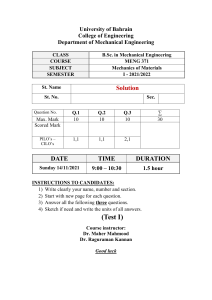

Example Problem 4 A dent containing a gouge has been found on a pipeline. The pipeline is constructed to ASME B31.3. Determine if the dent-gouge is acceptable for continued operation using a Level 1 approach. Pipeline Data: • Material • Dent Depth • Gouge Depth • Dent Radius • Outside Diameter • Measured Wall Thickness • Allowable Stress • Yield Strength • Operating Pressure • Minimum Temperature • Future Corrosion Allowance • Distance to discontinuity • Distance to nearest weld • Weld Joint Efficiency = API L Grade X Year 5 42 1999 = 25.4 (mm measured during shutdown) = 1.27 mm = 50 mm = 508 mm = 12.7 mm = 137.9 MPa = 290 MPa = 5.0 MPa = 0° C = 0.5 mm (internal) = 1000 mm = 300 mm = 1.0 (machine welded) Example Problem 4 – DENT-GOUGE ASSESSMENT Inspection data: The dent is located on the base metal away from a weld and has a smooth appearance. No cracking originating from the gouge has been detected. Perform a Level 1 Dent-Gouge Combination assessment per API 579-1. STEP 1 - Determine the input parameters. 1) Calculate the maximum allowable working pressure. Determine the future wall thickness: tc = trd − FCA tc = 12.7 − 0.5 = 12.2 mm Calculate the maximum allowable working pressure: Example Problem 4 – DENT-GOUGE ASSESSMENT Determine whether the operating pressure is greater than or equal to 70% of the Max. Allowable Working Pressure (MAWP): 5.0 MPa ≥ ((0.7) (6.7533) = 4.7273 MPa) True The dent depth on the pipe in pressurized condition is therefore calculated using equation the following equation: ddp = 0.7dd0 ddp = 0.7(25.4) = 17.7800 mm 2) Gouge depth, dg = 1.27 mm 3) The minimum specified yield strength, σys = 290 MPa 4) Dent spacing to the nearest weld joint, Lw = 300 mm 5) Dent spacing to the nearest structural discontinuity, Lmsd = 1000 mm STEP 2 - Determine the future wall thickness. See STEP 1. Example Problem 4 – DENT-GOUGE ASSESSMENT STEP 3 - Verify minimum required wall thickness. tmm = trd - dg tmm = 12.7 – 1.27 = 11.43 mm tmm - FCA ≥ 2.5 mm ((11.43 – 0.5) = 10.93 mm) ≥ 2.5 mm True Verify minimum required distance to structural discontinuities: Lmsd ≥ 1.8 √(Dtc) 1000 mm ≥ ((1.8) √(508)(12.2) = 141.7047 mm) True Verify minimum required distance to the weld: Lw ≥ max. [2tc, 25 mm] 300 mm ≥ (max.[(2)(12.2), 25] = 25 mm) True Example Problem 4 – DENT-GOUGE ASSESSMENT STEP 4 – Determine the circumferential (hoop) stress: STEP 5 – Determine the parameters needed in Fig. 12.3 (API 579) – the gouge depth to corroded wall thickness ratio: The dent depth to component diameter ratio: Example Problem 4 – DENT-GOUGE ASSESSMENT The circumferential (hoop) stress to the Specified Min. Yield Strength (SMYS) ratio: Entering the data into Figure 12.4 it is shown that the intersection point is above the relevant curve. The analyzed dent-gouge combination is unacceptable The Level 1 assessment criteria are not satisfied. Design a repair. Example Problem 4 – DENT-GOUGE ASSESSMENT Figure 12.4: Interaction Diagram for Determining the Acceptability of a Dent-Gouge Combination (API 579-1)