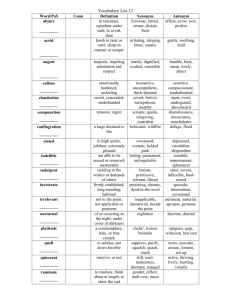

PRODUCTION OF CAUSTIC SODA “Chemical Engineering Department Graduation Project” Çağla YARMACI, Emine YETİM, Prof. Dr. Ayşe Nilgün AKIN Kocaeli University, Chemical Engineering Department, Kocaeli, 41380, Turkey 3. CAUSTIC PRODUCTION IN KORUMA CHLOR ALKALI PLANT ABSTRACT The chlor-alkali industry is one of the most energy intensive electrochemical processes in the world. Caustic soda is a product of alkali industry which is produced by the way of electrolyse of salty water. The industry of chlor alkali is an electrochemical process which consumes the most energy in the world. Thats why these processes which have a high energy productivity are important. Caustic soda is one of the most important raw material of chemical industry. The demand of caustic was 73 millions ton around the World in 2011. Caustic soda which has a large usage area is also used alcaline battery. Institutionally the process within mercury cell is used in the product of caustic but this method gives place to the process within diaphragm cell and today the membrane technology is dominant. The membrane technology which changes ion and has the biggest energy conversation, perfect product quality, not contaminant is a modern chlorine alkali. With this performance, the information about the industry of chlorine alkali; especially about caustic soda is given and the steps of production process is investigated. The membrane technology is concentrated. Lime soda process, trona process and electrolytic cell process are used in the produtivity in caustic. Membrane cell process is the best of all cell processes that are mentioned. Keywords: Caustic Soda, Chlor Alkali, NaOH, Elektrolyse, Membrane Cell General view; Electrolysis; 1. INTRODUCTION Caustic soda is a product of chlorine alkali industry. The main production method is the electrolysis of salty water. The process can be carried out in these three cell types: mercuric, diaphragm and membrane cells. The process of mercuric and diaphragm cells was developed in late 1800’s and the process of membrane cells was developed in 1970’s. By electrolysis of salty water, chlorine gas is produced in the positive pole and hydrogen and caustic soda are produced in the negative pole. Chlorine alkali industry is one of the most energy-consuming electrochemical processes. So developments about energy conservation are required. The least energy-consuming cell type in caustic soda production is membrane cell. Studies on membrane cell still continue. Energy conservation can be increased with the improvements on new membranes. In this work caustic soda production methods are investigated. Although mercuric cells provide high concentration (50%) of caustic soda production, they lose their significance because of high energy-consuming and including mercury. Diaphragm cells enable low concentration and low purity of caustic soda production. The most appropriate method can be shown as membrane cell process because of high purity caustic soda production and low energy-consuming. 2. CAUSTIC SODA 5% 2% 1% 1% 4% 4% 5% 31% 5% 12% 16% 14% Fıgure 2.1:Uses of Caustic Soda [1] Organics Types of Caustic Soda; Others Paper cellulose Other inorganics Aluminum and metals Food industries Water treatment soop Bleaching Mineral oil Artificial silk Sud Caustic Flake Caustic Prill Caustic Phospates Figure 3.1: Process of caustic production Table 3.1:Product quality control report of flake caustic Flake Caustic Product Date Parametre Unit Spec 18.05.2015 Appearange - White flake White flake NaOH % Min. 98 98,66 Na2CO3 % Max. 0,40 0,54 NaCl % Max. 0,1 0,014 Fe ppm Max. 15 5,65 CONCLUSION Figure 3.2: Caustic production process flow sheme [3] REFERENCES 1. Brinkmann, T., Santonja, G.G., Schorcht, F., Roudier, S., Sancho, L.D., Best Available Techniques (BAT) Reference Document for the Production of Chlor-alkali, JRC Science and Policy Reports, Luxemburg, Publications Office of the European Union, 2014. 2. O’Brien, T., F., Bommaraju, T., V., Hine, F., Chlor Alkai Technology Volume 1: Fundementals, New York, Springer, 2005 3. Koruma Chlor-alkali Company The chlor-alkali industry is developed and geographically dispersed in various time zones. It is a problem that sodium hydroxide and chlorine produced together and almost same amount. These two products have very different courses and different end-use market Dynamics and demand’s of them almost never overlap. Sodium hydroxide is usually marketed as a 50% aqueous solution, it can be maintained for a long time and can be easily transported. Mainly, caustic soda production method investigated in this report. Clearly the conclusions reached is that the most appropriate method is membrane cell electrolysis. Membrane cell process is advantageous than olders others because not mercury or asbestos not used and has lower energy consumption. Despite these advantageous, transition to membrane cell prosess is slowly in Europe. Because plants that established 1970’s have 40-60 years service life and there is no need increase capacity. There is no legislation that will accelerate this transition is not available. Nearly 56% of the World used membrane process. Three manufacturers that in our country today as the company realizes its production with membrane cell process. Graduation Project Baki Komsuoglu Culture and Conference Center 5th June 2015, KOCAELI