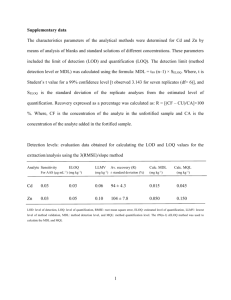

Methodology 1. Overview of Minimum Quantity Lubrication (MQL): • Used to reduce the use of cutting fluids by applying a small, precise amount of lubricant directly to the cutting zone. • In this project, we aim to design and fabricate an MQL system and evaluate its performance compared to traditional flood lubrication methods. 2. Design and Fabrication of MQL System: • MQL system consists of a lubricant reservoir, an air compressor, a mixing chamber, a nozzle, and control mechanisms for regulating flow rates of air and lubricant. • Environmentally friendly and biodegradable lubricants such as vegetable oil-based fluids are selected for their superior performance and reduced environmental impact. 3. Experimental Setup: • The MQL system will be tested during various machining operations such as milling, turning, and drilling. • Key cutting parameters such as cutting speed, feed rate, and depth of cut will be varied during the experiments to study the influence of MQL under different conditions. • The performance of MQL will be compared with traditional flood lubrication by evaluating factors such as tool wear, surface roughness, and machining temperature. 4. Measurement and Data Collection: • Tool wear will be measured using optical microscopy to observe and quantify the wear on cutting tools after machining with MQL and flood lubrication. • The surface roughness of machined parts will be measured using a surface profilometer to evaluate the quality of the finish under different lubrication methods. • A thermal imaging camera will be used to monitor the temperature of the workpiece and cutting tool during machining. Lower temperatures are expected under MQL, indicating effective cooling. • The amount of lubricant used in MQL versus flood lubrication will be recorded to assess the reduction in fluid consumption. 5. Data Analysis: • The data collected will be analyzed statistically to compare the performance of MQL and flood lubrication. • A cost-benefit analysis will compare MQL's economic advantages, considering factors like reduced lubricant consumption and extended tool life. 6. Validation of Results • The results of the experiments will be validated by repeating the tests under similar conditions to ensure repeatability and reliability of the findings. Any variations in results will be analyzed to understand the underlying causes. 7. Conclusion: • The methodology provides a comprehensive framework to design, implement, and evaluate an MQL system.