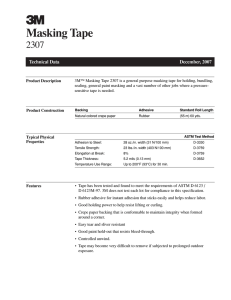

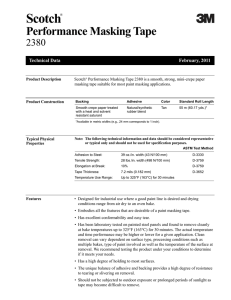

Why Quality Matters: A Deep Dive into Masking Tape Suppliers Masking tape is an essential tool across a wide range of industries, from painting and automotive work to DIY home projects and industrial applications. While it may seem like a straightforward product, the quality of masking tape can significantly impact the success of your projects. In this article, we explore why quality matters when choosing masking tape suppliers and what to look for in a reliable provider. The Role of Masking Tape in Various Industries Masking tape is more than just a sticky strip. Its primary purpose is to provide precise masking, allowing for clean lines and surfaces during tasks like painting or sealing. However, its functionality extends to: 1. Industrial Applications: Used for masking off areas during metalworking, powder coating, or sandblasting. 2. Automotive Repairs: Essential for achieving smooth, sharp finishes in painting and detailing. 3. DIY Projects: Ensures clean edges for crafts and home repairs without damaging surfaces. Given its diverse uses, choosing the right masking tape is paramount to achieving high-quality results. Why Quality Masking Tape Matters 1. Adhesion and Removal Low-quality masking tape often fails in two key areas: adhesion and residue. A high-quality masking tape sticks effectively during application yet peels off cleanly without leaving behind sticky residue. This is critical for maintaining the integrity of surfaces. 2. Temperature Resistance In industrial or automotive applications, masking tape may need to withstand high temperatures. A subpar product can fail under heat, causing paint bleeding or adhesive breakdown. 3. Precision in Results For detailed work like painting, precision is non-negotiable. High-quality masking tape ensures crisp, clean lines, enhancing the final outcome of your project. 4. Durability Quality masking tapes resist tearing or fraying, ensuring ease of use and reliable performance even in challenging conditions. What to Look for in a Masking Tape Supplier When choosing a masking tape supplier, focus on these key factors: 1. Material Quality Look for suppliers offering masking tape with robust backing materials and high-grade adhesives. This ensures reliability and performance. 2. Product Range A reputable supplier should provide a wide range of masking tapes tailored to various needs, such as heat-resistant tapes for industrial applications or UV-resistant tapes for outdoor use. 3. Certifications and Standards Suppliers who adhere to international quality standards, such as ISO certifications, are more likely to deliver dependable products. 4. Customer Support Reliable suppliers stand behind their products with excellent customer service, offering guidance and support when needed. 5. Sustainability Practices In today’s world, eco-friendly materials and sustainable manufacturing practices are increasingly important. Choosing a supplier committed to green practices benefits both your projects and the environment. The Impact of Choosing the Right Supplier Working with a reputable masking tape supplier can save time, reduce project costs, and elevate the quality of your work. Reliable products ensure fewer mistakes, less rework, and better overall results, making your investment in quality worthwhile. Conclusion Masking tape might be a simple tool, but its quality can make or break your project. By partnering with a reputable masking tape supplier, you can ensure optimal performance, reliability, and precision. When it comes to achieving professional-grade results, the importance of quality cannot be overstated. Choose wisely—your projects deserve nothing less than the best masking tape on the market.