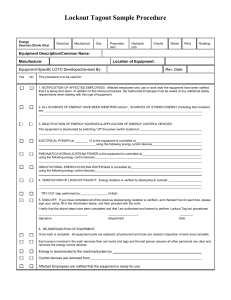

Understanding Lockout Tagout: A Comprehensive Guide to Saving Lives at the Workplace Workplace safety is a paramount concern for every organization, especially in industries where hazardous energy is present. Accidents caused by uncontrolled energy sources can lead to severe injuries or fatalities, which is why the Lockout Tagout system has become an essential practice. By isolating energy sources and preventing the accidental operation of machinery, LOTO programs save lives and ensure a safer work environment. This guide will walk you through the basics of Lockout Tagout, its importance, and how it protects workers from hazardous energy. What is Lockout Tagout? Lockout Tagout refers to a safety procedure used to isolate machinery or equipment from energy sources during maintenance or servicing. The goal is to prevent the unintended release of energy, such as electricity, gas, or hydraulic pressure, which can endanger workers. ● Lockout involves using physical locks to secure machinery in an off position, preventing activation. ● Tagout uses visible tags to warn others not to operate the equipment while maintenance is in progress. When used together, these methods provide a fail-safe mechanism to protect employees from hazardous energy. Why is Lockout Tagout Important? LOTO is critical in industries where workers interact with machinery, such as manufacturing, construction, and energy production. According to OSHA (Occupational Safety and Health Administration), failure to control hazardous energy is a leading cause of workplace injuries and deaths. Common incidents that LOTO prevents include: ● ● ● Accidental machine startups during servicing. Unexpected release of stored energy, such as springs or hydraulic pressure. Electrocution due to improper electrical isolation. By implementing a robust LOTO program, organizations can significantly reduce these risks, ensuring a safer work environment and protecting lives. Key Components of a Lockout Tagout Program A successful Lockout Tagout program involves several essential components: 1. Energy Source Identification: Identify all energy sources connected to equipment. These can include electrical, mechanical, hydraulic, pneumatic, chemical, and thermal energy. 2. Proper Lockout Devices: Use appropriate lockout devices such as valve lockouts, circuit breaker lockouts, or plug lockouts to secure machinery effectively. 3. Clear Tagout Labels: Tags must be durable, clearly visible, and display critical information such as the name of the person who applied the tag and the reason for the lockout. 4. Written Procedures: Document step-by-step instructions for locking out equipment, including identifying energy sources, applying locks and tags, and verifying isolation. 5. Employee Training: Train all employees, especially those authorized to perform lockouts, to understand LOTO procedures and the importance of compliance. 6. Periodic Inspections: Regularly inspect and audit the LOTO program to identify gaps, ensure compliance, and update procedures as necessary. Benefits of Lockout Tagout Programs A well-implemented LOTO program offers several advantages: ● ● ● ● Injury Prevention: Protects workers from accidents caused by uncontrolled energy. Regulatory Compliance: Meets OSHA and other safety standards, avoiding penalties and fines. Improved Productivity: Reduces downtime by creating a safer, more organized maintenance process. Enhanced Safety Culture: Demonstrates a company’s commitment to worker safety, boosting employee confidence. Steps for Implementing Lockout Tagout Follow these steps to ensure an effective LOTO process: 1. Prepare for Shutdown: Identify the equipment to be serviced and the energy sources to be isolated. 2. Notify Employees: Inform all affected workers about the maintenance activity and the lockout procedure. 3. Shutdown Equipment: Turn off the equipment following standard procedures. 4. Isolate Energy Sources: Disconnect or isolate all energy sources, such as unplugging electrical equipment or closing valves. 5. Apply Locks and Tags: Secure the lockout devices and attach tags to indicate that the equipment must not be operated. 6. Release Stored Energy: Safely discharge any stored energy in the system, such as releasing pressure from hydraulic lines. 7. Verify Isolation: Test the equipment to ensure all energy sources are effectively isolated before starting work. 8. Perform Maintenance: Proceed with maintenance or servicing tasks. 9. Remove Lockout Tagout Devices: Once work is complete, only the authorized person who applied the devices should remove them, following proper procedures. 10. Restart Equipment: Notify workers, inspect the area, and restore energy sources before restarting the equipment. Challenges in Implementing Lockout Tagout Despite its importance, implementing LOTO programs can face challenges: ● Lack of Awareness: Employees may not fully understand the hazards of uncontrolled energy. ● Non-Compliance: Workers may bypass LOTO procedures to save time, risking accidents. ● Improper Equipment: Using incompatible or low-quality lockout devices can undermine the program's effectiveness. To overcome these challenges, organizations must invest in comprehensive training, high-quality lockout devices, and continuous monitoring of LOTO practices. Conclusion Lockout Tagout is more than a compliance requirement; it is a lifesaving practice that ensures the safety of workers in hazardous environments. By isolating energy sources and preventing accidental machinery operation, LOTO programs protect lives, reduce workplace accidents, and foster a strong safety culture. Investing in proper training, high-quality lockout devices, and regular program audits ensures the effectiveness of LOTO procedures. Organizations that prioritize Lockout Tagout not only safeguard their employees but also enhance productivity, maintain compliance, and build a reputation for safety excellence. With proper implementation, Lockout Tagout becomes a powerful tool in saving lives and creating safer workplaces across industries.