Transport Problem: Northwest Angle vs. Minimum Element Methods

advertisement

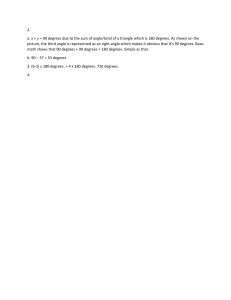

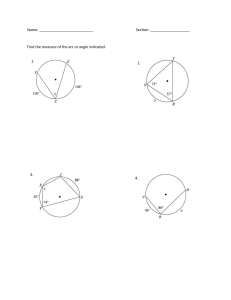

THE METHOD OF THE NORTHWEST ANGLE AND THE METHOD OF THE LEAST ELEMENT FOR SOLVING THE TRANSPORT PROBLEM Maria Lapina 1* [0000-0001-8117-9142], Denis Shvedunenko1 [0009-0008-2791-6939], Ramazan Ozdarbiyev 1 [0009-0005-1482-7775], Mikhail Babenko1 [] 1 North Caucasus Federal University, Stavropol, Russia mlapina@ncfu.ru Annotation. This article discusses and compares such methods for constructing a reference plan for a transport problem as the method of the northwest angle and the method of the minimum element. These methods are implemented in the C++ programming language, pseudocodes are presented. When constructing a reference plan for tasks of different sizes, it was revealed that the method of the minimum element is more effective, since the reference solution compiled according to this method, closer to the optimal solution than a plan drawn up using the northwest angle method. Keywords: transport problem, northwest angle method, minimal element method, C++, comparison of methods. 1. Introduction Currently, in science, special attention is paid to transport. Transport tasks are a necessary component for a logistics company, as they allow you to provide cargo transportation to the consumer at the right time and place with minimal total costs, which include labor, material and financial resources [1]. In the forecast of scientific and technological development of the Russian Federation for the period up to 2030, close attention is paid to the direction of "Transport" [2]. This document lists the most relevant areas of research, windows of opportunity for research, threats, and outcomes expected from science. In the work of Sultanov B.M. [6] the problem of determining the optimal plan for the transportation of flour is considered. The author of the study came to the conclusion that drawing up an optimal plan using the minimum element method allows minimizing costs, as well as effectively using all available resources. Sultanov determined that the use of the transport task makes it possible to effectively solve the problems of cargo transportation. In the work of Rudik I.D. and Velichko V.V. [7], the types and methods of solving the transport problem are investigated. The authors came to the conclusion that the solution of the transport problem by the method of the minimum element allows you to determine the minimum costs, find the shortest route, and reduce the delivery time. In the study of Takiya E. F. [8], the methods of the northwest angle and the method of the minimum element for solving the transport problem of linear programming are considered. The article shows the difference between the two methods. The author concludes that the least cost method provides a more optimized or reduced total cost of transportation compared to the least cost method for the same problem. 2. Description of methods The transport problem of linear programming (TZLP) is the problem of transporting goods from m points of production to n points of consumption, with given production volumes, the i-th supplier, and the consumption of 𝛼𝑖 the 𝛽𝑗 j-th 𝑐𝑖𝑗 consumer, and the cost of transporting a unit of product from point i to j . The solution to the problem is a transportation plan in which the needs are fully met, and the cost of transportation is minimal. [3] MLTP is solved in two stages: [4] 1. Determination of the initial plan of cargo transportation (Reference plan). 2. Improvement of the baseline to the optimal. There are various methods for constructing a reference plan: Northwest corner Minimum element Vogel approximations Dual preference In this article, we will consider and compare the method of the northwest angle and the minimum element. 2.1 Northwest angle method Consider the problem of 3 points of production, and 4 points of consumption 𝛼𝛽. Availability of goods: = 300, = 400, = 500.𝛼1 𝛼2 𝛼3 Cargo requirement: =250, =350, =400, =200.𝛽1 𝛽2 𝛽3 𝛽4 The cost of transportation (tariff) is presented in the matrix Cij. 3 𝐶 = (2 8 1 7 4 6 5 9) 3 3 2 Get: Table 1 A1 A2 A3 Needs B1 3 2 8 250 B2 1 6 3 350 B3 7 5 3 400 B4 4 9 2 200 Availability 300 400 500 1200 A typical transport problem, also called the Hitchcock-Koopmans transport problem, is mainly related to the movement of goods from sources to destinations [9]. The essence of the method is to sequentially iterate through the rows and columns of the transport table, starting with the left column and the top row, and write out the maximum possible shipments to the corresponding cells of the table so that the capabilities of the supplier or the needs of the consumer stated in the task are not exceeded. [5] Thus: Table 2 A1 A2 A3 Needs B1 250*3 2 8 250 B2 50*1 300*6 3 350 B3 7 100*5 300*3 400 B4 4 9 200*2 200 Availability 300 400 500 1200 The cost value of this reference plan: P = 250 * 3 + 50 * 1 + 300 * 6 + 100 * 5 + 300 * 3 + 200 * 2 = 4400 c.u. 2.2 Minimum element method In contrast to the north-west angle method, in the method of the minimum element, the choice of departure points and destinations is made based on transportation tariffs, i.e. in each step you need to select a cell with a minimum transportation tariff. If there are several such cells, then choose one of them. Solving the problem from Table 1 by this method, we get: Table 3 A1 A2 A3 Needs B1 3 250*2 8 250 B2 300*1 6 50*3 350 B3 7 150*5 250*3 400 B4 4 9 200*2 200 Availability 300 400 500 1200 The cost value of this reference plan: P = 300 * 1 + 2 50 * 2 + 150 * 5 + 50 * 3 + 250 * 3 + 200 * 2 = 2850 c.u. As can be seen, the costs of this reference plan for this task are lower than the costs of the reference plan drawn up using the northwest angle method. 2.3 Comparison Comparison of these methods according to some criteria occurs using codes written in C++ (https://gist.github.com/oramzan/5c788a73c06288a22f48aa9dffe221f9, https://gist.github.com/oramzan/00449f11ef4ba9db7b5bede550c89a9f). The pseudocode for the northwest corner is: Initialize the matrix result[number_of_suppliers][number_of_consumers] with zeros Initialize matrix result[num_products][ num_suppliers][num_customers] with zeros For each product, k from 0 to num_products - 1: Set i = 0 , j = 0 So far, i < num_suppliers and j < num_customers: quantity = min(supply[i][k], demand[j][k]) result[k][i][j] = quantity supply[i][k] -= quantity demand[j][k] -= quantity If demand[j][k] == 0, then: Increase j by 1 If i < num_suppliers and supply[i][k] == 0, then: Increase i by 1 The complexity of this algorithm is O(num_suppliers * num_customers * num_products) The pseudocode for the minimum element is: Initialize matrix result[num_products][ num_suppliers][num_customers] with zeros For each product, k from 0 to num_products - 1: For now , true: min_supply = INT_MAX min_demand = INT_MAX min_supplier = -1 min_customer = -1 For each provider i from 0 to num_suppliers - 1: For each consumer j from 0 to num_customers - 1: cost = supply[i][k] * tariff If supply[i][k] > 0 and demand[j][k] > 0 and cost < min_supply and cost < min_demand, then: min_supply = cost min_demand = cost min_supplier = i min_customer = j End if End of cycle End of cycle If min_supplier == -1 or min_customer == -1, then: Exit the loop End if quantity = min(supply[min_supplier][k], demand[min_customer][k]) result[k][min_supplier][min_customer] += quantity supply[min_supplier][k] -= quantity demand[min_customer][k] -= quantity End of cycle The complexity of this algorithm is O(num_products * num_suppliers * num_customers * max(num_suppliers, num_customers)). 3. Outcomes For problems of different dimensions, reference plans were drawn up using the methods of the northwest angle and the minimum element. As a result, the best operating time of the algorithm, the worst, average, as well as how much the costs of the plan differ in percentage from the costs of the optimal plan (last column) were obtained. Northwest Angle Method 4x4 5x5 6x6 7x7 8x8 9x9 The best time, with 0,0000075 0,0000189 0,0000094 0,000021 0,000012 0,0000122 Worst time, with Average time, s Difference, % 0,0000075 0,000058 0,0000161 0,0000407 0,0000282 0,0000131 0,0000075 0,00002799 0,00001059 0,00002767 0,00001529 0,00001265 61,55316279 89,13406553 112,7 53,56441923 74,12466529 98,63340582 10x10 0,0000143 0,0000157 0,00001488 123,1 Worst time, with Average time, s Difference, % 0,0000121 0,0000165 0,0000237 0,0000332 0,0000491 0,0000508 0,0000601 0,00001112 0,00001605 0,00002069 0,00002835 0,00004059 0,00004525 0,00005482 24,31047136 45,49264631 10,9 25,36408089 25,35813896 16,30202833 17,01392823 Smallest element method 4x4 5x5 6x6 7x7 8x8 9x9 10x10 The best time, with 0,0000104 0,0000156 0,0000196 0,0000247 0,0000355 0,0000433 0,0000471 Average time, s 0,0000600 0,0000500 0,0000400 0,0000300 0,0000200 0,0000100 0,0000000 4х4 5х5 6х6 7х7 8х8 9х9 Northwest Angle Method Smallest element method Polynomial(Northwest Angle Method) Linear(Smallest element method) 10х10 Difference, % 140 120 100 80 60 40 20 0 4х4 5х5 6х6 7х7 8х8 9х9 10х10 Northwest Angle Method Smallest element method Polynomial(Northwest Angle Method) Polynomial(Smallest element method) 4. Conclusion From this we can conclude: 1. The average time to find a plan for the minimum element method is linear, and depends on the size of the problem. 2. The costs of the reference plan differ from the costs of the optimal plan for the northwest angle method more than for the costs of the reference plan constructed by the least element method. 3. For 10x 10 problems, the code execution time differs by a factor of 3.6 in favor of the northwest angle method, but the baseline calculated by the smallest element method is 7.2 times closer to the optimal one. Based on this, it can be concluded that the use of the method of the smallest element to build a reference plan is more appropriate, since it is less different from the optimal, therefore, it will take less time to improve it to the optimal, however, with large volumes of tasks, it will take more time to build a reference plan using the method of the smallest element. 5. List of references 1. Sergeev, V.I. Supply chain management: a textbook for bachelors. - M.: Yurait Publishing House, 2014. 479 p. 2. Forecast of scientific and technological development of the Russian Federation for the period up to 2030 (approved by the Government of the Russian Federation) // [Electronic resource]. – 2014 URL: https://www.garant.ru/products/ipo/prime/doc/70484380/ (date accessed: 01.11.2020) 3. Pupkov K.A., Konkov V.G. Intelligent systems. Moscow: Bauman Moscow State Technical University Publ., 2003. 348 p. (in Russian). 4. Tikhomirova A. N., Sidorenko E. V. Mathematical models and methods in logistics: a textbook. - Moscow: NRNU MEPhI, 2010. – 320 p 5. A. V. Kuznetsov, N. I. Kholod, L. S. Kostevich. A guide to solving problems in mathematical programming. Minsk "Higher School", 1978. 6. Sultanov, B.M. Application of the transport problem in determining the optimal transportation plan // Symbol of science. 2016. №1-1 (13). 7. Rudik, I.D.; Velichko, V.V. Concept, types and methods of solving a transport problem // International Student Scientific Bulletin 2017. № 4-4. 8. Takiy E. F. Transport problems with the use of the method of the north-western angle and the method of the lowest costs // Humanities, socio-economic and social sciences. 2022. (p. 352) 9. Hamdy A. Taha. Operations Research: An Introduction, Prentice Hall, 7 editions 5, USA, 2006.