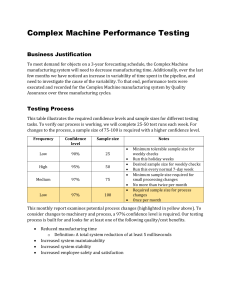

Lec 9 Work Schedule & Control (Lean Concepts Lec 10 Rapid Changeover (setup)/SMED Lec 13 Quality Systems Tools To minimize sources of variability: 5S, Visual controls & Changeover: Needed when products Bad Product: Reduces Prod. capacity, inc prod-related cost, inc graphical work instruc., Work, tool, & equipment change production variability (WIP, FT, & wait time), inc order lead time, standardization, Production rate leveling (Takt Time), WIP smaller batch sizes = more setups wastes material/energy control (CONWIP), Heijunka, Pull Systems Demand levelling Issues of Changeover: during setup -> 1-10-100 Rule: as a product or service moves through production 5S - Sort (get rid of clutter), Straighten/Stabilize (organize), not producing, setup delay intros system/supply chain->cost of correcting an error multiplies by 10 Shine (system cleaning), Standardize (work standards), variability (bad), quality costs, constrain for each stage of processing Sustain sequence of producing reducing Process Capability: process capability studies, tolerance analysis One Piece Flow (Continuous) - move through line one at a time, flexibility to meet demand, larger lots to Defect Detection: control charts, sampling (SPC/SQC) no process batching try to reduce setup -> larger inventory Defect Correction: brainstorming, pareto charts, cause & effect Priorities for 5s Sorting: Low(<1/yr), Avg(1/month,1/week), High produce in large batches to spread out diagrams, scatter diagrams, redesign, design of experiments, line (1/day) setup costs & reduce loss of capacity stop on error, correct your own errors Red Tag Technique for 5S Sorting: red labels to label items not ELS: economic lot size/batch size; Defect Prevention: Zero Defect Quality (ZDQ) & Poka Yoke (foolneeded, after a week toss suboptimal bc min cost occurs when no proofing), supplier certification / management, setup improvement, Metrics for 5s Straighten: Time saved in Searching/Material setup bc no holding cost housekeeping (5S), training Handling S= Setup cost>0 Continuous Improvement: TQM, Kaizen, Six Sigma Requirements for 5s Sustain: Top Mgmt support, accountability, D= Avg Demand Rate Goal alignment: production responsibility for quality, Overall performance measurement/rewards, regular audit i= carry rate % Equipment Effectiveness (OEE) metrics, quality circles, quality 5s Advantages: less time searching for items, waste reduced, c= unit prod. cost visibility better-maintained equipment, improved motivation/safety, Changeover steps: Preparation (ensure Total Quality Management (TQM): sustaining quality gains & gradual better utilization working tools & proper location, materials ongoing improvements by eliminating defects as they occur 5s is a STARTING POINT for Lean Improvements are available), Extraction/Mounting QS 9000: Supplier management, Materials control, Quality planning, Visual Controls: means, devices, or mechanisms designed to (removal of tools/materials after batch is Process control\ manage or control the operations (processes) to make completed and replace tools/materials for Kaizen Blitz: Area- or process-focused rapid improvement activity problems visible, display progress status, provide new), Establish Control Settings designed to produce significant improvements within a short time instruction/information/immediate feedback. Increases (settings prior to production period efficiency, effectiveness, and coordination (Ex: Color-coded run/calibrations), First Run Capability Six Sigma: assumed to produce long-term defect levels below 3.4 equipment, painted floor areas, status boards, visual instructions) (any adjustments after trial piece defects per million opportunities (DPMO); improve quality, DMAIC Push System: system schedules the release of work based on produced) Zero Defect Quality (ZDO): Inspect for defects at each step, rather demand regardless of current loading of system. External: Production Time than periodic inspect stations Pull System (Kanban): authorizes release of work based on WIP Internal: Production stopped Types of Inspection: Judgement (end of line), Informative (uses data, at each station, controls Station WIP, Closed queueing Techniques: internal to external, staged SPC/SQC, done intermediate), Source (each stage at source, not best systems w/ blocking, reduces inventory, WIP, & batching but tooling, eliminate “adjustments” through info) leads to longer FT, and low utilization visual controls/ ratchets/automation, Point of Origin Inspect: passive methods (not high tech,parts Production leveling involves: Takt Time (Pace prod. rate to Parallel processing (more people working designed w odd shape) proximity/property sensors, vision systems demand, not capacity), CONWIP (Pace sys, loading), Heijunka on same thing), Automation, Standardize (Pace prod. cycle to demand), demand leveling ( taking action to Lec 14 TPM/OEE Design reduce demand changes) Total Productive Maintenance (TPM): maintenance/reliability mgmt Things to look for: no advance prep, Takt Time: sets pace of productions, heartbeat of lean system system forms the foundation, emphasis on autonomous maintenance, movement after machine stopped, (available production time/rate of customer demand) improved training & higher skill level, performance mistakes, excessive removal Heijunka: scheduling of orders, level by volume/type/product, monitoring/benchmarking time/adjustments, many movements requires reducing setup times/costs Features: Goal alignment through OEE (overall equipm. effectiveness), during setup CONWIP: release of work in to the sys., real time control planned maintenance, maintainability, team based approach, Cost/Changeover: Line strategy, tries to maintain constant WIP, closed queuing speed(parts/min)*Contribution($/part)*A continuous improvement network Big “6” Productivitiy losses: Breakdowns, Setup/adjustment losses, vg CO Time Demand Leveling: focus on reduction demand (order arrival) Idling/minor stops, Speed losses, defects/rework, Startup / yield losses Annual Cost of CO: variability, can improve predictability/demand visibility Process Design Principles: minimize distance, one piece flow/no Cost/Changeover*Changeover/yr batching, minimize equipment size, Poka Yoke/ZQD, Linked Lec 17 Variability & Factor Physics Cell/UShape Controllable Variation: Caused by decisions (product mix, setup/changeover times, batch size) Supplier Management: Lean suppliers Random Variation: caused by uncontrolled factors (demand, natural processing time variation, machine Lean procurement: automated, integrated purchasing breakdown) Supplier commo./collab.: demand visibility to prevent bull-whip issues Why do we reduce variability?: more variability longer wait/FT,reduced system capacity, need for more Lean warehousing: automation/integration; eliminate defects or return inventory. customers want faster responsetime, consistency, lower costs shipments, excess inventory, extra space to reduce warehousing Factory Physics: understanding impact of variability in a sequence of operations (bottlenecks), efficiency, Excess motion/ handling, Inefficiency/unnecessary, wait approximate formula calc for system metrics times Flow Variability: variability of one process affects other downstream processes (upstream if blocking) Serial Production line: departures become arrivals to next, only first station sees arrival variability undistorted OEE= Availability*Performace*Quality Availability = Actual Operating Time/Planned Operating Time = Uptime Downstream stations see combo of arrival variability & upstrea process variability Performance = Actual Production/(Expected Production over the Actual FV: If process is highly utilized, output (departure) variability (CVd) will reflect the process's inherent Operating Time) variability (CVe), and arrival variability (CVa) has little impact. low utilization, its output variability (CVd) will Quality = Good Output/Actual Output = 1 – (Scrap & Rework / Actual largely mirror its arrival rate variability (CVa) Output) Flow Variability Behavior: processes that are both highly loaded AND highly variable have a much greater Lec 16 Value Stream & Process Mapping impact on system variability (and performance) in general and particularly if occur earlier rather than later in VSM: used to analyze flow of materials and info currently required the production or service process flow to bring product/service to a consumer, emphasis on wait/transpo Factory Phys Laws: times (NVA), useful for high volume; rough sketch tool (use Variability: Inc. variability degrades performance system) Process map for detail) Capacity: system with any variability, processes will release work at avg rate that is strictly less than their avg VSM Method: Identify main problems, set process boundaries, do capacity Gemba walk (waste identification exercise), document in VSM Utilization: If station inc utilization w/o other changes, avg WIP & CT will inc in a nonlinear fashion Process Maps: show time at each step, quality rates, setup times, Variability Placement: variability early in routing inc CT more than equivalent variability later in routing merging/assembly operations Variability Buffering (or "you can pay now or pay later"). Variability in a production system is buffered by Spaghetti Diagram: visual description of distances/paths for a combinations of Inventory, Capacity, Time process to see waste in transpo/steps Lead Time:The manufacturing LT for routing is an inc function of both the mean and std dev of the CT of the routing Rework/Scrap: For given throughput level, rework inc both the mean and Std Dev of the CTof a process. Batching: Inc variability and usually mean processing times as well. Setup time: Inc variability and mean processing times. Reduce process variability: Automation, better tools, fixtures, layout, training Reduce arrival variability: Work with customers/suppliers to smooth arrivals, Improved demand forecasting and info sharing Improve maintenance and maintainability: Increase TTF, reduce TTR, and reduce variability Improve Process Flexibility: Eliminate batching(move to single piece flow), Reduce/eliminate of both planned maintenance rather than reactive maintenance). setup/changeover Implement variability pooling: Shared queue Material/parts standardization – safety stock aggregation Lec 18 Material Handling Lec 19 Verification & Validation 80-85% of items total time in system is on material handling or waiting. Verification - process of determining the model operates as intended / specified. Modeling Types: Validation - process of developing an acceptable level of confidence that inferences drawn from the performance of Transporters: Free Space (Unconstrained shortest distance movement; the model are correct and apply to the real world system. e.g., hand trucks, people in open layouts), Network (Transporter must Verification Activities: Incorporate outside “doubters”, model walkthroughs, Perform test runs to check for output follow aisles, roads or other constrained paths. e.g., Forklifts), Zone correctness (Boundary conditions – resources, buffer sizes go to 0, etc.; Incremental inc or decn arrival / service controlled (Network with controlled zones limiting how many rates, buffer sizes, number of resources, failure rates have appropriate effects) transporters can be on a segment of the network at a time. e.g., trains, Watch for: Do queues or WIP continue to grow overtime?; Are flowtimes / wait times absurdly long? Look at max Automated Guided Vehicles (AGVs) values in report (same reasons as above); Utilizations absurdly low or zero?; No or few entities leaving the system? Conveyors: Accumulating (when blocked, items pack together/ Or leaving along a particular path?; Incorrect processing times, entities leaving with resources, incorrect logic distance between items gets smaller ), Non-accumulating (fixed expressions in holds, or decision/routing blocks. spacing between items) Verification Tools: Use numeric displays/ plots to track performance metrics, Use reports, pivot grid, responses to Transporters: are RESOURCES; if not at station, then more wait review end of simulation statistics; SIMIO: Model Trace, Breakpoints, Watches time/travel time; must define initial position, selection rules; consider COMMON ERRORS: Data Parameter, Math expression, Intilization, Statistic recording, units of measures, delays/load/unload times Blockages/ deadlooks, Flow control/connection, Failure to release/seize appropriate resources, Failure to dispose Networks: Congestion on network grid combined with control logic (entities never leave system), Overwriting State variable/entity attribute values by accident, Conceptual errors results in a condition where no transporter can move on all or part of a /misunderstood operation) network; Fix: Fewer carts to reduce # of conflicts, Avoid bidirectional Validation Types: links/spurs, or allow passing on the link, Add bypasses, More complex Conceptual Validity: Does the model structure represent the real world system (logical premises are control logic to detect and "break" deadlocks correct/rational)? Conveyors: the TRANSPORTER; fixed path device Operational Validity: model's behavioral data characteristic of real world system's behavioral data? empirically For accumulating conveyors: correct? Conveyor keeps moving even when parts are loading / unloading Believability (Face Validity): Do the ultimate users (decision makers) of model have confidence in results? Entities attempting to access the conveyor are held in a queue until Validation Tests for Resonableness: the required amount of unoccupied space is available, The conveyor Continuity: Small changes in parameters yield small appropriate changes in outputs. EX: incr arrival rate -> is blocked (accumulates) upstream until this space is free longer avg queue lengths. At the destination station, the entity stops and blocks the conveyor Consistency:Similar runs of the same model should yield similar results. until it exits the conveyor. Degeneracy: Removal of resources should be reflected in model results. EX: dec machine capacity from 2 to 1 -> Accumulating entities pack together more tightly then when moving reduced throughput, longer lines For non-accumulating: Absurd Conditions: no absurd conditions like zero flow times, neg weights/ lot sizes, “infinite” (very large) values Whole conveyor generally stops when loading or unloading (must be for flow times, queue sizes an empty "cell" in front of station to get on conveyor) Tests for Structure & Data: Synchronizing Converyors: •When one conveyor flows into another, or Face validity: Ask persons familiar and knowledgeable w/ system to judge model’s behavior. Often used w/ entities are redirected from conveyor onto another, the entity must get animation. space on the second conveyor before releasing space on the first Parameters & Relationships Verification. Conduct statistical analysis on input data (input data analysis). conveyor. Otherwise, can build up an infinite queue in the space Sensitivity Analysis: How sensitive are models’ outputs to small changes in inputs? If small changes in input between two conveyors! values yields change in decision on what alternative to adopt, may call into question models usefulness. Structural and Boundary Verification: Does model structure obviously contradict reality? Tests of Model Behavior (LEC 19): Behavioral Comparison. Compare simulation model output to real world output for similar conditions. ( ChiSquare/Goodness of Fit tests, etc) Symptom Generation: Does the simulation model recreate difficulties occurring in the real system? (long lines, blocking, etc) Behavior Anomaly: Does the model recreate flukes (anomalies) of the physical system for certain inputs? Behavior Prediction: helpful in building confidence in the model. Use the simulation to predict behavior / performance of the system for the near future VSM Steps ↑ * Draw this example Input @Good . . Input @Bad 2