Thermistor – a device whose resistance quickly decreases with an increase in temperature. Wiring systems for fire alarms Fire detectors and sounders must be wired in a continuous parallel formation arrangement as shown in Figure 4.8. No spurs are permitted, as this would prove difficult to monitor for breaks and short circuits. Circuits from the control panel should be as short as possible as shown in Figure 4.9. In order to continually monitor both cables and terminations for open and short circuit conditions, an end of line resistor should be connected across the terminals of the last sounder. It is wise to leave the wiring of the fire alarm system until most of the constructional work has been completed. This will help avoid accidental damage occurring to the cables. Keep the control panel in the packing carton and only remove when building work has been completed in the area where it is to be mounted, thus avoiding possible contamination to the unit. End of line resistors Smoke detectors Sounders Loop resistance must be less than 10 Ω Smoke detectors + – Zone 1 Control panel Figure 4.8 A wiring system for fire alarms Zone 1 Control panel Figure 4.9 Circuits for fire alarms 69 4.3 Wiring methods and terminations PVC-insulated (polyvinylchloride) and sheathed cables are used extensively for lighting and heating installations in domestic dwellings, being generally the most economical method of wiring for this work. Table 4.2 Types of cable and cord Polyvinylchloride (PVC): ● Tough, cheap, and easy to work with and install; PVC-insulated/sheathed cable is the most popular type of cable in current use ● PVC insulation has its limitations in conditions of excessive heat and cold ● Can be subject to mechanical damage unless additional mechanical protection is used in certain situations (e.g. installed in trunking) ● The most versatile of all the wiring systems Single-core PVC-insulated unsheathed cable: ● Made from PVC-insulated solid or stranded copper conductor, coloured red or black; other colours include blue, green, yellow, white, and green/yellow stripes for use as the earth ● A flexible and thin cable; it is generally installed into trunking or conduit for extra protection Single-core PVC-insulated and sheathed cable: ● Suitable for surface wiring where there is little risk of mechanical damage ● Normally used as ‘meter tails’ for connecting the consumer unit/distribution board to the supply company’s meter ● The construction of this cable is PVC-insulated and PVC-sheathed solid or stranded plain copper conductor ● The core colours are normally black or red, sheath colours are normally black, red, or grey; other colours are available Single-core PVC-insulated and sheathed cable with a circuit protective conductor (CPC): Used for domestic and general wiring where a (CPC) is required for all circuits ● Made from PVC-insulated copper conductor laid parallel with a plain copper circuit protective conductor and PVC-sheathed overall ● Core colours are red or black, the CPC is plain copper, and sheath colour is normally white or grey Key terms ● 70 Polyvinylchloride (PVC) – a material that acts as an insulator, normally the covering for electrical cables. Conduit – a tube made from metal or PVC in which insulated conductors are contained. PVC-insulated and sheathed flat wiring cables: ● Used for domestic and industrial wiring where there is little risk of mechanical damage ● Made from two or three plain copper, solid or stranded conductors, insulated with PVC and sheathed overall with PVC ● Core colours for two cores are brown and blue ● Three cores are brown, black, and grey ● The sheath colours are normally grey or white ● The construction of three core cables are exactly as mentioned above with the inclusion of an uninsulated plain copper earth between the cores of twin cables and between the grey and black cores of three core cables Heat-resisting PVC-insulated and sheathed flexible cords: ● Suitable for use in ambient temperature up to 85 °C; not suitable for use with heating appliances; construction is plain copper flexible conductors insulated with heat-resisting (HR) PVC and (HR) PVC-sheathed ● Core colours are single core brown or blue encased in a white sheath PVC-insulated and sheathed flat twin flexible cord: ● Intended for internal, light duty usage, e.g. table lamps, radios and TV sets where the cable may lie on the floor; should not be used with heating appliances ● Made from plain copper flexible conductor PVC, insulated two cores are laid parallel and sheathed overall with PVC ● Core colours are brown and blue; the sheath colour is white PVC-insulated bell wire: ● Used for wiring bells, alarms and other indicators, which operate at extra low voltage ● Made from one single-core plain soft copper conductor insulated with PVC; twin-core wire is produced from two single-core wires laid parallel and insulated overall with PVC compound to form a figure 8 section ● Standard colour of this wire is white; core identification is by a red or coloured stripe formed on one core Cables with thermosetting insulation (XLPE): ● Thermosetting insulation is used when higher operating temperatures are needed ● Maximum continuous operating temperature for XLPE is 90 °C compared with 70 °C for PVC insulation; increased temperature permits a reduction in conductor size if XLPE insulated cables are used in preference to cables having PVC insulation ● Used mostly for mains distribution 71 Installing PVC cables Cables are fixed at intervals using plastic clips, which incorporate a masonry-type nail. When bending PVC cable around corners, the radius of the bend should be such that the cable or conductor does not suffer damage. Where PVC cables are installed on the surface the cable should be run directly into the electrical accessory ensuring that the outer sheathing of the cable is taken inside the accessory to a minimum of 10 mm. If the cable is to be concealed, a flush box is usually provided at each control or outlet position. Figure 4.10 Cable clips Cable runs Cable runs should be planned to avoid cables having to cross one another, which would result in an unsightly and unprofessional finish. When cables are to be installed in cement or plaster they should be protected against damage. They should be covered with metal or plastic channel, or by installing them in oval PVC conduit. Care must be taken when installing PVC cables to ensure that they are not allowed to come into contact with gas pipes and water pipes and any other non-earthed metal work. PVC-sheathed cables should also not come into contact with polystyrene insulation, as a chemical reaction takes place between the PVC sheath and the polystyrene resulting in migration of polymers with the cable known as ‘marring’. Terminating cables and flexible cords The entry of the cable end into an accessory is known as a termination. In the case of a stranded conductor the strands should be twisted together with pliers before terminating. Care must be taken not to damage the wires, and to ensure the terminal or socket is correctly connected. When current flows in a conductor, heat is generated; the consequent expansion and contraction may be sufficient to allow a poorly connected conductor to be pulled out of the terminal or socket. This could lead to an electrically dangerous situation. One or more strands of wire (known as a whisker) left out of the terminal or socket will reduce the effective cross-sectional area of the conductor at that point. This may result in increased resistance and probable overheating, potentially leading to a fire. Pillar terminals A pillar terminal has a hole through its side into which the conductor is inserted and secured by a set-screw. If the conductor is small in relation to the hole it should be doubled back. When two or more conductors are to go into the same terminal they should be twisted together. Care should be taken not to damage the conductor by excessive tightening. Screwhead, nut and washer terminals Figure 4.11 A pillar terminal When fastening conductors under screwheads or nuts, it is best to form a conductor end into an eye using round-nosed pliers that should be slightly larger than the screw shank but smaller than the outside diameter of the screwhead, nut or washer. The eye should be placed in such a way that rotation of the screwhead or nut tends to close the 72 joint in the eye. If the eye is put in the opposite way round the motion of the screw or nut will tend to untwist the eye and will probably result in an imperfect contact. Figure 4.12 Screwhead, nut and washer terminals Claw washers In order to get a better connection, claw washes can be used. Lay the looped conductor in the pressing. Place a plain washer on top of the loop and squeeze the metal points flat using the correct tool. Figure 4.13 Claw washers Strip connectors The conductors to be terminated are clamped by means of grub screws in connectors, which are usually made of brass and mounted in a moulded insulated block. The conductors should be inserted as far as possible into the connector so that the pinchscrew clamps the conductor. A clean, tight termination is essential in order to avoid high resistance contacts resulting in overheating of the joint. Figure 4.14 Solderless lugs Solderless lugs are used extensively for terminating smaller-sized cables. Lugs of this type are made from solid copper and are tinned. They are fastened to cable ends by crimping. 73 4.4 Lighting circuits There are numerous switching arrangements which make up a lighting circuit. These circuits can be installed using either multi-core or single-core cables. If using single-core cables, this should be installed in conduit or trunking for mechanical protection. Here are the most common wiring arrangements using multi-core cables. Multi-core cables (referred to as twin and earth) are basically a three-core cable – a phase, a neutral and an earth conductor. Both the phase and neutral conductors consist of copper conductors insulated with coloured insulation (the earth is a non-insulated copper conductor sandwiched in between the phase and neutral). The outer white or grey covering is the sheath, and its main purpose is to prevent mechanical damage occurring to the insulation of the conductors. This cable is often used for wiring domestic and commercial lighting circuits, normally using 1.0 mm² or 1.5 mm² cable. Using this type of cable is slightly more complicated because the cable will always consist of a brown, blue, and earth conductor. Loop in ceiling rose Loop in ceiling rose is the most common method used to install lighting circuits. The power comes into the ceiling rose from either the consumer unit or the last lamp in the circuit. The power is then sent to the next lamp via the connecting blocks in the ceiling rose. The live wire coming in is connected to the live wire going out. This is the same for the neutral and earth wires. From previous light Earth terminal To next light To switch From switch (Live) Switch terminal (Live) Neutral terminal Live terminal To light Figure 4.15 Loop in ceiling rose In the simplest situation, one switch controls one light. However, you may want lights to be controlled by one or more switches in different locations around the room. Figure 4.16 shows a simple loop system in a three-room property, and Figure 4.17 shows a one-way switching arrangement. 74 Ceiling rose C Ceiling rose A Ceiling rose B Consumer unit (fuse board) Lamp Ro om 3 Light switch 2 om Ro Figure 4.16 A loop system 1 om Ro Figure 4.17 A one-way switching arrangement Two-way switching Where more than one switch position is required for one or more lights a different switching arrangement must be used. The most common is the two-way switch circuit which allows lights to be switched on or off from two positions. This arrangement is most commonly used on stairways and corridors. The switch feed feeds one two-way switch and the switch wire goes from the other two-way switch to the lights. Two wires known as ‘strappers’ join the two-way switch. This method of switching using multi-core cables requires the use of four-core cable, which has three coloured (brown, grey and black) and insulated conductors and a bare earth conductor. This type of cable is normally only stocked in 1 mm² and used in a lighting circuit where its application is for switching that requires more than one switch position, i.e. two-way and intermediate switching. It is also used for converting one-way switching into two-way switching. Figure 4.18 Two-way switching using multi-core cables 75 Intermediate switching If more than two switch positions are required, then intermediate switches must be used. The switches are wired in the ‘strappers’ between the two-way switches. The action of the intermediate switch is to cross connect the ‘strapping’ wires. Any number of intermediate switches may be used and they are all wired into the ‘strappers’. For example, you may find this switching arrangement in long corridors in hotels. A Power feed in from fuse board or previous light Twin and earth switch drop from C ceiling rose or juction box Switch back box Switch face plate C See Note A about this earth loop 3 core and earth between light switches L2 L2 Terminal block L1 L1 E Switch back box 3 core and earth between light switches Switch face plate COM L1 L2 Figure 4.19 Intermediate switching 76 9 -2 -3 -4 -5 -6 -7 COM L1 L2 D B Feed out to next light in the radial circuit -1 -8 Ceiling rose Live and neutral L to lamp holder N Notes Note A – if you are using metal light switches you should include this additional earth loop from the switch back boxes to the switch plates on both switches Wiring with a junction or joint box Wiring with a junction box has now been superseded by the loop in method, but older properties may still have a junction box installed. Care should be taken when wiring junction boxes: ● The protective outer sheath should be taken inside the junction box entries, to a minimum of 10 mm. ● Where terminations are made into a connector only sufficient insulation should be removed. ● Sufficient slack should be left inside the joint box to prevent excess tension on conductors. ● Cables should be inserted so that they are not crossing, they should be neat and fitted so that the lid fits without causing damage. ● Correct size joint boxes should be used. ● Joint boxes should be secured to a platform fitted between the floor and ceiling joists. Switch 1 Switch feed Switch wire Lamp 1 Phase Switch wire Neutral Neutral CPC Joint box Figure 4.20 The joint box method of control for one light 77 Did you know? 4.5 Lamps Illumination using electricity has been available for over 100 years, though it has changed in many ways. The first type of electric lamp was the ‘arc lamp’ which used electrodes to draw an electrode through the air. This was quite an unsophisticated use of electricity and resulted in many accidents and fires. The first lamp that was developed for indoor use was the carbon filament lamp. Although this was a dim lamp by modern standards, it was cleaner and far less dangerous than the exposed ‘arc lamp’. Incandescent lamps The General Lighting Service (GLS) lamp is commonly referred to as the ‘light bulb’. At its ‘core’ is a very thin tungsten wire, which is formed into a small coil and then coiled again. A fine filament of wire is connected across an electrical supply and is made to heat up until it is white-hot and gives off light. The filament wire reaches a temperature of about 2500–2900 °C. These lamps are very inefficient as only a small proportion of the available electricity is converted into light. Most of the electricity is converted into heat as infrared energy. The light bulb has many advantages, including: ● comparatively low initial costs ● immediate light when switched on ● no control gear ● can be easily dimmed. Figure 4.21 The light bulb Tungsten halogen lamps Tungsten halogen lamps were introduced in the 1950s. The tungsten filament is enclosed in a gas-filled quartz tube together with a carefully controlled amount of halogen such as iodine. When an electric current heats the filament the tungsten is evaporated from the surface of the filament and is carried by convection currents to the comparatively cool walls of the lamp. Here it combines with the halogen, which has vaporised and forms a tungsten halide. This compound returns to the filament where the high temperatures convert it back to tungsten and the halogen gas that is left sinks to be drawn again through the filament in a continuing cycle. The quartz glass bulbs must not be handled, as contamination from the skin will form opaque patches on the glass when it becomes hot. This can cause premature failure of the lamp, so when fitting these types of lamps it is advisable to leave the wrapping around the lamp until it is fitted in place, or alternatively handle only by the ends. Accidental contact with the glass bulb should be cleaned with a solvent such as carbon tetrachloride. The linear type of lamp must be operated within 4 ° of the horizontal to prevent the halogen vapour migrating to one end of the tube causing early failure. These types of lamps have many advantages, including: ● increased lamp life ● 100% lumen output ● increase in efficacy (up to 23 lumens per watt) ● reduction in lamp size. 78 Figure 4.22 The linear tungsten halogen lamp Low-pressure mercury vapour lamps The fluorescent lamp, or low-pressure mercury vapour lamp, consists of a glass tube filled with a gas such as Figure 4.23 The krypton or argon and a measured amount of mercury fluorescent lamp vapour. Coated on the inside of the glass tube is a phosphor and at each end there is a set of oxide-coated electrodes, cathodes. When a voltage is applied across the ends of a fluorescent tube the cathodes at the ends of the tube heat up and this forms a cloud of electrons, which ionise the gas in their immediate vicinity. The voltage to carry out this ionisation must be much higher than the voltage required to maintain the actual discharge across the lamp. Several methods are used to achieve this high voltage, usually based on a transformer or choke. This ionisation is then extended to the whole length of the tube so that the arc strikes and is then maintained in the mercury, which evaporates and takes over the discharge. The mercury arc being at low pressure emits little visible light but a great deal of ultraviolet, which is absorbed by the phosphor coating and transformed into visible light. The cathodes are sealed into each end of the tube and consist of tungsten filaments, which are coated with an electron emitting material. Larger tubes incorporate cathode shields. The gas in standard tubes is a mercury and argon mix, although some lamps (the smaller ones and the new, slim energy-saving lamps) have krypton gas in them. The phosphor coating is a very important factor affecting the quantity and quality of light output. When choosing different lamps there are three main areas to be considered: ● lamp efficacy ● colour rendering ● colour appearance. The glow starter circuit In the glow starter, normally open contacts are mounted on bimetal strips and are enclosed in an atmosphere of helium gas. When switched on, a glow discharge takes place around the open contacts in the starter, which heats up the bimetal strips causing them to bend and touch each other. This puts the electrodes at either end of the fluorescent tube in circuit and they warm up, giving off a cloud of electrons; simultaneously an intense magnetic field is building up in the choke, which is also in circuit. The glow in the starter ceases once the contacts are touching so that the bimetal strips now cool down and they spring apart again. This momentarily breaks the circuit causing the magnetic field in the choke to collapse, and provide the high voltage required for ionisation of the gas and enabling the main discharge across the lamp to take place. The voltage across Choke the tube under running conditions Lamp is not sufficient to operate the starter, and so the contacts remain open. The resistance of PF the mercury gets less and less correction as it warms up and conducts capacitor Starter more current. This could lead to switch disintegration of the tube; however, Figure 4.24 Glow starter switch circuit the choke has a secondary 79 function that of a current limiting impedance. Limiting the current across the lamp and keeping it in balance is one reason why it is often referred to as ballast. The capacitor shown connected across the supply terminals is to correct for the poor power factor that has been created by the inductor. This type of starter may not succeed first time and can result in the characteristic flashing when switching on. Stroboscopic effect A simple illustration of the stroboscopic effect is watching the wheels on a horse-drawn cart on television. You may have noticed the wheels appearing stationary, or even going backwards. This phenomenon is brought about by the fact that the spokes on the wheels are being rotated at about the same revolutions per second as the frames per second of the film being shot. This effect is known as the ‘stroboscopic effect’ and can also be produced by fluorescent lighting. The discharge across the electrodes is extinguished 100 times per second producing a flicker effect. This flicker is not normally observable, but can cause this stroboscopic effect which can be dangerous. For instance, rotating machinery illuminated from a single source will appear to have slowed down, changed direction of rotation or even stopped. This is a potentially dangerous situation if the phenomenon is not understood or recognised. Also certain frequencies can induce degrees of drowsiness, headaches, eye fatigue and, in extreme cases, disorientation. However, this stroboscopic effect can be harnessed to check the speed of a CD player and the speed of a motor vehicle for calibration purposes. Utilising one of the following methods can counteract the stroboscopic effect: 1. Tungsten filament lamps can be fitted locally to the lathe, pillar drilling machines, etc. This will lessen the effect, but will not eliminate it completely. 2. Adjacent fluorescent fittings can be connected to different phases of the supply. Because in a three-phase supply the phases are 120 ° out of phase with each other, the light falling on the machine will arrive from two different sources. Each of these will be flickering at a different time, which will interfere with each other and reduce the stroboscopic effect. 3. The use of high-frequency fluorescent lighting reduces the effect by about 60%. 4. Twin lamps can be wired on lead-lag circuits, thus counteracting each other. The lead-lag circuit, as the name implies, is a circuit that contains one lamp in which the power factor leads the other – hence the other lags. Using the leading current effect of a capacitor and the lagging current effect of an inductor produces the lead-lag effect. The lagging effect is 80 Lead circuit lamp Lag circuit lamp Series Capacitor P Figure 4.25 Lead-lag circuit N produced naturally when an inductor is used in the circuit. The leading effect uses a series capacitor, which has a greater effect than the inductor in the circuit. When these two circuits are combined as shown in Figure 4.25, there is no need for further power factor correction as one circuit will correct the other. The inverse square law The inverse square law states that the further the distance a surface is from the light source, then the illumination falling on that surface will reduce inversely as the square of the distance increases. Figure 4.26 illustrates this law. ity Light intens ¼ 1 1 Dista nc e from light sourc e 2 3 Figure 4.26 The inverse square law The cosine law The cosine law states that the luminous intensity of a surface is proportional to the cosine of the angle between the direction and the normal to the surface. The surface will then appear equally bright from all directions. Cosine law: Eθ = E * cos(θ) 0° 30° 100% 87% 60° 50% 85° 9% Figure 4.27 Lambert’s cosine law 81 4.6 Conduits Steel conduit Annealed mild steel tubing known as conduit is widely used as a commercial and industrial wiring system. Single core cables are run inside the steel tubing. Conduit can be bent without splitting, breaking or kinking, provided the correct methods are used. It offers excellent mechanical protection to the wiring and in certain conditions may also provide the means of earth continuity. The two types of commonly used steel conduit are known as black enamel conduit which is used indoors where there is no likelihood of dampness, and galvanised conduit which is used in damp situations or outdoors. Screwed conduit Screwed steel conduit can be either seam welded or solid drawn. Solid drawn is stronger but much more expensive. The thread used on steel conduit is not used on any other pipe, so special conduit dies are therefore required. Bending machines Bending machines give consistent results every time and require the minimum of practice. To position the stand, as shown in Figure 4.28, swing the rear leg (E) to its maximum. Place the safety pin (D) through the hole beneath where the pin hangs, locking the rear leg in place. The machine should now be standing with the swivel arm (A) hanging downwards. C is the conduit guide and B is the adjusting arm for the conduit guide. Types of bend C B A D E Figure 4.28 Positioning the stand Sharp bends must be avoided. The minimum radius of steel conduit is laid down as 2.5 times the outside diameter of the conduit. See Figure 4.29. D X The right-angled bend The right-angled bend is used to go around a corner or change direction by 90º. When bending, measurements may be taken from the back, centre, or front of the bend. Allowance should be made for the depth of the fixing saddle bases. Must be a minimum of 2.5 × D Figure 4.29 The minimum bending radius allowed The set The set is used when surface levels change, or when terminating into a box entry. Sets should be parallel and square, not too long and not too short. Where there are numerous sets together all sets must be of the same Figure 4.30 The set length. 82 The double set The double set is used when passing girders or obstacles. The kick The kick is used when a conduit run changes direction by less than 90º. Figure 4.31 The double set Figure 4.32 The kick The bubble or saddle set The bubble set or saddle set is used when passing obstructions, especially pipes or roof trusses, etc. The centre of the obstruction should be central to the set as shown below. Making a 90° set from a fixed point Fixed point Required set 200 mm Figure 4.33 Making a 90° set 1. Mark the conduit 200 mm from the fixed point, as shown in Figure 4.34. If the distance is given to the inside or centre of the tube, simply add on either the diameter or half the diameter respectively to give the back bend measurement and follow the same procedure as for the outside measurement. Fixed point Fixed point Mark 200 mm from fixed point Figure 4.34 Step 1 83 2. Place the tube in the ‘former’ with the fixed point to the rear. Position the tube so that a square held against the tube at the fixed point touches and forms a tangent to the leading edge of the former. Fixed point Too long to down bend Inital mark 200 mm Required distance from fixed point to back of bend Figure 4.35 Step 2 3. Where the remaining length of tube from the measured point is too long to down bend and where it is not convenient or possible to up bend, deduct three times the outside diameter of the tube from the initial mark. New mark Fixed point Initial mark 20 mm O.D 60 mm (20 mm x 3) Figure 4.36 Step 3 4. Place the tube in the former with a fixed point to the front with the mark at 90 ° to the edge of the former. This will give a 90 ° bend at the required distance from the fixed point to the back of the bend as shown in Figure 4.35. Fixed point Down bend to 90° Fixed point New mark Down bend to 90° Figure 4.37 Step 4 84 Conduit fixings Table 4.3 Type of fixing Illustration ● ‘strap saddle’ – used for fixing conduit to cable tray or steel framework ● ‘half saddle’ – used for fixing to steel framework or cable tray ● ‘spacer bar saddle’ – used when fixing to an even surface, gives a clearance of 2 mm ● ‘distance saddle’ – used if the surface is uneven and where brick on concrete can give rise to heavy condensation ● ‘hospital saddle’ – used where it is necessary to clean around the conduit fixing ● ‘multiple saddle strip’ – used to fasten multiple runs of conduit together ● ‘girder clamp’ – will fix conduit to girders and I beams without having to drill a hole in the girder ● ‘pipe hook or crampet’ – used when conduits are secured to a wall or cast in concrete Cutting and screwing conduit Conduit should be cut with a hacksaw with either a fine-toothed 12 teeth per centimetre or 32 teeth per inch progressive blade. The cut should be square and the full length of a hacksaw blade should be used taking steady strokes. The conduit should be held in a pipe vice and not a bench vice. The vice should be secured but not so tight that it cuts into the pipe. Figure 4.38 Using a pipe vice for cutting the conduit 85 Before threading, the conduit should be chamfered with a file to help the die start. Screwing is carried out using stocks and dies, the guide ensuring the screw cut is square. Stocks and dies should be kept clean and any lubricant or steel shavings should be removed after cutting. The cut is made by placing the stock and die on the conduit and then turning clockwise while applying forward pressure, sometimes a great deal of pressure may be required. Once the cut is started the stock and die are removed so that a cutting agent can be applied. Having applied the cutting agent the stock is placed on the conduit again and the threading begins. The stock and die is turned back every turn to clean out the cuttings. Figure 4.39 Using stock and die When the thread is finished the stock and die is removed and the inside of the conduit is cleaned and reamed. This removes all burrs, which would cut the cables when they were installed. Reaming can be carried out with a reamer or round file. The standard length of thread for a normal joint is half a coupling length (coupling of the same size conduit). All couplings, bushes and conduit boxes must be fully tightened before installation. Where possible, couplings, bushes and boxes should be tightened while the conduit is held firmly in a pipe vice. Figure 4.40 Tightening conduits Running coupling Sometimes two conduits must be joined together and neither can be turned. This may be due to one conduit coming through a wall or ceiling or long runs combined with bends making turning impossible. In these cases a running coupling must be used. Running couplings are made by having one thread a normal half coupling length and the other thread the length of a coupling plus locking ring. 86 Conduct Coupling Locknut Figure 4.41 Running coupling The coupling and locking ring are fixed on the long thread side and the two conduits are then butted together. The coupling is then removed from the long thread to the shorter thread and finally rests across the two sides. After tightening, the coupling is locked with the locking ring. Because the coupling is transversing two threads simultaneously, the thread must be very clean and well cut. Reversing the dies and running them over the thread can help this. This is particularly important where the running coupling is in an awkward position (as it often is). A locking ring must be used because lock nuts get caught on the ceiling in tight situations. Figure 4.42 Termination of conduit There are our several methods available for terminating conduit, for example, at a box using a conduit coupling and brass male bush. Use of non-inspection elbows and tees Non-inspection elbows are only used adjacent to an outlet box or inspection type fitting. One solid elbow may be used if positioned less than 500 mm from an accessible outlet in a conduit run of less than 10 m that has other bends which are not more than the equivalent to one right angle. 500 mm max Solid elbow One rightangle bend Tee or elbow beside inspection outlet Switchgear 10 m max Figure 4.43 Wiring conduit Cables should not be drawn into a conduit system until the conduit system is complete. When drawing in cables they must first be run off the reels or drum. If the cables are allowed to spiral off the reels they will become twisted and this would cause damage to the insulation. If a large number of cables are to be drawn into a conduit system at the same time, the cable reels should be arranged on a stand or support so as to permit them to revolve freely. In new buildings, cables should not be drawn in until the conduit is dry and 87 free from moisture. If there is any doubt, a draw tape with a swab at the end should be drawn through the conduit so as to remove any moisture that may have accumulated. It is usual to commence drawing in cables from a midpoint in the conduit system so as to minimise the length of cable that has to be drawn in. A steel tape should be used from one draw-in point to another. The draw tape should not be used for drawing in cables as it may become damaged – a steel tape should only be used to pull through a draw wire. The ends of the cables must be paired for a distance of approximately 75 mm and threaded through a loop in the draw wire. When drawing in a number of cables, they must be fed in very carefully at the delivery end while someone pulls them at the receiving end. Care should be taken to feed into the conduit in such a manner as to prevent any cables crossing. Always leave some slack cable in all draw-in boxes and make sure that cables are fed into the conduit so as not to finish up with twisted cables at the draw-in point. This operation needs care and there must be synchronisation between the person who is feeding and the person who is pulling. If in sight of each other, this can be achieved by some pre-arranged signal or, if within speaking distance, by word given by the person feeding the cables. Plastic conduit Plastic conduit is made from polyvinylchloride (PVC), which is produced in both flexible and rigid forms. It is impervious to acids, alkalis, oil, aggressive soils, fungi and bacteria, and is unaffected by sea, air and atmospheric conditions. It withstands all pests and does not attract rodents. PVC conduit is preferable for use in areas such as farm milking parlours. It may be buried in lime, concrete, or plaster without harmful effects. Advantages ● Lightweight ● Easy to handle ● Easy to saw, cut and clean ● Simple to bend ● Does not require painting ● Minimum condensation due to low thermal conductivity in walls ● Quick to install. Disadvantages ● Care must be taken when gluing joints to avoid forming a barrier across the inside of the conduit. ● If insufficient adhesive is used, the joints may not be waterproof. ● PVC expands around five times as much as steel and this expansion must be allowed for. Working with PVC conduit PVC conduit is easily cut using a junior hacksaw. Any roughness of cut and burrs should be removed by simply wiping with a cloth. The most common jointing procedure uses a PVC solvent adhesive. Generally the joint is solid enough for use after two minutes, although complete adhesion takes several hours. In order to ensure a sound joint the tube and fittings must be clean and free from dust and oil. Where expansion is likely and adjustment is necessary, a mastic adhesive should be used. This is a flexible adhesive, 88 which makes a weatherproof joint, ideal for surface installations and in conditions of wide temperature variation. It is also advisable to use mastic adhesive where there are straight runs on the surface exceeding 8 m in length. Care must be taken when using these adhesives as they are volatile liquids and the lid must be replaced on the tin immediately after use. Always read the manufacturer’s instructions. PVC conduit expands considerably more than metal conduit with an increase in temperature. The expansion can be ignored where the conduit is buried in concrete or plaster. In surface work, precautions must be taken to prevent such expansion from causing the conduit to bow. Usually where bends and sets are close together these take up any expansion. Where longer runs of conduit occur in conditions of varying temperatures, some provision for expansion must be made, using expansion couplers as shown in Figure 4.44. A good guide to the use of expansion couplers is one coupler per 6 m in straight runs. Silicon grease to keep watertight 75 mm 19 mm Free to slide Slide fit 25 mm free space Adhesive cement Figure 4.44 An expansion coupler PVC conduits not exceeding 25 mm diameter can be bent cold by using a spring. The bend is then made by either the hands or across the knee. In order to achieve the angle required, the original bend should be made at twice the angle required and the tube allowed to return to the correct angle. Under no circumstances should an attempt be made to force the bend back with the spring inserted, as this can damage the spring. It is easier to withdraw the spring if it is twisted in an anti-clockwise direction. This reduces the diameter of the spring, making it easier to withdraw. In cold weather it may be necessary to warm the conduit slightly at the point where the bend is required. One of the simplest ways is to rub the conduit with the hand or a cloth. The PVC will retain the heat long enough for the bend to be made. In order that the bend is maintained at the correct angle the conduit should be saddled as soon as possible. General points ● Ample capacity must be provided at junctions employed for cable connections. ● Where a steel conduit forms the protective conductor, a separate conductor must be used to connect from any socket outlet to its back box. ● Where flush switch boxes and switch grids are used, a circuit protective conductor (CPC) is required from an earthing terminal in the box to the earthing terminal in the switch grid. ● Where conduits pass through walls, the hole will have a fire-resistant material. 89 4.7 Testing and commissioning Tests should be carried out in a set sequence, and repeated if failed. Initial tests should be carried out in the following sequence before the supply is connected or with the supply disconnected as appropriate: 1. Continuity of protective conductors, including main and supplementary bonding conductors 2. Continuity of ring final circuit conductors 3. Insulation resistance 4. Polarity With the electrical supply connected re-test polarity before further testing: 5. Earth fault loop impedance 6. Residual current operated devices. Forms of completion or periodic inspection, inspection, test and an installation schedule (including test results) should be provided to the person ordering the work. 1. Continuity of protective conductors Every earth conductor including each bonding conductor needs to be tested to verify that it is electrically sound and correctly connected, using a low reading ohmmeter. Test method 1 Before carrying out this test the leads should be ‘nulled out’. This means the resistance of the leads should be measured and deducted from the readings taken. The phase conductor and the earth conductor are linked together at the consumer unit or distribution board. The ohmmeter is used to test between the phase and earth terminals at each outlet in the circuit. Link C.P.C P E N P Socket outlet C.C.U Low reading Ohmmeter Figure 4.45 Test method 1 Test method 2 One lead of the continuity tester is connected to the consumer’s main earth terminals. The other lead is connected to a trailing lead, which is used to make contact with earth conductors at light fittings, switches, spur outlets, etc. The resistance of the test leads will be included in the result, therefore the resistance of the test leads must be measured and subtracted from the reading obtained if the instrument does not have a nulling facility. In this method the earth conductor only is tested and this reading is recorded on the installation schedule. 90 Long ‘Wander’ lead N E Socket outlet P C.P.C C.C.U Low reading Ohmmeter N.B neutral and phase omitted for clarity Figure 4.46 Test method 2 Test of the continuity of supplementary bonding conductors Test method 2 is used with the ohmmeter leads connected between the points being tested, i.e. pipe work, sinks, etc. or between conductive parts and exposed conductive parts (metal parts of the installation). This test will verify that the conductor is sound. 2. Continuity of ring final circuit conductors The test results should ensure that the ring is complete and has no interconnections, and that the ring is not broken. The phase, neutral and protective conductors are identified and their resistances are measured separately (see Figure 4.47). N1 P1 P2 cpc 1 N2 cpc 2 Figure 4.47 The phase and neutral conductors are then connected together so that the outgoing phase conductor is connected to the returning neutral conductor and vice versa (see Figure 4.48). The resistance between phase and neutral conductors is then measured at each socket outlet. The readings obtained from those sockets wired into the ring will be substantially the same and the value will be approximately half the resistance of the phase or the neutral loop resistance. Any sockets wired as spurs will have a proportionally higher resistance value corresponding to the length of the spur cable. N1 cpc 1 P1 Link P2 Link N2 cpc 2 Figure 4.48 91 The previous test is then repeated with the phase and CPC cross-connected as before (Figure 4.49). The resistance between phase and earth is then measured at each socket. N1 Link cpc 1 Link P2 P2 N2 cpc 2 Figure 4.49 3. Insulation resistance Insulation resistance tests are to check that the insulation of conductors, electrical accessories and equipment is sound and not damaged, and that electrical conductors and protective conductors are not short-circuited, or do not have a low insulation resistance. Before testing ensure that: ● Pilot or indicator lamps and capacitors are disconnected from circuits to avoid an inaccurate test value being obtained ● Voltage-sensitive electronic equipment such as dimmer switches, delay timers, power controllers, electronic starters for fluorescent lamps, emergency lighting, Residual Current Devices, etc. are disconnected so that they are not subjected to the test voltage which could damage them ● There is no electrical connection between any phase or neutral conductor (e.g. lamps left in). Insulation resistance tests should be carried out using the appropriate d.c. test voltage. The installation will conform with the regulations if the main switchboard and each distribution circuit tested separately, with all its final circuits connected but with current using equipment disconnected, has an insulation resistance not less than that specified in Table 4.4. Table 4.4 Minimum values of insulation resistance Circuit nominal voltage Test voltage Minimum insulation d.c. (V) resistance (M ohms) SELV and PELV 250 0.25 Up to and including 500 V with the exception of the above systems 500 0.5 Above 500 V 1000 1.0 The tests should be carried out with the main switch off, all fuses in place, switches and circuit breakers closed, lamps removed, and fluorescent and discharge luminaires and other equipment disconnected. Where the removal of lamps and/or the disconnection of current using equipment is impracticable, the local switches controlling such lamps and/ or equipment should be open. 92 Simple installations that contain no distribution circuits should be tested as a whole, however, to perform the test in a complex installation it may need to be sub-divided into its component parts. Test 1: Insulation resistance between live conductors For single-phase circuits, test between the phase and neutral conductors at the appropriate switchboard. NP C.P.C Single pole switch Lamp holder Lamp out M High reading ohmmeter Figure 4.50 Testing insulation resistance on a single-phase lighting circuit For three-phase circuits, make a series of tests between live conductors in turn at the appropriate switchboard as follows (ensuring that the incoming neutral has been disconnected so there is no connection with earth): 1. Between red phase (and yellow phase, blue phase, and neutral) grouped 2. Between yellow phase (and blue phase, and neutral) grouped 3. Between blue phase and neutral. Test 2: Insulation resistance from earth to phase and neutral connected together For single-phase circuits, test between the phase and neutral conductors and earth at the appropriate distribution board. Where any circuits contain any two-way switching, the twoway switches will require to be operated and another insulation resistance test carried out including the two-way strapping wire, which was not previously included in the test. For three-phase circuits, measure between all phase conductors and neutral bunched together, and earth. C.P.C N P Phase Temporary link M Insulation resistance tester Figure 4.51 Testing insulation resistance from earth to phase to neutral 93 4. Polarity A test needs to be performed to check the polarity of all circuits. This must be done before connection to the supply, with either an ohmmeter, or the continuity range of an insulation and continuity tester. The live connection in socket outlets and the centre contact of screw-type lampholders must all be connected to the phase conductor. See Figure 4.52. Also a check should be made to ensure that the polarity of the incoming supply is correct, otherwise the whole installation would have the wrong polarity. S P switch C.P.C Neutral Phase Temporary link Edison screw lamp holder Switch closed Low reading ohmmeter Figure 4.52 Testing polarity 4.8 Fault diagnosis Electricians should have the ability to recognise when something is not up to standard or is not functioning correctly. For example, if a metal-clad switch is in a damp environment, the moisture would lead to the corrosion of the metal, thus reducing the integrity of the switch and making it unsafe to use. An example of a circuit not operating correctly could be a two-way lighting circuit only operating from one switch; this type of fault should be found before energising the circuit. Not all faults are easily visible, some are concealed and may develop over a period of time. Regular testing and inspection are not only needed at the completion of works, but should also take place during the installation process of the wiring system. Regular inspection, tests and maintenance checks should be used over periods of time to confirm the quality, and to extend the life of the electrical installation. Safe working procedures for fault diagnosis Remember! Before discussing symptoms, types of faults and the various problems which occur in electrical apparatus, circuits and systems, it is important to be aware of the safe isolation procedures and safe working practices. Before beginning work on any piece of electrical equipment or circuit you should make sure that it is completely isolated from the supply by following recognised procedures. Isolation In order to carry out work safely on electrical systems it is important to: ● identify sources of supply ● isolate 94 ● secure isolation ● test the equipment/system is dead. Test instruments All test equipment must be regularly checked to make sure it is in good and safe working order and has a current calibration certificate indicating that the instrument is working properly and providing accurate readings. When checking the equipment the following points should be noted: ● Check the equipment for any damage. Check to see if the case is cracked or broken. This could indicate a recent impact, which could result in false readings. ● Check that the batteries are in good condition and have not leaked (local action) and check that they are all of the same type. ● Check that the insulation on the leads and the probes is not damaged. Check that the insulation is complete and secure. ● Check the operation of the meter with the leads both open and short-circuited. ● Then zero the instrument on the ohm scale. ● If you have any doubt about an instrument or its accuracy ask for assistance. Test probes and leads used in conjunction with a voltmeter, multimeter, electrician’s test lamp or voltage indicator should be selected to prevent danger. Good test probes will have the following: ● Finger barriers, or shaped to guard against inadvertent hand contact with the live conductors under test ● Insulation to leave an exposed metal tip not exceeding 2 mm measured across any surface of the tip. Where practicable, it is strongly recommended that this is reduced to 1 mm or less or that spring-loaded retractable-screened probes are used ● Suitable high-breaking capacity fuse or fuses with a low current rating, usually not exceeding 500 mA or a current-limiting resistor and a fuse. Check the leads: ● are adequately insulated ● are coloured so that one lead can be easily distinguished from the other, are flexible and of sufficient capacity for the duty expected of them ● are sheathed to protect against mechanical damage ● are long enough for the purpose, while not too long so that they are clumsy or unwieldy ● do not have accessible exposed conductors other than the probes or tips, or have live conductors accessible to the person’s finger if a lead becomes detached from a probe ● are held captive and sealed into the body of the voltage detector. Fuses and/or current limitation Barrier to prevent access to live terminals Robust, flexible well insulated leads Minimum of exposed metal Shrouded or firmly attached connectors Figure 4.53 Testing polarity 95 Minimum of exposed metal Voltage indicating devices Instruments used solely for detecting a voltage fall into two categories: ● ● Detectors, which rely on an illuminated lamp (test lamp) or a meter scale (test meter). Test lamps are fitted with a 15 W lamp that has a guard to protect it. Lamp Minimum of exposed metal Robust, flexible well insulated leads Fuse and/or current limitation Detectors, which use two or more independent indicating systems (one of which may be audible) and Figure 4.54 A typical test lamp limit energy input to the detector. An example is a two-pole voltage detector, i.e. a detector unit with an integral test probe, an interconnecting lead and a second test probe. These detectors are designed and constructed to limit the current and energy that can flow into the detector. The limitation is usually provided by a combination of the circuit design using the concept of protective impedance and currentlimiting resistors built into the test probes. They have in-built test features to check the functioning of the detector before and after use. The interconnecting lead and second test probes are not detectable components, and they do not require additional current-limiting resistors or fuses to be fitted. Figure 4.55 A typical two-pole voltage indicator Test lamps and voltage indicators need to be clearly marked with the maximum voltage which may be tested by the device and any short time rating for the device if applicable. This rating is the recommended maximum current that should pass through the device for a few seconds. These devices are generally not designed to be connected for more than a few seconds. Warning notices It is important that once a circuit or item of electrical equipment has been isolated, it cannot be inadvertently switched back on. A good method of providing full electrical and mechanical isolation is to lock off the device or distribution board containing the device with a padlock. The person working on the isolated equipment keeps the key. A skilled person should be the only one allowed to carry out this, or similar responsible tasks concerning the electrical installation wiring. Many items of electrical equipment when installed are provided with a local means of switching or isolation. A good example of local isolation is when a motor is provided with a control unit, which can include the starter, switch and lock-off facility. Warning notices stating the maximum voltage present should be fixed to every item of equipment (or enclosure), which contains circuits operating at voltages in excess of 250 V and where the presence of such a voltage would not ON normally be expected. Where accessories, control gear or switch gear are wired on different phases of a threeOFF phase supply, but can only be reached simultaneously, a notice must be placed in a position where anyone ER NG DA NOT removing an accessory, or gaining access to the terminals DO H ON ITC of control gear, switchgear, etc., is warned of the maximum SW voltage which exists between parts. Warning notices should be displayed at the point of isolation of the circuit. Figure 4.56 A warning notice 96 Model question and answer 1 Model question and answer 2 What would limit the need for rectification of faults? Model question and answer 6 Model question and answer 5 Model question and answer 4 Model question and answer 3 What type of switch accessory is suitable for damp environments? The designer’s knowledge of electrical installation systems and practices should ensure that a polycarbonate type accessory is specified, which has special qualities including being waterproof and durable. Quality checks and tests at all stages of the installation process and regular maintenance. Why are neon type terminal screwdrivers unsuitable and dangerous? The principle of operation of this device relies on the user making contact with earth at zero volts and the screwdriver metal whose voltage is only limited by the use of a resistor. If this resistor breaks down and contact is made with live parts, the touch voltage to the user could reach 250 V, which could be fatal. Furthermore the terminal screwdriver has none of the qualities of GS38 type testers. Why is it not enough just to simply isolate a circuit before working on it? Which other major precautions should you take? The circuit could be inadvertently switched back on. The circuit should be checked for voltages present, and then the board or device should be locked off and warning notices posted. State three examples of situations where local isolators are used. ● Machine or motor ● Immersion heater ● Cooker, etc. State the basic difference between a switch and an isolator. A switch is an on-load device, whereas an isolator is primarily an off-load device. Although some switches can be used as isolators, an isolator should not be used as a switch. 97 Types of fault There are different types of faults, the consequence of the fault depending on its location within the installation or in a specific circuit. Faults can occur when installing electrical systems and from poor, or lack of, maintenance. As technology advances and as the systems we install are being constantly improved, then the faults developed become more complicated to solve. Therefore an understanding of the electrical installation and the equipment we install is really important. There are occasions when it may be impractical to rectify a fault, for example, the cost of the repair may be more than the cost of replacement. It is part of the electrician’s job to build into the design of the electrical installation fault protection and damage limitation. For example: ● Installing more than one circuit, when a fault occurs on one of the two circuits the fault can be limited to that circuit ● Installing fuses and circuit breakers to disable the fault and limit its effect ● Ability to access, maintain and repair, where access to the installation allows for maintenance and repair. It is easier to find faults on installations where there are plenty of circuits. Indeed it is a requirement of The IEE Wiring Regulations that every installation shall be divided into circuits as necessary to: ● Avoid danger and minimise inconvenience in the event of a fault ● Facilitate safe operation, inspection, testing and maintenance. This regulation will allow the electrician to locate faults easily, usually by process of elimination (operating each fuse individually), or simply looking at the device to see which one has operated. Protective devices and simple fuses are designed to operate when they detect large currents due to excess temperature. In the case of a short-circuit fault, high levels of fault current can develop causing high temperatures and breakdown of insulation. Such faults can cause fires. Position of faults The location of the fault can limit its severity with regard to disruption and inconvenience. For example, if the supply company’s protective device or fuses were rated at 100 A per phase and the designer loaded each phase up at 200 A, this would result in a 100% overload. The consequence of this would be the operation of the mains protective devices and the whole installation being without power. Operation of overload and fault current devices When a fault is highlighted, it is usually because a circuit or piece of equipment has stopped working. This is usually because the protective device has done its job and operated. The rating of a protective device should be greater or at least equal to the rating of the cable, circuit or equipment it is protecting, for example: ● 10 × 100 W lamps equate to a total current use of 4.35 A. Therefore a device rated at 5 or 6 A could protect this circuit. ● A portable domestic appliance which has a label rating of 2.7 kW equates to a total current of 11.74 A. Therefore a fuse rated at 13 A should be fitted in the plug. 98 Protective devices are designed to operate when an excess of current (greater than the design current of the circuit) passes through it. The fault current’s excess heat can cause a fuse element to rupture or the device mechanism to trip, dependent on which type of device is installed. These currents may not necessarily be circuit faults, but shortlived overloads specific to a piece of equipment or outlet. The regulations define these as: ● overload current ● over-current ● earth fault current ● short-circuit current. Whichever fault occurs, the electrician should take account of its effect on the installation wiring and choose a device suitable to disconnect the fault quickly and safely. The fundamental effect of any fault is a rise in current and therefore a rise in temperature. High temperature destroys the insulation, which in itself could lead to a short circuit. High currents damage equipment, and earth fault currents can cause dangerous or even fatal electric shocks. Typical overload faults: ● Adaptors used in socket outlets exceeding the rated load of circuit ● Extra load being added to an existing circuit or installation ● Not accounting for starting current on a motor circuit. Typical earth faults: ● Insulation breakdown ● Incorrect polarity ● Poor termination of conductors. Typical short-circuit faults: ● Insulation breakdown ● Severing of live circuit conductors ● Wrong termination of conductors, energised before being tested. Insulation failure Insulation is designed primarily to separate conductors and to ensure their integrity throughout their life. It is also used to protect against electric shock by protecting people against direct contact, and is often used as a secondary protection against mechanical damage, i.e. in the case of PVC/PVC twin and CPC cables. When insulation of conductors and cables fail, it is usually due to one or more of the following: ● Poor installation methods ● Poor maintenance ● Excessive ambient temperatures ● High fault current levels ● Damage by others. 99 Plant equipment and component failure There will be some faults that the electrician will attend which will be caused by breakdown simply due to wear and tear. Planned maintenance systems and regular testing and inspections can extend the life of equipment. Here are some common failures on installations and plant: ● Switches not operating due to age ● Motors not running because new brushes are required ● Lighting not working because a lamp’s life has expired ● Fluorescent luminaries not working because new lamps or starters needed ● Outside passive infrared sensor (PIR) not switching because of water ● Corridor socket outlet not working because of poor contacts due to excessive use/age. Faults due to misuse, abuse, and negligence A common reason for faults on any electrical system or equipment is due to misuse where the system or the equipment is simply not being used in relation to its design. Every item of electrical equipment comes with user instructions that usually cover procedures and precautions. Such instructions should be read, as misuse usually leads to invalidating the guarantee. When an electrical installation is completed, a manual is handed over to the customer that includes all product data and installation schedules and test results. This data will help the client when additions to the installation are made, inspections and tests are carried out, or to assist in maintaining the installation. Some faults are caused by carelessness during the installation process. Simple faults due to poor termination and stripping of conductors can lead to serious short circuits or overheating. Good mechanical and electrical processes should be carried out and every installation should be tested and inspected prior to being energised. Here are some examples of faults arising from misuse: ● Using a miniature circuit breaker (MCB) as a switch, where constant use could lead to breakdown ● Unplugging on-load portable appliances, damaging socket terminals ● Damp accessories, due to hosing walls in dry areas ● MCB’s nuisance tripping from connecting extra load to circuits. Here are some examples of installer misuse: ● Poor termination of conductors, causing overheating ● Loose bushes and couplings with no earth continuity, causing a risk of electric shock ● Wrong size conductors used, causing excessive voltage drop and excess current which could lead to an inefficient circuit and overheating of conductors ● Not protecting cables when drawing in to enclosures, causing damaged insulation ● Overloading conduit and trunking capacities, causing overheating and insulation breakdown. 100 Model question and answer 7 State the consequence when the protective device operates from a short-circuit at the following locations: a) in the supply company’s mains supply cable b) within a final circuit c) in a three-phase mains switch. a) There will be a total loss of supply within the installation. b) There will be a loss of supply in the circuit only. Model question and answer 8 c) All sub-circuits that are fed by the operated device will be dead. Briefly explain how protective devices such as fuses and circuit breakers operate. Such devices operate when heat is produced from increased levels of current that appear in the circuit. Such currents exist from overloads and faults from short circuits and earth faults. The device detects the heat and operates either by tripping, or by the fuse element rupturing. Model question and answer 9 Give three examples of plant, machine, or component failure. Any three from: ● ● ● ● ● ● Switches not operating – due to age. Motors not running – new brushes required. Lighting not working – lamp’s life expired. Fluorescent luminaire not working – new lamp or starter needed. Outside PIR not switching – ingress of water causing failure. Corridor socket outlet not working – poor contacts due to excessive use/age. State how misuse or negligence causes installation faults. Any explanation for: User misuse ● Model question and answer 10 ● ● ● Using an MCB as a switch – where constant use could lead to breakdown. Unplugging on-load portable appliances – damaging socket terminals. Damp accessory – due to hosing walls in dry areas. MCB’s nuisance tripping – connecting extra load to circuits. Installer misuse ● ● ● ● ● Poor termination of conductors – overheating poor electrical contact. Loose bushes and couplings – no earth continuity, electric shock risk. Wrong size conductors used – excessive voltage drop and excess current, which could lead to an inefficient circuit and overheating of conductors. Not protecting cables when drawing in to enclosures – damaged insulation. Overloading conduit and trunking capacities – overheating and insulation breakdown. 101 4.9 Fuses and circuit breakers Fuses are slower to operate and less accurate than circuit breakers. In order to work out how effective these fuses are we need to have some way of knowing their circuit breaking and ‘fusing’ performance. We can work this out for fuses by the use of a fusing factor formula: Fusing factor = fusing current current rating The fusing current is the minimum current causing the fuse to blow, and the current rating is the maximum current which the fuse can sustain without blowing. Fusing currents can be found in the IET wiring regulations. These tables are logarithmic so the scales increase by factors of 10, not uniformly as may be expected. The rating of the fuse is the current it will carry continuously without deterioration. Table 4.5 Fuses Type of device and rating Fusing current Fusing factor BS 3036 20 A 40 A 40 =2 20 BS 1361 20 A 38 A 38 = 1.9 20 BS 88 20 A 34 A 34 = 1.7 20 Type 1 20 A MCB 26 A 26 = 1.3 20 BS 3036 45 A 100 A 100 = 2.22 45 BS 1361 45 A 88 A 88 = 1.95 45 BS 88 45 A 66 A 66 = 1.47 45 Type 1 45 A MCB 52 A 52 = 1.15 45 Fusing factors for the following devices can be grouped as follows: 102 BS 3036 1.8–2 BS 1361 1.6–1.9 BS 88 1.25–1.7 MCBs up to 1.5 The number in kA stamped onto the end cap of an HBC fuse, or printed onto the body of a BS 1361 fuse, is known as the breaking capacity. When a short circuit occurs, the current may, for a fraction of a second, reach hundreds or even thousands of amperes. The fuse or circuit breaker must be able to break such a current or make it harmless to its surroundings by arcing, overheating or scattering hot particles. The breaking capacities of circuit breakers are indicated by a ‘M’ number, e.g. M6. This means that the breaking capacity is 6 kA or 6000 A. The breaking capacity will be related to the prospective short-circuit current. Miniature Circuit Breakers (MCBs) The modern MCB forms an essential part of the majority of installations at the final distribution level. The circuit breaker is an automatic switch, which opens in the event of carrying excess current. The switch can be closed again when the current returns to normal, because the device does not damage itself during normal operation. The contacts of a circuit breaker are closed against spring pressure, and held closed by a latch arrangement. A small movement of the latch will release the contacts, which will open quickly under spring pressure to break the circuit. Thermal tripping The load current is passed through a small heater, the temperature of which depends on the current it carries. This heater is arranged to warm a bimetal strip either directly, i.e. the current passes through the bimetal strip, which in effect is part of the electrical circuit, or indirectly, i.e. a coil of current carrying conductor is wound around the bimetal; excess current warms the bimetal. The bimetal strip is made of two different metals normally brass and steel, brass expanding more than steel. These two dissimilar metals are securely riveted or welded together along their length. The rate of expansion of the two metals is different so that as the strip is warmed, it will bend and will trip the latch. The bimetal strips are so arranged that normal currents will not heat the strip to tripping point. If the current increases beyond the rated value, the heater dissipates power and the bimetal strip is raised in temperature to trip the latch. Magnetic tripping The principle used here is the force of attraction, which can be set up by the magnetic field of a coil carrying the load current. At normal currents the magnetic field is not strong enough to attract the latch, but overload currents operate the latch and trip the main contacts. Combined tripping There is always some time delay in the operation of a thermal trip, since the heat produced by load current must be transferred to the bimetal strip. Thermal tripping is thus best suited to small overloads of comparatively long duration. Magnetic trips are fast-acting for heavy overloads. The two methods are therefore combined to take advantage of the best characteristics of each. 103 5. Electronics Devices such as security alarms, telephones, dimmers, boiler controls, and speed controllers have brought electronics into general electrical installation work. 5.1 Resistors There are two basic types of resistor: fixed and variable. The resistance value of a fixed resistor cannot be changed by mechanical means (though its normal value can be affected by temperature or other effects). Variable resistors have some means of adjustment (usually a spindle or slider). Fixed resistors Making a resistor involves taking some material of a known resistivity and making the dimensions (cross-sectional area (CSA) and length) of a piece of that material such that the resistance between the two points at which leads are attached (for connecting into a circuit) is the value required. Most of the very earliest resistors were made by taking a length of resistance wire (wire made from a metal with a relatively high resistivity) and winding this onto a support rod of insulating material. They are relatively difficult to mass produce, which makes them expensive. Techniques for making resistors from materials other than wire have now been developed for low power applications, for example, coating an insulating rod (usually ceramic or glass) with a thin film of resistive material. The resistive materials in common use today are carbon and metal oxides. Metal end caps fitted with leads are pushed over the ends of the coated rod and the whole assembly is coated with several layers of very tough varnish or similar material to protect the film from the atmosphere and from knocks during handling. These resistors can be mass-produced with great precision at very low cost. Metal oxide resistor End cap Vitreous enamel coating Resistance winding on ceramic former Figure 5.1 A typical wire wound resistor Silicon laquer or paint coating Resistive carbon compound Embedded connection leads Figure 5.2 A coated rod resistor Variable resistors Key term Variable resistors require some sort of sliding contact together with a fixed resistor element. Wire wound variable resistors are often made by winding resistance wire onto a flat strip of insulating material, which is then wrapped into a nearly complete circle. A sliding contact arm is made to run in contact with the turns of wire as they wrap over the edge of the wire strip. Straight versions are also possible, where a straight former is used and the wiper travels in a straight line along it. 104 Resistor – a component that limits the electrical current that flows through a circuit. Resistor coding Standard colour code Many resistors are so small that it is impractical to print their value on them. Instead, they are marked with a code that uses bands of colour at one end of the component. Most general resistors have four bands of colour, but high precision resistors are often marked with a five-colour band system. Black Brown Red Orange Yellow Green Blue Violet Grey White Gold Silver 0 1 2 3 4 5 6 7 8 9 Brown Red Gold Silver None 0.1 0.01 1 2 5 10 20 What this means Band 1 First figure of value Band 2 Second figure of value Band 3 Number of zeros/multiplier Band 4 Tolerance (+ _%) see below Note how the bands are closer to one end than the other Worked example 1 Did you know? Figure 5.3 Resistor coding Before you read a resistor, turn it so that the end with bands is on the left-hand side. Now you read the bands from left to right. A resistor is colour coded red, yellow, orange, gold. Determine the value of the resistor. First band red (First digit) 2 Second band yellow (Second digit) 4 Third band orange (No. of zeros) 3 Fourth band gold (Tolerance) 5% The value is 24 000 ±5% 105 Worked example 2 A resistor is colour coded yellow, yellow, blue, silver. Determine the value of the resistor. First band yellow (First digit) 4 Second band yellow (Second digit) 4 Third band blue (No. of zeros) 6 Fourth band silver (Tolerance) 10% The value is 44 000 000 ±10% Did you know? This rhyme helps to remember the resistor codings: Billy Black 0 Brown Brown 1 Runs Red 2 Over Orange 3 Your Yellow 4 Garden Green 5 But Blue 6 Violet Violet 7 Grey Grey 8 Won’t White 9 Resistance markings Resistance values are generally given in either W, kW,or MW using numbers from 1–999 as a prefix (e.g. 10 W, 567 kW etc.). In the code system we replace W, kW and MW with the following letters: W=R kW = K MW = M These letters are now inserted wherever the decimal point would have been in the value. So, for example, a resistor of value 10W would now be shown as 10R, and a resistor of value 567 kW would become 567 K. Power ratings Resistors often have to carry comparatively large values of current, so they must be capable of doing this without overheating and causing damage. As the current has to be related to the voltage, it is the power rating of the resistor that needs to be identified. The power rating of a resistor is a convenient way of stating the maximum temperature at which the resistor is designed to operate without damage to itself. 106 Thermistors A thermistor is a temperature-sensitive resistor. Electrode plating Laser trim area Ceramic material Thermistor without encapsulation Thermistor with encapsulation Figure 5.4 Thermistors They can be supplied in various shapes and are used for the measurement and control of temperature up to their maximum useful temperature limit of about 300 °C. They are very sensitive and, because of their small construction, they are useful for measuring temperatures in inaccessible places. Thermistors are used for measuring the temperature of motor windings and sensing overloads. The thermistor can be wired into the control circuit so that it automatically cuts the supply to the motor when the motor windings overheat, thus preventing damage to the windings. Thermistors are also used for monitoring the temperature of the water in a motor car. Light-dependent resistors Cadmium sulphide track Circuit symbol Figure 5.5 A light-dependent resistor Light-dependent resistors are sensitive to light. They consist of a clear window with a cadmium sulphide film under it. When light shines onto the film its resistance varies; as the light increases the resistance reduces. These resistors are commonly found in street lighting. Sometimes street lights switch on during a thunderstorm in the daytime, because the sunlight is obscured by the dark thunderclouds, thus increasing the resistance which in turn controls the light ‘on’ circuit. Questions 1 A resistor is colour coded violet, orange, brown, gold. Determine the value of the resistor. 2 A resistor is colour coded green, red, yellow, silver. Determine the value of the resistor. 3 Many resistors use the four banding colour code system. a) State the four band coding for a 27 kΩ ± 10% resistor. b) State the value and tolerance of a blue, grey, yellow, gold resistor. 4 Calculate the resistance and the current drawn from the supply, by the following equipment connected to a 230 V supply: 5 What value of resistance is required to have a current of 12 A, if the supply voltage is 415 volts? 6 Calculate the resistance of a resistor which absorbs 5000 W when a current of 15 A passes through it. a) a 4 kW 230 V immersion heater b) a 600 W 230 V microwave oven 107 Remember! 5.2 Capacitors Never pick a capacitor up by the terminals as it may still be charged and you will receive a shock. Always ensure the capacitor has been discharged before handling. Some capacitors have a discharge resistor connected in the circuit for this reason. A capacitor is basically two metallic surfaces, referred to as plates, separated by an insulator commonly known as the dielectric. The plates are usually metal and the dielectric is any insulating material such as air, glass, ceramic, mica, paper, oils and waxes. Dielectric Metal plates Lead to plates Lead to plates + Fixed (non-polarised) Fixed (polarised) Variable Preset Figure 5.6 Common symbols used for capacitors The two plates are not in contact with each other and as such they do not form a circuit in the same way that conductors with resistors do. However, the capacitor stores a small amount of electric charge so it can be thought of as a small rechargeable battery, which can be quickly recharged. The capacitance of any capacitor depends on: ● the working area of the plates, i.e. the area of the conducting surfaces facing each other ● the thickness of the dielectric between the plates ● the nature of the dielectric or spacing material used. Capacitor types There are two major types of capacitors, fixed and variable, both of which are used in a wide range of electronic devices. Fixed capacitors can be further sub-divided into electrolytic and non-electrolytic types. All capacitors possess some resistance and inductance because of the nature of their construction, resulting in limitations in their applications. 108 Electrolytic capacitors Electrolytic capacitors have a much higher capacitance, volume for volume, than any other type. This is achieved by making the plate separation extremely small by using a very thin dielectric (insulator), often mica or paper. The main disadvantage of an electrolytic capacitor is that they are polarised and must be connected to the correct polarity in a circuit, otherwise a short circuit and destruction of the capacitor will result. They look like a raindrop with two leads protruding from the bottom. The polarity and values may be marked on the capacitor or the colour code, shown later, can be used. Figure 5.7 The outside view of a typical electrolytic capacitor Capacitor coding The capacitance, working voltage, type of construction, and polarity need to be known to identify a capacitor. The identification of capacitors is not easy because of the wide variation in shapes and sizes. In the majority of cases the capacitance will be printed on the body of the capacitor, in farads (F) or the following: 1 microfarad = 1 µF = 1 × 10-6 F 1 nanofarad = 1 nF = 1 × 10-9 F 1 picofarad = 1 pF = 1 × 10-12 F Figure 5.8 A newer type of electrolytic capacitor using tantalum and tantalum oxide to give a further capacitance/size advantage The power factor correction capacitor found in fluorescent luminaries would have a value typically of 8 µF at a working voltage of 400 V. The working voltage of a capacitor is the maximum voltage that can be applied between the plates of the capacitor without breaking down the dielectric insulating material. It was quite common for capacitors to be marked with colour codes, but today relatively few capacitors are colour coded. This method is based on the standard four band resistor colour coding. The first three bands indicate the Value in picofarads value in normal resistor fashion, but the value is in 1st digit 2nd digit picofarad. To convert this into a value in nanofarad Tolerance Number of zeros green 5% simply divide by 1000. Divide the marked value by white 10% 1000 000 if a value in microfarads is required. The Maximum volts red = 250 V fourth band indicates the tolerance, but the colour yellow = 400 V coding is different to the resistor equivalent. The fifth band shows the maximum working voltage of the Figure 5.9 Capacitor colour component. bands 109 Worked example 1 Bands are then read from top to bottom. Digit 1 gives the first number of the component value; the second digit gives the second number. The third band gives the number of zeros to be added after the first two numbers, and the fourth band indicates the capacitor tolerance, which is normally black 20%, white 10% and green 5%. A plastic film capacitor is colour coded from top to bottom brown, red, yellow, black, red. Determine the value of the capacitor, its tolerance and working voltage. Brown = 1 Red = 2 Yellow = 4, multiply by 10 000 Black = 20% tolerance Red = 250 V Worked example 2 The capacitor has a value of 120 000 pF or 0.12 µF, with a tolerance of 20% and a maximum working voltage of 250 V. A plastic film capacitor is colour coded from top to bottom orange, orange, yellow, green, yellow. Determine the value of the capacitor, its tolerance and working voltage. Orange = 3 Orange = 3 Yellow = 4, multiply by 10 000 Green = 5% tolerance Yellow = 400 V The capacitor has a value of 330 000 pF, or 0.33 μF, with a tolerance of 5% and a minimum working voltage of 400 V. Polarity Key terms Some capacitors are constructed in such a way that if the component is operated with the wrong polarity its properties will be destroyed – this is especially true for electrolytic capacitors. Polarity may be indicated by a + or - as appropriate. 110 Capacitor – a component which stores an electric charge if a voltage is applied across it. Working voltage – the maximum voltage that can be applied between the plates of the capacitor without breaking down the dielectric insulating material. 5.3 Semi-conductor devices Key term Semi-conductors are materials that have an electrical quality somewhere between a conductor and an insulator, in that they are neither a good conductor nor a good insulator. Typically, we use semi-conducting materials such as silicon or germanium, materials in which the atoms are arranged in a ‘lattice’ structure. The lattice has atoms at regular distances from each other with each atom ‘linked’ to the four atoms surrounding it. Each atom then has four valence electrons. Figure 5.10 Valence electrons – the electrons in an atom’s outermost orbit. Atoms of pure silicon or germanium have no free electrons, so no conduction is possible. To allow conduction to take place, we add an impurity to the material via a process known as doping. When we have an extra electron, we have a surplus of negative charge and call this type of material ‘n-type’. When we have removed an electron we have a surplus of positive charge, and call this material ‘p-type’. The p–n junction A semi-conductor diode is basically created when we bring together an ‘n-type’ material and a ‘p-type’ material to form a p–n junction. The two materials form a barrier where they meet which we call the depletion layer. In this barrier, the coming together of unlike charges causes a small internal p.d. to exist. Depletion layer Anode p n Cathode We now need to connect a battery across the Figure 5.11 A p–n junction ends of the two materials, where we call the end of the p-type material the anode, and the end of the n-type material the cathode. If the anode is positive and the battery voltage is big enough, it will overcome the effect of the internal p.d. and push charges (both positive and negative) over the junction. In other words, the junction has a low resistance and current can flow. This type of connection is known as being forward biased. If the battery connections are reversed so that the anode is now negative and the junction becomes high resistance, no current can flow. This type of connection is known as being reverse biased. When the junction is forward biased, it only takes a small voltage (0.7 V for silicon) to overcome the internal barrier p.d. When reverse biased, it takes a large voltage (1200 V for silicon) to overcome the barrier and thus destroy the diode, effectively allowing current to flow in both directions. 111 A diode allows current to flow through it in one direction only. The symbol is shown in Figure 5.12, where the direction of the arrow can be taken to represent the direction of current flow. Zener diode A Zener diode is a silicon junction diode (not germanium) with a predetermined breakdown at reverse voltage. The breakdown conduction mechanism is very tightly controlled and, once breakdown occurs, the voltage across the diode changes very little over a wide range of currents. The stable reverse breakdown behaviour of these diodes accounts for their alternative and more accurate name: voltage regulator diodes. Anode Figure 5.12 The symbol for a diode Band (a) Cathode Anode IF /mA Cathode (b) –20 VZ –15 Forward bias –10 In its forward bias mode, when the anode is positive and the cathode –5 negative, the Zener will conduct at VF /V about 0.6 V, just like an ordinary 0 +2 +4 –6 –4 –2 diode. However, it is in the reverse A –5 mode that the Zener diode is normally used. When connected Reverse –10 with the anode made negative and bias B –15 the cathode positive, the reverse current is zero until the reverse voltage reaches a pre-determined Figure 5.13 A Zener diode value (VZ) when the diode switches on as shown in Figure 5.13. As current actually starts to flow slightly before the applied reverse voltage reaches 5.1 V, the Zener voltage (VZ) increases slightly above 5.1 V as the current through the Zener diode increases towards the maximum. Because of these two features of the curve, the nominal Zener voltage is always quoted on data sheets with reference to a stated limit of reverse current at breakdown and, to prevent overheating, the power rating of the diode should not be exceeded. The point at which the Zener curve turns down is usually referred to as the Zener knee. Ideally, as with the forward characteristic of diodes, once the voltage exceeds the value at the knee, the characteristic should become a vertical line, but it leans. As with any characteristic curve, the voltage at any given current, or the current at any given voltage can be found from the curve of a Zener diode. The power dissipated in a Zener diode when a current is flowing through it is invariably greater than that in an ordinary diode with the same current through it. This is because the power dissipated in any component is found by multiplying the voltage across the component by the current through it, and the Zener voltage of a Zener diode is greater than the forward voltage of an ordinary diode. To limit the current a resistor is placed in series with the Zener diode. 112 In Figure 5.14, the Zener diode is being used to stabilise a supply from a 9 V battery, so the resistor R will have to drop a voltage of (9 - 5.1) = 3.9 V. R + 9V 5.1 V 500 m W 5.1 V – Figure 5.14 The value of R can be found using Ohm’s law, where R= max = V Imax 0.5 W 5.1 V = 98mA Therefore R = 3.9 V 0.098 A = 40 Light emitting diodes (LEDs) The light emitting diode is a p–n junction especially manufactured from a semi-conducting material, which emits light when a current of about 10 mA flows through the junction. No light is emitted if the diode is reversed bias, and if the voltage exceeds 5 V then the diode may be damaged. If the voltage exceeds 2 V, then a series connected resistor may be required. Photocell and light-dependent resistor The photocell changes light (also infrared and ultraviolet radiation) into electrical signals and is useful in burglar and fire alarms as well as in counting and automatic control systems. Photoconductive cells or light-dependent resistors make use of semi-conductors whose resistance decreases as the intensity of light falling on them increases. The energy of the light sets electrons free from donor atoms in the semiconductor making it more conductive. This type of device is used for outside lights along the streets, roads and motorways. There are also smaller versions for domestic use within homes and businesses. Photodiode A photodiode consists of a normal p–n junction housed in a case with a transparent window through which light can fall onto the semi-conductor. The photodiode operates in the reverse bias. When light falls on the junction the energy from the light breaks down bonds in the lattice of the semi-conductor producing electrons and holes, allowing current to flow. This type of device is used as a fast counter, or in light meters to measure light intensity. 113 Diode testing The p–n junction diode has a low resistance when a voltage is applied in the forward direction and a high resistance when applied in the reverse direction. Connecting an ohmmeter with the red positive lead to the anode of the junction diode and the black negative lead to the cathode would give a very low reading. Reversing the lead connections would give a high resistance reading in a good component. When using a multimeter it needs to be put into the diode test mode, otherwise when testing on the ohm’s range you could get a reversed reading. Remember! High resistance connection 100 Ω MΩ Low resistance connection 0.01 Ω MΩ Figure 5.15 Diode connections 5.4 Rectification Rectification is the conversion of an a.c. supply into a d.c. supply. Many applications such as electronic circuits and equipment require a d.c. supply. Half-wave rectification A diode will only allow current to flow in one direction and it does this when the anode is more Supply Load positive than the cathode. In the case of an a.c. circuit, this means that only the positive half cycles are allowed ‘through’ Figure 5. 16 The waveform for half-wave rectification the diode and, as a result, we end up with a signal that resembles a series of ‘pulses’. This tends to be unsuitable for most applications, but can be used in situations such as battery charging. A transformer is also commonly used at the supply side to ensure that the output voltage is to the required level. 114 Full-wave rectification We have seen that half-wave rectification occurs when one diode allows the positive half cycles to pass through it. Two diodes can be connected together to give a more even supply, called a biphase circuit. Anodes of the diodes are connected to the opposite ends of the secondary winding of a centre-tapped transformer. As the anode voltages will be 180 ° out of phase with each other, one diode will effectively rectify the positive half cycle and one will rectify the negative half cycle. The output current will still appear to be a series of pulses, but they will be much closer together. Load Figure 5.17 The waveform for full-wave rectification The full-wave bridge rectifier This system uses four diodes connected in such a way that, at any instant in time, two of the four will be conducting. See Figure 5.18 where the route through the network for each half cycle is shown. Positive half cycle Negative half cycle D4 D1 D2 D3 D4 D1 D2 D3 Figure 5.18 The full-wave bridge rectifier The circuits that we have looked at so far convert a.c. into a supply, which, although never going negative, is still not a true d.c. supply. Smoothing To make it useful for electronic circuits, we need to smooth out the ‘ripples’ in the waveform. One way of doing this is by using filter circuits. 115 5.5 Transistors A bipolar transistor is a semi-conductor device, which has two p–n junctions. It is capable of producing current amplification and, with an added load resistor, both a load and voltage power gain can be achieved. The term ‘transistor’ is derived from the two words ‘transfer-resistor’. This is because in a transistor, approximately the same current is transferred from a low to a high resistance region. Collector Base Collector Collector P Base N P Emitter Base Emitter Collector N Base P N Emitter Emitter Figure 5.19 The two types of bipolar transistor and their circuit symbols The term ‘bipolar’ means both electrons and holes are involved. A bipolar transistor consists of three separate regions or areas of doped semi-conductor material. When the construction is such that a central n-type region is sandwiched between two p-type outer regions, a pnp transistor is formed. If the regions are reversed, an npn transistor is formed. Lead-out wires from For transistors to operate these conditions must be met: ● The base must be very thin. ● Majority carriers in the base must be very few. ● The base-emitter junction must be forward biased and the base-collector junction reverse biased. Emitter Silicon oxide NP N emitter and base Case Mounting Base Collector Transistor (soldered with collector side to gold-plated mounting) Figure 5.20 Transistor construction Current amplification The collector current is always a fixed proportion of the emitter current set by the thinness of the base and the amount of doping. Consider, for example, a base bias of some 630 mV has caused a base current of 0.5 mA to flow but, more importantly, has initiated a collector current of 50 mA. This relationship between IB and IC is termed the ‘static value of the short-circuit forward current transfer’, normally just referred to as the gain of the transistor. It is simply a measure of the amplification achieved, using the symbol hFE, which is the ratio between the continuous output current (collector current) and the continuous input current (base current). Thus when IB is 0.5 mA and IC is 50 mA, the ratio is: I hFE = C IB which is equal to 100. Note: There are no units since this is a ratio. It can therefore be said that a small base current initiated by the controlling forward base-bias voltage produces a significantly higher value of collector current to flow dependent on the value of hFE for the transistor. Thus current amplification has been achieved. 116 Voltage amplification The low resistive reference is the emitter circuit and the high resistive reference, the collector circuit; the current in both being almost identical. Electrons Holes Reverse biased p–n junction Electrons (collector current) Collector (n-type) The reason the emitter circuit Holes is classed as having a low (base current) Base resistance is because it contains (p-type) the forward biased base-emitter junction. Conversely, the collector Emitter + circuit contains the reverse (n-type) biased base-collector junction, Forward which is of course in the order of biased Electrons p–n junction tens of thousand ohms (it varies (emitter current) with an integrated circuit). In order to produce a voltage output Figure 5.21 Voltage amplification from the collector, a load resistor (RB) is added to the collector circuit. + B2 There is no input across Vi, which is called the quiescent (quiet) state. For transistor action to take place the base-emitter junction must be forward biased (and has to remain so when Vi goes negative due to the a.c. signal input). By introducing resistor RB between collector and base, a small current IB will flow from VCC through RB into the base and down to VO via the emitter, thus keeping the transistor running (ticking over). Component values are chosen so that the steady base current IB makes the quiescent collector–emitter voltage VCE about half the power supply voltage VCC. This allows VO to have its maximum swing capability and not interfere with the input signal Vi . IB +VCC IC RL RB C Vi = Alternating input VCE + 0 Vi VO VBE t – Figure 5.22 A circuit for an amplifier When an a.c. signal is applied to the input Vi and goes positive it increases VBE slightly to around (0.61 V). When Vi swings negative, VBE drops slightly to (0.59 V). As a result a small alternating current is superimposed on the quiescent base current IB, which in effect is a varying d.c. current. The collector–emitter voltage (VCE) is a varying d.c. voltage, or an alternating voltage superimposed on a normal steady d.c. voltage. The capacitor C is there to block the d.c. voltage, but allow the alternating voltage to pass on to the next stage. 117 So, a bipolar transistor will act as a voltage amplifier if: ● It has a suitable collector load RL. ● It is biased so that so that the quiescent value VCE is around the value of VCC, which is known as the class A condition. ● The transistor and load together bring about voltage amplification. ● The output is 180 ° out of phase with the input signal. ● The emitter is common to the input, output and power supply circuits and is usually taken as the reference point for all voltages, i.e. 0 V. It is called ‘common’, ‘ground’ or ‘earth’ if connected to earth. Transistor as a switch Transistors can operate as a switch. Compared with other electrically operated switches, transistors have many advantages, whether in discrete or integrated circuit form. They are small, cheap, reliable, have no moving parts, and can switch millions of times per second. A transistor is the perfect switch that has infinite resistance when ‘off’, no resistance when ‘on’, and changes instantaneously from one state to another, using up no power. Testing transistors 1000 0.06 Ω 1000 Ω 0.06 Ω – + – + – + – + B C E E C B E C B B C E Digital multimeter npn pnp Analogue multimeter As all transistors consist 1000 0 1000 0 1000 0 1000 0 of either an npn or a pnp High Low High Low resistance resistance resistance resistance construction, the testing of – + – + – + – + them is similar to diodes. B E B E B E B E C C C C Special meters with three npn pnp terminals for testing transformers are available and many testing instruments Figure 5.23 Testing transistors have this facility. However, an ohmmeter can be used for testing a transistor to check if it is conducting correctly. The following results should be obtained from a transistor assuming that the red lead of an ohmmeter is positive. Note: This is not always the case, with some older analogue meters, the battery connections internally are the opposite way round, so it is always good to check both ways across base and emitter, as shown in Figure 5.23. 118 A good npn transistor will give the following readings: Red to base and black to collector or emitter will give a low resistance. However, if the connections are reversed it will result in a high resistance reading. Connections of any polarity between the collector and emitter will also give a high reading. A good pnp transistor will give the following readings: Black to base and red to collector or emitter will give a low resistance reading. However, if the connections are reversed a high resistance reading will be observed. Connections of either polarity between the collector and emitter will give a high resistance reading. 5.6 Integrated circuits Integrated circuits (IC) are complete electronic circuits housed within a plastic case (known as the ‘black box’). The chip contains all the components required, which may include diodes, resistors, capacitors, transistors, etc. There are several categories, which include analogue, digital and memories. The basic layout is shown in Figure 5.24. ‘Chip’ Connection from ‘chip’ to pin Plastic case Notch Small dot Metal pin 0.1 inch Pin 1 Figure 5.24 An operational amplifier (linear IC) The plastic case has a notch at one end and if you look at the back of the case with the notch at the top Pin 1 is always the first one on the left-hand side, sometimes noted with a small dot. The other pin numbers follow down the left-hand side, 2, 3, and 4, then back up the right-hand side from the bottom right to the top, 5, 6, 7 and 8. This is an 8-pin chip, but you can get chips with up to 32 pins. These types of IC with the pins lined up down each side are known as ‘Dual in line’ ICs. 5.7 Thyristors Thyristors, also known as silicon-controlled rectifiers (SCRs), are semi-conductor devices, which act as high-speed switches. Devices are available that can operate at potentials of several thousand volts and which will carry currents up to hundreds of amps. Thyristors are being used increasingly to replace mechanical switches and relays, since they offer faster switching without arcing and offer greater reliability. This is particularly the case in continuous a.c. power control systems such as lamp dimmers, heater control and motor speed control. 119 Anode A Construction of thyristors The thyristor consists of a four-layer pnpn silicon sandwich. The circuit symbol is that of a rectifier diode with an additional terminal called the gate. It is this gate which enables the action of the rectifier to be controlled. In medium and high power devices, the case will be metal with a screw thread suitable for mounting on a heat sink. Smaller devices resemble transistors in physical size and packaging. p n p n Gate G Cathode C Figure 5.25 A thyristor Principle of operation The word ‘thyristor’ is derived from the Greek word thyra which means ‘door’. The thyristor can open or shut like a door, thus preventing or allowing current flow through the device. The thyristor can be made to act as an open circuit between anode and cathode and this is called the forward blocking state. Further applying a positive pulse of low power across the gate and cathode terminals can trigger it, so a low power signal on the gate can switch the current through a high power load. When forward biased, the thyristor will not conduct until a positive voltage is applied to the gate. Conduction will continue through the thyristor when the gate voltage is removed. The only time the thyristor will stop conduction is when the supply voltage is turned off, reversed or the anode current falls below a certain value. This is a simple method of controlling power in a d.c. circuit using a thyristor. The control of a.c. power can also be achieved with the thyristor by allowing current to be supplied to the load during part of each half cycle. If a gate pulse is applied automatically at a certain time during each positive half cycle of the input, then the thyristor will conduct during that period until it falls to zero for the negative half cycle. The triac This single component performs the same function as two thyristors connected in inverse parallel, but with a common gate terminal. Full wave power control can thus be achieved with the triac using a much simpler triggering arrangement than with the two separate inverse parallel thyristors. Triacs were originally developed for, and used extensively in, the consumer market. They are used in many low power control applications such as food mixers, electric drills and lamp dimmers. The two opposing arrowheads depict the bi-directional current flow characteristics of the component. The diac The diac is often used in triac triggering circuits because it, along with a resistor–capacitor network, produces an ideal pulse-style waveform. It does this without any sophisticated additional circuitry due to its electrical characteristics. Also it provides a degree of protection against spurious triggering from electrical noise (voltage spikes). The device operates like two breakdown (Zener) diodes connected in series, back to back. It acts as an open switch until the applied voltage reaches about 32/35 V, when it will conduct. 120 G MT1 Figure 5.26 The circuit symbol for a triac Figure 5.27 The circuit symbol for a diac Lamp dimmer circuit The GLS lamp has a tungsten filament which allows it to operate at about 2500 ° C and is wired in series with the triac. The variable (pot R) resistor is part of a trigger network providing a variable voltage into the gate circuit, which contains a diac connected in series. Increasing the value of the resistor increases the time taken for the capacitor to reach its charge level to pass current into the diac circuit. Reducing the resistance allows the triac to switch on faster in each half cycle. By this adjustment the light output of the lamp can be controlled from zero to full brightness. The capacitor is connected in series with the variable resistor; this combination is designed to produce a variable phase shift into the gate circuit of the diac. When the p.d. across the capacitor rises, enough current flows into the diac to switch on the triac. The diac is a triggering device having a relatively high switch on voltage (32–35 V), and acts as an open switch until the capacitor p.d. reaches the required voltage level. The triac is a two-directional thyristor, which is triggered on both halves of each cycle. This allows it to conduct current in either direction of the a.c. supply. Its gate is in series with the diac, allowing it to receive positive and negative pulses. Lamp + Pot R a.c. supply Diac Triac C – Figure 5.28 A triac lamp dimmer circuit Field effect transistors (FETs) Field effect transistor devices first appeared as separate (or discrete) transistors, but now the field effect concept is employed in the fabrication of large-scale integration arrays such as semi-conductor memories, microprocessors, calculators and digital watches. There are two types of field effect transistor, the junction gate field effect transistor, which is usually abbreviated to JUGFET, JFET or FET, and the metal oxide semiconductor field effect transistor known as the MOSFET. They differ significantly from the bipolar transistor in their characteristics, operation and construction. Logic gates A logic gate is an electronic component which processes a binary input and produces a binary output based on a set of rules. Examples: ● A NOT gate produces an output which is not the same as the input. This means that when there is a logic 0 input there is a logic 1 output but when there is a logic 1 input 121 there is a logic 0 output. As the output is always the opposite of the input these gates are sometimes called inverters. ● An OR gate produces a logic 1 output if one or other of its inputs is logic 1. ● An AND gate produces a logic 1 output if its first input and its second input are both logic 1. The complete list of the five logic gates you are required to know is shown in Table 5.1. Truth tables Truth tables show the output states of a logic gate for all of the possible inputs to the gate. These allow us to easily determine what the output would be when the gates are connected to input sources. When in doubt about what a logic gates does, you should always consult the truth table. For example the truth table shows that an OR gate will still produce a logic 1 output even if both of the inputs are logic 1. Table 5.1 Logic gates and their truth tables Truth table Gate OR AND NOR NAND Function (high voltage = 1, low voltage = 0) Symbol A OUTPUT B A OUTPUT B A OUTPUT B A OUTPUT B OUTPUT NOT INPUT OUTPUT = 1 if A OR B = 1 OUTPUT = 1 if A AND B = 1 OUTPUT = 0 if A OR B = 1 OUTPUT = 0 if A AND B = 1 OUTPUT = 1 if INPUT = 0 OUTPUT = 0 if INPUT = 1 INPUTS A B OUTPUT 0 0 1 1 0 1 0 1 0 1 1 1 0 0 1 1 0 1 0 1 0 0 0 1 0 0 1 1 0 1 0 1 1 0 0 0 0 0 1 1 0 1 0 1 1 1 1 0 0 1 1 0 Combining logic gates Logic gates have limited use individually but when they are combined together they can be used to process information and cause actions to be taken. 122 To work out the output for any collection of gates draw up a truth table representing all of the possible input combinations. For each set of inputs in turn, work your way through the logic combinations and find the output. Keep on going until you have found the outputs for all of the possible input combinations. What are the input conditions required for the logic gate system shown in Figure 5.29 to produce an output of 0? A Output B C Figure 5.29 Worked example 3 Draw up the truth table for the logic gate system, working in a sensible order and making sure all of the possible input combinations are covered (Table 5.2). Table 5.2 Input A Input B Input C Output 0 0 0 1 1 0 0 0 0 1 0 1 1 1 0 1 0 0 1 1 1 0 1 1 0 1 1 1 1 1 1 1 Remember! From the truth table we can see that the output of the logic gate system is logic 0 only when A is 1, B is 0 and C is 0. 1 Binary digits can be represented by high and low voltage levels. 2 Logic gates process binary inputs and produce binary outputs. 3 Simple logic gates can be combined to provide additional processing. 123 Glossary Ammeter An instrument used for measuring current. Atom The smallest part of an element that can take part in a chemical change. Capacitor A component which stores an electric charge if a voltage is applied across it. Circuit breaker A device which automatically disconnects the supply from a circuit in the event of excessive current flowing in the circuit. Conductor A material that conducts electricity. Conduit A tube made from metal or PVC in which insulated conductors are contained. Electricity Movement of free electrons. Electron A stable sub-atomic particle with a negative charge. Fossil fuels Formed by a natural process over millions of years and include petroleum, coal, and natural gas. Frequency The number of oscillations of alternating current in an electric system transmitted from a power station to the end-user per second. It is normally 50 Hz. Fuse Also known as ‘overcurrent protection’, disconnects a circuit when an overload or short circuit is present. Insulator A material that doesn’t readily conduct electricity. Ions Atoms or molecules that have gained or lost electrons. Molecule A group of atoms bonded together. Multimeter Combines the features and characteristics of both an ammeter and a voltmeter, and measures current, voltage and resistance. Digital multimeters are the most commonly used measuring devices. Neutron A stable sub-atomic particle with no charge. 124 Nucleus The positively charged central core of an atom made up of protons and neutrons. Polarisation The shift of positive and negative electric charge in opposite directions within an insulator, or dielectric, induced by an external e.m.f. Polyvinylchloride (PVC) A material that acts as an insulator, normally the covering for electrical cables. Proton A stable sub-atomic particle occurring in all atoms with a positive charge. Renewable energy Energy which is naturally replenished on a human timescale, such as sunlight, wind, rain, tides, waves, and geothermal heat. Resistor A component that limits the electrical current that flows through a circuit. Semi-conductor A material that can conduct electricity under certain conditions. Static electricity A build-up of charge on the surface of an object. The charge remains until it is discharged, for example, by touching the object. This can cause a mild electric shock. Thermistor A device whose resistance quickly decreases with an increase in temperature. Transformer An electrical machine with no moving parts which is used to change the value of an alternating voltage. Unity power factor When the voltage and current in a circuit are ‘in phase’ with each other. Valence electrons The electrons in an atom’s outermost orbit. Voltmeter An instrument used for measuring voltage. It measures the potential difference between two points. Working voltage The maximum voltage that can be applied between the plates of the capacitor without breaking down the dielectric insulating material. Index A a.c. 29–33, 35–42 rectification 114–15 alternators 52, 53 ammeters 13 AND gates 122 atoms 2–3, 4, 5, 111 B batteries 8, 44, 47 bending conduit 82–4, 89 biofuels 55 block diagrams 45 C cables 70–3, 74, 75 resistivity 21–3 wiring conduit 87–8 capacitance 6, 32–3, 108 in a.c. circuits 37–42 capacitive reactance 33, 38, 40 capacitors 32–3, 108–10 cells 44, 47 charge 2–3, 4, 5, 6, 7 capacitors store 32, 108 chemical effects 8 chemical energy 2 circuit breakers 25–6, 101, 103 circuit diagrams 45, 47–50 circuits 6, 7–8, 14–18 a.c. 29–33, 35–42 in installations 64–9 faults 94, 96, 98 testing 90–4 integrated 119 lamp dimmer 121 lighting 74–7 colour codes 105–6, 109–10 conductivity 3–4 conductors 3, 4, 7, 47 resistivity 21–3 conduit 82–9 consumer units 54, 64 continuity testing 90–2 corkscrew rule 10–11 cosine law 81 CPCs 89, 90–2 see also protective devices current 6, 7–8, 14–18 a.c. see a.c. amplification 116 in diodes 111–13 eddy currents 57 and electromagnets 10, 11 induced current 12, 30 measuring 13, 42 in parallel 16–17, 41–2 and protective devices 102–3 in transformers 56, 57, 58, 60–1 cycle 29 D d.c. 29, 30, 56, 114–15, 120 diacs 120 diagrams and drawings 45–51 diodes 13, 111–15 direct in line starters 27–8 doping 111 E Earth, symbol for 47 earth conductors 90 earth faults 99, 101 eddy currents 57 electrical energy 2, 7 electricity 2–4, 5, 6 production 52–5, 56, 58 electrolytic capacitors 109, 110 electromagnetic induction 8, 12 electromagnetism 9–13 electronics 104–23 capacitors 108–10 diodes 111–15 integrated circuits 119 logic gates 121–3 rectification 114–15 resistors 104–7 thyristors 119–21 transistors 116–19 electrons 2–3, 4, 5, 6 in circuits 7, 8, 14, 29 in semi–conductors 111, 113 emergency lighting 49, 66–7 e.m.f. 6, 7, 8, 12 induced 8, 30, 31, 56 energy 2, 6, 7, 8, 32 in devices 113 and lamps 78, 79 energy sources 52, 54–5 escape lighting 66 F fault diagnosis 94–101 field effect transistors 121 fire alarm systems 68–9 fluorescent lamps 49, 79–81 forward bias 111, 112 fossil fuels 52 frequency 6, 29 fuels 52, 55 full–wave rectification 115 fuses 24, 98–9, 101, 102–3 G gain of transistors 116 gases 2 geothermal energy 52, 55 glow starter circuits 79–80 H half–wave rectification 114 heat detectors 68 hydroelectricity 55 hysteresis 57 I impedance 33, 36–7, 38 and RCL circuits 39–40 incandescent lamps 78 induced current 12, 30 induced e.m.f. 8, 30, 31, 56 inductance 6, 31–2, 35–7 mutual 56 in RLC circuits 39–42 inductive circuit 33 inductive reactance 31, 40 installations 54, 62–103 circuits 64–9 conduits 82–9 fault diagnosis 94–101 lamps 78–81 lighting circuits 74–7 scale drawings 51 standards 62–3 testing 90–4 wiring methods 70–3 insulation 92–3, 99 insulators 3, 4 integrated circuits 119 inverse square law 81 ions 3, 4 isolation 94–5, 96, 97 J joint/junction boxes 77 125 K kinetic energy 2, 7 L lagging 31–2 lamps 49, 78–81, 121 layout diagrams 46 LCDs 13 LEDs 13, 113 left–hand rule, Fleming’s 11 light energy 7 light–dependent resistors 107, 113 lighting 49, 66–7, 74–7 liquids 2 logic gates 121–3 loop in ceiling rose 74–5 M magnetic energy 2 magnetism 6, 8, 9–13, 26 and transformers 56, 57 maximum/peak value 29 MCBs 25–6, 103 meters 13, 95, 118 molecules 2, 3, 4 motors 11, 26–8, 48, 107 multimeters 13, 114, 118 N NAND gates 122 neutrons 4 NOR gates 122 NOT gates 121–2 nuclear power 52 nuclei (nucleus) 2, 3, 4 O Ohm’s law 14–18 OR gates 122 overloads 99, 101 P p–n junctions 111–14, 116 parallel circuits 16–18 a.c. in 41–2 particles 2, 7 phase angle 30, 31, 32 phasors 30–3, 35, 39 photocells 113 polarity 94, 95, 109, 110 potential difference 6, 7, 8 see also voltage power 6, 8, 15–16 and a.c. 29, 30, 31–2 and transformers 56, 57, 61 126 power factor 29, 30, 31–2, 40 power ratings, resistor 106 power stations 52–3 protective conductors 89, 90–2 protective devices 24–8, 98–9, 101 performance 102–3 protons 2–3, 4, 5 PVC 70–1, 72, 88–9 R radial circuits 65 reactance 31, 33, 38, 40 rectification 114–15 regulations 62, 98, 102 renewable energy 52, 54–5 resistance 6, 13, 14–18 and a.c. 30, 33, 35–42 and resistivity 21–3, 104 resistive circuits 30, 32, 33 resistivity 21–3, 104 resistors 14–18, 104–7 light–dependent 107, 113 reverse bias/voltage 111, 112 right–hand grip rule 10 ring circuits 64–5, 91–2 r.m.s. value 29 S safe working 94–5, 96, 97 scale drawings 46, 51 schematic diagrams 46 semi–conductors 3, 4 devices 111–14, 116, 119 series circuits 15–16, 18 a.c. 35–40, 42 short–circuit faults 99, 101, 103 sinusoidal waveforms 29–30, 31, 32 smoke detectors 68, 69 smoothing 115 socket outlets 50, 64, 65 solar power 2, 52, 55 solenoids 10 solids 2 spurs 65 standards 47–50, 62–3 standby lighting 66 static electricity 5 stroboscopic effects 80–1 Sun see solar power switches 74–6, 94, 97 symbols for 48, 50 thyristors as 119 transistors as 118 symbols 47–50, 108, 112, 120 units and quantities 6 T technical diagrams 45 temperature 22–3, 107 terminals 72–3 termination 72–3, 87 testing 90–4, 114, 118–19 equipment for 95–6 thermal effects 8 thermistors 68, 69, 107 thermocouples 8, 68 three–phase 52, 80, 93, 96 and motors 26, 27, 28 and transformers 58 thyristors 119–21 tidal power 52, 55 transformers 53, 54, 56–61 transistors 116–19, 121 triacs 120 tripping 25–6, 103 truth tables 122, 123 tungsten halogen lamps 78 turns ratio 56, 59–61 V voltage 6, 8, 14–18 in a.c. circuits 30–3, 35–42 amplification 117–18 in diodes 112–13, 114 and electricity distribution 53, 54 measuring 13, 42, 95–6 and transformers 56, 58, 59–61 working voltage 109 see also e.m.f. voltmeters 13, 95 W warning notices 96, 97 wind power 52, 55 windings 56–61 wiring 70–3, 77 and conduit 82, 87–8 for fire alarms 69 regulations 62, 98 wiring diagrams 46 Z Zener diodes 112–13 Electrical and Electronic Technology for CSEC® Less Stress, More Success Written by experienced teachers and experts, this study guide focuses on the development of skills, critical thinking and teamwork — a great foundation for your SBA, further study and entry into the world of work. Features include: ● Why don’t you: an opportunity to apply the skills you have studied by way of an activity ● Key terms: definitions of key words and terms highlighted for easy reference ● Detailed diagrams and step by step instructions aid in understanding concepts Candidates who successfully complete the CSEC examinations in the Industrial Technology programmes will be awarded two sets of certificates: the CSEC Technical Proficiency and a CVQ* (Caribbean Vocational Qualification) Statement of Competence. The Caribbean Examinations Council (CXC®) has worked exclusively with Oxford University Press to produce a series of CSEC® and CAPE® Study Guides. * CVQ is the Registered Trademark of the Caribbean Association of National Training Authorities (CANTA). eBook Available eBook Available 1 How to get in touch: web www.oup.com/caribbean email schools.enquiries.uk@oup.com tel +44 (0)1536 452620 fax +44 (0)1865 313472 ISBN 978-0-19-839547-8 9 780198 395478